A Better Way to Thrive – One Community Weekly Progress Update #444

Is there a better way to thrive? Are we ready to move beyond the competitive structures or capitalism and embrace something more for The Highest Good of All? One Community thinks we are and we’re supporting this by creating open source and sustainable solutions for food, energy, housing, education, for-profit and non-profit economic design, social architecture, fulfilled living, global stewardship practices, and more.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world. This is the September 26th, 2021 edition (#444) of our weekly progress update detailing our team’s development and accomplishments:

A Better Way to Thrive

One Community Progress Update #444

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

ONE COMMUNITY WEEKLY UPDATE DETAILS

A BETTER WAY TO THRIVE – HIGHEST GOOD HOUSING PROGRESS

One Community is demonstrating a better way to thrive through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is demonstrating a better way to thrive through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

This week the core team continued working on the “Earthbag Construction Footers, Foundation, and Flooring” review for finalizing the live page. We moved changes from the proofread version in the google doc to the webpage, added more images and descriptions for tools and equipment, and added more questions to the Frequently Asked Questions Section.

The pictures below share some of this work.

The core team also worked with the compression testing team and made the decision to try a different foaming agent and purchase more cylinders, had phone calls with the team, and responded to various comments to keep the team moving forward.

The same team member also worked on the energy demand for solar sizing and is in the process of more accurately determining the time usage matrix and percent use and managed comments from City Center Dome Hub connector team to get them on the same page for efficiency.

A Better Way to Thrive ” Energy demand for solar sizing

Jose Luis Flores (Mechanical Engineer) completed his 62nd week helping finish the Net-zero Bathroom component of the Earthbag Village. This week Jose Luis continued researching and developing a spreadsheet for the net-zero bathroom water storage system.

The spreadsheet’s purpose is to calculate the pressure and flow rate of the system in order to determine the specific pump needed for the system and to add flexibility to the design for open source purposes.

The calculations involved gathering data and graphs from a fluid mechanics documents providing sufficient data to determine losses and gains within the system. The losses include pipe bends, tees, and inlets, while the gains involve height differences. The pictures below show some of this work.

David Na (Project Management Adviser/Engineer) completed his 28th week helping with input and management of the Parking Lot and Sustainable Roadways, Walkways, and Landscaping tutorial development, now mainly focused now on the Earthbag Village aspects of this.

This week David reviewed the cost analysis table that Carol and Daniela had prepared. Jae noticed that the prices were very inflated and had David check for any discrepancies. David used the kmz file One Community had regarding the project site’s location and measured the square footage and distances of the boundary lines for the location.

He then compared them to the CAD file for the roadway design and noticed that the file was scaled improperly. David went and rescaled the drawing to its approximate size and saved it into dropbox so that Daniela can use the file to accurately recalculate the costs of the roadways for the entire site and for Earthbag Village Ring Road. Pictures below are related to this work.

Aidan Geissler (Sustainability Researcher) completed his 21st week helping with 2nd-to-final review, feedback, and content editing that is now focused on the Most Sustainable Insulation tutorial. This week’s focus was primarily writing introduction paragraphs for the various products to provide additional background information, and a brief explanation of why the product received its overall rank.

Below are some images related to this work.

Shreyas Dayanand (Battery Research Engineer) also completed his 12th week helping with the solar microgrid design specifics related to electric vehicles and battery sizing. This week Shreyas worked on editing and analyzing the final report on Solar Farm Battery Analysis – EV Integration.

He re-ran 3 cases of the techno-economical analysis for AC and DC charging of the EVs to obtain the commercials for individual chargers instead of the previously obtained combination of chargers.

Regarding editing, Shreyas worked on image formatting, text editing, labeling figures, making tables, and adding information where necessary to make the analysis more clear to the readers. He also researched and reviewed a few Solar Farm Battery storage case studies. Pictures below are related to this work.

The Compression Team consisting of Dominick Banuelos (Civil Engineering Intern), Jarot Tamba (Civil Engineering Intern), John Paul D. Matining (Civil Engineer Intern), and Marcus Nguyen (Civil Engineering Intern) completed their 12th week helping with the Aircrete and earthbag compression testing.

This week, the team created a document to keep tasks for the week organized. They also completed a compression test, foam tests, addressed open comments, and consolidated information for the earthbag mixture. They added data to the spreadsheet from the multiple jar tests that were previously done but deemed unusable, because the clay content wasn’t able to be determined.

