Vermiculture Eco-toilet Container Transport Solution

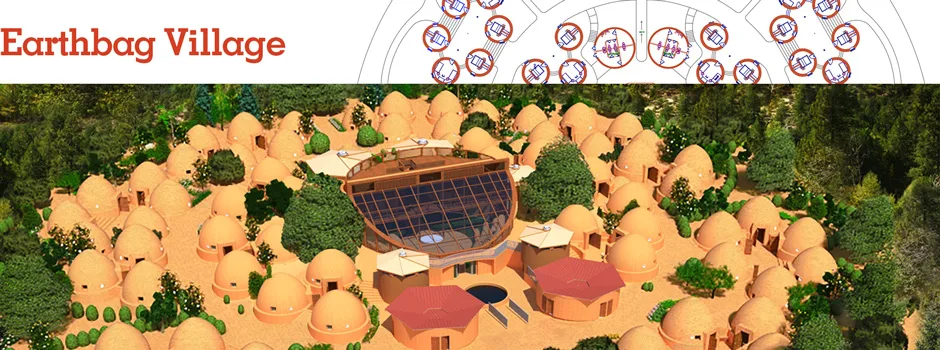

As part of the the open source Earthbag Village (Pod 1), we will be building and are open source project-launch blueprinting an ultra-eco vermiculture transport solution for worm composting solid waste processing option. This page discusses the designs for transporting the filled containers with the following sections:

- What is a Vermiculture Container Transport Solution

- Why open source a Vermiculture Container Transport Solution

- Electric Utility Vehicle (EUV)

- How Was the EUV Selected? (Initial Analysis & Criteria)

- How to Calculate if an EUV Can Tow a Specific Trailer

- What are the Minimum Power and Towing Capacity Requirements for EUVs

- What are the General Power & Capacity Requirements

- What are the Top 5 EUV Options to Consider

- Electric Utility Vehicle: Final Summary

- How to Operate an Electric Utility Vehicle Safely

- Utility Trailer

- Electric Winch

- What Accessories Improve Transportation Efficiency

- Ways to Contribute and Consultants

- Resources

- Summary

- FAQ

NOTE: THIS PAGE IS NOT CONSIDERED BY US TO BE A COMPLETE AND USABLE TUTORIAL UNTIL

WE FINISH OUR OWN CONSTRUCTION OF THIS COMPONENT, CONFIRM ALL THE DETAILS, AND ADD

TO THIS PAGE ALL THE RELATED VIDEOS, EXPERIENCE, AND OTHER UPDATES FROM THAT BUILD.

IN THE MEANTIME, YOU CAN HELP US COMPLETE IT ALL SOONER WITH THE FOLLOWING OPTIONS:

INPUT & FEEDBACK | JOIN OUR TEAM | HELP US BUY THE PROPERTY

RELATED PAGES (click icons for complete pages)

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

WHAT IS A VERMICULTURE CONTAINER TRANSPORT SOLUTION

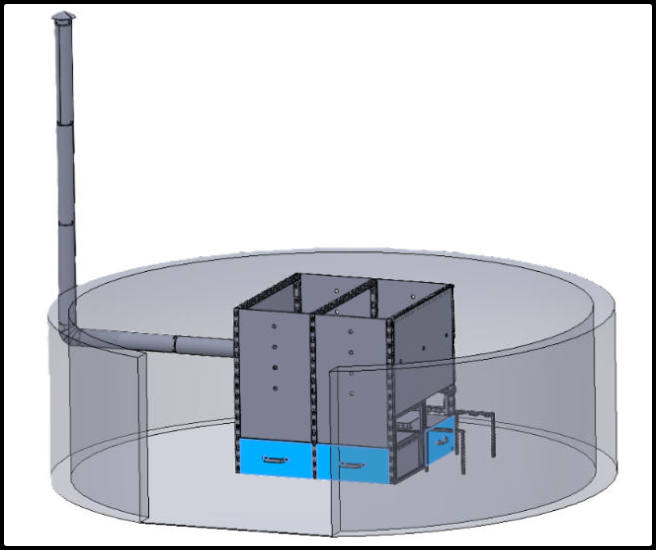

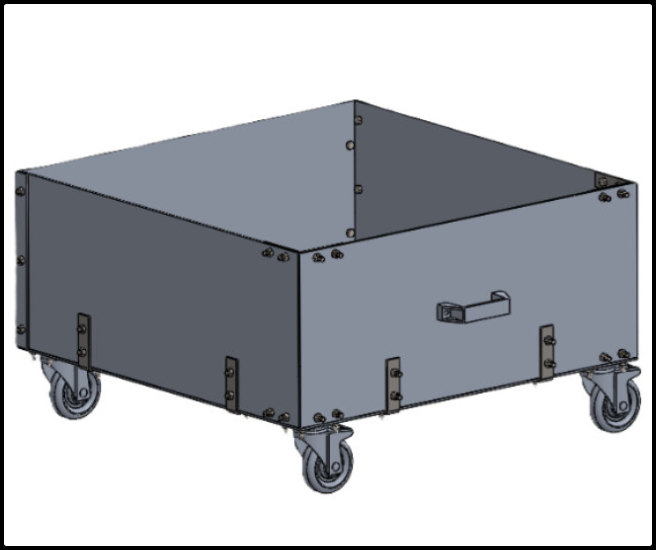

The vermiculture toilet system consists of four drawers filled with waste that has gone through the vermicomposting (worm composting) process. These drawers need to be emptied approximately every six months, after the worms have processed everything in them. The pictures below show the main unit and these drawers, and this report examines the sustainable resources required for the efficient vermiculture transport solution to move these drawers to the designated dumping site.

The vermiculture toilet system consists of four drawers filled with waste that has gone through the vermicomposting (worm composting) process. These drawers need to be emptied approximately every six months, after the worms have processed everything in them. The pictures below show the main unit and these drawers, and this report examines the sustainable resources required for the efficient vermiculture transport solution to move these drawers to the designated dumping site.

Vermiculture Collection Chamber

Compost Drawer

The four drawers, each with dimensions of 50″ x 48″ x 21″, have a weight of approximately 1,066 lbs when filled with compost. These drawers are equipped with four wheels for easy mobility and must be emptied every six months as part of the composting cycle.

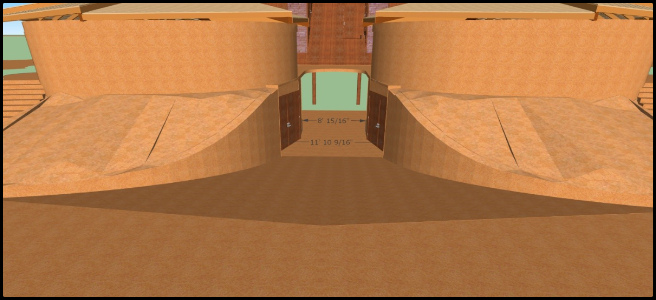

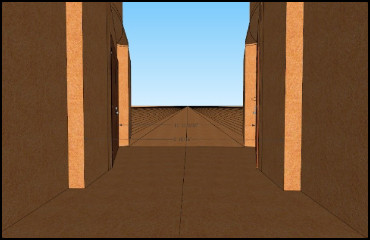

The drawers are situated in the bottom section of a vermiculture compound below the collection container, which is accessible via an inclined ramp leading down to the lower level of the structure:

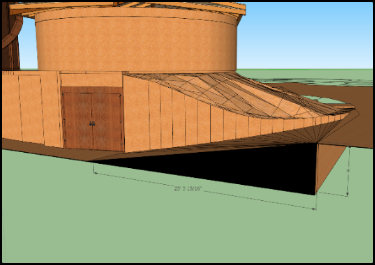

SketchUp Vermiculture Compound Rendering

The vermiculture structure includes a door that opens onto a horizontal ramp. The ramp has a width of 11 feet up to the doors, narrowing to 8 feet beyond that. The ramp extends for a total length of 26.85 feet.

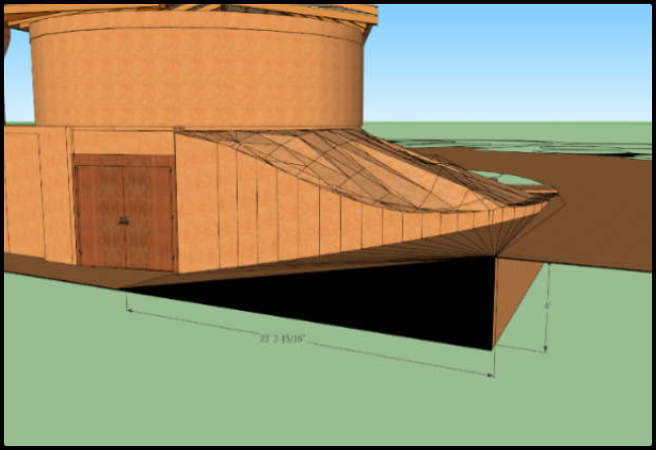

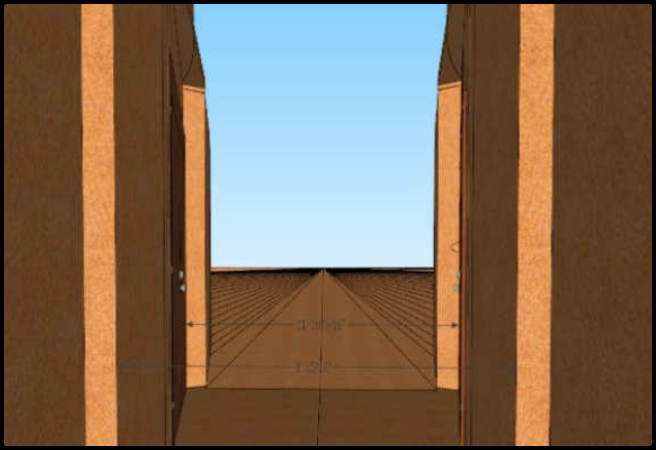

An inclined ramp extends from the opposite side of the horizontal ramp, leading up to the upper road. It has a 9.74° incline, begins with a minimum width of 11 feet that widens as it ascends, and spans a length of 23.6 feet.

Inclined Ramp Rendering

Isometric View of Ramp

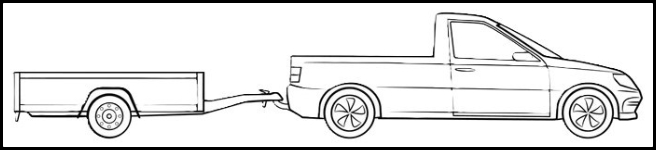

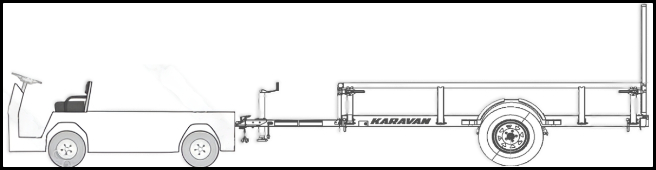

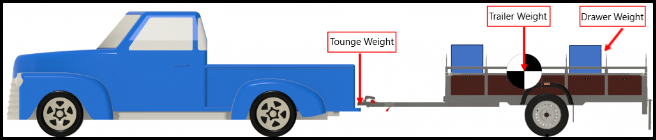

Moving the drawers from the unit to the location where they will be dumped will utilize a multi-purpose electric vehicle and trailer like the one shown below.

