Global Eco-cooperative Movement – One Community Weekly Progress Update #447

One Community is forwarding a global eco-cooperative movement for “The Highest Good of All“. We are supporting this through open source and sustainable solutions for food, energy, housing, education, for-profit and non-profit economic design, social architecture, fulfilled living, global stewardship practices, and more.

We’re combining these to build teacher/demonstration hubs purposed to make replication easy enough, affordable enough, and demonstrate the lifestyle as attractive enough to spread on its own.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world. This is the October 17th, 2021 edition (#447) of our weekly progress update detailing our team’s development and accomplishments:

Global Eco-cooperative Movement

One Community Progress Update #447

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

ONE COMMUNITY WEEKLY UPDATE DETAILS

GLOBAL ECO-COOPERATIVE MOVEMENT – HIGHEST GOOD HOUSING PROGRESS

One Community is supporting a global eco-cooperative movement through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is supporting a global eco-cooperative movement through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

This week the core team connected Greg (a relative of the team) and George so the hub connector work can be reviewed by another mechanical engineer.

We prepared weekly assignments for the compression testing team, reviewed and provided feedback to Frank on the HVAC system for the Tropical Atrium, and assigned tasks and reviewed and responded to comments from the Compression Team. Pictures below are related to this work.

Global Eco-cooperative Movement ” compression testing team management

Jose Luis Flores (Mechanical Engineer) completed his 65th week helping finish the Net-zero Bathroom component of the Earthbag Village. This week Jose Luis began researching proper pump selection analysis to ensure the correct pump is used to provide adequate pressure and ensure an economical and reliable choice.

He began by researching the relationship between inadequate pressure to frictional losses and operating pump pressures. Upon reading theoretical text for a knowledgeable analysis, he began calculating the frictional head losses of the system at various points and plotting the values with their respective flow rate.

With that in place, Jose Luis generated a trendline from the graph and used the function describing the average change of head loss with respect to flow rate and generated a graph using the function at various flow rates. The purpose was to compare the graph to decreasing head loss of the pump.

The intersection between the resistance curve and the pump curve is the flow rate the pump will operate at when in steady state. The next step will be comparing various pumps and seeing which one will provide the necessary flow rate without applying too much pressure to the system and not overworking the pump. The pictures below show some of this work.

David Na (Project Management Adviser/Engineer) completed his 30th week helping with input and management of the Parking Lot and Sustainable Roadways, Walkways, and Landscaping tutorial development, now mainly focused on the Earthbag Village aspects of this.

This week David received clarification from Jae on the remaining tasks needed for the roadways doc. He also met with Daniela to delegate these tasks and answered any questions that may have caused any confusion. David and Daniela are also working on making edits to the updated water catchment page due to the ring roadway width changes made for Earthbag Village.

Pictures below are related to this work.

Daniela Andrea Parada (Civil Engineering Student) completed her 16th week helping with the Sustainable Roadways, Walkways, and Landscaping tutorial development, mainly focused now on the Earthbag Village components. This week Daniela started by uploading PDFs to the dropbox and attempted to share google sheets that contained tables with last week’s works.

Daniela then started measuring the roadways that connected the parking lot, City Center, Earthbag Village, and Aquapini/Walipini. With this information she recalculated the roadway costs. She then itemized a list of materials for the water catchment/drainage system of the Earthbag Village.

After that, Daniela worked on updating the water conservation webpage, which included creating a new CAD image of the Earthbag Village, rewriting some paragraphs explaining the decisions behind the design of the drainage system, and meeting with David and editing and revising her previous work based on that meeting.

Pictures below are related to this work.

The Compression Team consisting of Dominick Banuelos (Civil Engineering Intern), Jarot Tamba (Civil Engineering Intern), John Paul D. Matining (Civil Engineer Intern), and Marcus Nguyen (Civil Engineering Intern) completed their 13th week helping with the Aircrete and earthbag compression testing.

This week the Compression Testing Team tested Drexel as an alternative to 7th Generation Dish Soap to determine if the team can more reliably make aircrete that resists collapsing. The team successfully made a 3 cylinder batch (approximately 4.5 gallons). After 2 hours the results showed no noticeable collapsing.

The team also looked for soil in the local classifieds and searched for clay to use for stabilized earth cylinders. The Team calculated needing about 0.7 cubic yards of soil. Supplies for cement were also restocked for current and future tests. They also continued organizing the documents in preparation for pre-testing.

Pictures below are related to this work.

And Emmanuel Okwechime (Mechanical Engineer) completed his 2nd week working on the plumbing aspects of the Net-zero Bathroom component of the Earthbag Village. This week Emmanuel did research on US plumbing codes and drainage codes for both residential and commercial applications.

He also researched codes for safety and grades of pipes which must be met for our system to work properly. Emmanuel then made some AutoCAD drawings to equip him with the necessary plumbing drafting skills. Pictures below show some of this work.

