1000 Years of Sustainability – One Community Weekly Progress Update #415

How do we launch 1000 years of sustainability? One Community has spent the last ten years creating the roadmap for this. Simplified, it is to demonstrate a model of sustainable living that is easy enough, affordable enough, and attractive enough to spread on its own. Teacher/demonstration hubs will help anyone interested in participating. Once it spreads sufficiently to cross the tipping point where we can say we have achieved year ONE as a truly sustainable civilization, we’ll have succeeded in launching the 1000 years.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world. This is the March 7th, 2021 edition (#415) of our weekly progress update detailing our team’s development and accomplishments, emphasizing 1000 years of sustainability:

1000 Years of Sustainability

One Community Progress Update #415

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

ONE COMMUNITY WEEKLY UPDATE DETAILS

HIGHEST GOOD HOUSING PROGRESS – 1000 YEARS OF SUSTAINABILITY

One Community is forwarding 1000 years of sustainability through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is forwarding 1000 years of sustainability through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

This week the core team finished beautifying the Structural Engineering and Calculations tables for the Earthbag Village “Earth-Dome Loft Structural Engineering and Calculations” page.

The core team also updated the complete open source library Work Breakdown Structure, marking complete the items that were done and crossing them off, adding a couple missing items, updating all the assigned tasks, double checking the sequence of numbers, and making sure that any Resources with general names like Civil Engineer or Video Editor were labeled as ‘No’ under Assigned. See pictures below.

And the core team conducted edits on the Earthbag Village Footer, Foundation and Flooring development Doc sections 5.4, 5.5, 6.4, 6.5, 6.6, and 6.7. This included the exterior waterproofing membrane, vertical interior insulation, vapor barrier installation, welded wire fabric placement, pouring and screeding of concrete, setting of control joints, and broom finish, cure and seal. See pictures below for some screenshots related to this.

1000 Years of Sustainability – Earthbag Village Footer, and Flooring Development Doc ” Click for Page

Dean Scholz (Architectural Designer) continued helping with the Earthbag Village (Pod 1) 4-dome cluster designs. This week was week #215 of Dean’s work and the focus was creating and testing the kitchen table texture, fixing broken dome textures, and importing SketchUp models into 3DS Max for texturing.

Jose Luis Flores (Mechanical Engineer) completed his 32nd week helping finish the Net-zero Bathroom component of the Earthbag Village. This week Jose Luis completed the rough draft of the Insulation and Heating Element sections of the Net-Zero Bathroom tutorial/instructions. In the instructions he included the steps required to construct the necessary structures to help further insulate the rainwater storage room of the Net-Zero Bathroom. The steps were written out clearly and included details on the reasoning behind the process to help the user determine whether it is applicable to their environment.

With the rendering he was able to determine the amount of aircrete needed to complete the second half of the structure connecting the roof to the top barrel and the aircrete insulating the ceiling. The additional section of heating elements was included to give the user preventative options in the case of freezing environments. It also elaborated how the elements were not necessary to every user, but needed to be gauged as necessary depending on the weather patterns in the location selected. The final touch ups to these sections will involve adding calculations and elaborating more if necessary. The pictures below show some of this work.

Stacey Maillet (Graphic Designer) completed her 30th week working on the final edits and revisions to the Murphy bed instructions. This week Stacey focused on the wall section and updating the details, working to finalize the pages by checking the layouts are consistent and adding the greyed-out pieces to the header as they were used. She also continued to work on the components pages.

At this point the files are getting larger and some of the steps had to be separated into different files which won’t matter as to the continuity but it was an unexpected setback taking the time to work on files that were slowing down due to technology restrictions and rechecking little details this week. This brings us closer to completion in the instruction manual but there is still a bit more work to be done. Screenshots below are related to this latest progress.

Hannah Copeman (Structural Engineer) completed her 27th week helping complete all the Earthbag Village tutorials. This week Hannah continued the development of the Earthbag Village dome construction by continuing work on the Footer, Foundation and Flooring tutorial. She completed Section 6 (Floor Construction) of the tutorial document by writing the remaining sections for installing the thermal insulation and vapor barrier, placing the welded wire fabric reinforcement in the slab, finishing the concrete floor slab, and applying metal sheet flashing around the interior perimeter of the dome.

