Aircrete Engineering and Research: Compression Testing, Mix Ratios, R-value, and More

Welcome to the Aircrete Engineering open source engineering hub. The purpose of this page is to share the engineering steps, research, resources, and tools we’ve used to verify the safety of our Aircrete designs and structures. We will continue to evolve this page until our Aircrete dome home is permitted. If building that structure demonstrates Aircrete is a better choice than Earthbag construction, we will build the entire Earthbag Village as Aircrete instead – open source sharing complete plans for both an Aircrete and an Earthbag Village.

For easy reference, the page is divided into the following sections:

- Related Pages

- What is Aircrete Construction

- Why Open Source Aircrete Engineering

- Ways to Contribute to Evolving This Sustainability Component With Us

- Aircrete Research Details

- Past Aircrete Testing

- Common Mistakes and Considerations While Making Aircrete

- Aircrete Testing:

- End of Aircrete Testing Summary and Findings

- Compression results using different Aircrete Densities

- Compression Results Using Different Cure Times

- Compression Results Adding Stucco Reinforcement

- Compression Results Using Different Mix Methods

- Compression Results Comparing Standard Mixes to Variations

- Compression Results Using Different Foams

- Limitations of This Testing Process

- Our Thoughts On This As a Building Method

- Viability As a Building Material

- Discusion

- Analysis of Primary Aircrete Foaming Agents

- Aircrete Mixing Tutorials

- Waste Management

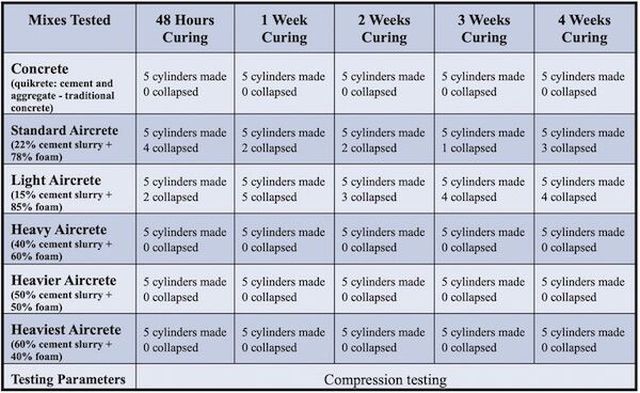

- Past Compression Testing Results

- Future Plans for Aircrete and Other Sustainable Building Materials

- Resources

- Summary

- FAQ

NOTE: AFTER HUNDREDS OF HOURS OF MIXING AND TESTING, WE WERE ABLE TO GET CONSISTENT RESULTS TO PRODUCE THE DATA ON THIS PAGE. READ THE “LIMITATIONS OF THIS TESTING PROCESS” TO UNDERSTAND WHY LARGE-SCALE PRODUCTION MAY YIELD MORE CONSISTENT RESULTS THAT JUSTIFY ADDITIONAL COMPRESSION TESTING.

PLEASE ALSO NOTE: WHILE OUR RESEARCH HERE IS EXTENSIVE, IT SHOULD BE USED FOR EDUCATIONAL PURPOSES ONLY. WE DO NOT RECOMMEND BUILDING ANYTHING WITHOUT PROPER ENGINEERING AND STAMPED AND APPROVED ENGINEERING PLANS.

RELATED PAGES (Click icons for complete pages)

WHAT IS AIRCRETE CONSTRUCTION

Aircrete is a building material that resembles concrete but is closer to cement. Aircrete is aerated cement made with three simple, easy-to-find ingredients: cement powder, water, and detergent foam. It is not considered concrete because it doesn’t include a solid aggregate mixed with cement, like sand or gravel. Instead, the “filler” in Aircrete is foam, and microscopic bubbles are produced by it. The many bubbles distributed throughout the Aircrete make it a far lighter alternative to traditional concrete with better insulation. Like concrete, Aircrete is often poured into molds and then cured over a certain period to allow the product to harden and strengthen. The result is a cementitious block with a uniform composition.

Benefits of Aircrete for the sustainable home include:

- Fairly inexpensive

- Lightweight

- Fire-resistant

- Resistant to moisture and sulfates

- DIY friendly

- Better thermal performance

- Uses less concrete, so it’s more sustainable

- Not susceptible to pests such as termites, insects or rodents

Aircrete is intended to be utilized to build structures, but as of now, the compressive strength of Aircrete is not well documented. This team’s mission was to document their scientific approach to defining the compressive strength of Aircrete with different ratios of foam, cure times, and with an added fiber stucco coating. This effort was pursued because of the many benefits associated with Aircrete, primarily its replicability and increased R-Value/insulation properties.

As stated above,Aircrete only consists of three relatively affordable ingredients that are available around the world: detergent, water, and cement. It can also be produced without heavy machinery or intensive labor. As a result, Aircrete has the potential to be a cost-effective, lightweight, and easily accessible building material that is more eco friendly than concrete.

WHY OPEN SOURCE AIRCRETE ENGINEERING

Open-sourcing our Aircrete research is essential to replicate it, allowing other builders to use it for themselves, improve upon our work, or add to it. At the moment, there is very little information on the engineering and structural applications of Aircrete. So, by creating this comprehensive Aircrete resource, we’re attempting to fill the void we see in this area.

Our goal in sharing what we’ve learned is to increase the safety and improve the performance of Aircrete-made structures. We hope this work can serve as a solid foundation for further research into the properties and applications of Aircrete, with others building off of our findings.

Research into sustainable and reliable building materials is at the core of One Community’s open-source strategy for building a global collaboration of self-sufficient and self-sustainable teacher/demonstration communities, villages, and cities for The Highest Good of All. One of the most significant steps to building more sustainably is conducting well-designed research to answer questions of structural strength for furthering the use of non-mainstream building materials. With this in mind, we have researched the compressive strength of Aircrete as part of our open-source contribution to comprehensive sustainable living. This page is a collection of our initial research and will evolve with our experience.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Charles Gooley: Web Designer

Dominick Banuelos: Civil Engineering Intern

John Sullivan: CBU Chemical Engineering Student

Jonathan Crago: Civil Engineering Intern

Jarot Tamba: Civil Engineering Intern

Julia Meaney: Web and Content Reviewer and Editor

John Paul D. Matining: Civil Engineer Intern

Marcus Nguyen: Civil Engineering Intern

Preston Thompson: Civil Engineering Student

Tad Matlock: Environmental Science Student

Sarah Boyd: Civil Engineering Student Researcher

Yiwei He: Mechanical Engineer

Zhide Wang: Mechanical Engineer

AIRCRETE RESEARCH DETAILS

Below we discuss our engineering findings and the process we used to get the results we did. We also share how to use the various spreadsheets we created. Note that all structures using Aircrete must still be checked and signed off on by an engineer licensed in your state before beginning any construction. The research and hands-on experimentation journey are shared in the following sections:

- Past Aircrete Testing

- Common Mistakes and Considerations While Making Aircrete

- Aircrete Testing

- End of Aircrete Testing Summary and Findings

- Compression results using different Aircrete Densities

- Compression Results Using Different Cure Times

- Compression Results Adding Stucco Reinforcement

- Compression Results Using Different Mix Methods

- Compression Results Comparing Standard Mixes to Variations

- Compression Results Using Different Foams

- Limitations of This Testing Process

- Our Thoughts On This As a Building Method

- Viability As a Building Material

- Discusion

- Analysis of Primary Aircrete Foaming Agents

- Aircrete Mixing Tutorials

- Waste Management

- Past Compression Testing Results

- Future Plans for Aircrete and Other Sustainable Building Materials

- Resources

- Summary

- FAQ

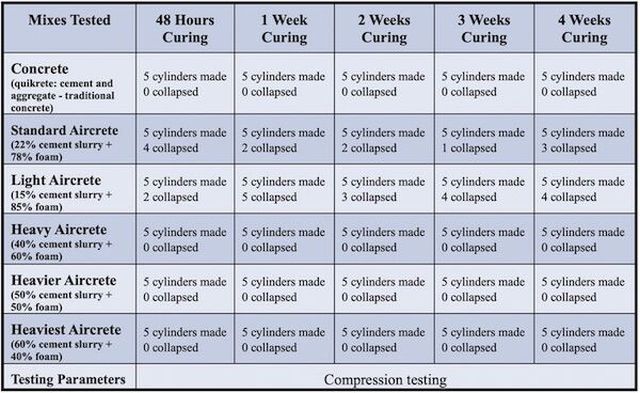

PAST AIRCRETE TESTING

In the past few years, we have conducted trials to test the viability and compression strength of various Aircrete mixes, working to evaluate the “standard” mix and evaluate the properties of lighter mixes too. We tested lighter mixes because they have a higher air-bubble content that creates a better R-Value. R-value is the capacity of an insulating material to resist heat flow. The higher the R-value, the greater the insulating power.

Overall, the results were inconsistent, with no repeatable successes found. Still, some general trends were observed as the teams worked with many mixes, using different tools, recipes, and varied concentrations of foam and cement.

What was made clear early on was that online resources and recipes for creating Aircrete were scarce. Using them, we also found it hard to generate consistent results. This led to a lengthy process of trial and error, providing more information for future teams to build on.

One prominent trend observed was the instability and inconsistency of standard Aircrete batches and those with higher concentrations of foam (lighter batches). The heavier Aircrete mixes with 60% or less foam (and more cement) did not experience collapse but were more challenging to thoroughly mix, leading to weight inconsistencies. High moisture content was another significant trend with these Aircrete samples, especially in high-foam mixtures. Some proposed fixes were longer curing times or outdoor curing.

Click these links to learn about our Past Successes from previous testing:

- Trial 9: Narrow Mixing Container

- Trial 15: Heavy Aircrete Mix

- Trial 16: Foaming Agent Tests

- Trial 21: Higher Dose of Drexel

- Trials 22 & 23: Varied Mixing Recipe

- Testing Dragon vs Aircrete Harry’s Foam Quality/Durability

- Trial 26: Testing the Foam Limit

PAST SUCCESSES

The past set of trials (linked here) did not produce consistent results, but there were still many successful tests that provided helpful information. Below, we share the most significant/useful of these.

This spreadsheet shares the complete testing results and the trial details that follow share the most applicable findings and things learned.

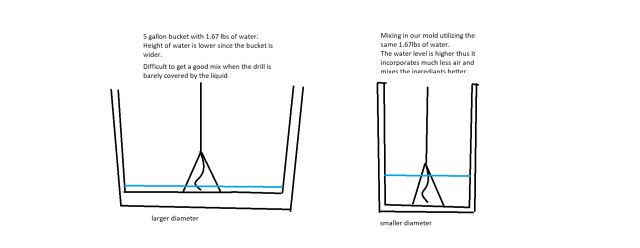

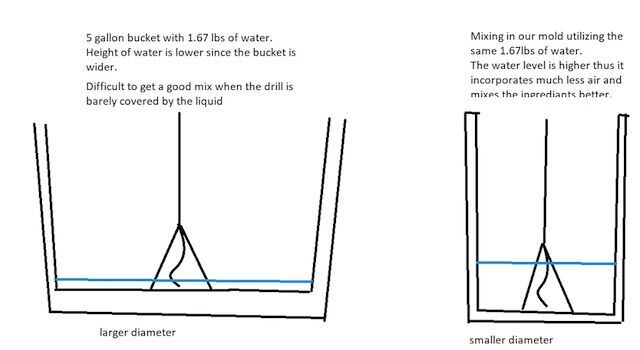

TRIAL 9: NARROW MIXING CONTAINER

Trial 9 was the first successful trial. Instead of mixing the cement slurry in a wide 5 gallon bucket, the team mixed the slurry in a narrower testing cylinder directly. Mixing the same volume of slurry in a container with a smaller diameter allowed the mixing drill bit to be fully submerged in the slurry, ensuring that it was properly mixed.

TRIAL 15: HEAVY AIRCRETE MIX

Trial 15 was the second successful trial. In this test, the team formulated the “heaviest” Aircrete mix with the highest concentration of cement slurry and the lowest concentration of foam (60% slurry and 40% foam). The higher concentration of cement led to the success of this trial.

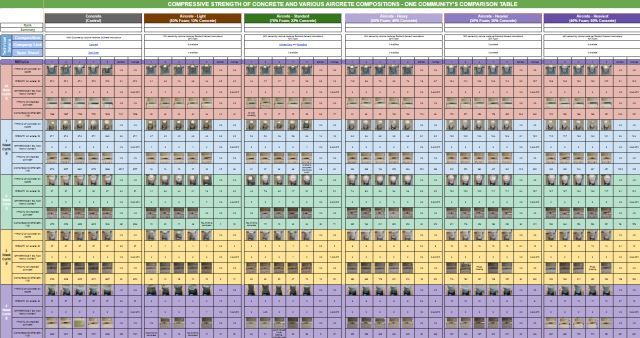

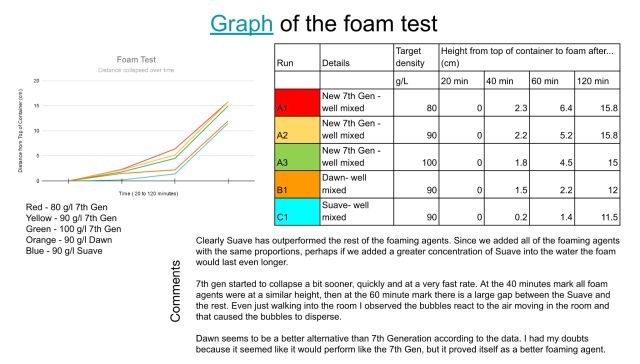

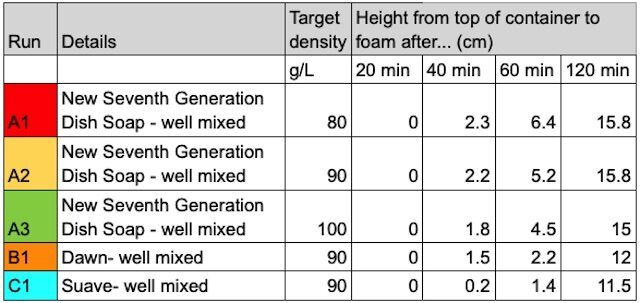

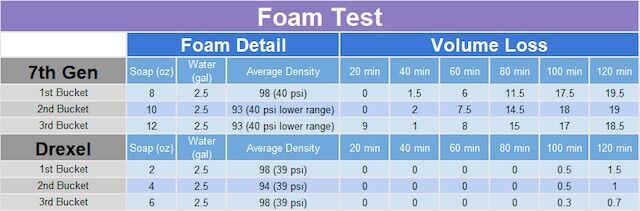

TRIAL 16: FOAMING AGENT TESTS

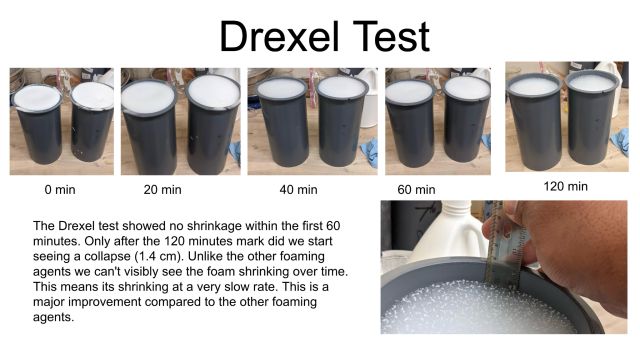

Trial 16 was the third successful trial, even though it wasn’t a normal mixing trial. Trial 16 evaluated the integrity of foam made with different brands of dish soap and Drexel. Detailed results can be found here. In summary, foam made with Suave dish soap held its volume best and Drexel greatly outperformed 7th Generation Dish Soap in a one-on-one test.

