Better Living Through Cooperative Systems – One Community Weekly Progress Update #467

We can create better living through cooperative systems. By working together, we have the ability to create a lifestyle with less work, more free time, more to do with our free time, better food and overall health, less stress, etc. One Community is developing and open sourcing detailed DIY plans for how to achieve all this. We’re also adding artistic, sustainable, and healthier housing, renewable energy infrastructure, and what we call “Highest Good” approaches to education, for-profit and non-profit economic design, social architecture, fulfilled living, global stewardship practices, and more.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world. This is the March 6th, 2022 edition (#467) of our weekly progress update detailing our team’s development and accomplishments, emphasizing better living through cooperative systems:

Better Living Through Cooperative Systems

One Community Progress Update #467

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

ONE COMMUNITY WEEKLY UPDATE DETAILS

HIGHEST GOOD HOUSING PROGRESS – BETTER LIVING THROUGH COOPERATIVE SYSTEMS

One Community is addressing better living through cooperative systems through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is addressing better living through cooperative systems through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

This week Jose Luis Flores (Mechanical Engineer) completed his 84th week helping finish the Net-zero Bathroom component of the Earthbag Village. This week Jose Luis continued the development of a support structure for the rain barrels. He focused on facilitating the installation process, while maintaining structural rigidity and strength. The design focused on using unistrut channels with fastener holes on all three sides as the main supporting columns and beams.

The three sided unistrut channel has the benefit of being more versatile and a wider range of orientations than a traditional one side slotted ones. The one side slotted unistrut channels were used for the secondary beams that form the base for the rain barrel. The advantage they have over the three sided type is the lower price and lower tolerance for fastener hole alignment, facilitating they’re installation. An FEA was performed to analyze the stress distributions and the amount of deflection in the beams.

It was found that the stress was concentrated toward the edges of the main beams supporting the secondary beams, but still under the yield stress of the structure. It was also seen that the maximum amount of deflection occurs toward the center of the secondary beams. The maximum amount of deflection was found to be 0.7mm, well below the maximum allowable deflection of 2.4mm. An additional concept for the structure was also rendered using only slotted unistruts. The use of these struts would reduce costs, but would add many more steps and precision to assemble it. The pictures below show some of this work.

Daniela Andrea Parada (Civil Engineering Student) completed her 35th week helping with the Sustainable Roadways, Walkways, and Landscaping, Earthbag Village, and the final Aquapini & Walipini website updates. This week Daniela started off the week by reviewing all new comments and emails. She contacted Tugce, answered questions and provided documents and dropbox links that would further help. A new tab was also created so that the Hazen William calculations could be worked on for the pipe sizing of the Earthbag Village.

Daniela then went through the City Center Project Specification and Design Basis report and properly formatted all headings. In doing so Daniela was then able to construct a more accurate table of contents. She came across some issues with the numbering so she downloaded a google docs add on that would allow the table of contents to be numbered as such. Daniela came across other formatting issues and plans to continue working on it in the week to come. Pictures below are related to this work.

The Compression Team consisting of Dominick Banuelos (Civil Engineering Intern), Jarot Tamba (Civil Engineering Intern), John Paul D. Matining (Civil Engineer Intern), and Marcus Nguyen (Civil Engineering Intern) completed their 24th week helping with the Aircrete and earthbag compression testing. This week the Compression Testing Team prepped for Saturday cylinder making day. On Tuesday, the team met with their on-site supervisor to go over the facility use for the week, as well as finish the materials list that was necessary to make 175 total cylinders.

On Thursday, the team had a chance to practice with compression testing the cylinders with and without stucco. They also went to Home Depot to pick up the items such as Portland cement and equipment for the mixes. On Friday, they put together a work plan to make all the cylinders on a single day. On Saturday, the team completed making the 175 cylinders for all mixes. Pictures below are related to this work.