Here’s a video of the complete process of loading the filled drawers onto the trailer:

VIDEO COMING OF: VERMICULTURE DRAWER LOADING: FROM DOOR ONTO TRAILER

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

WHY OPEN SOURCE A VERMICULTURE CONTAINER TRANSPORT SOLUTION

Due to the nature of vermiculture composting, the compost, which weighs around 1,066 lbs per drawers, needs to be removed from the system approximately every six months, but this interval may vary. To ensure the safe and efficient transport of all four drawers, it is essential to develop a reliable transportation system that can handle this process effectively.

Due to the nature of vermiculture composting, the compost, which weighs around 1,066 lbs per drawers, needs to be removed from the system approximately every six months, but this interval may vary. To ensure the safe and efficient transport of all four drawers, it is essential to develop a reliable transportation system that can handle this process effectively.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

KEY CONSULTANTS TO THE EARTHBAG VILLAGE VERMICULTURE TOILET DESIGNS

Adil Zulfiquar: Mechanical Engineer (research and design)

Keerthi Reddy Gavinolla: Software Developer (website design for this page)

ELECTRIC UTILITY VEHICLE (EUV)

An electric utility vehicle (EUV) is a key component of our transportation solution, as it will be used to tow trailers loaded with filled compost drawers.

In this section, we will outline our initial considerations and challenges in selecting the right EUV. We’ll also provide an illustrative example to assess whether the EUV can tow a trailer with a specified weight. Finally, we will present our top five EUV choices and conclude with our final recommendation.

HOW WAS THE EUV SELECTED (INITIAL ANALYSIS & CRITERIA)

In this section, we explore the thought process and key considerations involved in selecting an electric utility vehicle (EUV). We will outline the critical criteria that shaped our decision-making, including factors such as towing capacity, vehicle dimensions, power requirements, and overall cost-effectiveness. These considerations were essential in identifying the most suitable EUV to meet our operational needs efficiently and safely.

VEHICLE WIDTH

Vehicle width was a key factor in our selection of an electric utility vehicle and, as shown below, vehicle dimensions can vary significantly. We initially had dimensional constraints for navigating ramps with a width limit of 89” (soon to be extended to 10 feet).

Cushman Titan XD Dimensions

Pack Mule BCT-6200 Dimensions

We only considered vehicles with an overall width of less than 80” that also met our towing capacity and power requirements. However, once we determined that the vehicle wouldn’t need to go down the ramp*, this criterion became less critical. Despite this, we still prioritized vehicles with a narrower width to ensure easier, more flexible mobility, especially around tight corners.

Question: What if someone chooses to take the vehicle down the ramp anyway?

The trailer and vehicle are sufficiently equipped to descend the ramp as initially planned, with power requirements carefully evaluated to meet the demands of this scenario. The selected Electric Utility Vehicle (EUV) is designed to manage the necessary towing forces on an incline, with a 20% safety margin incorporated into the power requirement calculations to enhance performance reliability under these conditions. It is important to note that this power requirement and margin are based on a maximum total trailer weight of 4,400 lbs. Any additional load could impact the vehicle’s performance. Detailed calculations, provided below, account for both the incline and the additional trailer load, ensuring operational safety and efficiency.

VEHICLE COST

Electric utility vehicles come in a wide price range, from $5,000 to $50,000, depending on their features and build quality. To keep our solution cost-effective, we focused on vehicles that met or exceeded our requirements while also being priced at the lower end of the spectrum. This approach allowed us to find reliable options that delivered the necessary performance without unnecessary expense.

VEHICLE TOWING CAPACITY

The electric utility vehicle (EUV) must have a towing capacity that exceeds the combined weight of the trailer and its load. It’s important that the EV’s towing capacity is significantly higher than the trailer’s GVWR (Gross Vehicle Weight Rating) to ensure safe operation and provide a safety buffer for performance.

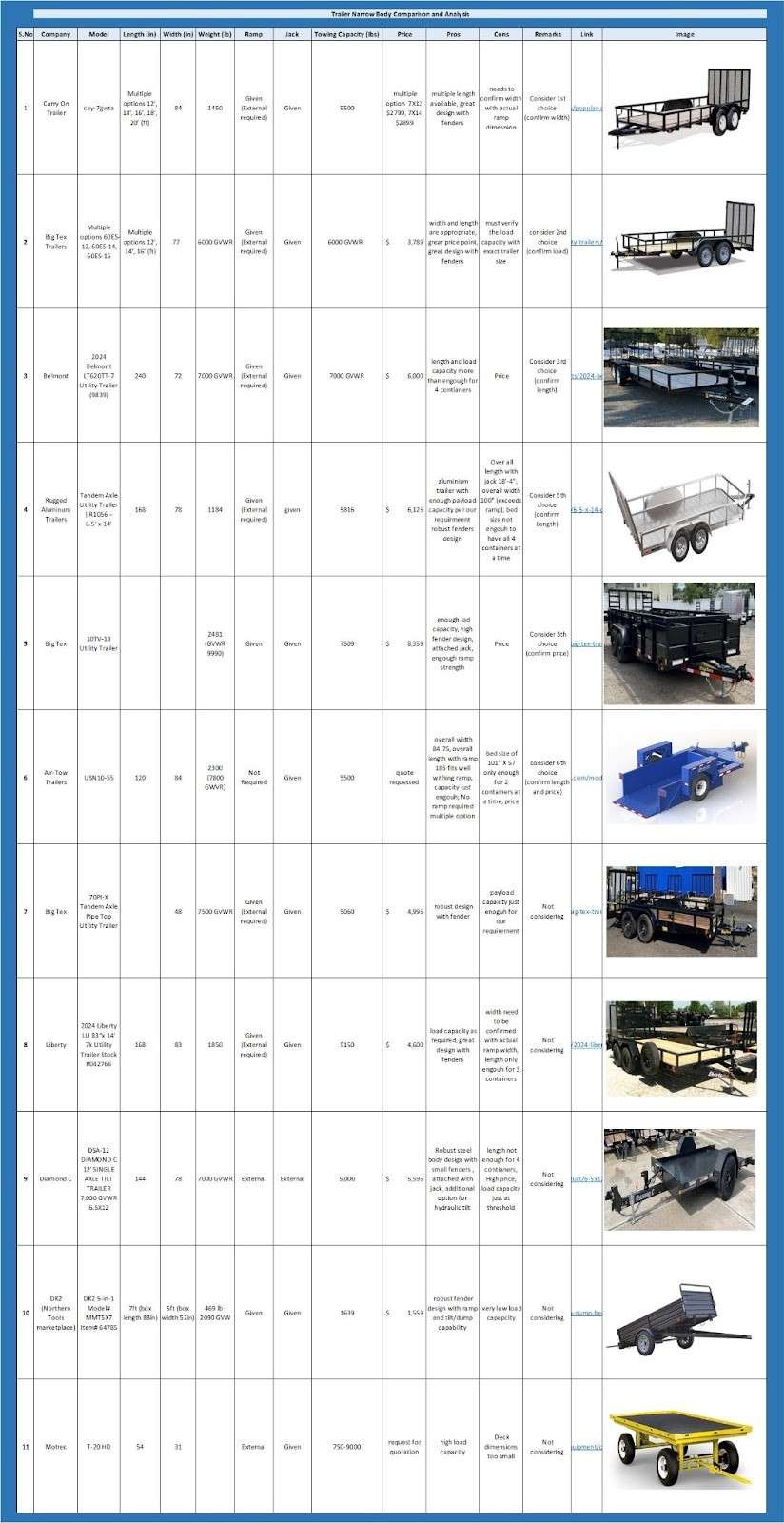

The final towing capacity is largely influenced by the choice of trailer. We analyzed 16 trailer options from various brands, with weights ranging from 1,200 lbs to 4,000 lbs. Given that the combined weight of our drawers is 4,264 lbs, we determined that the minimum required towing capacity is 5,500 lbs, with an ideal range up to 10,000 lbs. A higher load capacity would allow for additional uses without concern.

Below, we present a list of EUV options we considered:

EUV Comparison and Analysis

Our selection process involved evaluating each option against several key criteria. Many vehicles met our minimum width requirement, with the majority passing this criterion. For towing capacity, we found good options in the 5,500 to 6,000 lbs range, but since this was borderline for our needs, we opted for EUVs with higher towing capacity to ensure a safety margin and accommodate potential on-site constraints.

Price was also a major consideration, as many suitable EUVs were priced above $20,000. To maintain cost-effectiveness, we carefully analyzed our requirements to identify the best value options. In addition to width, towing capacity, and price, we considered the vehicle’s range and power rating, which are crucial for navigating inclines in the earthbag village. We also looked at the vehicle’s battery performance and additional load capacity, allowing for versatility in tasks beyond towing.

Based on these factors and the calculations mentioned below, we finalized our top 5 EUV choices, which are shared later in this section.

HOW TO CALCULATE IF AN EUV CAN TOW A SPECIFIC TRAILER

We also needed to determine if our choice of Electric Utility Vehicle would be able to tow our trailer option. This section assesses the capabilities of an (EUV) by determining the minimum power required for optimal performance.

We also needed to determine if our choice of Electric Utility Vehicle would be able to tow our trailer option. This section assesses the capabilities of an (EUV) by determining the minimum power required for optimal performance.

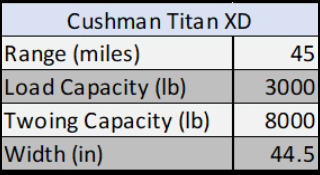

Specifically, we evaluate whether the Cushman Titan XD (for analysis purpose only) can tow a trailer and drawers combination up an 8-degree incline. Building on this analysis, we further explore the power and capacity requirements for an improved solution using a lighter trailer. The goal is to ensure that the vehicle can efficiently manage the load and towing forces. At the end of this section we provide the final recommendation for choosing the most suitable Electric utility vehicle.

- EUV: Cushman Titan XD (17.2 hp, Load capacity: 3,000 lbs, Tow capacity: 8,000 lbs)

- Trailer: Carry On Trailer (Model: cay-7gwta, Weight: 1,450 lbs, Tow capacity: 5,500 lbs)

- Trailer load weight: 4,400 lbs

- Trailer self-weight: 1,450 lbs

- Total trailer weight: 5,850 lbs

- Incline angle: 8 degrees (for calculation purpose)

- Towing speed: 3 mph (approx. 4.4 ft/s)

WHAT ARE THE MINIMUM POWER AND TOWING CAPACITY REQUIREMENTS FOR EUVS

This section presents an analysis of the minimum power and towing capacity required for the electric utility vehicle (EUV) based on the above specified parameters.