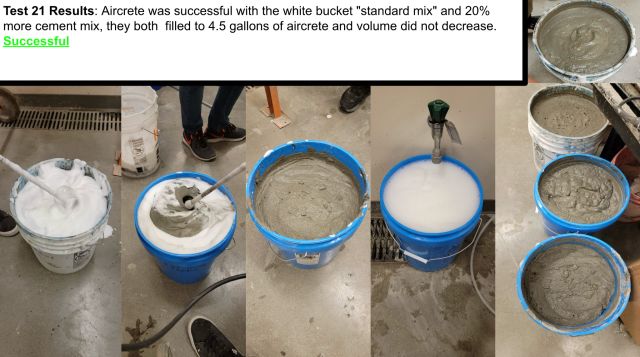

TRIAL 21: HIGHER DOSE OF DREXEL

Trial 21 was the fourth successful trial. The foam in this test was made with a higher dose of Drexel, 6 oz instead of the recommended 4 oz. As a result, the foam was noticeably stronger, revealing that higher doses of foaming agent can improve foam quality.

Timed Drexel Foam Comparison – Trial 21

TRIALS 22 & 23: VARIED MIXING RECIPE

Trials 22 and 23 were the fifth and sixth successful trials. Trials 22, 23, and 24 were run in the same span of time with similar methodologies, but minor changes. Each was meant to produce 4.5 gallons of Aircrete. Trial 22 was a standard mix made with 9.4 lbs of cement, 0.6 gallons of water, and 5.6 gallons of foam. Trial 23 used 20% more cement mix in the slurry, with 11.28 lbs of cement, 0.7 gallons of water, and 4.5 gallons of foam. Trial 24 was a standard mix with less water in the slurry, and was a failure.

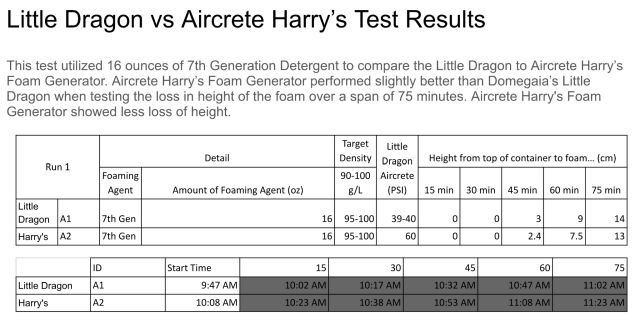

TRIAL 25: TESTING DRAGON VS AIRCRETE HARRY’S FOAM QUALITY/DURABILITY

Trial 25 compared the Little Dragon to Aircrete Harry’s Foam Generator. Aircrete Harry’s Foam Generator performed slightly better than Domegaia’s Little Dragon when testing the loss in height of the foam over a span of 75 minutes.

TRIAL 26: TESTING THE FOAM LIMIT

Trial 26 was the seventh successful trial. It tested the maximum foam limit for a successful Aircrete mix. The upper limit of foam that worked the best was 85% foam to 15% cement slurry by volume. The successful foam limit was 7% more foam than the standard mix.

PAST SUCCESSES SUMMARY

While past Aircrete testing wasn’t entirely successful, useful information was gained through the process. The central finding was that heavier mixtures made with high doses of Drexel are sturdier. Reducing the diameter of the mixing container and mixing more thoroughly also produce more reliable results. Even though heavier mixes were found to be stronger, lighter Aircrete batches with more foam are desired; they have also been the target for One Community’s Aircrete testing.

Progress has been made towards formulating a reliable, light Aircrete mix, but these past successes still show that higher volumes of cement mix can be a temporary fix for failing batches. Later testing also showed that our method of weighing and/or measuring foam before mixing it in led to collapse.

For more information on these past trials and the resources created and used by past teams, visit these links:

COMMON MISTAKES AND CONSIDERATIONS WHILE MAKING AIRCRETE

Looking past the valuable successes in these past trial runs (found here), there is much to be learned from failed tests. Even though the results were not perfectly consistent, both the scrapped ideas and variables analyzed are still very useful.

FINDINGS FROM PAST AIRCRETE TESTING

Here are our key findings for 100s of hours of past Aircrete testing.

MIXING DEVICE DIFFERENCES

Auger (Left) & Egg Beater (Right) Drill Attachments

Three different mixer styles were used: the egg beater drill attachment, cement mixer, and auger drill attachment. The egg beater was implemented after the auger was used for three failed trials. The main contribution of the egg beater was a faster mixing time, but the trial it was used in still failed. The quicker mixing led the Aircrete to be overmixed or the foam bubbles to be beaten out. The effect could also have been negligible. However, the egg beater drill attachment was rarely used after. The cement mixer was used in the seventh trial, but it was never used again. The Aircrete mixed in the cement mixer stuck to the sides, leading to lost material and incomplete integration. The mixing device that was used most consistently was the auger drill attachment. In later trials, a more significant auger attachment replaced the regularly used auger attachment.

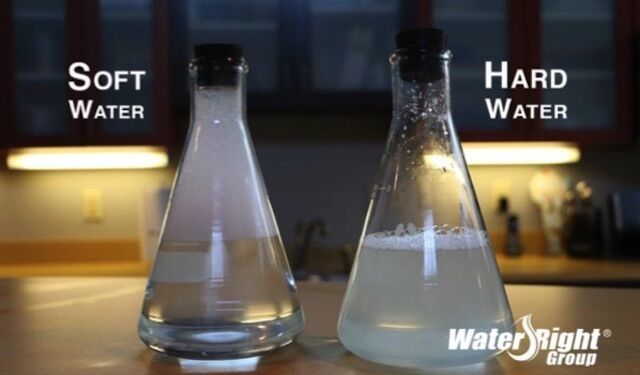

WATER HARDNESS

Water quality, hardness specifically, has been mentioned in various online Aircrete forums as one determinant of foam stability. Hard water, which has more dissolved calcium and magnesium, is more challenging to produce bubbles when mixed with a foaming agent. Also, the bubbles produced are less resilient than those with softer water. Trial 8 was conducted using deionized water (water treated with reverse osmosis to remove excess particles and ions, resulting in zero hardness), and no effect was observed; the trial still failed. This test of varying water hardness was only attempted once, so the impact of water quality in these trials could have been more evident. However, companies utilizing Aircrete, like Domegaia, have had success simply using water from a hose.

MIXING CONTAINER DIFFERENCES

The use of smaller mixing containers could lead to lost bubbles in foam. Mixing in a small container means that the foam could be overmixed, losing precious bubbles. Similarly, in a small container, vibrations caused by mixing or contact with container walls would be more aggressive and cause more disturbance to the foam. If foam stability is a concern, mixing the slurry and foam in a larger container would be an ideal solution. Another approach when trying to preserve foam stability is to create a denser Aircrete mix with more concrete.

FOAMING AGENT DIFFERENCES

The primary two foaming agents used were 7th Generation Dish Soap and Drexel. Dawn and Suave were also tested and compared in Trial 16. Throughout the trials, Drexel performed better than all other options. The foam made with Drexel was better at retaining volume, and less material was used to make the same volume of foam. Aircrete can be made successfully using 7th Generation Dish Soap (and it’s easier to purchase), but Drexel has been seen to deliver better results. Sustainability and cost analyses of both foaming agents can be found here.

FOAM GENERATOR DIFFERENCES

Two different foam generators were used by past teams, the Little Dragon (seen here) and Aircrete Harry’s model (seen here). The Little Dragon, from Domegaia, was used for the past trials linked throughout this page. Still, a pros and cons list was created comparing both:

| Model | Little Dragon (found here) | Aircrete Harry (found here) |

|  | |

| Pros |

|

|

| Cons |

|

|

RECENT COMPLICATIONS WITH THE DOMEGAIA MIX

In the most recent set of Aircrete compression tests, conducted in 2024, batches with greater percentages of foam* using Domegaia’s mixing method consistently resulted in collapse. There are two likely reasons for this: choice of foaming agent and the scale of the mixer.

* Note: Domegaia’s standard mix using 7th Generation Dish Soap was successful

CHOICE OF FOAMING AGENTS: DREXEL VS 7TH GENERATION DISH SOAP

The explanation for this repeated failure of higher-foam mixes with the most evidence is that the traditional foaming agent used by Domegaia, 7th Generation Dish Soap, is the batch’s central issue. Many other Aircrete mixing methods use Drexel as the foaming agent, and trials that substituted 7th Generation Dish Soap for Drexel while following the rest of Domegaia’s general procedure succeeded. Domegaia’s standard mix using 7th Generation Dish Soap was successful but the only reliable success of higher-foam mixes following Domegaia’s method was achieved after swapping foaming agents.

The more stable Drexel comes at increased cost and lower sustainability though.

SCALE OF THE MIXER

Another likely reason for the collapsing cylinders is that Aircrete does not down-scale well. Domegaia typically uses an entire 94 pound bag of cement for their Aircrete batches while these tests only use about 15 to 20 pounds. They also have been seen creating their mixes in a 50 gallon drum with their larger foam generator the Dragon XL, while this team only mixed Aircrete in 7 gallon, or less frequently 5 gallon, buckets. Additionally, DomeGaia uses a mixer that releases foam while mixing, called a foam-injection mixer, which may make their mixes have more consistently mixed foam throughout.

When scaling down as much as we did, it is possible that the foam doesn’t mix as well, increased vibration causes more foam collapse during the mixing process, and/or the amount of foam doesn’t scale linearly/as accurately with the cement and water.

In short, we think the Dragon XL would make a significant difference. Being able to pour the foam towards the bottom of the mixing container should create a more uniform mixture. The difference in densities of foam and cement will help mix if the foam is infused at the bottom.

COMMON MISTAKES AND CONSIDERATIONS SUMMARY

At times, working with Aircrete can be tedious. The foam needed is delicate and mixing cement requires a great deal of precision. The Aircrete mixing device, mixing container, hardness of water, cement quality, mix ratio, foaming agent, and foam generator have all contributed to at least one failed trial. When mixing Aircrete at home, it is helpful to consider seemingly minute variables like these if faced with consistent failure. In addition to these small sources of error, the previous set of Aircrete trials revealed that the foaming agent recommended by Domegaia could be unreliable.

Based on our experience, here’s how we’d rank these areas from highest (#1) to lowest potential to create problems in your Aircrete mixes:

- Variation in mixing time

- Drying conditions

- Cure time

- Mix Ratio

- Age of cement

Note: Standard Aircrete batches are normally much larger than our test batches and this could improve results by reducing large bubble build ups and giving more exposure for evaporation to occur.

AIRCRETE TESTING

In the most recent series of Aircrete tests, mixing trials were performed to determine the most reliable mixing methods that had the highest concentration of foam to create the lightest possible mixes. Two primary mixing procedures were followed: one from Domegaia and one from Aircrete Harry. Trials following Aircrete Harry’s mixing methodology were more successful and batches high in foam were able to be achieved. On the other hand, Domegaia’s Aircrete mixes were observed to be much too moist and were oftentimes unable to be subjected to further compression testing. We think this is a result of the foaming agent, as you’ll see in the notes below. We think this because variations in mixing containers, mixing devices, and cement content were made, but the only thing that was able to meaningfully change this general trend was using Drexel instead of 7th Generation Dish Soap.

Below are the results of all our tests.

INITIAL TRIAL PHASE

The primary goal of the initial trial phase was to test the viability of different Aircrete mixes varying in foam or cement concentration. It was necessary to get a solid grasp of the Aircrete mixing process and to streamline each method before moving onto the final compression testing phase. Additionally, this initial testing was used to reveal any flaws in the proposed and previously used mixing methods before the final data was gathered. Some noteworthy findings from this phase include: the unreliability of 7th Generation Dish Soap as a foaming agent and the consistent success of Aircrete Harry’s recipe.