They also detailed the steps to do future jar tests. A compression test was completed on one of the test quikrete cylinders. Foam generation was tested, because this may be why previous batches of aircrete collapsed. They made foam using three different soaps to help determine which soap could serve as the best foaming agent in order to make a successful cylinder batch of aircrete.

The team also created a cylinder count log to see how many additional cylinders need to be ordered. Pictures below are related to this work.

And Tiffany Gao (Sustainability Researcher) completed her 9th week as a researcher, reviewer, and web developer. This week Tiffany finished up her basic proposal of a potential community-scale solution to non recyclables.

She also discovered co-processing, a process used by cement production that can cleanly utilize mixed plastics as fuel and actually reduce CO2 emissions within cement factories. Tiffany sees potential in this solution and is looking into how to adapt such systems to focus on non recyclable waste management rather than an alternative of cement-making fuel.

The pictures below share some of this developing work.

A Better Way to Thrive ” solutions to non recyclables

A BETTER WAY TO THRIVE – DUPLICABLE CITY CENTER PROGRESS

One Community is demonstrating a better way to thrive through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is demonstrating a better way to thrive through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

This week Qiuheng Xu (Landscape Designer) completed her 50th week by returning to helping with the Duplicable City Center. This week Qiuheng added the planting plan to the “CITY CENTER MASTER” AutoCAD file. The planting plan was adjusted based on the final walk through video. Also, Qiuheng drew 4 planting elevations with the structures this week. Pictures below show some of this work.

Luis Manuel Dominguez (Research Engineer) completed his 21st week helping with research related to the City Center Eco-spa designs. This week, after reviewing with the team, it was determined that a sand filtration system would be a more sustainable solution for the spa’s design.

This option produces less waste than the other filtration systems and the sand type can be modified for finer filtration. After selecting the filtration system, the pump can now be selected because each filtration method requires different flow rate and horsepower requirements. Luis is now looking for a power-efficient option suited for a sand system.

The pump also has to be designed for backwashing, a method used to remove clogged debris from the filtration system. The search for the perfect pump continues and will be complete in the coming weeks. It was also discovered that common practice is to use a submersible pump to assist with draining the spa for cleaning.

An updated schematic will also be available soon in order to understand the flow of water and the electrical circuitry. Pictures below are related to this work.

Venus Abdollahi (Architectural Designer) completed her 11th week helping finish the Duplicable City Center designs, now focused on the dormer window designs. This week, Venus added the dormer details, sections and roof sections for City Center Living Dome and Cupola roof designs to the AutoCAD master files. She then prepared and submitted for review a final report on the dormers.

See pictures below.

Andrew Wilbert Vidianto (Mechanical Engineer) completed his 9th week working on the Duplicable City Center connectors we’ll use to build the domes. This week Andrew re-examined the final hole size for the bracket with George. At first, Andrew planned on using screws instead of bolts for connecting the bracket.

However, after discussing things with George, the team chose bolts instead of screws for the connector due to the simplicity that it offers for the final design. Hole sizes of 0.25″ and 0.109″ was the most common hole that was found for joist hangers. Pictures below are related to this work.

Xuanji Tang (Architectural Designer) completed her 4th week working on Duplicable City Center architectural review and updates related to the structural code. This week she added an exit to the second floor of the Social Dome, moved the bathrooms into the bedroom suites and added public restrooms to the Living Dome first floor.

She also added an additional staircase to meet the requirement of egress. The pictures below relate to this work.

And George Koshy (Design Engineer) completed his 2nd week working on the Duplicable City Center connectors we’ll use to build the domes. This week, George researched the loads that a geodesic dome undergoes, and analyzed each member’s load. He also researched other possible hub options using only V brackets.

George studied various stainless steel properties and their applications. He also 3D modeled the various parts needed for the Finite Element Analysis, and researched the bolts that are best suited for this application and their properties. The pictures below relate to this work.

A BETTER WAY TO THRIVE – HIGHEST GOOD FOOD PROGRESS

One Community is demonstrating a better way to thrive through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is demonstrating a better way to thrive through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

This week the core team continued working on the Chicken Coop Assembly document. We updated the sequence of steps for assembling of the roof framing, generated images related to this sequence with details for cutting the frame rafters, frieze blocks, outriggers and fascia parts. We also started working on generating images for sheeting for the roof, providing two options for possible placement.