Yuran Qin (Volunteer Web Editor) completed her 15th week helping with web design, this week focusing on the Tools and Equipment page and Rainwater Harvesting, Water Catchment, and Swale Building Open Source Hub and Portal. This week Yuran filled in columns B and G from the T&Q Live Page on the Tools/Equipment Master tab and checked tools, equipment and materials lists to confirm that there aren’t items on the wrong list. She also compared the Water Catchment page to the Google Doc, repasting everything and checking the format and the table of contents and adding missing items. Pictures below are related to this work.

DUPLICABLE CITY CENTER PROGRESS – BETTER LIVING THROUGH COOPERATIVE SYSTEMS

One Community is addressing better living through cooperative systems through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is addressing better living through cooperative systems through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

This week the core team finished working with the Duplicable City Center 3D model to create the outer layer of the Living Dome with walls 12 3/8″ thickness. This week we finished modeling the outer-shell in the SketchUp application for the Social Dome and Dining Dome.

Luis Manuel Dominguez (Research Engineer) completed his 40th week helping with research related to the City Center Eco-spa designs. This week Luis finalized his calculation of the head loss for the City Center Spa design. The calculation required knowledge of fluid dynamics with an emphasis on friction.

The approximated head loss was assumed for 50 feet of plumbing and a water temperature of 120º which are high estimates to assume a worst case scenario. Luis is still verifying his findings to confirm the units and values, and next week will continue his documentation of the updated design. Pictures below are related to this work.

Frank Roland Vilcapaza Diaz (Mechanical Engineer) completed his 35th week helping, now focused on content related to the Solar Microgrid sizing. This week Frank checked the necessary energy drawn from the lights and energy items that are going to be present in the Ultimate Classroom building. He also worked in the HVAC system by fixing some numbers in the energy balance calculation for the greenhouses designs. This approximation also helps with later HVAC system design. The pictures below relate to this.

Carlos Lillo (Engineering Technician) completed his 27th week helping with the pallet furniture designs for the Duplicable City Center guest rooms. This week, Carlos finished successfully exporting all the furniture into the CAD environment. This included all the technical views with screws, fittings and other items. He noticed that there are a few things missing and some others extra, but he can delete them/add them in no time. Having said that, the blueprints updates are expected to be finished by next week. This means, only adding color and changing line types and dimensions if needed. Pictures below are related to this work.

Xuanji Tang (Architectural Designer) completed her 23rd week working on Duplicable City Center updates, now focused on the City Center Lighting updates. This week she updated the landscape plans and the door and window plan for the Social Dome on the second floor. She also had a meeting with the architectural team, assigned tasks, and discussed the window and door detail and schedule. Pictures below are related to this work.

Huiya Yang (Volunteer Architectural Designer) completed her 22nd week working on the Duplicable City Center architectural review and updates related to the structural code. Huiya continued working on updating the window schedule. She did some research about the windows that can meet the need of LEED, and she found that Milgard® offers diverse products that meet or exceed the LEED requirements.

They also have the Milgard Energy Calculator that can provide a quick and easy way to help select windows and doors that can meet local energy codes and project requirements. Besides that, she accomplished the work of fixing the wrong size of Window 1 and Window 4, fixing the related items in the floor plans, and building up the models for window 1 and window 4. Pictures of some of this work are below.

Yuxi Lu (Architectural Designer) also completed her 20th week working on the Duplicable City Center architectural review and updates related to the structural code. This week Yuxi had a discussion with the team about changes needed for the Social Dome second-floor door and window designs.

The issue was that windows are not effectively placed to ensure sight into the social space and, at the same time, the building shell curvature is limiting wall heights and options for window placement. The team then went over the occupancy and egress requirements to double check door requirements and a few exterior and interior door products were selected based on previously determined aesthetics and energy performance. Pictures of some of this work are below.

Raj Patel (Mechanical Engineer) completed his 11th week helping with the Duplicable City Center hub connectors design and testing. This week Raj worked on increasing the thickness of the center ring to see if there was any possible solution to fix the stress concentration problem. He increased the thickness from 0.25in to 0.35in to 0.45in and finally 1in, and found that the issue still persisted. Raj also ran the analysis on the full assembly to see the new stress distribution. Pictures below are related to this work.