Here are the summaries of the trials we did:

- Trial 1: First Attempts

- Trial 2: First Attempts

- Same Procedure, scaled upTrial 3: Same Procedure, Scaled Up

- Trial 4: Trial 3 Without Lids

- Trial 5: Longer Mixing Time

- Trial 6: Lightest Mix Tests Begin – Standard Mix

- Trials 7 & 8: Lightest Mix Tests – Standard Mix – 5% More Foam

- Trial 9: Lightest Mix Tests – Standard Mix – 10% More Foam

- Trial 10: Lightest Mix Tests – Standard Mix – 15% More Foam

- Trial 11: Lightest Mix Tests – Higher Cement Concentration – 5% More Foam

- Trial 12: Lightest Mix Tests – Standard Mix – 5% More Foam Repeat

- Trial 13: Lightest Mix Tests – Domegaia Mix

- Trial 14: Lightest Mix Tests – Domegaia Mix – Less Dish Soap

- Trial 15: Lightest Mix Tests – Domegaia Mix – Less Dish Soap and a 5 Gallon Bucket

- Trial 16: Lightest Mix Tests – Aircrete Harry Mix

- Trial 17: Lightest Mix Tests – Aircrete Harry Mix – With Added Foam

- Trial 18: Lightest Mix Tests – Domegaia Mix – Concrete Mixer

- Trial 19: Lightest Mix Tests – Domegaia Mix – Concrete Mixer and Sand

- Trial 20: Lightest Mix Tests – Domegaia Mix – Concrete Mixer and High Cement Mix

- Trial 21: Lightest Mix Tests – Domegaia Mix – Accounting for Extra Water

- Trial 22: Lightest Mix Tests – Domegaia Mix – High Cement Mix and 5 Gallon Bucket

- Trial 23: Lightest Mix Tests – Domegaia Mix – High Cement Mix and Drill Mixer

- Trial 24: Lightest Mix Tests – Domegaia Mix – High Cement Mix in a 5 Gallon Bucket

- Trials 25-27: Lightest Mix Tests – Domegaia Mix – High Cement Mix With 5% More Foam

- Trial 28: Lightest Mix Tests – Domegaia Mix – High Cement Mix With Separated Foam

- Trial 29: Lightest Mix Tests – Aircrete Harry Mix – Standard Procedure

- Trial 30: Lightest Mix Tests – Aircrete Harry Mix – Concrete Mixer

- Trial 31: Lightest Mix Tests – Aircrete Harry Mix – 5% More Foam

- Trial 32: Lightest Mix Tests – Aircrete Harry Mix – 10% More Foam

- Trial 33: Lightest Mix Tests – Aircrete Harry Mix – 15% More Foam

TRIAL 1: FIRST ATTEMPTS

The first trial set followed the standard procedure for mixing Aircrete, found in the Aircrete Procedures Manual and Instructional Video

from the past volunteer team. However, some minor changes were made to test for more consistent results: the cement was mixed with a mortar mixer and a 5 gallon bucket was filled with foam instead of a 7 gallon bucket. Still, this batch ended as a failure. While mixing, the cement got stuck to the walls of the mixer, so 4 more pounds of cement and 2 more pounds of water were added to remedy this. In the end, this trial only produced 1.5 cylinders of Aircrete. The mortar mixer also broke in the process, so the cement, water, and foam will be mixed in a 7 gallon bucket instead of the mortar mixer.

Here is the most current video tutorial covering the standard Aircrete mixing procedure:

TRIAL 2: FIRST ATTEMPTS

In the second trial, the two small changes made in Trial 1 (use of the mortar mixer and 5 gallon bucket) were undone. Trial 2 followed the past team’s procedure exactly, and the objective of this trial was to gain a better understanding of their process. This test still ended in a failure, only producing 2.75 cylinders of Aircrete, and the Aircrete cylinders that were made were noticeably weak and had water at their bases. The individual weights of each cylinder were not taken.

TRIAL 3: SAME PROCEDURE, SCALED UP

The third trial was scaled up after Trial 2 failed to produce a full 3 cylinders of Aircrete, so enough materials were used to produce a theoretical 3.5 cylinders. The same procedure was followed in Trial 3, but in this test, lids were put on the cylinders. Trial 3 ended up producing 3 cylinders, but they had drastically different weights. The lightest cylinder weighed 5.1 pounds, slightly collapsed, had water at the base after 5 days, and was given the shortest curing time. One of the cylinders weighed in at 7.9 pounds, was removed from the mold after 36 days, but failed due to breaking while opening. The third cylinder weighed 11.6 pounds, was removed after 23 days, and remained stable while opening. The 11.6 pound cylinder had a stress load of 114.1. There was great weight disparity among the batch.

5.1 lb Cylinder Before & After Removal From Mold

TRIAL 4: TRIAL 3 WITHOUT LIDS

The fourth trial followed the same procedure as Trial 3, except without lids on the cylinders. The three cylinders produced had drastically different weights again. The lightest cylinder weighed 5.8 pounds, the next highest weight was 8.5 pounds, and the heaviest cylinder weighed 11.4 pounds. Only the lightest cylinder collapsed, likely because it contained the most foam. The suspected issue with Trials 3 and 4 was the mixing. It was assumed that the cement and foam needed to be homogenized, leading to different foam contents and weights across the three cylinders. Also, the lids showed no apparent effect on the process.

TRIAL 5: LONGER MIXING TIME

The fifth trial followed the same standard procedure as the past four, but the Aircrete was mixed for a longer time and poured differently to reduce weight disparity. The cement, water, and foam mixture was drill-mixed until the consistency was uniform. Also, the cylinders were first filled up halfway and then topped off. This trial saw more consistent cylinder weights, but there was still some variation. The three cylinders weighed 6.17, 6.18, and 7.08 pounds, respectively. The lightest cylinder, with a weight of 6.17 pounds, had a cure time of 4 days, and its Aircrete had a high moisture content. The cylinder weighing 6.18 pounds ended up weighing 5.89 pounds after 14 days of curing. Again, this cylinder had a high moisture content after curing. This prevented successful compression testing on both the 6.17 and 6.18-pound cylinders. However, the longer mixing time and new pouring method fixed the initial weight variation problem.

These results also lend credibility to the hypothesis that mixing larger batches and mixing them more thoroughly helps produce more consistent results.

Compression Test of 6.17 lb Cylinder After 4 Days

Compression Test of 6.18 lb Cylinder After 14 Days

TRIAL 6: LIGHTEST MIX TESTS BEGIN – STANDARD MIX

Since there has only been minimal collapse in the past few trials, testing begins for the lightest possible Aircrete mix using three different procedures. The standard mixing method used in Trials 1-5 is being followed, and the new pouring method from Trial 5 is being added. However, the cement-to-foam ratio is adjusted across each batch in each set of tests. Most/all are 2:1 Concrete to Water. You can see specifics on our excel file. Trial 6 follows the standard cement-to-foam ratio. The 6.49-pound cylinder produced in this trial weighed 5.87 pounds after nine days of curing; this was the lightest cylinder. A compression test was done on this cylinder but was unsuccessful as the Aircrete squished down and didn’t crack, indicating that this sample was too moist.

.

Compression Test of 6.49 lb Cylinder After 9 Days

TRIALS 7 & 8: LIGHTEST MIX TESTS – STANDARD MIX – 5% MORE FOAM

In the seventh and eighth trials, the second of the standard Aircrete Harry method lightest mix tests, 5% less cement slurry (cement and water) was used. In its place, 5% more foam was added. In Trial 7, some cylinders showed a slight decrease in volume at first but eventually remained constant. Overall, this trial was a success. In Trial 8, the same procedure was followed, but the cylinders were left to cure outside instead of inside the lab. The results of Trial 7 mirrored those of Trial 6, with a moderate decrease in volume (e.g. 6.84 pounds to 6.09 pounds after 9 days) and a failed compression test due to high moisture content. The cylinders in Trial 8 also had a moderate decrease in volume (e.g. 8.18 pounds to 7.15 pounds after 9 days). However, Trial 8’s cylinders could not be compression tested as the Aircrete cracked as it was removed from the cylinders. This was due to the weakness of the mix.

Compression Test of 6.84 lb Cylinder After 9 Days (Trial 7)

TRIAL 9: LIGHTEST MIX TESTS – STANDARD MIX – 10% MORE FOAM

In the ninth trial, 10% less cement slurry was used, in relation to the original recipe. Again, the standard mixing procedure was followed, but 10% more foam was added. The lightest cylinder, weighing 6.94 pounds, dropped to a weight of 5.99 pounds after 8 days. This cylinder also was squished during compression testing, showing a similar excess of moisture.

Compression Test of 6.94 lb Cylinder After 8 Days

TRIAL 10: LIGHTEST MIX TESTS – STANDARD MIX – 15% MORE FOAM

In the tenth trial, 15% less cement slurry was used in relation to the original recipe. Again, the standard mixing procedure was followed, but 15% more foam was added. The lightest cylinder, weighing 7.76 pounds, dropped to 7.32 pounds after 8 days. This cylinder had a more significant excess of moisture, with water pooling at the base. This meant that compression testing could not be conducted, and the higher moisture content explains the low decrease in volume.

7.76 lb Cylinder After 8 Days – No Compression Test

TRIAL 11: LIGHTEST MIX TESTS – HIGHER CEMENT CONCENTRATION – 5% MORE FOAM

In the eleventh trial, 5% less cement slurry was used, in relation to the original recipe. The standard mixing procedure was still followed, except a higher quantity of cement was used. Normally, a standard batch with 5% more foam would have 14.3 pounds of cement mix and 7.67 pounds of water. In this batch, 19.17 pounds of cement mix and 7.67 pounds of water were used to test the effects of cement concentration on cylinder collapse volume. The lightest cylinder, weighing 7.65 pounds, ended up with a weight of 6.77 pounds after 7 days. It was dry enough for a successful compression test, having a peak load of 2080 psi and a stress load of 73.59 psi.

Compression Test of 7.65 lb Cylinder After 7 Days

TRIAL 12: LIGHTEST MIX TESTS – STANDARD MIX – 5% MORE FOAM REPEAT

In the twelfth trial, Trial 7 was repeated as 5% less cement slurry was used in the standard mixing process. This trial aimed to test for more consistent results, namely, final volume and collapse. The lightest cylinder weighed 8.58 pounds and 7.78 pounds after 7 days. This cylinder was also dry enough for a compression test. The peak load was 1930 psi, and the stress load was 68.16 psi. However, the cylinder compressed quite a bit during this process, and a crack in the center formed, so this data should be taken with a grain of salt. This was the final test using the standard Aircrete Harry procedure in the lightest mix test set; the next set of trials will use the mixing method from Domegaia.

Compression Test of 8.58 lb Cylinder After 7 Days

TRIAL 13: LIGHTEST MIX TESTS – DOMEGAIA MIX

In the thirteenth trial, the mixing procedure from Domegaia is being used (found here). The main variable being changed (from the standard procedure) is the foaming agent. In this trial, 16 ounces of 7th Generation Dish Soap were used in the 5 gallons of water in place of 4 ounces of Drexel. In the 7 gallon bucket after mixing, there was minimal collapse, which was likely due to the higher concentration of 7th Gen. Dish Soap. This mix filled up 4 cylinders, and the first 3 cylinders poured were consistent in weight, but the 4th cylinder was 3 pounds heavier. After around 30 minutes, all cylinders started bubbling and eventually collapsed. Again, this was most likely due to the higher concentration of 7th Gen. Dish Soap.

Collapse After ~5 Minutes and ~20 Minutes. The Range of Collapse After 20 Minutes Was 1 ½ in – 5 ½ in

TRIAL 14: LIGHTEST MIX TESTS – DOMEGAIA MIX – LESS DISH SOAP

In the fourteenth trial, the same Domegaia procedure was followed, but 12 ounces of 7th Gen. Dish Soap were used instead of 16 ounces. Still, the cylinders collapsed around the same amount as they did in the previous trial. This method also filled 4 cylinders and maintained an even weight distribution between all four, like Trial 13. However, during the creation process, the foam was not fully mixed in the bucket, so the foam will be added to the top of the 5 gallon bucket instead of the 7 gallon bucket in Trial 15.

How Smaller Containers Allow for More Consistent Mixing

TRIAL 15: LIGHTEST MIX TESTS – DOMEGAIA MIX – LESS DISH SOAP AND A 5 GALLON BUCKET

In the fifteenth trial, the same Domegaia method used in Trial 14 was followed, except the foam was poured to fill a 5 gallon bucket instead of the 7 gallon bucket. Even though a different pouring method was used, the results were the same as in Trial 14 and the cylinders collapsed.

Based on this, we feel the Domegaia approach won’t work for lighter mixes, mainly due to its use of foaming agent: 7th Generation Dish Soap. Going forward, the Aircrete Harry recipe will be followed, with its use of Drexel (see Aircrete Harry Aircrete Recipe and Mixing Instructions)

TRIAL 16: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX

In the sixteenth trial, Aircrete Harry’s mixing method was followed again. Like normal, the cement and water were mixed into a slurry, then the 7 gallon bucket they were being mixed in was topped off with foam and thoroughly mixed again. While mixing, the foam lost some air and the final volume of the mixture was lower than normal. Only 2.5 cylinders were able to be filled. No compression tests were conducted.

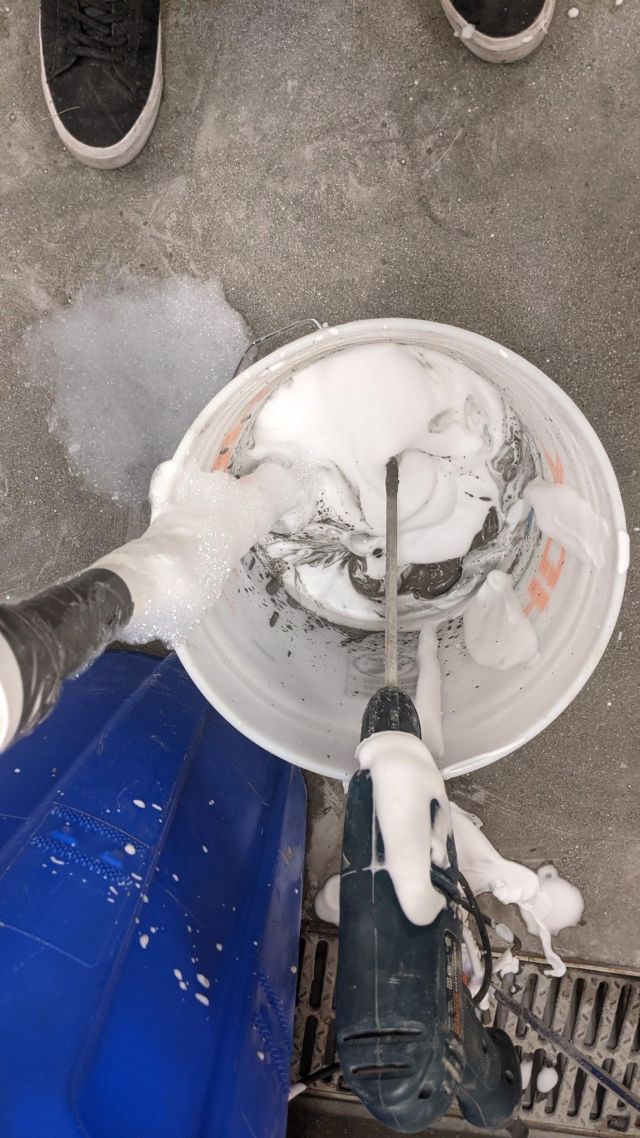

Thoroughly Mixed Cement Slurry and Foam

TRIAL 17: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – WITH ADDED FOAM

In the seventeenth trial, the same procedure was followed. The only change made was to continue adding foam to the 7 gallon bucket during mixing to fix the foam compression problem. As the volume of the foam decreased, more was added to maintain a constant volume of foam. This strategy worked, and 3 cylinders were produced. These 3 cylinders did not collapse.