GRAVITATIONAL FORCE ALONG INCLINE

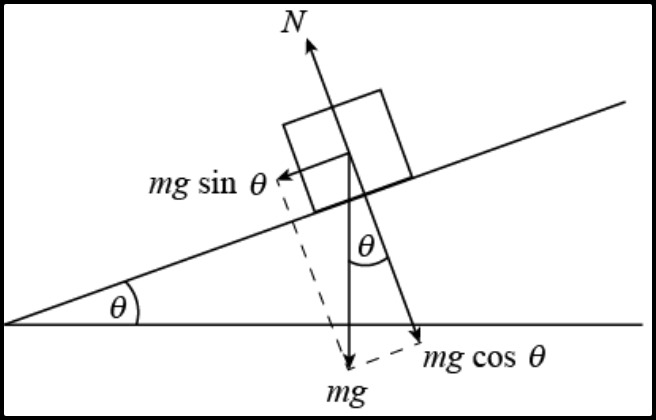

When towing a trailer up an incline, the force resisting the motion comes primarily from the component of gravitational force acting along the slope.

The force of gravity acting along the incline equals the weight of the trailer multiplied by the sine of the angle of the incline:

Fgravity = Wtrailer × sin(θ)

Where:

- Wtrailer is the total weight of the trailer (5,850 lbs)

- θ is the incline angle (8 degrees)

Convert the weight into force (since weight in lbs is already in force units):

Fgravity = 5,850 (lbs) x sin(8∘)

Fgravity ≈ 5,850 (lbs) x 0.1392 = 814.32 lbs

So, the gravitational force pulling the trailer back down the ramp is approximately 814.32 lbs.

It means when towing a trailer up an incline, approximately 814.32 pounds of its weight pulls it back down due to gravity, making it more challenging to ascend. Therefore, we need an Electric Utility Vehicle (EUV) capable of overcoming this load.

WORK DONE AGAINST GRAVITY

The work done to tow the trailer upwards is calculated by the force acting along the incline and the speed at which the vehicle moves. However, power also plays a significant role in determining whether the vehicle can successfully tow the load.

The required power equals the force of gravity acting along the incline multiplied by the velocity:

Prequired = Fgravity × v

Where:

- Prequired is the required power to move the trailer up the incline.

- Fgravity = 814.32 is the force acting along the incline.

- v is the velocity at which the vehicle will move (we’ll assume a reasonable speed to assess the power).

The formula P = F × V is important because it shows that power depends on both the force applied and the velocity of an object, with real-life applications like measuring engine performance or understanding how machines operate efficiently.

The video explains the concept of power in physics, defining it as the rate at which work is done or energy is transferred. It derives the formula by showing that work is the product of force and displacement, and substituting displacement over time as velocity

Here is a quality video “How to Derive Power, Force and Velocity Quickly – A Level Physics” discussing this

We will add our own video covering this concept of physics that relates force and velocity to power.

VIDEO COMING OF: POWER AS A PRODUCT OF FORCE AND VELOCITY

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

First, we convert the electric utility vehicle’s horsepower to watts:

The formula 1 hp = 745.7 watts is important as it bridges the gap between traditional horsepower and modern electrical power measurements, helping compare engine outputs and machinery performance.

The video explains how 1 horsepower equals 746 watts. It defines horsepower in terms of foot-pounds per second and watts as joules per second. By converting units from the FPS system to the metric system, the presenter demonstrates how 1 hp translates to approximately 746 watts.

Here is a quality video “From Horsepower to Watts – The Simple Explanation You’ve Been Waiting For!” discussing this

We will add our own video covering this concept on how 1 HP equates to 745.6 watts.

VIDEO COMING OF: HORSEPOWER TO WATTS CONVERSION

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

- 1 hp = 745.7 watts

- Pvehicle = 17.2 (hp) × 745.7 = 12,845.04 watts

Now, let’s assume a reasonable towing speed of 3 mph (a slow speed given the load and incline). Convert 3 mph to feet per second:

3 mph = 3 × 5,280 (ft) / 3,600 (sec) ≈ 4.4 ft/s

EUV POWER REQUIRED FOR TOWING

Next, we need to determine the power required for towing.

Using the force calculated earlier and the assumed velocity:

- Prequired = 814.32 lbs x 4.4 ft/s

- Prequired ≈ 3,582.01 ft-lbs/s

Convert this to watts (1 ft-lb/s = 1.35582 watts).

- Prequired ≈ 3,582.01 (ft-lb/s) x 1.35582 = 4,855.39 Watts

AVAILABLE POWER OF THE EUV

The power available from the Cushman – Titan XD can be calculated by converting the horsepower to watts: 1 hp = 745.7 watts. Therefore, the available power is calculated to be approximately 12,845.04 watts.

COMPARISON OF REQUIRED AND AVAILABLE EUV POWER

The available power of 12,845.04 watts is significantly greater than the required power of 4855.39 watts, confirming that the EUV can tow the trailer up the incline efficiently.

EUV TOWING CAPACITY CONFIRMATION

The total trailer weight is 5,850 lbs, well within the EUV’s towing capacity of 8,000 lbs. This ensures that the vehicle can safely tow the trailer, including when fully loaded, across all surfaces and on inclines.

WHAT ARE THE GENERAL POWER & CAPACITY REQUIREMENTS

To optimize the setup, we consider a lighter trailer with reduced overall weight. The goal is to find the minimum power and towing capacity required to safely tow the drawers.

KEY DATA FOR LIGHTER TRAILER

The criteria for trailer selection are:

- Drawers weight: 4,400 lbs

- Trailer weight: 1,200 lbs

- Incline angle: 8 degrees (for calculation purpose)

- Towing speed: 3 mph (approx. 4.4 ft/s)

TOTAL LOAD ON EUV

The total load on the EUV is the sum of the drawers, accessories and trailer weights, which is 5,600 lbs

GRAVITATIONAL FORCE ON INCLINE FOR EUV

The force of gravity acting along the incline for towing the lighter trailer equals the weight of the trailer multiplied by the sine of the angle of the incline

Fgravity = 5,600 x sin(8∘) ≈ 5,600 (lbs) x 0.1392 = 779.52 lbs

The gravitational force acting on the total load is calculated to be approximately 779.52 lbs

EUV POWER (HP) REQUIRED TO TOW FOR LIGHTER TRAILER

The required power equals the force of gravity acting along the incline multiplied by the velocity.

- Prequired = 779.52 (lbs) × 4.4 (ft/s) = 3,429.89 ft-lbs/s

Convert to watts:

- Prequired = 3429.89 (ft-lbs/s) x 1.35582 = 4,647.97 Watts

Convert to horsepower:

- Prequired = 4647.97 (Watts) / 745.7 ≈ 6.23 hp

With a 20% safety margin:

- Pmin = 6.23 (hp) × 1.2 = 7.48 hp

The power required to tow the load up the incline at 4.4 ft/s is calculated to be approximately 4647.97 watts, which converts to approximately 6.23 hp. Considering a 20% safety margin, the minimum power requirement is 7.48 hp.

MINIMUM REQUIREMENTS OF EUV

To ensure the EUV can handle the load, the following minimum specifications should be met:

- Trailer load capacity: 5,500 lbs (with a 20% margin over the drawers weight of 4,400 lbs)

- EUV towing capacity: 6,800 lbs

- EUV power: 7.48 hp

FINAL SUMMARY OF EUV CALCULATION EXAMPLE

The Cushman – Titan XD EUV with a power rating of 17.2 hp and a towing capacity of 8,000 lbs has sufficient power and capacity to tow the trailer and drawers up an 8-degree incline. The calculated required power (4,855.39 watts) is well within the available power (12,845.04 watts). For a more optimized setup with a lighter trailer, the EUV must have a towing capacity of at least 6,800 lbs and a power rating of 7.48 hp to tow a combined load of 5,600 lbs up the incline with a 20% safety margin.

WHAT ARE THE TOP 5 EUV OPTIONS TO CONSIDER

Based on the previously established minimum requirements, the following are the top five Electric Utility Vehicles (EUVs) under consideration. Notably, most of these top choices are priced between $12,000 and $15,000 on average as of 2024

Based on the previously established minimum requirements, the following are the top five Electric Utility Vehicles (EUVs) under consideration. Notably, most of these top choices are priced between $12,000 and $15,000 on average as of 2024

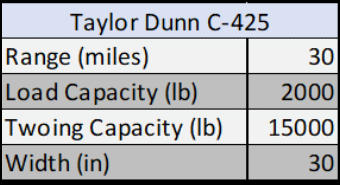

#1: THE TAYLOR DUNN C-425

The Taylor Dunn C-425 emerged as our top choice, boasting the highest towing capacity of 15,000 lbs, which meets the requirements of our selected trailer. Additionally, it offers a reasonable cost (see below) and has a rated power capacity of 16.3 hp, which is sufficient to tow the trailer up and down the incline to reach the ramp below. With this EUV, we can safely tow up to 10,000 lbs of load, maintaining a margin of 2,750 lbs when paired with our recommended trailer.

#2: CUSHMAN TITAN XD

In second place is the Cushman Titan XD, which features a respectable towing capacity of 8,000 lbs and a load capacity of 3,000 lbs. It ranks second primarily because our chosen trailer requires a towing capacity of 14,000 lbs. However, it still provides solid specifications with a rated power of 17.2 hp and is similarly priced to the Taylor Dunn C-425.

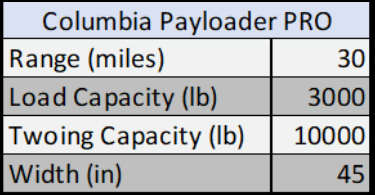

#3: COLUMBIA PAYLOADER PRO

The Columbia Payloader PRO follows in third, with a towing capacity of 10,000 lbs. Its cost is comparable to the Cushman Titan XD, but it is placed lower on our list due to its slightly lower rated power of 15.3 hp

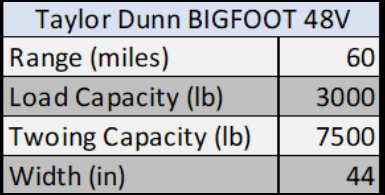

#4: TAYLOR DUNN BIGFOOT 48V

The Taylor Dunn BIGFOOT 48V is our fourth choice. It provides a respectable towing capacity of 7,500 lbs and a load capacity of 3,000 lbs. However, its rated power is relatively low at 12.5 hp, and it is priced at least $5,000 to $7,000 more than our top three options.