Hannah also researched sealant products for the foundation and floor insulation and revised previous sections to include the new information. You can see some pictures of this work below.

Mark Wambua (Civil Engineer) completed his 8th week working on the Parking Lot and Sustainable Roadways, Walkways, and Landscaping guides. This week Mark worked on defining the regulations necessary for a road that is IFC compliant. He also worked on giving brief descriptions of different pavement options. Pictures below show some of this work-in-progress.

1000 Years of Sustainability – Regulations Necessary for a Road That Is IFC Compliant – Click for Page

Zhiheng “Samson” Su (Civil Engineer) also completed his 8th week on the team and woking on the Parking Lot and Sustainable Roadways, Walkways, and Landscaping guides. This week Samson wrote paragraphs about his suggestions for pavement, researched de-icing material, cost estimation of porous asphalt pavement, and permeable interlocking concrete pavers. He also wrote the final narrative for porous asphalt pavement including the benefit, cost, challenges, and solution. Additionally, Samson reviewed the comments from Aidan and added some details about the recycling of the materials. He also added some information about types of flexible and rigid pavement materials in the Pavement Types section. See pictures below.

Vicente J Subiela (Project Management Adviser) completed his 7th week working on the solar microgrid design, sizing, and cost analysis specifics. Vicente has completed a first version of the economic balance, with an example of the economic flows along one day, estimating an idea of the economic deficit. He also discussed with Jae the study of the energy demand for the hot tub and how to incorporate the new collaborators into it.

He has added new data to the solar sizing tool, namely the hourly profile (1 – 8760) of thermal demand for the City Center (based on the environmental temperature given by the SAM software weather database) and following the methodology described in the description document. Pictures below show some of this work.

1000 Years of Sustainability – Solar Micro-grid Design, and Cost Analysis Specifics ” Click for Page

Aidan Geissler (Sustainability Researcher) completed his 4th week helping with 2nd-to-final review, feedback, and content editing. Aidan contributed further to the Glass Recycling content by researching and beginning to write tutorials for DIY glass kilns and glass crushers. He also revisited the Styrofoam Recycling webpage, where he added supplemental information about comparing the R-values of various insulation materials in order to assess the effectiveness of DIY insulation projects using surplus Polystyrene materials.

Aidan continued to review and provide guidance and suggestions for other current research, including Pavement Engineering and the latest updates to the Health Insurance research too. Pictures of some of this work are below.

1000 Years of Sustainability – 2nd-to-final Review and Content Editing – Click for Glass Recycling Page

Jeson Hu (Mechanical Engineer Assistant) joined the team and completed his 1st week helping with research related to the solar microgrid design, sizing, and cost analysis specifics. This week Jeson completed the initial setup and orientation, and started the research on the best solar hardware. The pictures below share some of this developing work.

1000 Years of Sustainability – Solar Micro-grid Design, and Cost Analysis Specifics – Click for Page

Luis Manuel Dominguez (Research Engineer) also joined the team and completed his 1st week helping with research related to the solar microgrid design, sizing, and cost analysis specifics. This week Luis began his research for our Eco-spa Design and how to increase its power efficiency. He began by understanding all of the internal components that draw the most power: the pump and the heater.

His next step was to understand where the heat was lost for most in-ground hot tubs. Luis discovered that heat is lost primarily to the atmosphere and evaporation along with heat transfer to the ground. His solution to this issue was to provide insulation from the ground through polyurethane or an expandable foam layer and sand beneath that. These would allow the heat loss effects to be decreased significantly and optimize the hot tub. The pictures below share some of this developing work.

DUPLICABLE CITY CENTER PROGRESS – 1000 YEARS OF SUSTAINABILITY

One Community is forwarding 1000 years of sustainability through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is forwarding 1000 years of sustainability through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

This week the core team continued modeling in SketchUp 3D the window framing for the shed dormer windows of the second floor of the Duplicable City Center Living Dome. We designed the dome frame section using 2×12 lumber and created the initial detailed framing shown below.