TRIAL 18: LIGHTEST MIX TESTS – DOMEGAIA MIX – CONCRETE MIXER

In the eighteenth trial, the concrete mixer was fixed, so the Domegaia method was tested again using the concrete mixer instead of a drill in an attempt to get better results. The standard Domegaia procedure to make the cement slurry was followed, but the foam was added on top of the slurry rather than mixed in immediately. The 7 gallon bucket with a top layer of foam was then put into the concrete mixer and mixed until it all was well integrated. 10% more cement slurry could be added to account for the material stuck to the sides of the mixer by the end. Even though a new method was employed, the cylinders all collapsed. However, they took longer to collapse and collapsed less than in previous trials.

Cement Slurry and Foam in Concrete Mixer

TRIAL 19: LIGHTEST MIX TESTS – DOMEGAIA MIX – CONCRETE MIXER AND SAND

In the nineteenth trial, one change was made to the Domegaia method performed in Trial 18. 6 pounds of sand were added to the 7 gallon bucket and mixed into the cement slurry before the foam was poured. This was all put into the concrete mixer again, and mixed until everything was integrated. This addition only worsened the results, with heavier cylinders and deeper collapse.

TRIAL 20: LIGHTEST MIX TESTS – DOMEGAIA MIX – CONCRETE MIXER AND HIGH CEMENT MIX

In the twentieth trial, the procedure of Trial 18 was followed, and the higher cement mixture seen in Trial 11 was used as well. The high cement mix is a 0.4 water to cement ratio meant to increase the strength of the mixture and prevent collapse. Enough materials were used to produce 3.3 cylinders, because a 10% loss of material to the concrete mixer was estimated. Also, 2 pounds of water were added to flush out all cement in the 7 gallon bucket. This mix produced 4 cylinders of Aircrete, but the material in each cylinder collapsed soon after pouring, later maintaining a constant volume.

Here’s the video tutorial covering this trial’s mixing procedure (failing results):

Domegaia Procedure – Trial 20 Concrete Mixer and High Cement Mix

Failed Cylinders After Initial Collapse

TRIAL 21: LIGHTEST MIX TESTS – DOMEGAIA MIX – ACCOUNTING FOR EXTRA WATER

In the twenty-first trial, the same Domegaia method from Trial 20 was used, but with one small change. This time, the water that was used to flush out the 7 gallon bucket was accounted for when preparing the proper ingredients. 19.03 pounds of cement were used with 6.5 pounds of water, mixed, poured into a 7 gallon bucket, and then the bucket was filled with foam. This was then poured into the concrete mixer and 1 pound of water was used to flush out the material in the 7 gallon bucket. 3 cylinders were filled and none collapsed, so this trial was a success.

Here’s the video tutorial covering this trial’s mixing procedure (successful results):

TRIAL 22: LIGHTEST MIX TESTS – DOMEGAIA MIX – HIGH CEMENT MIX AND 5 GALLON BUCKET

In the twenty-second trial, the same Domegaia method from Trial 20 was used, again with one small change. In this trial, both the cement slurry and foam were added to a 5 gallon bucket instead of a 7 gallon bucket, this reduces the volume of foam in the mixture and makes the Aircrete stronger. As in Trial 20 and 21, a high cement mix was used. 3 cylinders were filled and again, none of them collapsed. Trial 22 was a success.

An up-to-date video tutorial covering this trial’s mixing procedure can be found here (successful results):

TRIAL 23: LIGHTEST MIX TESTS – DOMEGAIA MIX – HIGH CEMENT MIX AND DRILL MIXER

In the twenty-third trial, the Domegaia method from the past three trials was repeated due to consistent success. However, in this trial, the cement mixer was replaced with the handheld drill mixer. In a 7 gallon bucket, 19.03 pounds of cement mix and 7.6 pounds of water were mixed. This slurry was mixed with the drill, then foam was added to the top and mixed again until everything was uniformly combined. The drill ran slowly and contact with the bucket’s sides was avoided to prevent vibrations that we think were leading to the loss of too many foam bubbles. In the end, enough material was created to fill 4 cylinders. As a result, the pouring method was thrown off and the cylinders varied in weight. The cylinders also collapsed, so this trial was a failure.

An up-to-date video tutorial covering this trial’s mixing procedure can be found here (failed results):

DOMEGAIA PROCEDURE – Trial 23

Mixing Cement Slurry and Foam Using a Drill

TRIAL 24: LIGHTEST MIX TESTS – DOMEGAIA MIX – HIGH CEMENT MIX IN A 5 GALLON BUCKET

In the twenty-fourth trial, the Domegaia method from Trial 23 was repeated, but the material was mixed in a 5 gallon bucket, again with a drill mixer. The goal of this change was to make fewer cylinders with a smaller bucket, reducing the weight inconsistency. Again, the cylinders collapsed.

An up-to-date video tutorial covering this trial’s mixing procedure can be found here (failed results):

Domegaia Procedure – Trial 24

TRIALS 25-27: LIGHTEST MIX TESTS – DOMEGAIA MIX – HIGH CEMENT MIX WITH 5% MORE FOAM

In the twenty-fifth and twenty-sixth trials, the same process from Trials 20-22 was used, only with 5% more foam. The foam was added to the top of the slurry in a 7 gallon bucket, then poured into the concrete mixer. The high cement mix ratio was used in the concrete mixer. In the end, Trial 25 resulted in failure, all but one of the cylinders collapsed. The cylinder that didn’t collapse had an air pocket in the center, and was not viable. The same method was employed in Trial 26, but the cylinders collapsed again.

In the twenty-seventh trial, both the slurry and foam were mixed in a 5 gallon bucket instead of a 7 gallon bucket. Aside from this, the same method from the past two trials was followed.

The same as the past two trails, Trial 27 also resulted in failure.

“Stable” Cylinder With an Air Bubble – Trial 25

TRIAL 28: LIGHTEST MIX TESTS – DOMEGAIA MIX – HIGH CEMENT MIX WITH SEPARATED FOAM

In the twenty-eighth trial, two changes were made to the typical Domegaia mixing method. However, this test still used the high cement mix and concrete mixer. The first change was that all the water in this recipe was added at the beginning, and no extra water was used to flush the cement stuck in the concrete mixer. The second change was that the foam was measured in a separate container and then added directly into the concrete mixer, reducing the time it takes to add the foam into the mixer. Still, this trial resulted in failure.

Since tests following the Domegaia method have been inconsistent and usually result in collapse, more planning is needed for these trials and upcoming tests will follow the Aircrete Harry mixing procedure that reliably produces sturdy cylinders that are ready for compression testing, primarily through the use of a more powerful foaming agent, Drexel, and a lower foam density of 68 g/qt. Both have led to sturdier foam that takes longer to decompress.

An up-to-date video tutorial covering this trial’s mixing procedure can be found here (failed results):

Collapsed Domegaia Cylinders

TRIAL 29: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – STANDARD PROCEDURE

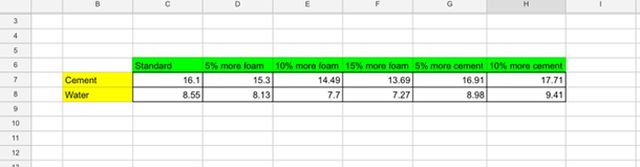

In the twenty-ninth trial, Aircrete Harry’s mixing method was employed. 16.1 pounds of cement and 8.5 pounds of water were mixed in a 7 gallon bucket with a drill mixer, then foam was added until the bucket was filled. The density of the foam was 63 grams per quart, which is the ideal density for this mixing method. This was all mixed in the bucket for 5 minutes, and then poured into 3 cylinders. This trial was a success, and none of the cylinders collapsed.

TRIAL 30: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – CONCRETE MIXER

In the thirtieth trial, Trial 29 was repeated, but the slurry and foam were both mixed in the concrete mixer rather than the bucket directly. After the foam was added to the 7 gallon bucket, the bucket’s contents were immediately poured into the concrete mixer. The concrete mixer ran for 10 minutes, and the trial resulted in success.

TRIAL 31: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – 5% MORE FOAM

In the thirty-first trial, the standard Aircrete Harry mixing recipe was followed, but with 5% more foam. This trial resulted in success.

TRIAL 32: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – 10% MORE FOAM

In the thirty-second trial, the standard Aircrete Harry mixing recipe was followed, but with 10% more foam. This trial resulted in success, and none of the cylinders collapsed.

TRIAL 33: LIGHTEST MIX TESTS – AIRCRETE HARRY MIX – 15% MORE FOAM

In the thirty-third trial, the standard Aircrete Harry mixing recipe was followed, but with 15% more foam. This trial also resulted in success as none of the cylinders collapsed. After this, final testing could begin.

END OF INITIAL TRIAL TESTING PHASE SUMMARY

Overall, the initial testing phase revealed how much more reliable Aircrete Harry’s mixing method is compared to Domegaia’s, when performed under our lab’s conditions. Aircrete Harry uses Drexel with a foam density of 68 g/qt. From our observation, the foam takes longer to decompress. Domegaia uses 7th Gen dish soap with a foam density of 90-100 g/qt and has faster decompression.

As a result, more compression tests will be performed and more data collected on batches following Aircrete Harry’s procedure. One additional possible explanation for Domegaia’s unreliability is their foam generator, the Little Dragon, which was used for their trials. It is no longer sold and they now only offer their Dragon XL, which adds the foam towards the bottom of the mixing container to create a more uniform mixture. This would mean a more uniform mix and less time for it to collapse.

FINAL TESTING PHASE

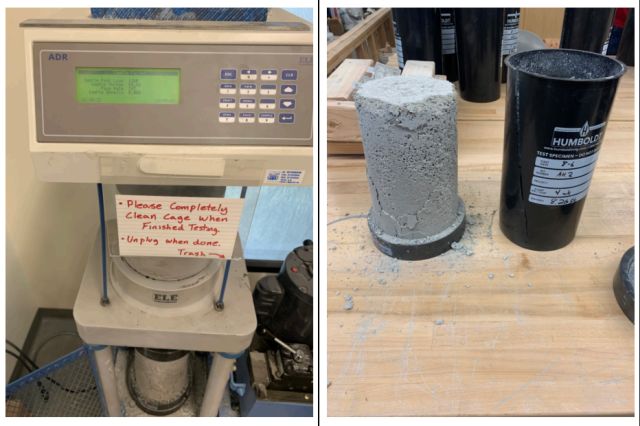

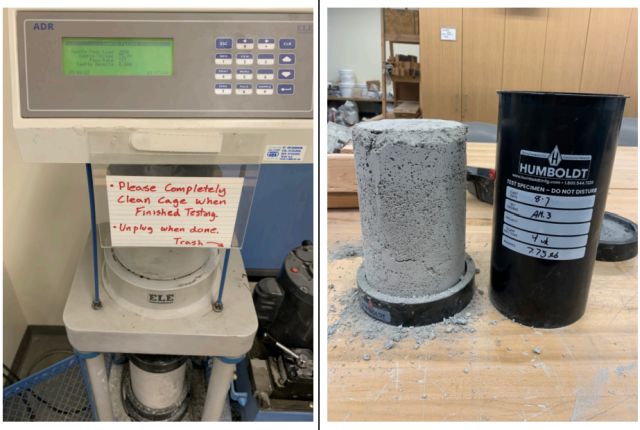

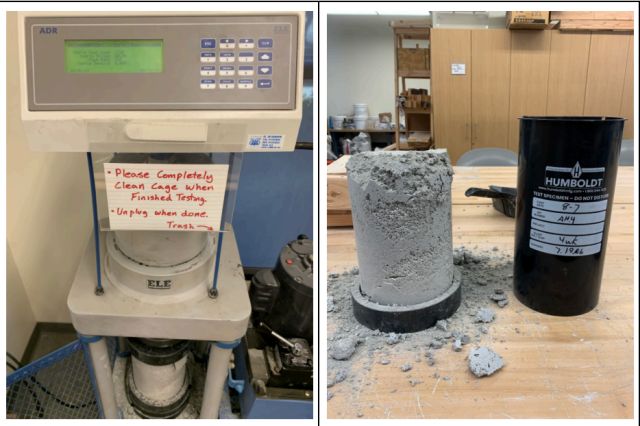

After preliminary Aircrete tests were complete and consistent results were achieved, each mixing method was repeated in batches of 6 cylinders. The standard Aircrete Harry and Domegaia mixing procedures were followed, then performed again with slight variations.

Additional cylinders made with Aircrete Harry’s recipe had stucco mesh reinforcement added along the cylinders’ walls and additional Domegaia batches were made with a substituted foaming agent, Drexel instead of 7th Generation. The foam-cement ratios were altered as well.

Using Aircrete Harry’s mixing method, additional foam (5%, 10%, and 15%) and cement (5% and 10%) variations were tested successfully. When Domegaia’s mixing procedure was

employed, the only ratio change we were confident testing was 10% more cement. Cure times varied from 2 to 4 weeks.