Further discussion is needed.

Another team member collaborated via Google Docs and collaborative calls on the Chicken Coop roof assembly details and made additional edits to the instructions through page 65. The same team member also worked on the Soar Hardware report, addressing comments, and resolving those that were rectified.

Frank Roland Vilcapaza Diaz (Mechanical Engineer) completed his 12th week helping with the Aquapini & Walipini and Tropical Atrium climate battery designs. This week, Frank worked on summarizing the energy consumption of traditional HVAC systems for both of these.

He detailed the procedure for finding the correct numbers, as well as the method to calculate energy losses. Frank also concluded the energy analysis for these systems. The pictures below relate to this.

And Brian Storz (Culinary Project Manager) completed his 2nd week helping lead the completion of the Transition Food Self-sufficiency Plan, Transition Kitchen designs, Food Procurement and Storage plan, and related menu and meal plans. This week Brian finished the final draft for the application and lesson plan outline for the culinary student intern program.

Brian also started the process of pricing all the ingredients with wholesale vendors. This will allow him to determine which products are appropriate for this project. The culinary students will then also have access to current market prices for the products they will be using to design recipes for the menu plan.

Brian also wrote the first draft of the cook’s guide for food safety and job responsibilities. Below are some images related to this work.

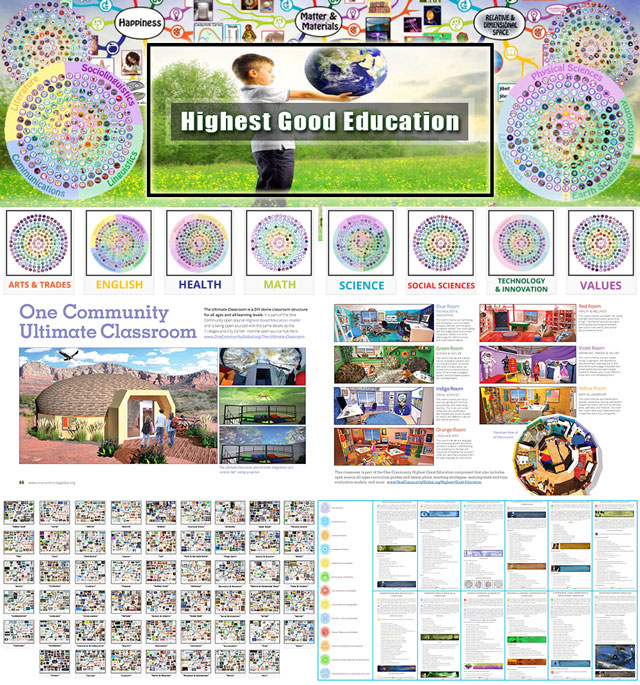

A BETTER WAY TO THRIVE – HIGHEST GOOD EDUCATION PROGRESS

One Community is demonstrating a better way to thrive through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

One Community is demonstrating a better way to thrive through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

Highest Good Education: All Subjects | All Learning Levels | Any Age – Click image for open source hub

A BETTER WAY TO THRIVE – HIGHEST GOOD SOCIETY PROGRESS

One Community is demonstrating a better way to thrive through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is demonstrating a better way to thrive through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

This week the core team completed 30 hours managing One Community volunteer-work review not included above, emails, social media accounts, and interviewing and getting set up new volunteer team members. They also completed hours of additional testing and bug identification and correction confirmations for the Highest Good Network software. Pictures below show some of this.

Aleksandra “Alex” Gorkovenkø (Graphic Designer) also completed her 7th week working on images for our open source social media strategy. Alex worked on new posters, created 40 posters for this week, and fixed 5 from the previous week. What you see below is a sample of the approved ones.

Hannah Gardner Hattersley (Software Engineer) joined the team and completed her 1st week working on the Highest Good Network software. This week Hannah went through onboarding materials, researched technologies that will be used for testing, and attempted to begin testing badges.

However, the document that detailed creating test accounts did not reflect the current code base and she was unable to run any tests. Hannah reached out to two people and is in the process of resolving the bug.

In order to contribute sufficient time, she supplemented with continued learning that would support HGN App’s goals”Functional components with react, modern React implementation, and technologies specific to the badge assignment.

Next week, she will follow up with team members in order to create user test accounts and begin badge testing. Pictures below are related to this work.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE | WAYS ANYONE CAN HELP | MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

One Community

One Community