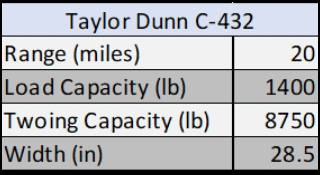

#5: TAYLOR DUNN C-432

Finally, the Taylor Dunn C-432 ranks fifth. It has a towing capacity of 8,750 lbs, but a lower load capacity of 1,400 lbs. Priced similarly to the Cushman Titan XD, it has the lowest rated power among our top five choices at 6 hp

All the above options offer excellent towing capacities and substantial additional load capacities. However, we had to eliminate them from consideration since we’re now looking at a trailer with a GVWR of 14,000 lbs. As a result, we are now considering the Taylor Dunn C-425 as our top choice.

EUV RECOMMENDATION

As we proceed with the 96″ Deckover Dump (D8) trailer, which has a Gross Vehicle Weight Rating (GVWR) of 14,000 lbs (as outlined in the next section), we recommend the Taylor-Dunn C-425 as the optimal choice for the Electric Utility Vehicle (EUV). This model, with a towing capacity of 15,000 lbs, comfortably exceeds the required GVWR due to the following reasons:

As we proceed with the 96″ Deckover Dump (D8) trailer, which has a Gross Vehicle Weight Rating (GVWR) of 14,000 lbs (as outlined in the next section), we recommend the Taylor-Dunn C-425 as the optimal choice for the Electric Utility Vehicle (EUV). This model, with a towing capacity of 15,000 lbs, comfortably exceeds the required GVWR due to the following reasons:

- The high towing capacity easily supports the trailer’s load.

- The additional load capacity of 2,000 lbs provides flexibility for future needs.

- The Taylor-Dunn C-425 meets all necessary specifications, and we suggest exploring used options priced between $8,000 and $14,000 for cost efficiency.

ELECTRIC UTILITY VEHICLE: FINAL SUMMARY

In our quest to identify the most suitable Electric Utility Vehicle (EUV) for towing trailers loaded with compost drawers, we began by considering 16 different options. Our selection was guided by a critical constraint: all vehicles had to adhere to a maximum width of 7 feet to ensure compliance with spatial limitations at the implementation site.

In our quest to identify the most suitable Electric Utility Vehicle (EUV) for towing trailers loaded with compost drawers, we began by considering 16 different options. Our selection was guided by a critical constraint: all vehicles had to adhere to a maximum width of 7 feet to ensure compliance with spatial limitations at the implementation site.

Throughout the selection process, we encountered several promising models that offered significant towing capacities. However, many of these options fell short of our overall power requirements. For instance, some vehicles that met our towing capacity criteria lacked adequate power to perform effectively under load. Conversely, while other EUVs possessed sufficient power, they were often priced beyond our budget constraints, making them impractical choices.

To illustrate our findings, we examined the Cushman Titan XD as a representative EUV. This model demonstrates an impressive towing capacity of 8,000 lbs and can manage a total weight of 5,850 lbs on an 8-degree incline with its rated power of 17.2 hp. Although we based our calculations on an 8-degree incline, we have included enough margin in our requirements to ensure that the vehicle will also perform optimally on the current 9.74-degree incline. Given our operational needs, we established minimum requirements of 6,800 lbs towing capacity and 7.48 hp to ensure optimal performance, particularly in challenging conditions.

After evaluating the various options, we concluded that the Taylor-Dunn C-425 is the optimal choice for our needs. This vehicle boasts a towing capacity of 15,000 lbs and is priced between $8,000 and $14,000, making it fully compatible with our requirements for a trailer with a Gross Vehicle Weight Rating (GVWR) of 14,000 lbs. This selection is particularly suited to our specific constraints, which include the 9.74-degree incline ramp and the maximum ramp width of 11 feet.

This thorough analysis is based on our current requirement as per Earthbag village considering the importance of balancing power, towing capacity, and cost-effectiveness when selecting an EUV for our specific application. Our recommendation of the Taylor-Dunn C-425 is a reflection of these considerations, ensuring we meet operational demands without exceeding budgetary limitations.

It’s important to note that if the current conditions at the implementation site do not necessitate these strict constraints, we would be open to considering more cost-effective options. Additionally, should we identify other EUV models that meet or exceed our towing and power criteria while remaining budget-friendly, we will also evaluate those as potential candidates.

HOW TO OPERATE AN ELECTRIC UTILITY VEHICLE SAFELY

When operating an Electric Utility Vehicle with a trailer, prioritizing safety is essential to ensure smooth and secure performance. This guide outlines key practices for preoperative inspections, speed and turning safety, trailer stability control, and safe braking during incline navigation. By addressing these critical areas, operators can minimize risks such as equipment failure, trailer sway, or loss of control, and maintain optimal functionality throughout the operation.

When operating an Electric Utility Vehicle with a trailer, prioritizing safety is essential to ensure smooth and secure performance. This guide outlines key practices for preoperative inspections, speed and turning safety, trailer stability control, and safe braking during incline navigation. By addressing these critical areas, operators can minimize risks such as equipment failure, trailer sway, or loss of control, and maintain optimal functionality throughout the operation.

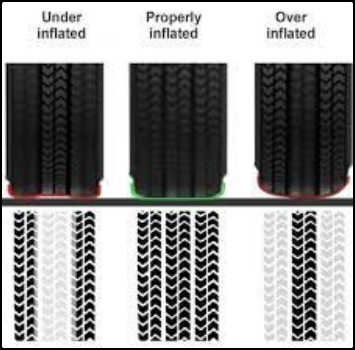

PRE-OPERATION SAFETY INSPECTION

Before starting any operation, conduct a thorough inspection of the EUV, trailer, and towing components. Ensure that the vehicle is in good working condition, the hitch is securely attached, the tires are properly inflated, and the load is evenly distributed. Address any maintenance issues immediately to avoid equipment failure during operation.

SPEED AND TURNING SAFETY

Operate the EUV at a safe and controlled speed, especially when towing heavy loads or navigating inclines and declines. Reduce speed significantly when turning, as the combined load of the vehicle and trailer increases the risk of overturning. Gradual steering adjustments should be made to prevent sudden shifts in the center of gravity.

TRAILER STABILITY CONTROL (OPTIONAL)

Implement or ensure the use of anti-sway devices or trailer stability features to minimize the risk of trailer sway caused by high speeds, crosswinds, or uneven loading. Regularly monitor the trailer’s movement during operation and adjust speed or load distribution if sway is observed.

SAFE BRAKE OPERATION AND INCLINE NAVIGATION

Familiarize yourself with the braking system of the EUV and practice controlled braking, especially when traveling downhill. Engage lower gears or regenerative braking systems (if available) to manage speed on inclines. Avoid sudden stops, as they can destabilize the trailer and lead to jackknifing.

We will add our own video covering how to safely operate an Electric Utility Vehicle, including braking and incline navigation.

VIDEO COMING OF: SAFELY OPERATING AN ELECTRIC UTILITY VEHICLE

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

UTILITY TRAILER

When selecting a trailer for the task, several key factors need to be considered to ensure it meets our operational requirements. We needed a trailer capable of carrying four heavy drawers in a single trip while maintaining safety and stability. This made weight capacity, trip frequency, and structural features essential considerations in our decision-making process.

When selecting a trailer for the task, several key factors need to be considered to ensure it meets our operational requirements. We needed a trailer capable of carrying four heavy drawers in a single trip while maintaining safety and stability. This made weight capacity, trip frequency, and structural features essential considerations in our decision-making process.

The factors and considerations that guided the selection process were:

- Number of Trips

- Gross Vehicle Weight Rating (GVWR)

- Additional trailer accessories

- Selection of Narrow vs Wide trailer bed design

WHAT ARE THE CRITERIA FOR SELECTING A UTILITY TRAILER

Selecting the right utility trailer for transporting four drawers required balancing efficiency, safety, and load capacity. We prioritized minimizing trips by opting to transport all drawers at once, and ensured the trailer’s Gross Vehicle Weight Rating (GVWR) could handle the total weight. Additional considerations included essential components like fenders, a ramp, and a tongue, as well as the advantages of a wide-body design for easier unloading and added versatility. Ultimately, the wide-body trailer was chosen for its practicality and efficiency in handling the transport and unloading needs. Below, we examine each major selection criterion in detail.

NUMBER OF TRIPS CONSIDERATION

We evaluated two options for transporting the drawers:

- Two trips carrying 2 drawers per trip: This approach would add approximately 2.5 hours to the overall process.

- One trip carrying all 4 drawers at once: This option would save significant time and streamline the process.

Given the time savings, we decided to transport all 4 drawers in a single trip.

TRAILER GROSS VEHICLE WEIGHT RATING (GVWR)

GVWR is a critical factor in determining the trailer’s suitability. The combined weight of the 4 drawers is 4,264 lbs. In addition, the weight of the trailer itself and any accessories, such as the ramp and tongue, must be accounted for. The sum of these weights will guide the trailer’s load-bearing capacity.

ADDITIONAL TRAILER COMPONENTS

Certain accessories are essential for safe and efficient operation, including:

- Fenders & Railing for added safety during transport.

- A ramp for loading the drawers onto the trailer.

- A tongue to connect the trailer to the electric utility vehicle.

Fender Protection

Trailer Railing Guard

Reliable Tongue Link

Ramp for Access

WHICH IS BETTER: NARROW OR WIDE BED TRAILER DESIGN

Narrow vs. wide bed trailer design was one of the most important discussions we had while selecting the trailer for our transportation solution, as each option presents its own advantages and disadvantages. A narrow body trailer offers better access to tight spaces, but its longer length can hinder mobility. Conversely, a wide body trailer allows for a single trip option but necessitates adjustments to the ramp width. Below, we will discuss each option in detail.

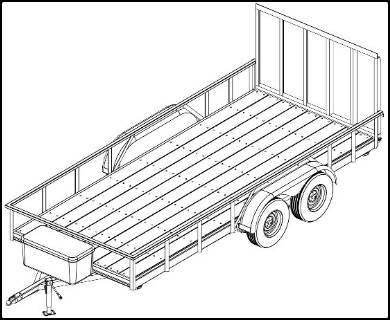

Narrow Bed Trailer

Wide Bed Trailer

NARROW BODY TRAILER SELECTION

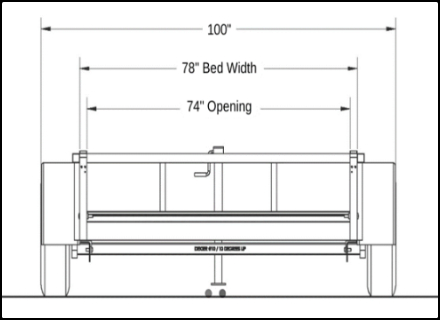

A narrow-body trailer typically has a bed width ranging from 5 to 7 feet. To accommodate four drawers in a 1 x 4 configuration, the trailer requires a minimum length of 16 feet, with an additional 10 inches for spacing between the drawers and fenders. One key consideration is that, despite the narrower bed width, the overall trailer width can be comparable to a wide-body design. This is because, in narrow-body designs, the wheels are positioned on the sides rather than beneath the bed. For instance, with a bed width of 6.5 feet (78 inches), the total trailer width can extend up to 8.3 feet (100 inches), as demonstrated in the example of Rugged Aluminum Trailers below.