Click the links below to visit the following summaries for the following trials:

Click the links below to visit the following summaries for the following trials:

- Trial 34: Final Testing – Standard Mix

- Trial 35: Final Testing – Standard Mix – 5% More Foam

- Trial 36: Final Testing – Standard Mix

- Trial 37: Final Testing – Standard Mix – Heavier Mix

- Trial 38: Final Testing – Aircrete Harry Mix

- Trial 39: Final Testing – Aircrete Harry Mix – 5% More Foam

- Trial 40: Final Testing – Aircrete Harry Mix – 10% More Foam

- Trial 41: Final Testing – Aircrete Harry Mix – 15% More Foam

- Trial 42: Final Testing – Aircrete Harry Mix – 5% More Concrete

- Trial 43: Final Testing – Aircrete Harry Mix – 10% More Concrete

- Trial 44: Final Testing – Aircrete Harry Mix – Added Stucco Reinforcement

- Trial 45: Final Testing – Aircrete Harry Mix – 5% More Foam and Added Stucco

- Trial 46: Final Testing – Aircrete Harry Mix – 10% More Foam and Added Stucco

- Trial 47: Final Testing – Aircrete Harry Mix – 15% More Foam and Added Stucco

- Trial 48: Final Testing – Aircrete Harry Mix – 5% More Concrete and Added Stucco

- Trial 49: Final Testing – Aircrete Harry Mix – 10% More Concrete and Added Stucco

- Trial 50: Final Testing – Domegaia Mix – High Cement Mix

- Trial 51: Final Testing – Domegaia Mix – 10% More Concrete

- Trial 52: Final Testing – Control Group – Normal Cement

- Trial 53: Final Testing – Aircrete Harry Mix – 5% More Foam and 3 Week Cure Time

- Trial 54: Final Testing – Aircrete Harry Mix – 10% More Foam

- Trial 55: Final Testing – Aircrete Harry Mix – 15% More Foam

- Trial 56: Final Testing – Aircrete Harry Mix – 5% More Concrete

- Trial 57: Final Testing – Aircrete Harry Mix – 10% More Concrete

- Trial 58: Final Testing – Aircrete Harry Mix – Standard and 2 Week Cure Time

- Trial 59: Final Testing – Aircrete Harry Mix – 5% More Foam

- Trial 60: Final Testing – Aircrete Harry Mix – 10% More Foam

- Trial 61: Final Testing – Control Group – Normal Cement

- Trial 62: Final Testing – Aircrete Harry Mix – 15% More Foam

- Trial 63: Final Testing – Aircrete Harry Mix – 5% More Cement

- Trial 64: Final Testing – Aircrete Harry Mix – 10% More Cement

Comprehensive compression data from these final tests can be found in this spreadsheet:

TRIAL 34: FINAL TESTING – STANDARD MIX

In the thirty-fourth trial, the standard Aircrete Harry mixing procedure from Trial 6 was followed. This mixing method was similar to Domegaia’s, but Drexel was used as the foaming agent, rather than 7th Generation Dish Soap. Both the cement slurry and foam were mixed in a 7 gallon bucket with the drill mixer. This trial was a success as none of the cylinders collapsed.

TRIAL 35: FINAL TESTING – STANDARD MIX – 5% MORE FOAM

In the thirty-fifth trial, the same standard procedure from Trials 6 and 34 was followed, but 5% more foam was used. This trial was also a success, and all of the cylinders were stable.

TRIAL 36: FINAL TESTING – STANDARD MIX

In the thirty-sixth trial, Trial 34 was repeated, and the foam-cement ratio was not changed. This trial produced 3 cylinders,

TRIAL 37: FINAL TESTING – STANDARD MIX – HEAVIER MIX

In the thirty-seventh trial, the same standard procedure was followed, but with more water and cement to make a heavier mix. This process, which makes 3 cylinders, was repeated, creating a total of 6 cylinders.

TRIAL 38: FINAL TESTING – AIRCRETE HARRY MIX

In the thirty-eighth trial, the Aircrete Harry mixing method from Trial 29 was followed. It was repeated twice and produced a total of 12 cylinders, half of which will be cured for 3 weeks while the other half will cure for 4 weeks.

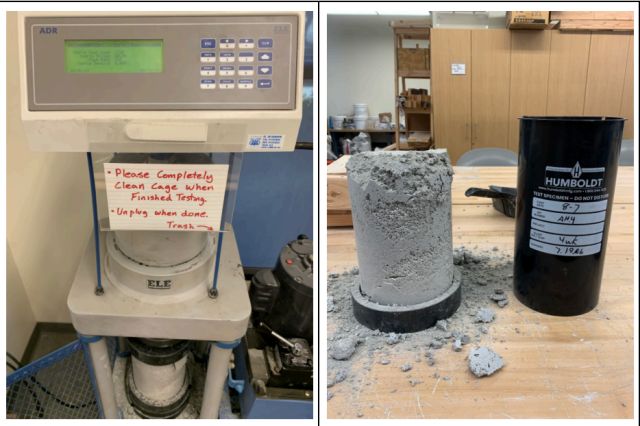

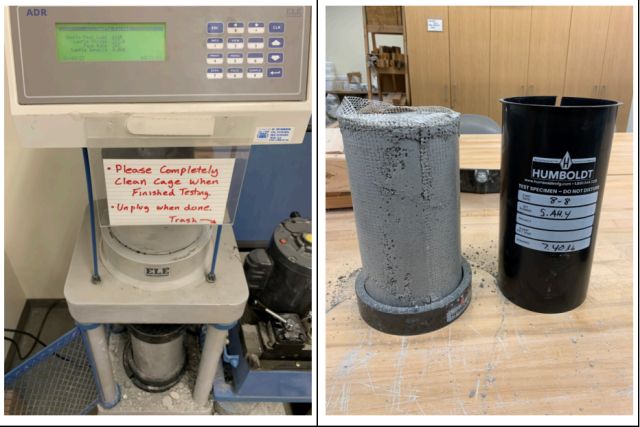

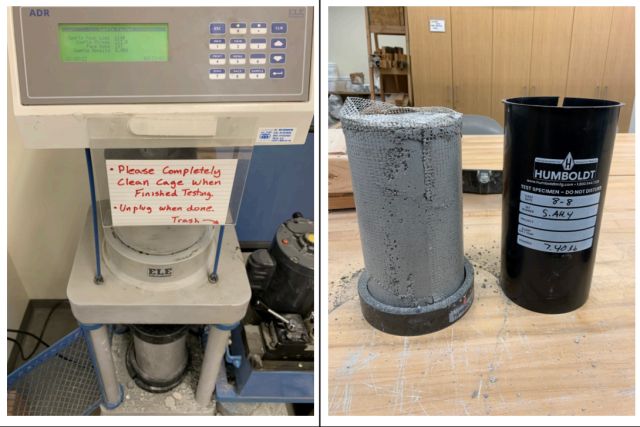

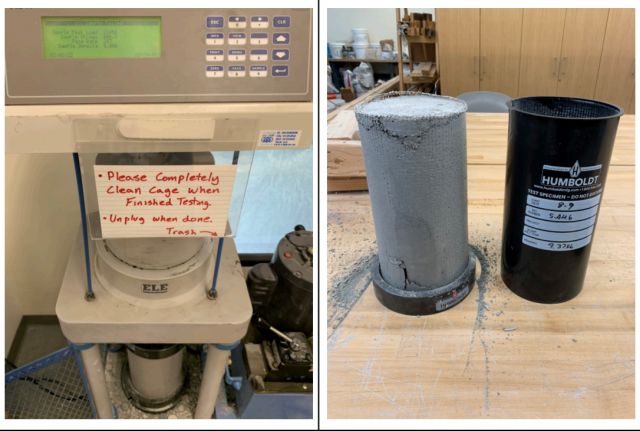

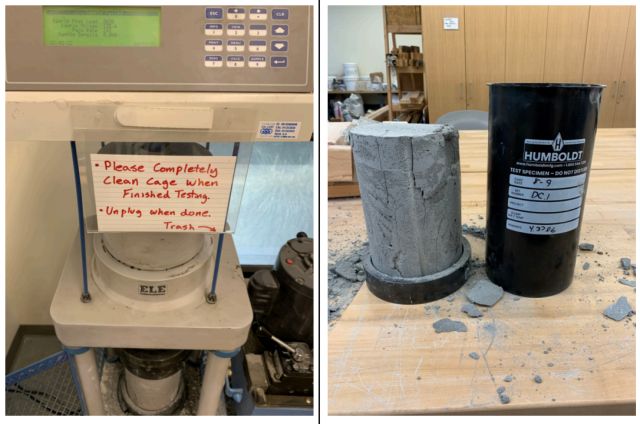

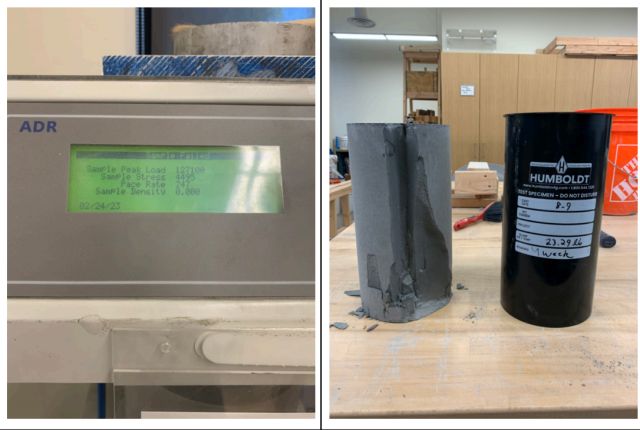

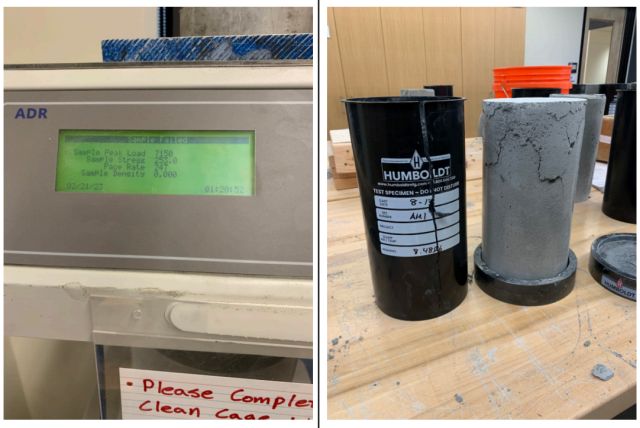

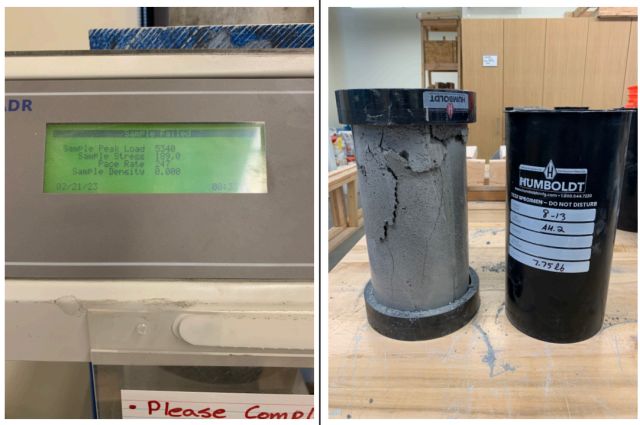

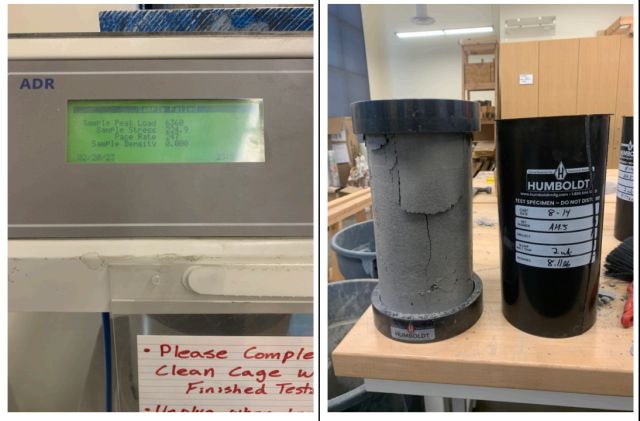

Aircrete Harry Standard Mix (Cylinder 2) – Peak Load: 2200 psi, Stress Load: 77.7 psi – 3 Week Curing

TRIAL 39: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE FOAM

In the thirty-ninth trial, the Aircrete Harry mixing method was followed, but 5% more foam was used. The mix was repeated twice, producing a total of 6 cylinders that will be cured for 4 weeks.

Aircrete Harry Mix, 5% More Foam (Cylinder 4) – Peak Load: 1260 psi, Stress Load: 44.68 psi – 4 Week Curing

TRIAL 40: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE FOAM

In the fortieth trial, the same Aircrete Harry mixing method was followed, but 10% more foam was used. Again, the trial was repeated to produce 6 cylinders in total, curing for 4 weeks.

Aircrete Harry, 10% More Foam (Cylinder 4) – Peak Load: 2080 psi, Stress Load: 73.49 psi – 4 Week Curing

TRIAL 41: FINAL TESTING – AIRCRETE HARRY MIX – 15% MORE FOAM

In the forty-first trial, Aircrete Harry’s mixing method was followed, but 15% more foam was used. It was repeated and produced 6 cylinders, they will again be cured for 4 weeks.

Aircrete Harry, 10% More Foam (Cylinder 4) – Peak Load: 2080 psi, Stress Load: 73.49 psi – 4 Week Curing

TRIAL 42: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE CEMENT

In the forty-second trial, the same Aircrete Harry mixing method was followed, but 5% more concrete was used, instead of additional foam. As in the past few tests, this trial was repeated to produce 6 cylinders that would cure for 4 weeks.

Aircrete Harry, 10% More Foam (Cylinder 4) – Peak Load: 2080 psi, Stress Load: 73.49 psi – 4 Week Curing

TRIAL 43: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE CEMENT

In the forty-third trial, Aircrete Harry’s mixing method was still followed, but 10% more concrete was used, creating the heaviest Aircrete Harry batch. This trial was repeated, producing 6 cylinders that will again be cured for 4 weeks.