1000 Years of Sustainability – Shed Dormer Windows in Sketchup 3D – Click for Duplicable City Center

Ksenia Akimov (Plumbing Engineer) completed her 23rd week working on the Duplicable City Center plumbing designs. This week, Ksenia discussed with Christopher the most efficient way to collaborate on the remaining plumbing details. She made PDF files for Christopher for calculating and put the sinks in the boiler room and mechanical rooms. She also joined water fountains into the water pipes and sewer. Pictures below are related to this work.

Qiuheng Xu (Landscape Designer) completed her 22nd week helping with the Duplicable City Center, now focused solely on the landscaping design. This week Qiuheng concentrated on further development of the plant design with the herb garden. She also drew some diagrams to explain the overall design ideas. Pictures below show some of this work-in-progress.

1000 Years of Sustainability – Plant Design With the Herbal Garden – Click for Duplicable City Center

Ian Oliver Malinay (Energy Modeler/Analyst) completed his 11th week helping run the energy analysis calculations to help us achieve LEED Platinum status for the Duplicable City Center. This week Ian checked the overall details of the HVAC system. He tried to understand the installation, heating and cooling results and all the spreadsheet calculations and summary of the HVAC analysis developed by previous Engineers, combining this and their efforts for us to attain our goal of LEED Platinum certification of the building. Ian also created preliminary HVAC designs using the DesignBuilder software for the mini-splits air-conditioner. The pictures below relate to this work.

1000 Years of Sustainability – Overall Details of the HVAC System – Click for Heating and Cooling Page

Haozhen “Andrew” He (Civil Design Engineer) completed his 9th and final week as a member of the team helping with the City Center Water Catchment Designs. In Haozhen’s final week working on the project, he completed all the 3D drafting for the City Center rainwater catchment expected Zone D3. He then researched the materials that the zone D-3 can use for its downspout. Two of the materials were identified, polyester and TPE (Thermoplastic Elastomer).

PVC laminate polyester duct hoses are flame-retardant and self-extinguishing and resist damage from moisture, oils, ozone, and UV rays. Thermoplastic rubber duct hoses have an external wear strip that protects the hose from abrasion when dragged, preventing premature wear-through. The wear strip is molecularly bonded to the hose wall and will not delaminate from the hose. These hoses resist chemicals, moisture, ozone, and UV rays and are 4″ in diameter too, which is the perfect size to connect it to the piping system underground. The team was thinking of using TPE as our final product of zone D-3 downspout because TPE is 10% cheaper than polyester while they both can do the job as downspout.

Unfortunately though, this ducting hose is meant for transporting gases, fumes, dust, etc. To use this product (due to its flexible application) in replacement of a rainwater downspout is an interesting alternative, but we have never seen it in application before and therefore cannot say with full confidence that this would be okay. We’ll continue seeking another product. Pictures of some of this work are below.

David Na (Project Management Adviser/Engineer) completed his 4th week helping with input and management of the Parking Lot and Sustainable Roadways, Walkways, and Landscaping tutorial development, as well as the City Center Water Catchment Designs. David started the week by organizing and running a meeting with his team to set the pace and deadlines for specific action items. During the week, David worked with Mark to finish up the temporary parking lot tutorial for final submission.

He also worked with Samson to prepare the roadway and parkway design tutorial for a review by Jae. Along with this, David prepared the civil site design plan and layout for the City Center project so that he can assign Mark and Samson CAD responsibilities for after next Monday’s meeting. Pictures below are related to this work.

1000 Years of Sustainability – Sustainable Roadways Tutorial Development – Click for Parking Lot Page

Saffet Kilçer (Structural Engineer) completed his 3rd week working on the Duplicable City Center beam and column designs using SAP2000. This week the earthquake records required to determine the earthquake load were downloaded from PEER. The California earthquake (Kern country-1952 / Mw = 7.36) was chosen among many earthquakes and its intensity acceleration-velocity and time file was downloaded. This one was selected because it was the largest and most severe earthquake in California. The earthquake file was edited in the SAP2000 program and drawn in the Time History area. Pictures below are related to this.