Rugged Aluminum Trailers width dimensions

Considerations for narrow body trailer are listed below:

Trailer Narrow Body Comparison and Analysis

PROS:

- Narrower width can fit through tight spaces.

- May provide better weight distribution, reducing strain on the EV.

CONS:

- Difficult to maneuver in tight spaces or sharp turns.

- Challenging when reversing or parking.

MAJOR CONCERNS OF NARROW BODY TRAILER

Using a narrow-body trailer for unloading operations presents significant logistical challenges, particularly when dealing with multiple drawers. The unloading process becomes cumbersome as each drawer must be handled individually. Here’s a breakdown of the current unloading procedure:

- Individual Drawer Management: Each drawer needs to be unloaded one at a time. This requires manual effort and coordination to ensure that the drawers are safely and effectively removed from the trailer.

- Placement on the Dumping Structure: After being unloaded, each drawer must be positioned onto a dumping structure. This task demands careful handling to prevent spillage of the contents and ensure the drawer is secured during the dumping process.

- Ground Placement: Once the contents of a drawer have been dumped, the empty drawer must then be placed on the ground. This needs to be repeated for all four drawers, further complicating the process as it involves multiple movements and the need for adequate space on the ground.

- Re-loading of Drawers: After all drawers have been emptied and placed on the ground, they must be re-loaded onto the trailer. This task may require the assistance of an electric winch at the dumping site, as the drawers could be heavy or cumbersome to lift manually, particularly after multiple unloadings.

Given these complications, the efficiency of the unloading process can be significantly hindered, leading to increased labor time and potential safety hazards.

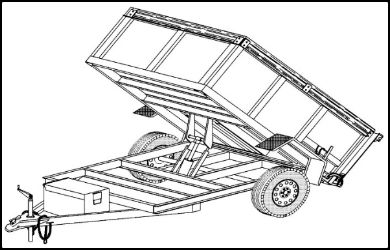

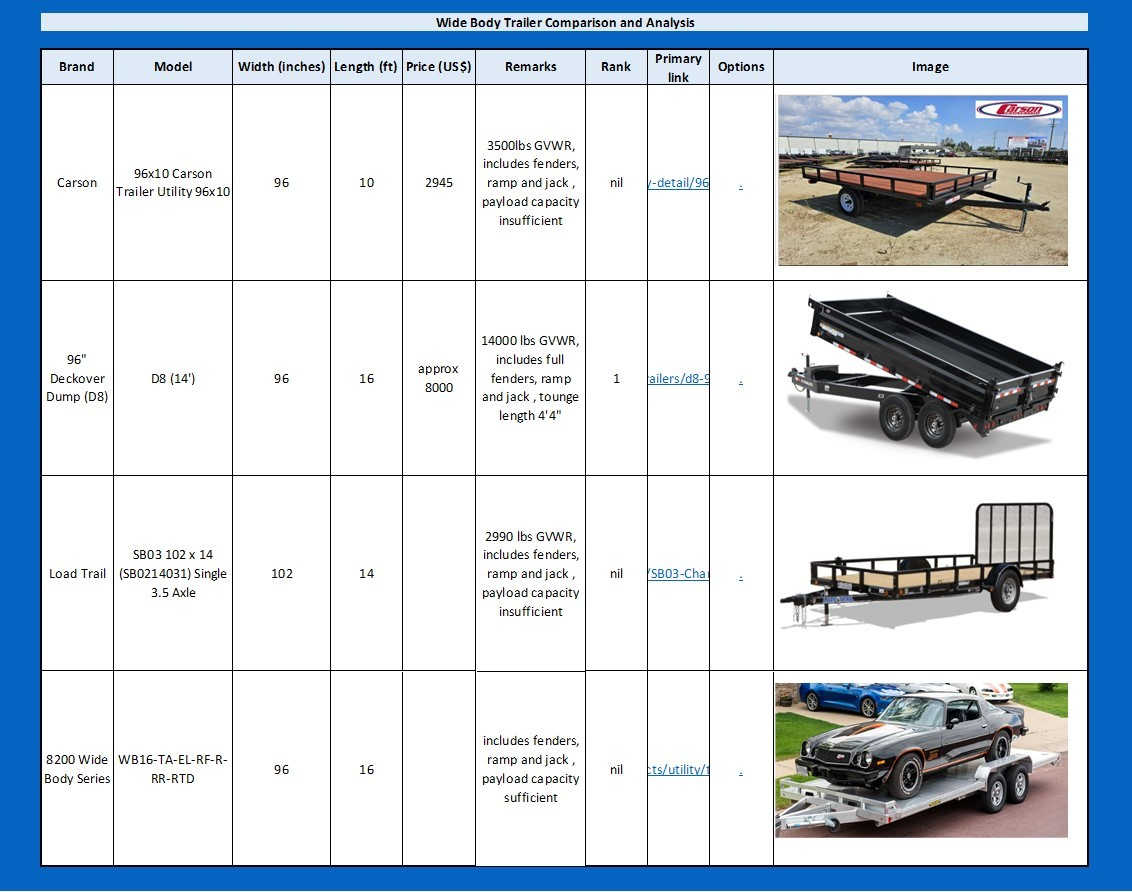

WIDE BODY TRAILER SELECTION

A wide body trailer typically has a width of 8 to 12 feet and can easily fit all four drawers in a 2 x 2 configuration. This design simplifies transport and handling. Some of the considerations for Wide body trailer are listed below

Considerations for narrow body trailer are listed below:

Trailer Wide Body Comparison and Analysis

PROS:

- Easier to maneuver than a longer trailer.

- Allows for quicker and more efficient unloading.

CONS:

- Heavier trailers may increase strain on the EV.

MAJOR ADVANTAGES OF WIDE BODY TRAILER

The wide-body trailer simplifies the unloading process by allowing drawers to be dumped directly without needing to place them on the ground, enhancing efficiency and facilitating easier management of the four drawers. Below is a breakdown of the streamlined unloading process using the wide-body trailer. Additionally, the trailer offers extra space for various transportation needs within the village, including the movement of construction equipment.

- Loading the Drawers: An electric winch can be employed to easily load the drawers onto the trailer bed via the ramp, minimizing manual effort.

- Individual Drawer Rotation: The ample space provided by the wide-body trailer allows for the drawers to be rotated one by one. This facilitates easy placement of each drawer onto the dumping structure.

- Direct Dumping: By utilizing the wide-body design, drawers can be directly dumped into the structure without needing to handle them multiple times, ensuring a quicker and safer unloading process.

- Re-loading of Drawers: Once emptied, the drawers can be conveniently re-loaded onto the trailer without the hassle of ground placement, reducing the effort required and enhancing safety during operations.

UTILITY TRAILER RECOMMENDATION

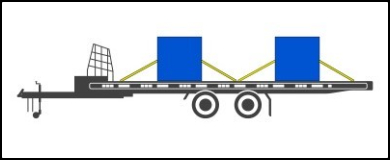

Considering the advantages of wide-body-design trailers over narrow body trailers, it is recommended to go with wide body design. Based on these factors, we have selected a wide body trailer with a 16-foot length. The 96″ Deckover Dump (D8) has 14,000 lbs GVWR which far exceed the minimum requirement of 5500 lbs and includes fenders, inbuilt ramp and tongue.

Considering the advantages of wide-body-design trailers over narrow body trailers, it is recommended to go with wide body design. Based on these factors, we have selected a wide body trailer with a 16-foot length. The 96″ Deckover Dump (D8) has 14,000 lbs GVWR which far exceed the minimum requirement of 5500 lbs and includes fenders, inbuilt ramp and tongue.

Trailer: 96″ Deckover Dump (D8)

This design offers flexibility, ease of use, and the ability to transport all drawers in a single trip, while also enabling the waste dumping process without the need to place drawers on ground while also providing additional utility for other tasks.

UTILITY TRAILER: FINAL SUMMARY

In the selection process for a utility trailer designed to transport four drawers, several critical factors were evaluated, including the number of trips required, gross vehicle weight rating (GVWR), essential trailer components, and design considerations. Initially, we examined 11 narrow-body trailer options, each presenting distinct challenges, such as their long lengths and the likelihood of requiring two trips for unloading. The inefficiency of making multiple trips was a significant concern, as it could add approximately 2.5 hours to the overall process. To optimize time efficiency and streamline operations, we prioritized a solution that would allow for a single trip capable of transporting all four drawers simultaneously.

In the selection process for a utility trailer designed to transport four drawers, several critical factors were evaluated, including the number of trips required, gross vehicle weight rating (GVWR), essential trailer components, and design considerations. Initially, we examined 11 narrow-body trailer options, each presenting distinct challenges, such as their long lengths and the likelihood of requiring two trips for unloading. The inefficiency of making multiple trips was a significant concern, as it could add approximately 2.5 hours to the overall process. To optimize time efficiency and streamline operations, we prioritized a solution that would allow for a single trip capable of transporting all four drawers simultaneously.

Following a comprehensive comparison of narrow-body and wide-body trailer designs, the latter was ultimately favored due to its superior unloading capabilities and enhanced maneuverability. The decision to choose a wide-body design was influenced by its ability to facilitate easier access to the drawers, thereby reducing the time and effort required during both unloading and reloading processes. This analysis led to the selection of a 16-foot wide-body trailer, specifically the 96″ Deckover Dump D8, which effectively addresses the operational needs of transporting the drawers.

This selected trailer boasts an impressive GVWR of 14,000 lbs, significantly exceeding the minimum requirement of 5,500 lbs, thereby ensuring safety and reliability during transport. It is equipped with essential features such as sturdy fenders, an integrated ramp for easier loading and unloading, and a robust tongue for secure attachment to the towing vehicle. These attributes not only guarantee efficient transport of the drawers but also provide added utility for a variety of tasks within the village, enhancing overall operational effectiveness.

HOW TO OPERATE A UTILITY TRAILER SAFELY

Safe and efficient trailer operation begins with proper load management and attention to detail. This guide highlights essential practices for weight distribution, hitch connection, regular maintenance, driving precautions, and unloading safety. By following these recommendations—such as evenly distributing weight, securing loads, and maintaining equipment—operators can minimize risks like tipping, swaying, or equipment failure. Prioritizing these steps ensures smoother transport, compliance with regulations, and a safer working environment.