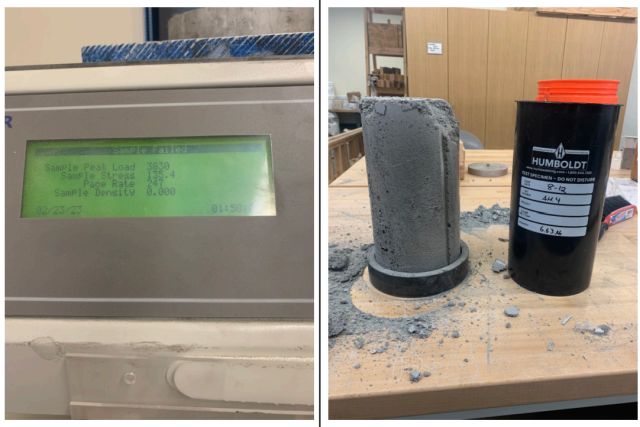

Aircrete Harry Mix, 10% More Cement (Cylinder 1) – Peak Load: 3140 psi, Stress Load: 111 psi – 4 Week Curing

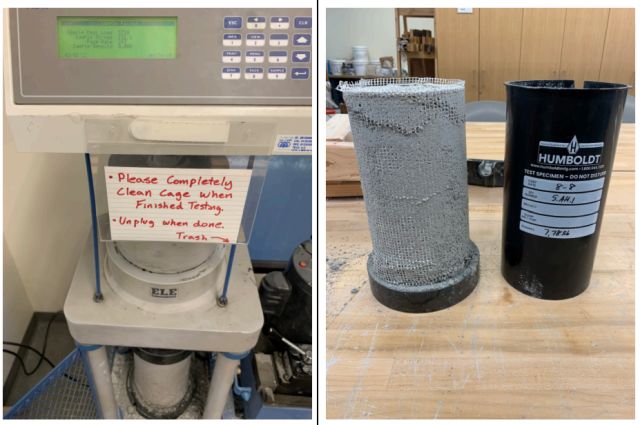

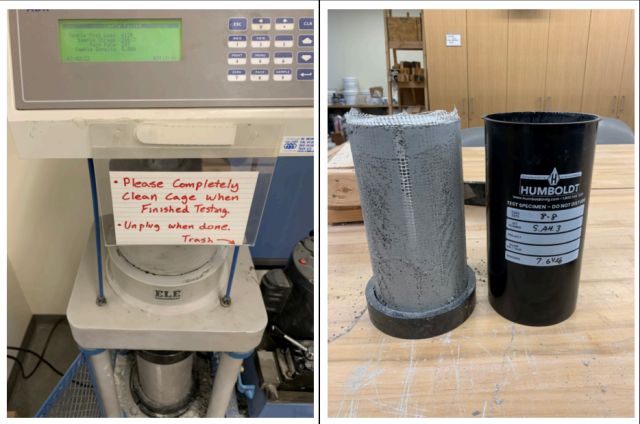

TRIAL 44: FINAL TESTING – AIRCRETE HARRY MIX – ADDED STUCCO REINFORCEMENT

In the forty-fourth trial, Aircrete Harry’s standard mixing method (from Trial 38) was followed, but stucco mesh fiber was added to the walls of the Aircrete cylinders. This trial was also repeated to produce 6 cylinders.

Aircrete Harry Mix, With Added Stucco (Cylinder 6) – Peak Load: 3710 psi, Stress Load: 131.1 psi – 4 Week Curing

TRIAL 45: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE FOAM AND ADDED STUCCO

In the forty-fifth trial, Aircrete Harry’s mixing method was followed, using 5% more foam and stucco reinforcement along the cylinders’ walls. This trial was repeated to produce 6 cylinders.

Aircrete Harry Mix, With Added Stucco, 5% More Foam (Cylinder 5) – Peak Load: 3030 psi, Stress Load: 107.3 psi – 4 Week Curing

TRIAL 46: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE FOAM AND ADDED STUCCO

In the forty-sixth trial, the Aircrete Harry mixing method was still followed, but 10% more foam was used and stucco reinforcement was added. 6 cylinders were produced after the trial was repeated.

Aircrete Harry Mix, With Added Stucco, 10% More Foam (Cylinder 6) – Peak Load: 6120 psi, Stress Load: 216.3 psi – 4 Week Curing

TRIAL 47: FINAL TESTING – AIRCRETE HARRY MIX – 15% MORE FOAM AND ADDED STUCCO

In the forty-seventh trial, Aircrete Harry’s mixing method was followed, using 15% more foam and stucco reinforcement along the cylinders’ walls. This trial was repeated, producing 6 cylinders.

Aircrete Harry Mix, With Added Stucco, 15% More Foam (Cylinder 1) – Peak Load: 6140 psi, Stress Load: 217 psi – 4 Week Curing

TRIAL 48: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE CEMENT AND ADDED STUCCO

In the forty-eighth trial, the Aircrete Harry mixing method was followed, but 5% more concrete was used and stucco reinforcement was added. 6 cylinders were produced after the trial was repeated.

Aircrete Harry Mix, With Added Stucco, 15% More Foam (Cylinder 1) – Peak Load: 6140 psi, Stress Load: 217 psi – 4 Week Curing

TRIAL 49: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE CEMENT AND ADDED STUCCO

In the forty-ninth trial, Aircrete Harry’s mixing method was used with 10% more concrete and added stucco; this was the last of Aircrete Harry’s 4 week cure tests. Again, this test was repeated to produce 6 cylinders.

Aircrete Harry Mix, With Added Stucco, 10% More Cement (Cylinder 1) – Peak Load: 11450 psi, Stress Load: 404.9 psi – 4 Week Curing

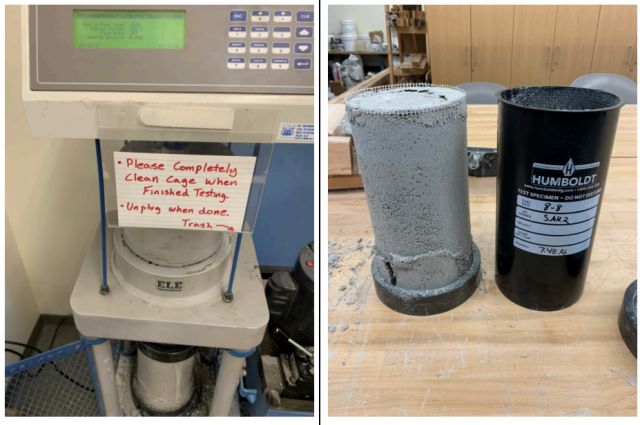

TRIAL 50: FINAL TESTING – DOMEGAIA MIX – STANDARD HIGH CEMENT MIX

In the fiftieth trial, mixing methods were switched and Domegaia’s was used again. This was the high cement mix, and the concrete mixer was used. Foam was added by topping off a 5 gallon bucket. As in the previous trials, this one was repeated to produce 6 cylinders.

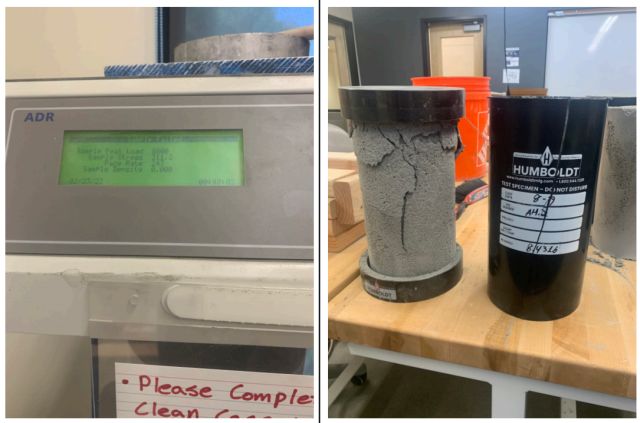

Domegaia Standard High Cement Mix (Cylinder 4) – Peak Load: 3830 psi, Stress Load: 135.6 psi – 4 Week Curing

TRIAL 51: FINAL TESTING – DOMEGAIA MIX – 10% MORE CONCRETE

In the fifty-first trial, Domegaia’s mixing method was used again. The high cement mix was followed, but with 10% more cement and water in a 5 gallon bucket. This batch was mixed in the concrete mixer. Again, it was repeated to produce 6 cylinders.

Domegaia Mix, 10% More Cement (Cylinder 3) – Peak Load: 3330 psi, Stress Load: 117.8 psi – 4 Week Curing

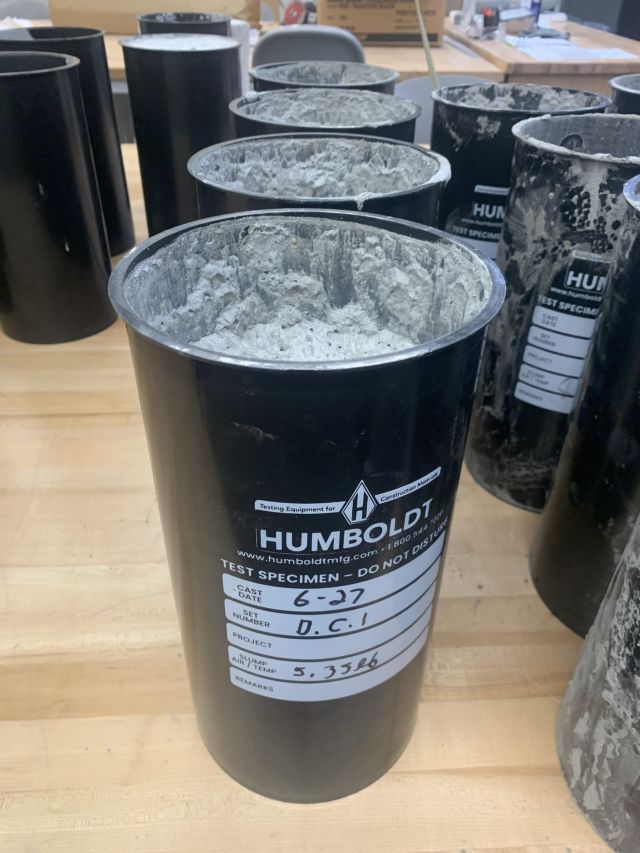

TRIAL 52: FINAL TESTING – CONTROL GROUP – NORMAL CEMENT

In the fifty-second trial, no Aircrete mixing method was used. Instead, normal cement was made to be a control group for compression testing. One bag of Portland Cement, which was 94 pounds, produced just under 5 cylinders. This cement mix was scaled up to produce 18 cylinders in total.

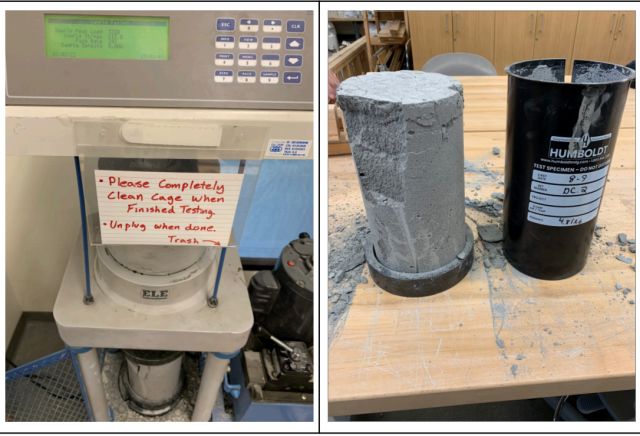

Cement Mix (Cylinder 4) – Peak Load: 127100 psi,

TRIAL 53: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE FOAM AND 3 WEEK CURE TIME

In the fifty-third trial, the Aircrete Harry mix was used again. 5% more foam was used, but this batch will cure for 3 weeks. As in recent trials, this process was repeated to produce 6 cylinders.

Aircrete Harry Mix, 5% More Foam (Cylinder 2) – Peak Load: 8800 psi, Stress Load: 311.2 psi – 3 Week Curing

TRIAL 54: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE FOAM

In the fifty-fourth trial, the Aircrete Harry mix was still used, but with 10% more foam. This batch was repeated to produce 6 cylinders and will cure for 3 weeks.

Aircrete Harry Mix, 10% More Foam (Cylinder 4) – Peak Load: 2970 psi, Stress Load: 105 psi – 3 Week Curing

TRIAL 55: FINAL TESTING – AIRCRETE HARRY MIX – 15% MORE FOAM

In the fifty-fifth trial, the Aircrete Harry mixing method was followed, but with 15% more foam. This batch was repeated to produce 6 cylinders and will again cure for 3 weeks.

Aircrete Harry Mix, 15% More Foam (Cylinder 2) – Peak Load: 3830 psi, Stress Load: 135.4 psi – 3 Week Curing

TRIAL 56: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE CEMENT

In the fifty-sixth trial, the Aircrete Harry mixing method was followed, but with 5% more cement for a heavier mix. This batch was repeated to produce 6 cylinders and will cure for 3 weeks.

Aircrete Harry Mix, 5% More Cement (Cylinder 3) – Peak Load: 6710 psi, Stress Load: 237.4 psi – 3 Week Curing

TRIAL 57: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE CEMENT

In the fifty-seventh trial, the Aircrete Harry mixing method was followed, but with 10% more cement for a heavier mix. This batch was repeated to produce 6 cylinders and will cure for 3 weeks. This is the last of the Aircrete Harry 3 week cure time mixes.

Aircrete Harry Mix, 5% More Cement (Cylinder 3) – Peak Load: 6710 psi, Stress Load: 237.4 psi – 3 Week Curing

TRIAL 58: FINAL TESTING – AIRCRETE HARRY MIX – STANDARD AND 2 WEEK CURE TIME

In the fifty-eighth trial, the Aircrete Harry mixing method was still followed, but with no changes in the foam-concrete ratio. This batch was repeated to produce 6 cylinders and will cure for 2 weeks.

Aircrete Harry Mix, 10% More Foam (Cylinder 6) – Peak Load: 9900 psi, Stress Load: 350.1 psi – 3 Week Curing

TRIAL 59: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE FOAM

In the fifty-ninth trial, the Aircrete Harry mixing method was followed, but with 5% more foam. This batch was repeated, producing 6 cylinders and will cure for 2 weeks.

Aircrete Harry Standard Mix (Cylinder 5) – Peak Load: 7150 psi, Stress Load: 253 psi – 2 Week Curing

TRIAL 60: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE FOAM

In the sixtieth trial, the Aircrete Harry mixing method was followed, but with 10% more foam. This batch was repeated to produce 6 cylinders and will cure for 2 weeks.