Christopher Kinney (Environmental/Civil Engineer) also completed his 2nd week working on the Duplicable City Center plumbing designs. This week Christopher collaborated with Ksenia about current progress and what needs to be done. He reviewed the latest plumbing plan details and also investigated gray water Systems Plumbing Codes and water fixture flow rates. He compared currently-used water fixture values in the design against those published in the latest international Plumbing Codes and verified its accuracy.

The Utah building codes department notified that there is no enforcement against not having coverage over plumbing pipe in over a food storage area. However, this may still be enforced by health inspectors or the agricultural department. Pictures below show some of this work.

Sunitha Paraselli (Mechanical Design Engineer) joined the team and completed her 1st week working on the Duplicable City Center connectors we’ll use to build the domes. This week Sunitha designed an initial City Center Hub component testing both stainless steel AISI Type 316L and Aluminum 2024-T3 and checked deflection and stress under different loads. As far as loading factor is concerned Aluminum was determined to be a good design. It is readily available and you can also make them by bending.

If you are bending, the bending radius can be 2.5 times the material thickness, and there are multiple ways to bend the metal. This coming week Sunitha will work on designing, testing and comparing other designs. The pictures below relate to this work.

HIGHEST GOOD FOOD PROGRESS – 1000 YEARS OF SUSTAINABILITY

One Community is forwarding 1000 years of sustainability through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is forwarding 1000 years of sustainability through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

This week Jiayu Liang (Landscape Designer) completed her 23rd week helping with the Aquapini & Walipini internal and external landscaping details. This week, Jiayu updated the new structures for the models both in Rhino and Lumion. She has updated the new material of sola wrap for the roofs. She also added new railings and handicap access for the central pond and made a new animation for the outdoor landscape design.

Henry Vennard (Mechanical Engineer) completed his 21st week helping continue the development of the climate batteries for the Aquapini/Walipini structures. It was decided this week that the only way to validate our aquapini/walipini models will be to build the first one and test it. We expect the climate battery system to work perfectly regardless of the Matlab code and based on the assumption that it has worked great for many other people and has allowed a Nebraska farmer to grow citrus with a very small energy bill.

When this system is finished and installed, data will be taken to validate its effectiveness and consider its cost effectiveness and whether to install it in the remaining greenhouses. Henry then worked on Walipini research to see how much that could make a difference given data that is already out there. He did not find any conclusive evidence that could be used to update his Matlab model. Pictures below show some of this work-in-progress.

1000 Years of Sustainability – Climate Batteries for the Aquapini/walipini Structures – Click for Page

Mayur Rajput (Mechanical Engineer) also completed his 7th week working on the Aquapini/Walipini structures. Mayur met with the team members this week and discussed the future plans based on the calculations completed for the climate battery. He looked into the walipini structures, totally passive greenhouses, and rocket mass heaters and researched how all of it would affect and help in a more energy efficient and sustainable design of the greenhouses.

Mayur continued his work to look for heaters and fans for the greenhouse based on the calculations. He found the different available options for the heaters and compared their performances in order to identify the best solution for the greenhouse. He will continue learning about all the different types of heaters and fans, and decide how to select the appropriate equipment for the greenhouse. The pictures below represent his work on all of the above.