Safe and efficient trailer operation begins with proper load management and attention to detail. This guide highlights essential practices for weight distribution, hitch connection, regular maintenance, driving precautions, and unloading safety. By following these recommendations—such as evenly distributing weight, securing loads, and maintaining equipment—operators can minimize risks like tipping, swaying, or equipment failure. Prioritizing these steps ensures smoother transport, compliance with regulations, and a safer working environment.

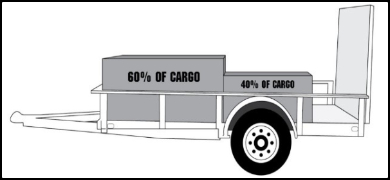

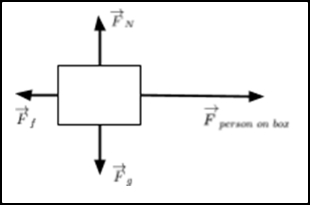

WEIGHT DISTRIBUTION AND SECURING THE LOAD

The following points will help with safety, efficiency, and longevity of your utility trailer:

- Ensure even weight distribution across the trailer bed to avoid tipping or swaying during transport. As a general practice, approximately 60% of the total weight should be loaded towards the front, as illustrated below.

- Use appropriate straps and tie-downs to securely fasten the drawers to avoid shifting while in motion.

Trailer: Weight Distribution

Trailer: Securing Container with Straps

We will add our own video covering how to safely operate an Electric Utility Vehicle, including braking and incline navigation.

VIDEO COMING OF: HOW TO PROPERLY LOAD AND DISTRIBUTE WEIGHT ON THE TRAILOR

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

PROPER HITCH CONNECTION

Ensure a safe and secure connection between the trailer and towing vehicle.

- Verify the trailer tongue is securely attached to the towing vehicle hitch.

- Confirm that safety chains are crossed and properly connected to act as a backup in case the hitch fails.

Trailer: Tongue

Trailer: Safety Chains

REGULAR INSPECTION AND MAINTENANCE

Conduct routine checks to ensure all trailer components are in optimal condition.

- Inspect tires, brakes, lights, and other components before each trip to ensure they are in proper working condition.

- Check for signs of wear or damage on the trailer and its accessories, such as the ramp and fenders.

Trailer: Tire Check

Trailer: Brake Light Check

DRIVING PRECAUTIONS

Practice safe driving habits to prevent trailer sway and ensure road compliance.

- Avoid sudden braking, sharp turns, or excessive speeds, especially when carrying heavy loads, to reduce the risk of trailer sway.

- Ensure compliance with local road regulations, including adhering to speed limits and load capacity restrictions.

UNLOADING SAFETY

Utilize mechanical aids and maintain a safe workspace for efficient unloading.

- Use an electric winch or other mechanical aids to minimize manual handling of heavy drawers.

- Maintain a clear and stable unloading area to prevent accidents and ensure ease of operation.

VIDEO COMING OF: HOW TO LOAD DRAWERS USING A WINCH

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

ELECTRIC WINCH

We have a drawer weighing 1,060 lbs that needs to be pulled using an electric winch. The process begins on a flat surface before the drawer is moved up an inclined ramp with an 8° slope that is 12 feet long. After reaching the top of this ramp, the drawer must be pulled up a trailer ramp with a 25° incline onto a platform. Given that the winch will be mounted at the top of the trailer ramp, the angle of pull will affect the required force exerted by the winch.

To ensure the winch can handle potential challenges such as increased friction or load instability, a safety margin of 20% has been incorporated into our calculations. Taking all these factors into account, we determined that the winch must exert a minimum force of 618.5 lbs to effectively pull the drawer up the ramps. Below, we provide the detailed calculations that support this requirement.

HOW TO CALCULATE THE FORCE EXERTED BY A WINCH

To understand the force exerted by the winch while pulling the drawer, we will break down each force component and examine the requirements and minimum forces involved. This analysis will include the forces exerted on both flat surfaces and inclined surfaces.

ASSUMPTIONS FOR WINCH CALCULATIONS

- Coefficient of rolling friction (μ): 0.02

- Gravitational acceleration (g): 32.2 ft/s²

- The winch pulls in a direction aligned with the slope of the ramps.

FORCE EXERTED ON FLAT SURFACE (12 FT) BY WINCH

At the flat ramp located at the exit door of the vermiculture compound, the only resistance to motion arises from rolling friction.

Forces Acting on Flat Surface

Flat Ramp at Vermiculture Compound Exit

As depicted in the diagram above, the normal forces acting on the object are balanced, meaning they cancel each other out. In this context, for an object to begin moving, the applied force F must exceed the frictional force Ff. This relationship is crucial because it highlights the need to overcome static friction, the force that resists the initial movement of the object

The force of friction varies depending on the friction coefficient. It is important to understand the real-life importance of friction, why it’s harder to move objects on rough surfaces, like sand, compared to smooth ones, like water, with applications in transportation and engineering.The video uses the example of pulling a boat on a sandy beach versus the sea to demonstrate how friction opposes motion. It explains that rough surfaces, like sand, create higher friction due to their texture, while smooth surfaces, like water, reduce friction, making movement easier.

Here is a quality video “Friction – Why is it difficult to pull a boat on the beach than on the sea?” discussing this

We will add our own video covering this concept frictional force on different surfaces.

VIDEO COMING OF: FORCE OF FRICTION ON DIFFERENT SURFACES

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

The force of friction (Ff depicted as F_friction flat) acting on a flat surface is equal to the coefficient of friction (μ) multiplied by the weight (W) of the object.

F_friction flat = μ × W = 0.02 × 1060 (lbs) = 21.2 lbs

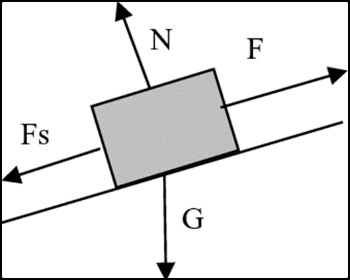

FORCE EXERTED ON 8° INCLINED RAMP (12 FT) BY WINCH

In this section, When moving the drawer from a flat surface onto an incline, both gravitational pull and friction must be overcome. The gravitational pull is denoted as G, and the frictional force is represented by Fs. The applied force by the winch is F, while N is the normal force acting perpendicular to the incline. On the incline, the normal force balances the perpendicular component of the gravitational force, allowing for a clearer analysis of the forces acting parallel to the incline.

Forces Acting on an Inclined Surface

Inclined Ramp Following Flat Surface

Friction on Inclined Plane has real-life importance, as it helps design safer roads, ramps, and machinery by calculating frictional forces on slopes.

The video explains the forces acting on an object moving at constant speed down an inclined plane, including gravity, normal force, and friction. Using a free-body diagram, it shows how these forces balance and derives that the coefficient of kinetic friction (μ) equals the tangent of the incline angle (θ).

Here is a quality video “Friction on Inclined Plane” discussing this

We will add our own video covering the force of friction acting on an inclined plane.

VIDEO COMING OF: FORCE OF FRICTION ON INCLINED PLANES

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

Gravitational force component along the incline: The gravitational force component along the incline equals the weight of the object multiplied by the sine of the angle of the incline

F_gravity incline = W × sin(8°) = 1,060 (lbs) x 0.1392 = 147.55 lbs

Rolling friction on the incline: The rolling friction on the incline equals the coefficient of friction multiplied by the weight of the object and the cosine of the angle of the incline.

F_friction incline = μ × W × cos(8°) = 0.02 × 1,060 (lbs) x 0.9903 = 21 lbs

Total force required on the 8° incline: The total force equals the gravitational force component along the incline plus the rolling friction on the incline.

F_total incline = F_gravity incline + F_friction incline = 147.55 (lbs) + 21 (lbs) = 168.55 lbs

FORCE EXERTED ON TRAILER RAMP (25°) BY WINCH

The most significant force is required when pulling the drawers up the trailer ramp, as this has the steepest incline.

- Gravitational force component along the 25° incline: The gravitational force equals the weight of the drawer multiplied by the sine of the angle of the incline

F_gravity trailer = W × sin(25°) = 1,060 (lbs) x 0.4226 = 447.96 lbs

- Rolling friction on the trailer ramp: The rolling friction equals the coefficient of friction multiplied by the weight of the drawer and the cosine of the angle of the incline.

F_friction trailer = μ × W × cos(25°) = 0.02 × 1,060 (lbs) × 0.9063 = 19.21 lbs

- Total force required on the 25° trailer ramp: The total force on the winch equals the gravitational force component along the incline plus the rolling friction on the trailer ramp

F_total trailer = F_gravity trailer + F_friction trailer = 447.96 + 19.21 = 467.17 lbs

CORRECTING FOR WINCH ANGLE ON TRAILER RAMP

Given the winch will be mounted at the top of the trailer ramp, the effective pulling force must account for the angle of the cable relative to the incline:

The force required from the winch equals the total force on the trailer divided by the cosine of the angle of the incline.

F_winch = F_total trailer / cos(25°) = 467.17 (lbs) / 0.9063 = 515.49 lbs

TOTAL FORCE REQUIRED FOR WINCH

- Flat Surface: 21.2 lb

- 8° Inclined Ramp: 168.55 lb

- 25° Trailer Ramp (with winch correction): 515.49 lb

The maximum force occurs on the trailer ramp, where 515.49 lbs is needed.

*What if we place the trailer on an incline and use the winch to load the drawer?

Given that a 25-degree incline necessitates a maximum force of 515.5 lbs, positioning the trailer on this incline will allow our recommended winch, which has a rated capacity of 2,500 lbs, to manage forces without any issues. Furthermore, since the winch is attached to the trailer, it will also be inclined during operation, which will reduce the additional correction needed for the force required. Therefore, operating the winch under these conditions will be safe, provided that we monitor the winch’s duty cycle.

SAFETY MARGIN FOR WINCH

To ensure the winch can handle additional load factors (like extra friction, slight bumps, or uneven surfaces), a 20% safety margin is applied to the maximum force:

The final force on the winch equals the maximum force required multiplied by 1.2 to account for a 20% safety margin

F_winch final = 515.49 (lbs) x 1.2 = 618.59 lbs

WHAT ARE THE TOP 5 ELECTRIC WINCH OPTIONS

The electric winch should have a minimum rated capacity of 620 lbs, as it will be used to pull the drawer across a flat surface, an 8-degree incline, and a 25-degree ramp for loading onto the trailer. To enhance robustness and reliability, it is advisable to choose a winch with a capacity of at least 750 to 1,000 lbs. This will accommodate any unforeseen factors and ensure safe and efficient operation during the loading process.