GLOBAL ECO-COOPERATIVE MOVEMENT – DUPLICABLE CITY CENTER PROGRESS

One Community is supporting a global eco-cooperative movement through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is supporting a global eco-cooperative movement through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

This week Ian Oliver Malinay (Energy Modeler/Analyst) completed his 32nd week helping run the energy analysis calculations to help us achieve LEED Platinum status for the Duplicable City Center. This week, Ian continued the narrative report for the whole-building simulation of LEED.

He processed the interior and exterior lighting, receptacle and process loads and HVAC systems for Baseline whole building simulation. This guide is applicable to model the building based on LEED guidelines. This Baseline design is another energy model to compare the energy savings of the two design cases.

Please see below related screenshots of activity for reference.

Luis Manuel Dominguez (Research Engineer) completed his 24th week helping with research related to the City Center Eco-spa designs. This week Luis made some modifications to the City Center Spa design schematic, incorporating a submersible pump. This pump allows for rapid draining without the permanent installation of a pump and plumbing.

This would make it significantly more convenient to drain the spa quickly for cleaning and any maintenance that might be necessary. Further research has also been completed with regards to the pump and the blower. Finding the perfect pump has taken some time, but after Luis’s collaboration with the team, a selection should be coming soon.

Pictures below are related to this work.

Venus Abdollahi (Architectural Designer) completed her 14th week helping finish the Duplicable City Center designs. This week, Venus started editing section A_A according to the new cut line and new positions of the stairs.

She created a presentation to get clarification on some questions she had and uploaded all the past Revit and AutoCAD files to the “Final Files – Dormer and Cupola and Living Dome Roofs” folder. See pictures below.

And Carlos Lillo (Engineering Technician) completed his 12th week helping with the pallet furniture designs for the Duplicable City Center guest rooms.

Carlos’ focus this week was finishing the edits needed for delivering the longest render of all the furniture: The Pallet Bed. Given the time it takes to process longer renders, he increased the frame rate and assembly speed so it would look like the other renders when edited in a video edition software. Pictures below are related to this work.

Xuanji Tang (Architectural Designer) completed her 7th week working on Duplicable City Center architectural review and updates related to the structural code. This week, Xuanji continued the floor plan updates. She shrank the boiler room and updated the stairs to make a fire approved enclosed staircase.

She also started the roof design along with the change of the two staircases. Pictures below are related to this work.

And George Koshy (Design Engineer) completed his 5th week working on the Duplicable City Center connectors we’ll use to build the domes. The week George designed variations of the bracket to see the effects of stress. He found that the stress in the wide brackets are lower by 2*e^8, but still higher in yield stress.

He concluded that more design iterations are required and other factors need to be reassessed. He conducted FEA for different load conditions when the brackets are fully suspended. He interpreted the results to confirm the inferences and assumptions. He also completed assembly of the center hub, including the redesign of the LVL beams, brackets, and fasteners.

The pictures below relate to this work.

Huiya Yang (Volunteer Architectural Designer) completed her 34d week working on the Duplicable City Center architectural review and updates related to the structural code. This week, Huiya had a few meetings with Xuanji and Yuxi to discuss the best way to place the staircases on the north and south sides.

She also helped update the architectural plans and built a SketchUp model of the staircases to help check the details in the floor plans. Pictures of some of this work are below.

Bryan Lee Budiman (Industrial Designer) completed his 2nd week working on the Duplicable City Center dormer assembly instructions. This week, he began with deeper research on how to build shed dormers and how to increase dormer’s insulation on a dome building like ours.

In addition, he also researched the standard hardwares needed, this included the costs, materials, and the 3D model. After understanding the problem and solution scope, he sketched and pitched a better frame construction and design and began to update the dormer 3D model in Rhino3D.

The pictures below share some of this developing work.

Yuxi Lu (Architectural Designer) also completed her 2nd week working on the Duplicable City Center architectural review and updates related to the structural code. This week Yuxi met with the team involved in edits with the egress staircase and discussed changes based on feedback.

With several proposals of changes through sketches, she updated the sketches into CAD with proper measurements. Later, the team found that the previous stair design is causing problems for entry and storage spaces. Yuxi verified the code for egress stair requirements and updated the CAD file for further feedback.

Pictures of some of this work are below.

GLOBAL ECO-COOPERATIVE MOVEMENT – HIGHEST GOOD FOOD PROGRESS

One Community is supporting a global eco-cooperative movement through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is supporting a global eco-cooperative movement through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

This week the core team continued working on the Chicken Coop Assembly document.

We set up a template format for images and text, added detailed measurements for fascia board cut outs, finished the section about sheeting of the roof with all necessary images and instructions, designed the drip edge SketchUp component, and started to generate images and provide instructions for drip edge installation starting with the eave drip edge on the north side of the roof.

Pictures below are related to this work.

Another team member worked more on the chicken coop roofing system too. This week’s focus was adding photos that distinguish regular studs from king studs, step-by-step assemblage and text descriptions of exterior OSB, window, and upper and lower plate placements, and providing further descriptions of the rafter design.

This entailed describing the necessary cuts so the rafters, while at an angle, are seated firmly and squarely on the top plates while accommodating the roof pitch.