Prathik Nirmal Jain (Mechanical Engineer) also completed his 6th week of work on the Duplicable City Center hub connectors design and analysis. This week Prathik conducted research on the analytical load distribution over the dome. He also researched how the load is distributed at each hub in the dome, and the hub at which there is maximum load that would affect the stability of the dome. He looked for open-source software to perform structural analysis of the dome for the various loads. Pictures below show some of this work-in-progress.

HIGHEST GOOD FOOD PROGRESS – BETTER LIVING THROUGH COOPERATIVE SYSTEMS

One Community is addressing better living through cooperative systems through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is addressing better living through cooperative systems through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

This week the core team continued working on the Aquapini & Walipini designs. We integrated comments, added questions for clarification, and added a paragraph summarizing the use of berms for internal temperature control and assessed an old heat loss study. We had a meeting with the City Center Hub Connector team and multiple communications with Marcus (the team lead) as the Compression testing team prepared to make all the cylinders needed.

We created unique IDs for each cylinder and helped iron out other compression testing arrangements and researched and began answering questions around stucco application on test aircrete cylinders.

Another core team member completed additional edits on the Chicken coop details. We worked more on addressing comments on the Google Doc from the start of the doc through page 105. Then we reviewed the text on the same doc though page 115 and researched and reviewed standing seam videos, as this will replace the delta rib metal roofing panels.

Standing seam priority is due to less maintenance and better longevity, though the initial cost is more. Also a decision was made for the following sheathing standards throughout our entire project: 3/4″ floors, 5/8″ roofing and 1/2″ walls. Some of this can vary with joist spacing and snow loads. We also updated images with bigger font size and better view points on specific images.

The core team also finished the Permaculture Design “case study” for our planned property. This is all part of another of our members getting permaculture certified. This week’s focus was finalizing all the written details for his written certification, updating the fencing plan to be more accurate, efficient, and cost effective, adding fire truck turnaround areas, and adding in our initial food forest area. The collage below shows all the final graphics that we’ll be integrating into the website next.

Anna Cheal (Culinary Nutritionist) also completed her 12th and final week helping with the completion of the Transition Food Self-sufficiency Plan and related menu and meal plans. This week Anna completed 6 recipes: Chai-Spiced Butternut Squash Smoothie, Tandoori Salmon and Butternut Squash, Spicy Thai Peanut Salad, Spaghetti-Squash Fritter, Spicy Chickpea Wraps, and Vegan Potato Salad.

The last three of these are under “recipes using leftovers” as per Brian’s idea. In addition she’s focused on filling in gaps on rows E and F within her 2-week menu. She was able to complete the first 2-week menu and began a second 2-week menu, using recipes from her archive that were not yet used. She has marked cells red and left recipe suggestions in gaps within her second 2-week menu. The pictures below relate to this work.

Maya Callahan (Sustainability Researcher) completed her 8th week helping with research and web design, currently focused on final review and edits to the DIY Permaculture Design staging page. This week Maya continued her work of editing and proofreading the Open Source Permaculture DIY webpage and began a new task, proofreading the Solar Farm Battery Analysis final report. For the permaculture webpage, her primary focus was ensuring that all hover text was consistent, accurate, and uniform.

The new task regarding the Solar Farm Battery Analysis entails proofreading the report and correcting grammar, spelling, and structure errors. For content that was vague or difficult to understand, she made a comment on the google document for additional feedback and clarification. Once Maya received this feedback the necessary changes on the previously mentioned content were made, she then would resolve the comment so that others editing the page were aware of these changes. The pictures below are related to this work.

Adam Weiss (Chef) completed his 3rd week helping with the completion of the Transition Food Self-sufficiency Plan and related menu and meal plans. Adam spent the week reviewing recipes submitted by Anna and providing feedback. Anna’s recipes are very good, but every now and then a detail can be pointed out. Adam also spent the time working on the Recipe conversion calculator to help convert recipes to different types of measurements, and also to help scale recipes for more people. The pictures below relate to this work.