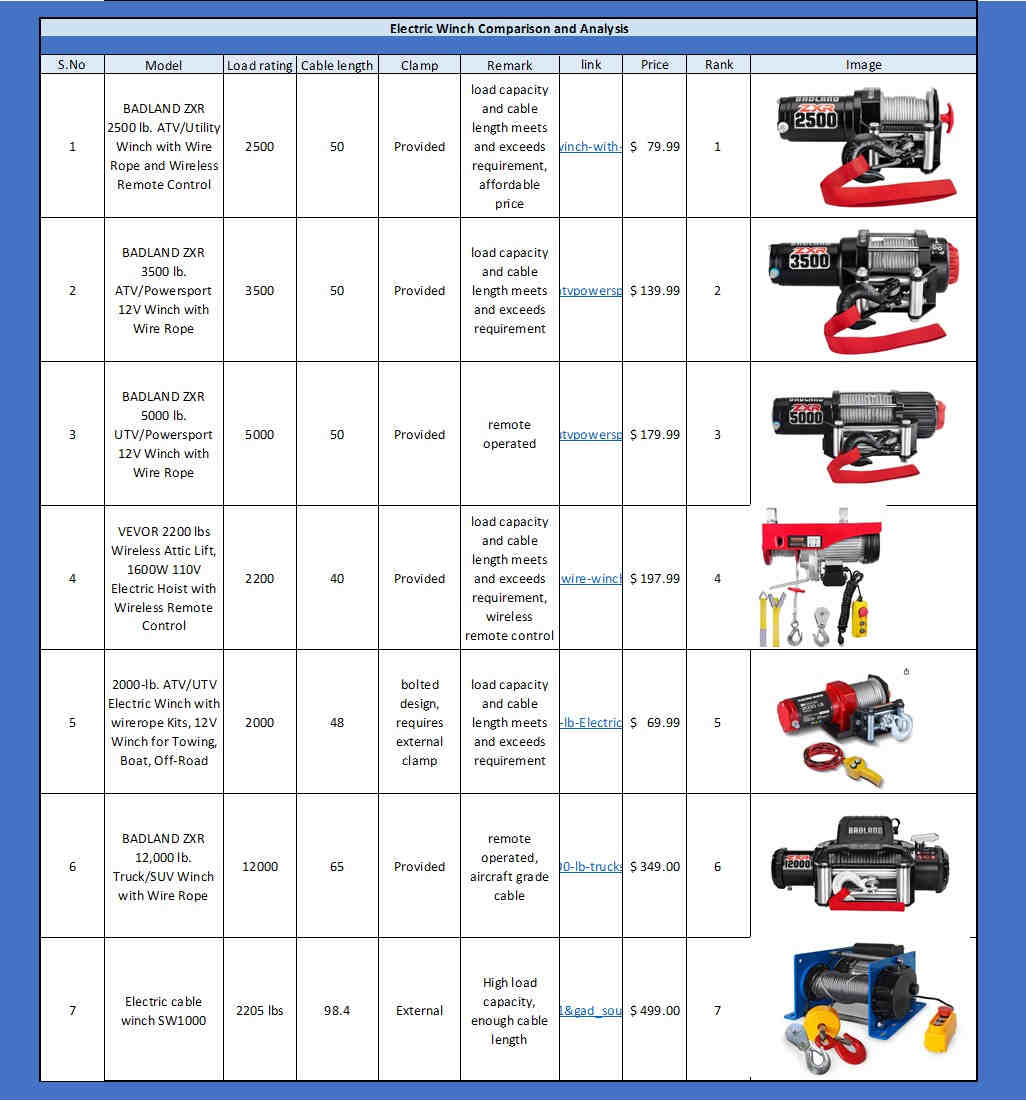

Based on the requirement below is the list of electric winches that were being considered:

Electric Winch Comparison and Analysis

ELECTRIC WINCH RECOMMENDATION

Based on the calculations and requirement, the BADLAND ZXR 2,500 lb. ATV/Utility Winch with Wire Rope and Wireless Remote Control is recommended as the ideal choice. It offers a sufficient load capacity of 2500 lbs and is cost-effective, priced at $79.99. With a 50ft cable length and additional clamps included, it is well-suited for our need

ELECTRIC WINCH: FINAL SUMMARY

In this section, we evaluated the requirements for an electric winch to safely load a 1,060 lb drawer onto a trailer from a flat surface, navigating both an 8° ramp and a 25° trailer ramp. Our analysis revealed that the maximum pulling force required to move the drawer up the 25° incline is approximately 515.49 lb. To ensure a safe operating margin, we applied a 20% safety factor, resulting in a total force requirement of 618.59 lb.

Based on these calculations, we recommend the BADLAND ZXR 2500 lb. ATV/Utility Winch. This winch not only provides more than adequate capacity for our needs, but it is also cost-effective at $79.99. Additionally, it comes equipped with a 50 ft cable, which facilitates effective maneuvering during the loading process, ensuring reliability and safety.

Furthermore, we analyzed the process for mounting and operating the electric winch, as well as the necessary accessories for optimal performance. We highlighted several critical safety considerations that must be adhered to while operating the electric winch. These include understanding the winch’s specifications, proper gear selection, maintaining a safe distance during operation, being aware of the winch’s duty cycle, and allowing for adequate cooling periods after use. Following these guidelines will help mitigate risks and ensure safe and efficient winch operation during the loading process.

WHAT ARE THE ESSENTIAL WINCH MOUNTING ACCESSORIES

Mounting an electric winch on trailer fendering is essential for safe and effective operation. Proper installation boosts performance and minimizes hazards. Below are the key points to consider:

Winch Mounting Bracket

Winch Wire Rope with Slip Hook

- Bracket Securement: Ensure the winch is securely fastened using the provided bracket. Use appropriate bolts or screws that can withstand the forces exerted during operation. A tight and stable installation is crucial for safe winch performance and to prevent movement during use.

- Optimal Positioning: Mount the winch at a height that allows for easy access to the cable while ensuring it’s aligned with the load being pulled. Consider the angle of the cable to avoid excessive friction or wear during operation. Proper positioning helps enhance efficiency and reduces strain on the winch components.

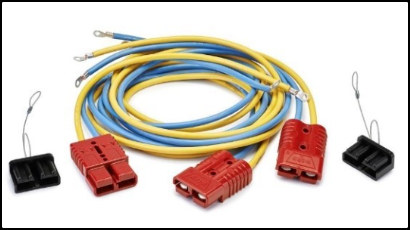

Winch Electric Cables

Winch Operating Remote

- Wiring Setup: Follow the wiring instructions included with the winch to ensure all connections are made correctly and securely. Pay attention to wire routing to prevent damage from moving parts or environmental exposure. Proper wiring is essential for reliable operation and to minimize the risk of electrical failure during use.

- Remote Accessibility: Position the remote control in an easily reachable location for safe and convenient operation from a distance.

- Safety Inspection: Regularly check for loose hardware, frayed wires, and the overall integrity of the winch installation before use.

Frayed Wires Inspection

Broken Hardware Inspection

HOW TO OPERATE AN ELECTRIC WINCH SAFELY

Safety is paramount when operating an electric winch, as they can exert significant force under heavy loads. Ensure the work area is clear, and all personnel are aware of the operation. Always wear appropriate personal protective equipment (PPE), including gloves, helmets, and eye protection. Inspect the winch and its components for wear or damage before use.

Safety is paramount when operating an electric winch, as they can exert significant force under heavy loads. Ensure the work area is clear, and all personnel are aware of the operation. Always wear appropriate personal protective equipment (PPE), including gloves, helmets, and eye protection. Inspect the winch and its components for wear or damage before use.

Operating a winch without adhering to safety guidelines can lead to severe risks, including equipment failure, personal injury, or even fatalities. Improper use may result in cable snapping, which can cause heavy objects to fall or swing unpredictably. Additionally, neglecting to monitor the winch’s duty cycle can overheat the motor, leading to potential breakdowns.

Some important safety factors are listed below to help maintain a safe working environment while effectively utilizing the electric winch.

Electric winch with protective gears

UNDERSTANDING THE ELECTRIC WINCH

Before operating an electric winch, familiarize yourself with the specific model’s features and safety guidelines. Consult the manufacturer’s manual for detailed instructions and specifications.

PROPER GEAR SELECTION

Ensure that the right gear is selected for the task at hand. This includes choosing the appropriate winch model and accessories that match the load capacity and specific requirements of your operation.

WIRE THICKNESS

Select the correct thickness of the wire rope or cable based on the intended load. The wire should be strong enough to handle the weight without risk of snapping or excessive wear.

SAFE DISTANCE

Always maintain a safe distance while operating the winch. This is crucial to protect yourself and bystanders from potential hazards such as wire snapping or equipment malfunction.

DUTY CYCLE AWARENESS

Be aware of the winch’s duty cycle. The duty cycle indicates the amount of time the winch can be operated in a given period. For example, if the rated duty cycle is 25%, the winch can run for a maximum of 15 minutes within a 1-hour period. After this duration, allow the motor time to cool down to prevent overheating and ensure longevity.

COOLING PERIOD

After operating the winch, give it sufficient time to cool down. This cooling period is essential to prevent damage to the motor and to maintain the overall functionality of the winch over time.

It is very important to understand the fundamentals of choosing and operating winches correctly to ensure safety, efficiency, and equipment longevity in lifting and pulling applications.

Pat Clark from LGH North America explains key factors, including purpose of use, capacity, mounting orientation, power requirements, wire rope maintenance, and environmental protection. The video emphasizes following manufacturer guidelines to operate electric winches safely and effectively.

Here is a quality video “How to Properly Select and Use an Electric Winch” discussing this

We will add our own video covering the selection and usage of electric winch.