Qiuheng Xu (Landscape Designer) also completed her 54th week volunteering, now helping with the Aquapini & Walipini external landscaping details. This week Qiuheng organized her recent work and uploaded the files so they are backed up to the cloud.

She also did another round of updates and revision of the landscape design as well as the video walkthrough, mainly updating the structure details and the terraces around them. Pictures below are related to this.

Frank Roland Vilcapaza Diaz (Mechanical Engineer) completed his 15th week helping with the Aquapini & Walipini and Tropical Atrium climate battery designs. This week Frank worked on a different approach for calculating infiltration energy losses.

The new approach is more exact and helps with predicting the real energy consumption of the Tropical Atrium and the Aquapini and Walipini designs. A comparison was made between both methods and graphs were adjusted to show the difference. The pictures below relate to this.

And Brian Storz (Culinary Project Manager) completed his 5th week helping lead the completion of the Transition Food Self-sufficiency Plan, Transition Kitchen designs, Food Procurement and Storage plan, and related menu and meal plans. This week Brian worked on preparing recipes that can be used for the transitional kitchen, specifically soup recipes.

He developed nutritious recipes that are exciting and interesting, including Sweet Potato with Miso, Coconut Milk Soup, a Thai and Chicken Soup, Base Soup Stock recipes, as well as some recipes interns/externs can use as examples for their projects. Below are some images related to this work.

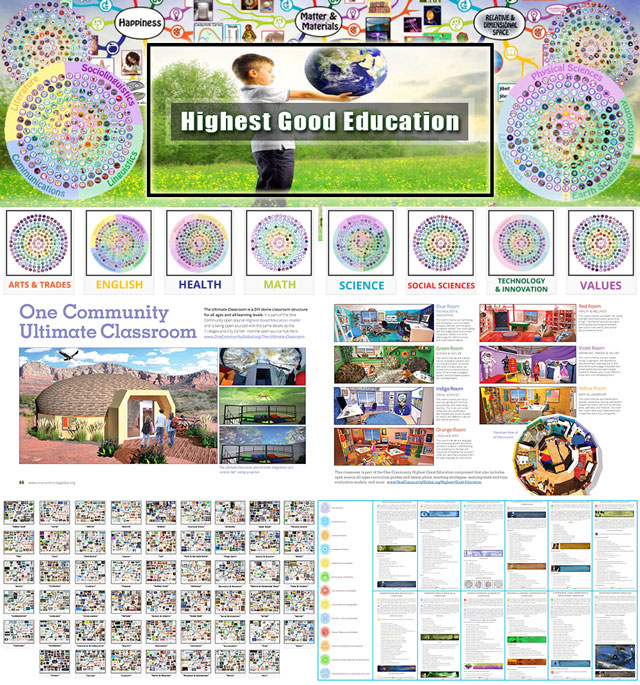

GLOBAL ECO-COOPERATIVE MOVEMENT – HIGHEST GOOD EDUCATION PROGRESS

One Community is supporting a global eco-cooperative movement through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

One Community is supporting a global eco-cooperative movement through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

Highest Good Education: All Subjects | All Learning Levels | Any Age – Click image for open source hub

GLOBAL ECO-COOPERATIVE MOVEMENT – HIGHEST GOOD SOCIETY PROGRESS

One Community is supporting a global eco-cooperative movement through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is supporting a global eco-cooperative movement through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

This week the core team completed 15 hours managing One Community volunteer-work review not included above, emails, social media accounts, and interviewing and getting set up new volunteer team members.

Also additional testing and bug identification and correction confirmations for the Highest Good Network software were completed. Pictures below show some of this.

Guy Grossfeld (Graphic Designer) returned to the team to help with badge design for the Highest Good Network software. This week Guy integrated feedback on the first round of badges for the Stewardship category and began design work on the Economics category. You can see some of the related conversations and design process below.

Narek Tsaturyan (Software Engineer) completed his 10th week working on the Highest Good Network software. This week Narek worked more on testing badge award functionality. He found more bugs and added them to the bugs report docs. The pictures below are related to this work.

Aleksandra “Alex” Gorkovenkø (Graphic Designer) also completed her 10th week working on images for our open source social media strategy. This week, Alex improved her 12 posters from week 9 and then created around 60 new posters with quotes that were already approved. She also created an additional 30 slogans and found around 100 new images that seemed suitable.

What you see below is a sample of some of our favorites.

Hannah Gardner Hattersley (Software Engineer) completed her 4th week working on the Highest Good Network software. This week, Hannah continued to work on badge testing, adding the new profile dot/isAcive dot features, and deepening her understanding of the badge logic. See pictures below that are related to this work. Pictures below are related to this work.

Pranav Borole (Software Engineer) also completed his 3rd week working on the Highest Good Network software. This week Pranav completed resolving 2 low-priority issues in the Beta Test Bugs document. He mainly worked with the Admin functionality to Create New User and built features solving the issues on the existing form.

He modified the form to look cleaner and added validations on the form fields. Pictures of some of this work are below.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE | WAYS ANYONE CAN HELP | MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

One Community

One Community