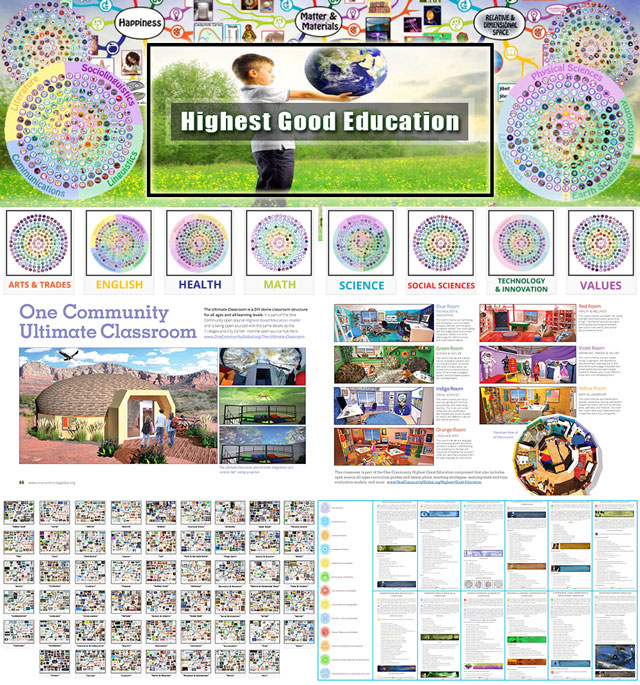

HIGHEST GOOD EDUCATION PROGRESS – BETTER LIVING THROUGH COOPERATIVE SYSTEMS

One Community is addressing better living through cooperative systems through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

One Community is addressing better living through cooperative systems through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

HIGHEST GOOD SOCIETY PROGRESS – BETTER LIVING THROUGH COOPERATIVE SYSTEMS

One Community is addressing better living through cooperative systems through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is addressing better living through cooperative systems through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

This week the core team completed 32 hours managing One Community volunteer-work review not included above, emails, social media accounts, web development, new bug identification and bug fix integration for the Highest Good Network software, and interviewing and getting set up new volunteer team members. Pictures below show some of this.

The core team also added a new section about the latest plastic block technology to the Best Small and Large-scale Community Plastic Recycling, Reuse, and Repurposing Options page, updated the SEO information, added it to our Open Source Social Media Strategy and shared it across all our social media networks.

Aidan Geissler(Sustainability Researcher) also completed his 35th week helping, now focused on both the Most Sustainable Urinals page, in addition to finishing the Health Insurance research and page. This week Aidan worked on final revisions to the Community Health Insurance Webpage. In addition to minor revisions, he conducted additional analysis in the health insurance spreadsheet to calculate the amount of community members’ Out-of-Pocket Limits that can be covered by the cost-savings generated by our community-based health insurance approach.

Impressively, for ANY community size, it was found that this approach can cover the full Out-of-Pocket limit for 30% of the population. This is a fantastic, straightforward benchmark that can be used to assess whether this approach is cost-effective for a given community. This means that if more than 70% of the population is generally healthy and unlikely to require extensive medical care, then this community-based health insurance approach will likely be cost-effective. Pictures below show some of this work-in-progress.

Irene Clare (Full Stack Developer) completed her 3rd week helping with the Highest Good Network software. This week Irene worked on the People reporting component. She has finished populating basic user details in the UI and started to work on creating tables. Currently Irene is facing a challenge with upgrading the react table version to support the required functionality and checking the possibilities to do with the existing table version. She also reviewed and approved a couple PR’s. The pictures below relate to this work.

Kevin Begin (Full Stack Web Developer) also completed his 2nd week helping with the Highest Good Network software. This week, Kevin fixed the delete badge confirmation dialog (pull #363) to display the requested text. He also changed the dialog from window.confirm(), which has a fixed styling, to a React-strap modal, which can be fully customized.

This required the code to be refactored and new states added. In addition, Kevin changed the ‘can’t select more than 5 badges’ error from window.alert() to a toast.error() so it is consistent with other errors across the app. Lastly, he found two new bugs and added them to the bugs doc. Pictures of some of this work are below.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE | WAYS ANYONE CAN HELP | MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

One Community

One Community