Aircrete Harry Mix, 10% More Foam (Cylinder 4) – Peak Load: 3830 psi, Stress Load: 135.4 psi – 2 Week Curing

TRIAL 61: FINAL TESTING – CONTROL GROUP – NORMAL CEMENT

In the sixty-first trial, another control group of normal cement was created. A bag and a half of Portland Cement was used to produce 6 cylinders that will be cured for 2 weeks.

Cement Mix (Cylinder 1) – Peak Load: 179500 psi, Stress Load: 6348 psi – 2 Week Curing

TRIAL 62: FINAL TESTING – AIRCRETE HARRY MIX – 15% MORE FOAM

In the sixty-second trial, Aircrete Harry’s mixing method was followed, but with 15% more foam. This procedure was repeated to produce 6 cylinders that will cure for 2 weeks.

Cement Mix (Cylinder 1) – Peak Load: 179500 psi, Stress Load: 6348 psi – 2 Week Curing

TRIAL 63: FINAL TESTING – AIRCRETE HARRY MIX – 5% MORE CEMENT

In the sixty-third trial, Aircrete Harry’s mixing method was followed, but with 5% more cement mix. This procedure was repeated to produce 6 cylinders that will cure for 2 weeks.

Aircrete Harry Mix, 5% More Cement (Cylinder 6) – Peak Load: 6360 psi, Stress Load: 224.9 psi – 2 Week Curing

TRIAL 64: FINAL TESTING – AIRCRETE HARRY MIX – 10% MORE CEMENT

In the sixty-fourth trial, Aircrete Harry’s mixing method was followed, but with 10% more cement mix. This procedure was repeated to produce 6 cylinders that will cure for 2 weeks.

Aircrete Harry Mix, 10% More Cement (Cylinder 2) – Peak Load: 7940 psi, Stress Load: 280.7 psi – 2 Week Curing

END OF FINAL TESTING PHASE SUMMARY

In the final testing phase, more compression tests were conducted with the Aircrete Harry mix than with Domegaia’s, mostly due to the inconsistency in results observed with Domegaia’s mixes and their high moisture content. In addition to standard Aircrete Harry and Domegaia mixing methods, stucco reinforcement was added to many of Aircrete Harry’s cylinders and Domegaia’s procedure was repeated using Drexel. Unlike the initial trial phases, these tests were repeated to produce 6 cylinders each and with organized curing-time variability, so we had more data to draw clearer conclusions from.

END OF AIRCRETE TESTING SUMMARY AND FINDINGS

Despite the inconsistency of some mixing methods, certain trends were observed that can help streamline the Aircrete making process in the future. Following the Domegaia procedure, better results were achieved when their standard foaming agent, 7th Generation Dish Soap, was swapped for Drexel. It is less sustainable and more costly though, see the analysis below.

Batches using 7th Generation Dish Soap could not be cured or tested within 48 hours because … We think the reason for this is… Include something about the Little Dragon not being sold anymore. I think that’s why his bigger mixer mixes in 50 gal drums and puts the foam directly in at the mixing point, getting more even mixing. We should talk about this.

Also, it is recommended to use a concrete mixer for trials using Domegaia’s mixing method.

Across both main mixing methods, Domegaia’s and Aircrete Harry’s, there was initially a weight disparity when observing the cured cylinders. This was remedied by a new pouring method, where freshly mixed Aircrete is poured to fill a mold halfway, poured the same way for as many molds as necessary, then each mold was fully filled with the remaining aircrete. This mixes the top of the batches with the bottom and seems to balance them out better.

The summary of all we learned can be seen in these graphics:

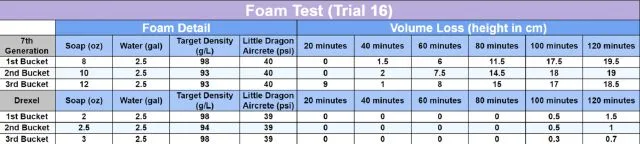

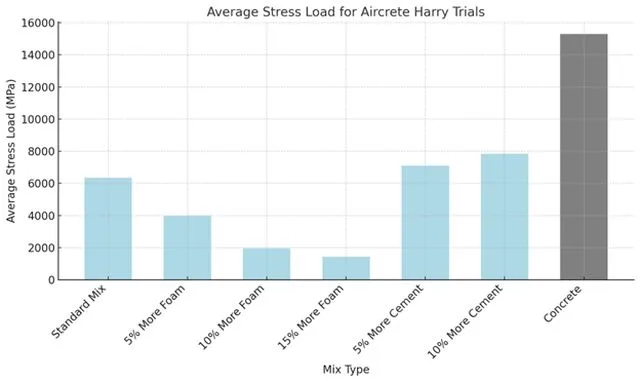

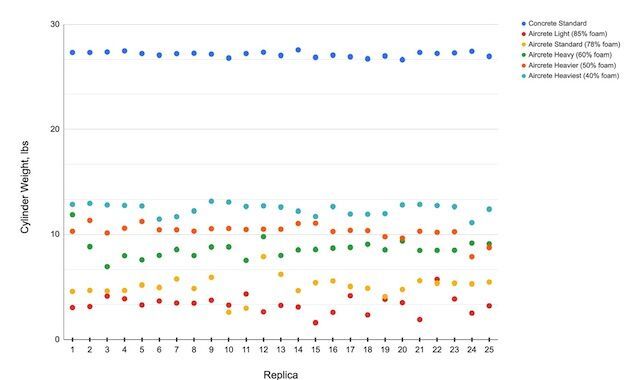

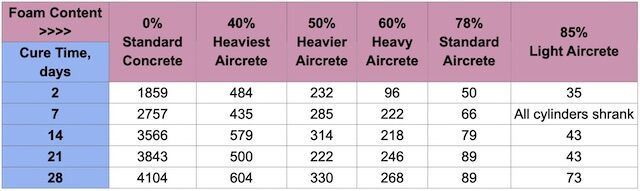

COMPRESSION RESULTS USING DIFFERENT AIRCRETE DENSITIES

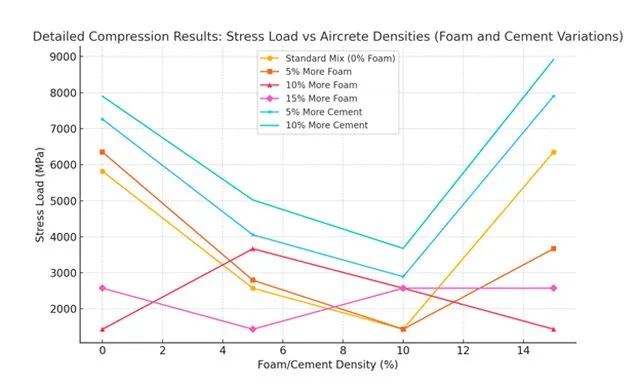

Higher foam was tested because it is a lighter building material that would function as a better insulator (higher R-value). This graphic compares the stress loads for aircrete with different foam densities (standard, 5%, 10%, and 15% more foam). The purpose was to see how increasing foam content affects compressive strength. This analysis helps assess how aircrete’s density impacts its structural integrity, showing that higher foam content leads to lower strength.

Foam/Cement Density (%)

Average Stress Load For Aircrete Harry Trials

Standard Mix: 6348 MPa

5% More Foam: 3977 MPa

10% More Foam: 1953 MPa

15% More Foam: 1444 MPa

5% More Cement: 7103 MPa

10% More Cement: 7847 MPa

Concrete: 15307 MPa

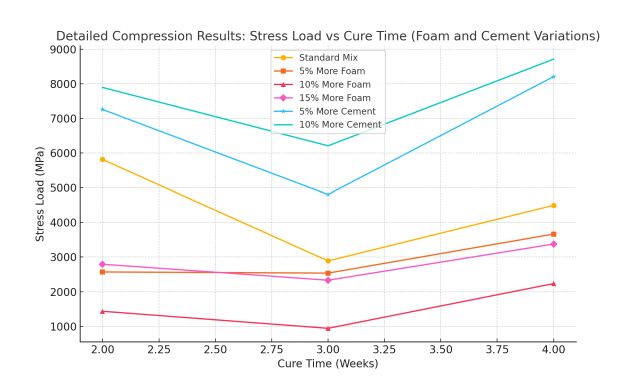

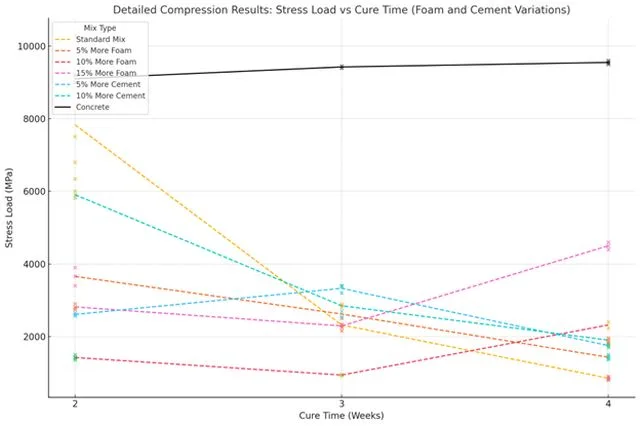

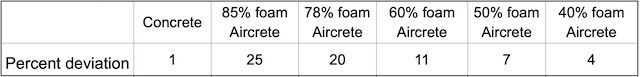

COMPRESSION RESULTS USING DIFFERENT CURE TIMES

This graphic looks at stress loads for Aircrete with different curing periods (2-week, 3-week, and 4-week curing times). Curing time is critical in building materials as it affects compressive strength. This analysis shows how Aircrete becomes stronger with longer curing periods, though it still remains weaker compared to traditional concrete. The week 3 error likely resulted from the use of older cement in the mix, which had small clumps. These clumps may not have mixed thoroughly, leading to uneven distribution of the material and weaker bonding within the Aircrete. This inconsistency reduced the compressive strength of the material, causing a noticeable dip in the stress load values during testing.

Cure Time (Weeks)

Cure Time (Weeks)

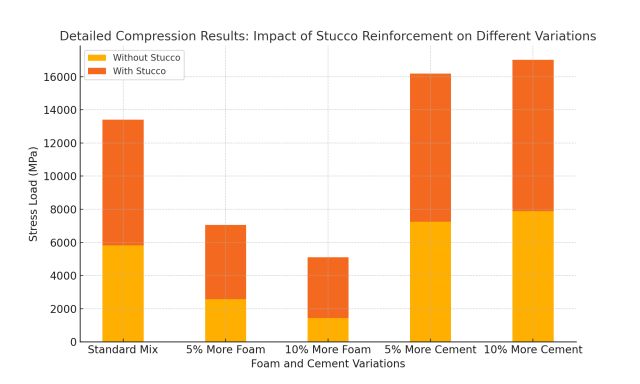

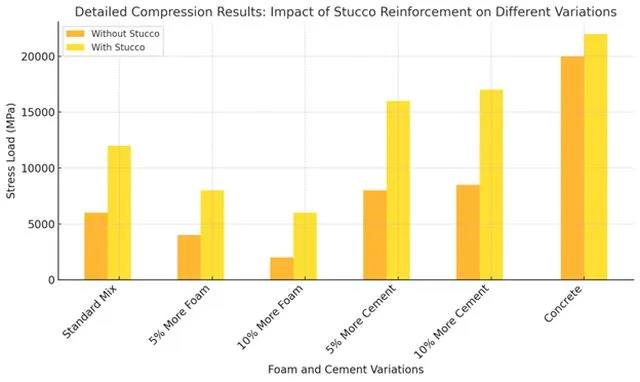

COMPRESSION RESULTS ADDING STUCCO REINFORCEMENT

This compares the compressive strength of Aircrete with and without stucco reinforcement for different foam and cement variations. Stucco reinforcement is used to strengthen Aircrete, and this analysis demonstrates how the addition of stucco significantly improves its compressive strength, making it more viable for certain applications.

Foam And Cement Variations

Foam And Cement Variations

Observations –

Standard Mix:

Without stucco, the stress load is around 6,000 MPa.

Stucco reinforcement increases the strength to approximately 12,000 MPa, doubling the compressive strength.

Foam Variations:

As foam content increases (5%, 10%), compressive strength

decreases without stucco.

Stucco reinforcement mitigates this loss and improves strength, although it remains lower compared to the standard mix.

Cement Variations:

Increasing cement content (5%, 10%) improves compressive strength.

Stucco reinforcement enhances these gains, bringing compressive strength levels closer to that of concrete.

Concrete:

Without stucco, concrete achieves the highest stress load (~15,000 MPa).

With stucco reinforcement, concrete exceeds 20,000 MPa, further solidifying its superiority in structural applications.

Insights :

Stucco Reinforcement Improves Strength: Compressive strength is significantly higher with stucco across all variations.

Foam Reduces Strength: Increased foam content lowers compressive strength, though stucco mitigates the reduction.

Cement Enhances Strength: Higher cement content boosts strength, especially with stucco reinforcement.

Concrete is Strongest: Concrete shows the highest compressive strength, with or without stucco.

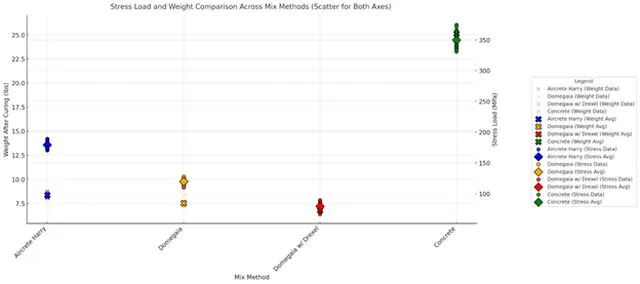

COMPRESSION RESULTS USING DIFFERENT MIX METHODS

This graphic compares the stress load and weight after curing for three different mix methods: Aircrete Harry, Domegaia, and Domegaia with Drexel. The mixing method can dramatically impact the material’s performance. This comparison shows that Aircrete Harry outperforms the others in compressive strength, while the other methods are lighter but weaker. Aircrete Harry had the highest compressive strength and was heavier, while Domegaia and Domegaia with Drexel were lighter but had significantly lower stress loads, with Domegaia with Drexel being the weakest.