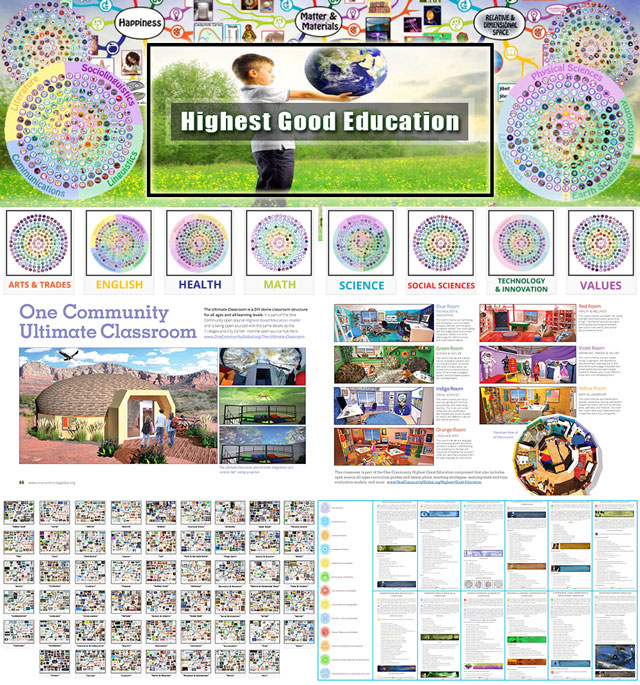

HIGHEST GOOD EDUCATION PROGRESS – 1000 YEARS OF SUSTAINABILITY

One Community is forwarding 1000 years of sustainability through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

One Community is forwarding 1000 years of sustainability through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

HIGHEST GOOD SOCIETY PROGRESS – 1000 YEARS OF SUSTAINABILITY

One Community is forwarding 1000 years of sustainability through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is forwarding 1000 years of sustainability through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

This week the core team completed 34 hours managing One Community emails, social media accounts, interviewing potential new volunteer team members, and managing volunteer-work review and collaboration not mentioned elsewhere here.

The core team additionally completed our 12th week working on improving the content for all our Values Pages. This week we created 3 mind maps covering the values of Highest Good of All Stewardship, Community Contribution, and Fulfilled Living.

And the core team gave detailed feedback on the final drafts of the One Community’s insurance options research and spent time improving the aesthetics of the tables that will be featured on the webpage. Below are some images related to this work.

Wen Zhang (Software Engineer) completed her 40th week as a volunteer working on the Highest Good Network software. For this week of Wen’s work, merge conflicts were solved and new pull requests created for back-end and front-end repositories. The function to delete badges was completed. She also spent quite a lot of time working on the mongoose $pull on the backend (nested data type of badges), and UI fixes on the frontend (Modal and Alert in reactstrap don’t work nicely together). The implementation of alert messages (used in create badge, assign badge, and delete badge) was improved and code cleaned up too. Pictures below are related to this work.

1000 Years of Sustainability – Solved Merge Conflicts and Created New Pull Requests – Click for Page

TEKtalent Inc.(a custom programming solutions company) also continued with their 36th week helping with the Highest Good Network software. This week Nithesh and the TEK Talent team were working on the changes in the forget password flow. A new column for reset password has been introduced in user profile and the same will be getting updated with random password on forgot password option. This will allow the user to login with the password they received in email as well as their original password. Once logged in using the random password they have to reset their password and the random password will expire (this is yet to complete). Pictures below show this work.

Chris Weilacker (Software Engineer) completed his 24th week working on the Highest Good Network software. This week, Chris completed his work on making the Summary Bar responsive as well as building out the backend for the Bug Report form on the Summary Bar. Chris also built out the backend for the Leaderboard to get the information on the entire organization for the summary values not just the leaderboard based on the teams that a person is a part of. You can see some pictures related to this below.

Jaime Arango (Graphic Designer) completed his 23rd week helping, returning to creating images for the One Community Updates Blogs like this one. This week we created images for weekly progress updates #445, #446, and #447. He also started creating JPG versions of the images for video intro for future use on inspirational quotes. So far he has been able to create around 20 of those JPG images. You can see all these new images below.

Vy Dao (Software Developer) completed his 6th week working on the Highest Good Network software. For this week, Vy continued work on reviewing, testing multiple Pull-Requests for both Back-End and Front-End branches. Vy also updates the HGN Functional Specification Documentation with a screenshot of a few unit-testing files. He also worked on multiple unit-test files under the UserProfile component such as UserProfile.jsx, UserProfileEdit.jsx, and more. Pictures below show some of this work.

Yueru Zhao (Software Engineer) completed her 6th week working on the Highest Good Network software. This week Yueru worked on updating the “custom range” section in the dropdown. When the user clicks the “custom range”, they will be able to select a random start and end time. She also worked on showing all the tasks that belong to a specific project and all the project members. Pictures below are related to this work.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE | WAYS ANYONE CAN HELP | MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

One Community

One Community