VIDEO COMING OF: SELECTING AND OPERATING ELECTRIC WINCH

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

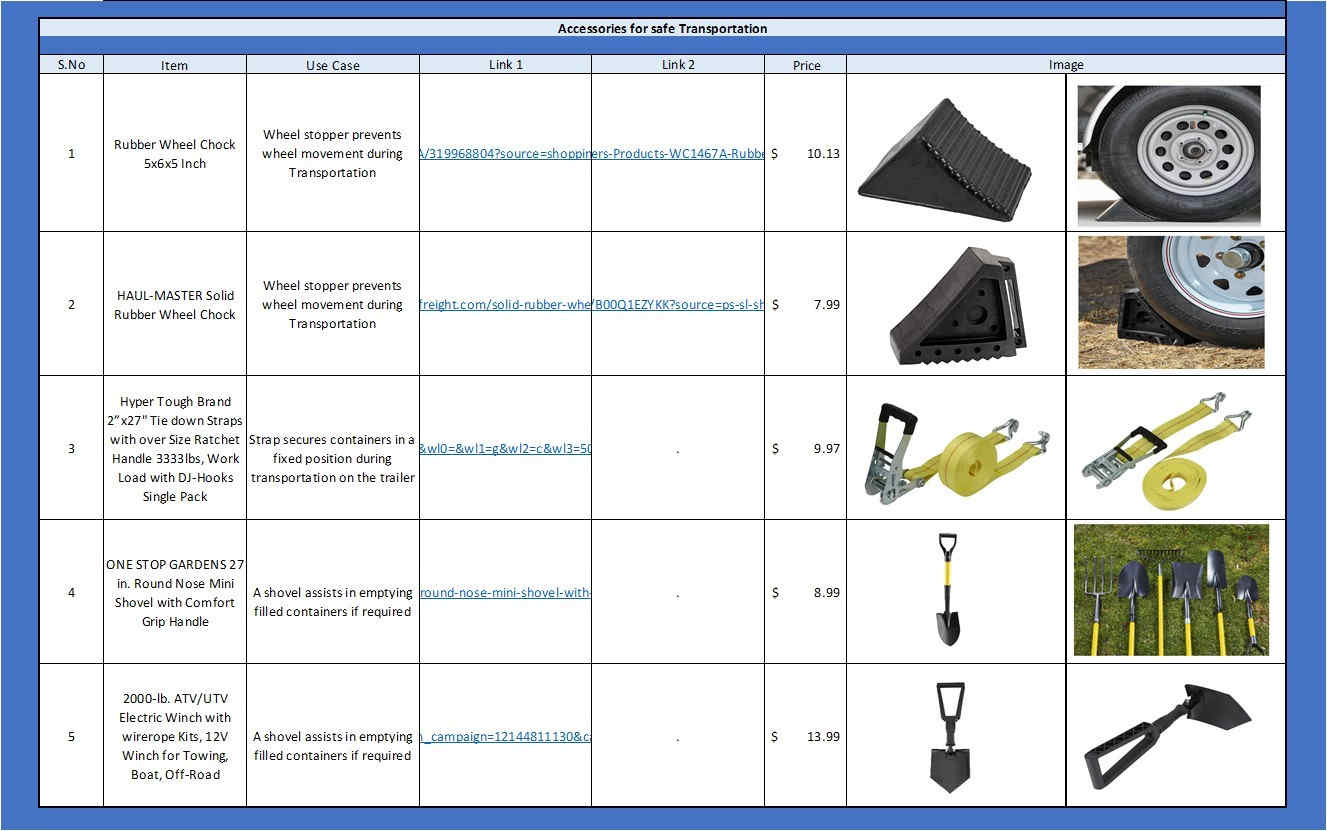

WHAT ACCESSORIES IMPROVE TRANSPORTATION EFFICIENCY

These additional accessories are essential for optimizing the entire transportation process

Accessories list

FINAL SUMMARY: ACCESSORIES

In this section, a list of accessories is recommended to ensure the safe loading, unloading, and dumping of the drawers. These accessories are intended to facilitate smoother operations and enhance safety during the process.

SUMMARY

The transportation solution for emptying compost drawers from a vermiculture toilet system involves moving four drawers, each weighing 1,066 lbs, every six months. These drawers are located in a vermiculture compound with an inclined ramp leading to an upper road. To transport them, an electric utility vehicle (EUV) and a utility trailer are used. After evaluating multiple EUV options, the Taylor-Dunn C-425 was selected for its towing capacity of 15,000 lbs, which is sufficient for handling the 9.74° incline and meeting the spatial constraints. A wide-body trailer, the 96″ Deckover Dump D8 with a GVWR of 14,000 lbs, was chosen for its ability to transport all four drawers in a single trip, improving time efficiency. For loading the drawers onto the trailer, an electric winch is required, and calculations show that a pulling force of 618.59 lbs is necessary, factoring in friction and load instability. The BADLAND ZXR 2500 lb. ATV/Utility Winch was selected for its adequate capacity and cost-effectiveness at $79.99. Several accessories were recommended to enhance safety and facilitate smoother operations during loading, unloading, and dumping. This solution balances power, towing capacity, cost-effectiveness, and safety, ensuring reliable and efficient transportation of the compost drawers while meeting operational needs.

The transportation solution for emptying compost drawers from a vermiculture toilet system involves moving four drawers, each weighing 1,066 lbs, every six months. These drawers are located in a vermiculture compound with an inclined ramp leading to an upper road. To transport them, an electric utility vehicle (EUV) and a utility trailer are used. After evaluating multiple EUV options, the Taylor-Dunn C-425 was selected for its towing capacity of 15,000 lbs, which is sufficient for handling the 9.74° incline and meeting the spatial constraints. A wide-body trailer, the 96″ Deckover Dump D8 with a GVWR of 14,000 lbs, was chosen for its ability to transport all four drawers in a single trip, improving time efficiency. For loading the drawers onto the trailer, an electric winch is required, and calculations show that a pulling force of 618.59 lbs is necessary, factoring in friction and load instability. The BADLAND ZXR 2500 lb. ATV/Utility Winch was selected for its adequate capacity and cost-effectiveness at $79.99. Several accessories were recommended to enhance safety and facilitate smoother operations during loading, unloading, and dumping. This solution balances power, towing capacity, cost-effectiveness, and safety, ensuring reliable and efficient transportation of the compost drawers while meeting operational needs.

FREQUENTLY ANSWERED QUESTIONS

Q: Why is the transportation system required here?

The transportation system is essential in this context because it facilitates the efficient movement of heavy materials, such as compost drawers, within the Earthbag village project. Specifically, the need for an Electric Utility Vehicle (EUV) arises to safely and reliably tow trailers loaded with compost drawers, ensuring that they can be transported across varying terrains, including inclines. The EUV, when paired with a suitable trailer, supports the operational requirements for material handling, contributing to the overall success of the project

Q: Why is the towing capacity an essential component of the transportation system’s requirements?

The towing capacity is crucial because it directly determines the ability of the Electric Utility Vehicle (EUV) to safely pull a trailer with a GVWR of 14,000 lbs. A higher towing capacity ensures that the vehicle can handle the weight of the loaded trailer, especially under challenging conditions like inclines and uneven terrain, without compromising safety or performance. This is why the EUV needs to exceed the required towing capacity to maintain a safety margin and provide flexibility for future needs.

Q: Why is the Taylor-Dunn C-425 chosen as the top EUV recommendation?

The Taylor-Dunn C-425 is chosen as the top recommendation because it meets and exceeds the required towing capacity of 15,000 lbs, making it well-suited for a trailer with a GVWR of 14,000 lbs. The vehicle also provides a sufficient margin of additional load capacity, ensuring flexibility for future needs. Additionally, its cost efficiency, priced between $8,000 and $14,000, makes it an optimal choice that aligns with both performance and budgetary constraints.

Q: Can other EUVs be considered if they meet the towing and power requirements but are more cost-effective?

Yes, if future assessments indicate that the implementation site does not require the strict constraints of the current selection, more cost-effective EUVs can be considered. The report mentions that if other models meet or exceed the towing and power criteria while remaining within a budget-friendly range, they will also be evaluated as potential candidates. However, for the current scenario, the Taylor-Dunn C-425 remains the most suitable option.

Q: Why was a wide-body trailer chosen over a narrow-body trailer?

A wide-body trailer was chosen over a narrow-body trailer due to its superior unloading capabilities and enhanced maneuverability. While narrow-body trailers can fit through tighter spaces, the wide-body design allowed for all four drawers to be transported in a single trip, saving time and improving efficiency. The wide-body trailer also facilitated easier access to the drawers during unloading, eliminating the need to place them on the ground and simplifying the reloading process.

Q: What advantages does the wide-body trailer offer in terms of unloading efficiency?

The wide-body trailer simplifies the unloading process by allowing drawers to be directly dumped into the dumping structure without the need for manual handling or ground placement. This not only speeds up the unloading process but also enhances safety by reducing the risk of accidents during the handling of heavy drawers. The wide-body design also provides ample space for easy rotation of the drawers, making it easier to manage them during the unloading and reloading stages.

Q: How does the Gross Vehicle Weight Rating (GVWR) impact the trailer selection?

The GVWR is crucial in ensuring that the trailer can safely transport the load. In this case, the combined weight of the four drawers is 4,264 lbs, and the trailer’s GVWR needed to accommodate not only the drawers but also the weight of the trailer and its accessories. The chosen 96″ Deckover Dump (D8) trailer has a GVWR of 14,000 lbs, which far exceeds the minimum requirement of 5,500 lbs, ensuring that the trailer can safely carry the load without risk of overloading.

Q: What happens if the total load exceeds the trailer’s GVWR?

Exceeding the Gross Vehicle Weight Rating (GVWR) can lead to several risks, including tire blowouts, brake failure, and potential damage to both the trailer and the towing vehicle. Additionally, it can compromise road safety, as overloaded trailers are harder to control and may cause accidents. To prevent these issues, it’s crucial to stay within the GVWR and regularly check the load weight, ensuring it’s distributed correctly. If the load is too heavy, consider using a trailer with a higher GVWR.

Q: What would be the consequences of improper weight distribution in the trailer?

Improper weight distribution can lead to several issues, including:

- Trailer Sway: If the load is too heavy at the rear, it can cause the trailer to sway, making it harder to control while driving.

- Tire Wear: Uneven weight distribution can cause uneven tire wear, potentially leading to flat tires.

- Vehicle Instability: It may affect the stability of both the trailer and the towing vehicle, increasing the risk of accidents, especially during turns or when braking.

- Increased Wear on Suspension: Poor weight distribution places additional strain on the trailer’s suspension system, leading to faster wear and potentially costly repairs.

To avoid these problems, it’s critical to load the trailer with approximately 60% of the weight at the front, ensuring balanced distribution.

Q: What is the purpose of selecting a winch in this report?

The purpose of selecting a winch in this report is to determine the best equipment for safely and effectively moving a drawer along an inclined ramp. Each container weighs 1,066 lbs, which makes manual movement impractical and difficult. The winch is needed to provide the necessary force to overcome both the gravitational and frictional forces acting on the drawer, ensuring smooth movement without overloading the equipment. This allows for safe transportation of the heavy load, making it easier to move the containers along the ramp.

Q: What is the recommended capacity for the winch, and why is it important to choose a winch with a higher rating than the minimum requirement?

The winch should have a minimum rated capacity of 620 lbs, as this is the force required to safely move the drawer. However, to account for unforeseen variables and ensure reliability, it is recommended to choose a winch with a capacity of at least 750 to 1,000 lbs. This higher capacity will accommodate additional factors like extra friction or slight bumps and ensure safe and efficient operation.

Q: Are there any other winches considered for this task?

The report specifically focused on the BADLAND ZXR 2,500 lb. ATV/Utility Winch due to its suitability in terms of capacity, cost, and available features. However, a list of other winches that meet or exceed the requirements for this task was also considered. The current option was selected because it was the most cost-effective choice at the time. Depending on pricing and specific requirements at the time of usage, if another winch meets the necessary criteria, it may be selected instead. This provides flexibility in ensuring the best possible solution based on the available options.

WAYS TO CONTRIBUTE TO THE EARTHBAG VILLAGE TOILET DESIGN

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

One Community

One Community