Mix Method

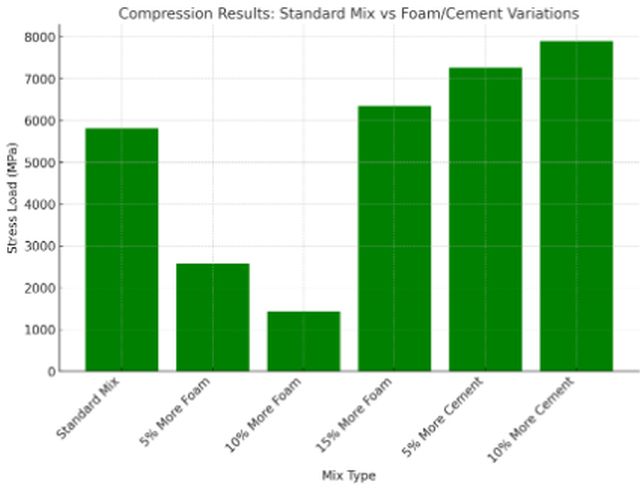

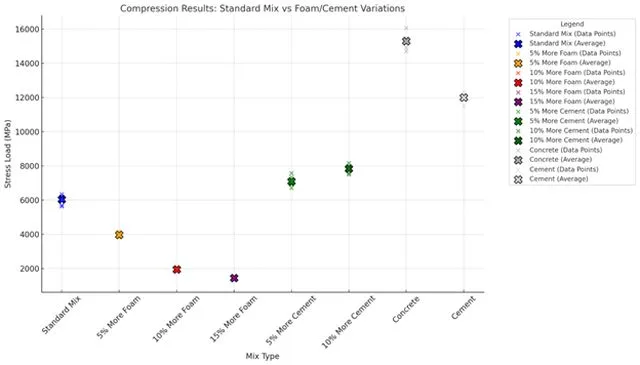

COMPRESSION RESULTS COMPARING STANDARD MIXES TO VARIATIONS

This compares the compressive strength of the standard mix to various foam (5%, 10%, 15% more foam) and cement variations (5%, 10% more cement). The goal was to see how altering the foam and cement ratios affected the material’s performance. The analysis shows that more foam reduces compressive strength, while increasing cement content helps boost strength.

Mix Type

Compression Results, Standard Mix vs Foam/Cement Variations

Standard Mix: 6049.10 MPa

5% More Foam: 3977.24 MPa

10% More Foam: 1953.09 MPa

15% More Foam: 1444.06 MPa

5% More Cement: 7103.47 MPa

10% More Cement: 7847.23 MPa

Concrete: 15307.30 MPa

Cement: 12008.39 MPa

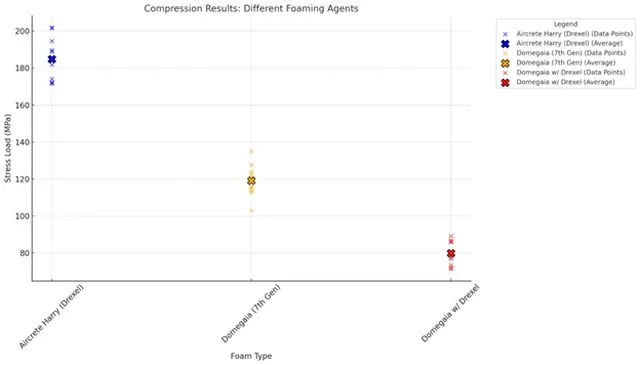

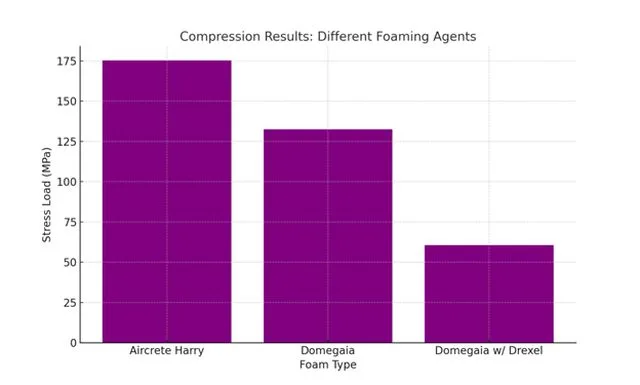

COMPRESSION RESULTS USING DIFFERENT FOAMS

This graphic compares the stress load of different foaming agents (Aircrete Harry, Domegaia, and Domegaia with Drexel). Different foaming agents can affect the performance of aircrete. This analysis highlights that Aircrete Harry’s foam performs better than Domegaia’s and Domegaia with Drexel, with the latter being the weakest in terms of compressive strength.

Foam Type

AVERAGES

Aircrete Harry (Drexel): 184.79 MPa (highest performance)

Domegaia (7th Gen): 119.14 MPa

Domegaia w/ Drexel: 79.90 MPa (lowest performance)

Here’s a simplification of these results:

Compression Results: Different Foaming Agents

AIRCRETE HARRY (DREXEL)

Shows the highest compressive strength among the tested foams.

The data points cluster above 200 MPa, indicating consistent performance.

DOMEGAIA (7TH GEN)

Compressive strength is lower than Aircrete Harry but higher than Domegaia with Drexel.

Data points center around 120-140 MPa.

DOMEGAIA W/ DREXEL

Demonstrates the weakest performance, with compressive strength clustering below 120 MPa.

SUMMARY

The visualization highlights that Aircrete Harry’s foam provides superior compressive strength, while Domegaia w/ Drexel results in the weakest.

LIMITATIONS OF THIS TESTING PROCESS

The testing process faced several limitations, particularly due to the small batch sizes used in the trials. Aircrete Harry recommends large-scale batches that use 94 pounds of cement, whereas the testing relied on much smaller batches of about 15-20 pounds. These small batches were then further divided into three cylinders, introducing potential inconsistencies in density and compressive strength. In a larger batch, small differences in foam or cement distribution would likely be minimized, leading to more consistent results. However, in these small-scale tests, slight variations had a significant impact, affecting the uniformity and performance of the Aircrete. Additionally, the relative intensity of the drill typically used to mix the foam and slurry changes based on container size. In a small mixing bucket, the vibrations produced by the drill will not spread and dampen as they would in a large container, making them more aggressive given the smaller volume. Also, the drill mixer created bubbles of uneven sizes which later produced weak points in the dried Aircrete, made worse by the smaller batch sizes.

A major issue with the Domegaia method arose from the choice of foaming agent. The tests revealed that when higher percentages of foam were used with Domegaia’s method and 7th Generation Dish Soap, the Aircrete consistently collapsed. This issue was mitigated when Drexel, a more stable foaming agent, was used instead. However, Drexel comes at a higher cost and lower sustainability value, which makes its use less desirable. However, the failure of higher-foam mixes with 7th Generation Dish Soap highlights the importance of selecting the right foaming agent for the mix.

Another limitation was the scale of the mixer. Domegaia typically uses a 50-gallon drum with a foam-injection mixer call the Dragon XL, but our tests were conducted with smaller 7-gallon or 5-gallon buckets and the “Little Dragon”, a much smaller foam creator that is no longer sold by them; possibly because of challenges like the ones we experienced.

This downscaling likely led to uneven foam distribution and increased foam collapse, as smaller mixers don’t inject the foam into the bottom of the mix like the Dragon XL and may not blend the materials as consistently. The small-scale batches had more issues with maintaining the correct foam-to-cement ratio too, which could have also been a source of the inconsistency of the results.

Another possible limitation was the mixing and curing environment. These trials were performed in a sterile, indoor lab environment and the batches were cured in plastic containers. Domegaia cures their Aircrete outdoors, often in hotter and drier climates, and not in plastic. This could be an additional contributor to Domegaia’s successes with shorter curing times.

Our experimentation showed several common factors also contributed to the variability in results, including mixing time, cure time, water hardness, and cement quality. Even minor differences in these variables can have a significant effect on the performance of the Aircrete.

Despite these challenges, the team overcame some issues by switching to Drexel as the foaming agent and carefully controlling mixing times. However, the limitations of using small batches and non-industrial equipment mean that the results do not fully reflect the performance of Aircrete in larger-scale construction. Overall, while the tests provided valuable insights, they highlight the challenges of scaling down Aircrete production and the importance of careful control over variables in the mixing process.

OUR THOUGHTS ON THIS AS A BUILDING METHOD

- Compressive Strength:

- Aircrete’s compressive strength is significantly lower than traditional concrete, especially as more foam is added. Even with stucco reinforcement, the material is still weaker compared to regular concrete.

- The data shows that adding foam (e.g., 5%, 10%, 15%) greatly reduces the material’s ability to withstand compression. For example, Aircrete Harry’s standard mix had a stress load of around 175.4, but this dropped significantly with foam variations.

- Weight and Density:

- Aircrete is much lighter than traditional concrete, which could be beneficial for applications where weight reduction is a priority, such as insulation or non-load-bearing walls. However, this reduced weight comes at the cost of strength.

- Stucco Reinforcement:

- Stucco appears to improve the compressive strength of aircrete, as seen in the tests with and without reinforcement. This could be a key factor in making aircrete more viable for specific uses.

- Foaming Agents:

- The different foaming agents (Aircrete Harry, Domegaia, and Domegaia with Drexel) produced varying results. Aircrete Harry consistently outperformed the others in terms of compressive strength, while Domegaia with Drexel had the lowest stress load. This suggests that the choice of foaming agent is crucial in determining the material’s strength.

- Curing Time:

- Curing time also affects compressive strength, with longer curing periods generally leading to higher stress loads. However, Aircrete still lags behind traditional concrete in this regard.

VIABILITY AS A BUILDING MATERIAL

While Aircrete is appealing for its lightweight properties and potential cost savings, the significantly lower compressive strength compared to traditional concrete limits its use in structural applications. Aircrete may be more suited for projects like insulation, partition walls, or other non-load-bearing components where strength is not a primary concern. The addition of stucco reinforcement helps, but it does not fully bridge the gap in performance between Aircrete and conventional concrete.

DISCUSSION

All in all, this round of Aircrete testing was successful in building upon the results of past volunteer teams. The previous team ended with generally inconsistent results, but their successes and notable mistakes left a solid foundation for new trials. This most recent testing highlighted the reliable success of Aircrete Harry’s mixing method when compared with Domegaia’s, mainly a result of the foaming agents used and target foam densities of both procedures (a lower foam density, of around 68 g/qt, paired with Drexel was ideal). However, Domegaia’s mixing method should not be completely disregarded due to our smaller batch sizes and sterile curing environment, both of which did not match Domegaia’s recommended mixing conditions. More testing limitations are discussed above (see Limitations of This Testing Process).

Similar to past results, it was again observed that lighter Aircrete mixes (batches that had a higher percentage of foam) were weaker than those with more cement. Also, longer cure times were seen to lead to greater compressive strength. Still, lighter batches had greater insulative properties (higher R-values). For more information on possible uses for Aircrete, based on these findings, see Our Thoughts as a Building Material.

In the end, these results should serve as a solid starting point for future research or for replicators looking to mix Aircrete themselves. Mixing Aircrete is a delicate process, and small environmental or technical changes could lead to drastically different outcomes, so minor adjustments should be expected when attempting to recreate these results.

ANALYSIS OF PRIMARY AIRCRETE FOAMING AGENTS

During this set of trials, two foaming agents were primarily used: 7th Generation Dish Soap and Drexel. An analysis of the sustainability and cost of these products was conducted, and it was revealed that both have their own distinct, contrasting strengths and weaknesses. During testing, 7th Generation Dish Soap performed much worse when it came to Aircrete stability, but it is the more sustainable, affordable, and easily accessible option when compared to Drexel. For lighter mixes (mixes with more foam), Drexel was shown to be the only viable option.

Regardless of the foaming agent we use in the future, One Community plans to buy these products in bulk containers to improve their sustainability.

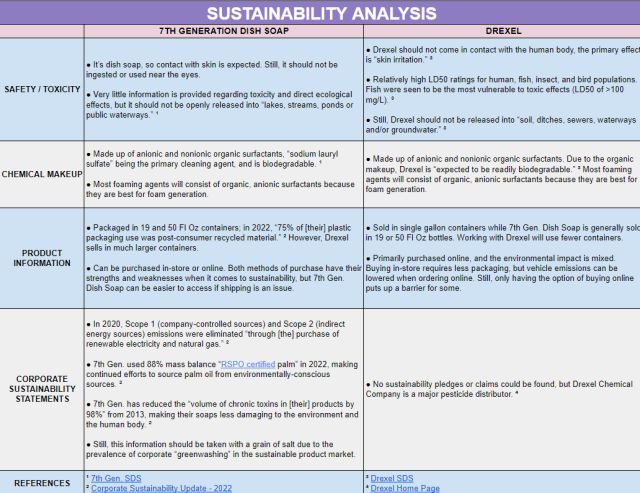

SUSTAINABILITY ANALYSIS

The safety and sustainability of Aircrete’s two main foaming agent options (7th Generation Dish Soap and Drexel) were analyzed, and the findings have been compiled in the table below:

Regarding the plastic packaging each company uses (current details can be found under “Product Information”). To improve sustainability, Instead of buying many small containers from other retailers, One Community hopes to organize purchasing our foaming agents in large batches from the seller. This will reduce packaging waste and should reduce the transportation carbon footprint.

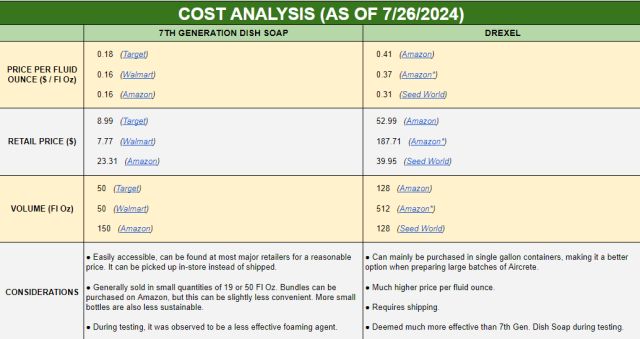

COST ANALYSIS

The costs of Aircrete’s two main foaming agent options (7th Generation Dish Soap and Drexel) were analyzed, and the findings have been compiled in the table below:

We think organizing purchasing our foaming agents in large batches from the seller should also increase the profit margin for the producer and reduce per-ounce costs for us as the consumer.

AIRCRETE MIXING TUTORIALS