Earthbag Village Plumbing Design and Setup

Welcome to the Earthbag Village plumbing design and setup hub. This page is where we will be posting all the multi-media tutorials and resources for the complete Earthbag Village plumbing design and installation. Once we’ve finished this tutorial and open sourced all the details for the Earthbag Village (Pod 1) and Duplicable City Center®, we’ll do the same for the other 6 villages.

SOME OF THE WORK HAS BEEN DONE FOR THIS PAGE BUT WE NEED ADDITIONAL PROFESSIONAL CONSULTATION TO DOUBLE CHECK AND CONTINUE DEVELOPING THE DETAILS AND ADDITIONAL WEB DESIGNERS TO HELP US OPEN SOURCE SHARE THEM

CLICK HERE IF YOU’D LIKE TO HELP

- Related Pages

- What is Earthbag Village Plumbing

- Why Open Source Earthbag Village Plumbing

- Ways to Contribute to this Open Source Component

- Key Consultants to this Component of One Community

- Earthbag Village Septic Tank Design

- Resources

- Summary

- FAQ

RELATED PAGES

WHAT IS EARTHBAG VILLAGE PLUMBING

Content coming…

WHY OPEN SOURCE EARTHBAG VILLAGE PLUMBING

Content coming…

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

KEY CONSULTANTS TO THIS COMPONENT

Alena Thompson: Mechanical Engineer

Beatriz Rocha: Mechanical Engineering Student

Charles Gooley:Web Designer

Diogo Rozada: Civil Engineering Student

Diwei Zhang: Mechanical Engineer

Jorge Antonio Ricardo: Mechanical Engineering Student

Jose Luis Flores: Mechanical Engineer

Julia Meaney: Web and Content Reviewer and Editor

Loza Ayehutsega: Civil Engineer/Assistant Civil Engineer

Matheus Manfredini: Civil Engineering Student specializing in Urban Design

Samuel Soroaster: Permaculturalist, Sustainable Builder, PhD, and founder of Green New World

Zhide Wang: Mechanical Engineer

EARTHBAG VILLAGE SEPTIC TANK DESIGN

A septic tank is an underground chamber which is used for domestic wastewater treatment. Solids in sewage flow are reduced with settling and anaerobic digestion processes. The septic tank system is suitable for rural areas or urban areas where a sewer system is not reachable. The main goal of the septic design is to determine the storage capacity of the septic tank.

‹â€¹We discuss the design and implementation of the septic tank with the following sections.

- Volume of Wastewater Flow

- Septic Tank Minimum Effective Capacity

- British Standard Calculation for Septic Tank

- Septic Tank Types

- Selection of Septic Tank

- Location of Septic Tank

- Resources

- Summary

- FAQ

VOLUME OF WASTEWATER FLOW

To calculate the storage capacity of the septic tank, we need to know the total daily volume of wastewater. For the net-zero bathroom, the volume of wastewater is equivalent to the water uses of toilet flushing, showers, and faucets. The calculation of wastewater is similar to the evaluation of water demand for the rainwater harvesting system. In our design, we are going to equip one septic tank to one net-zero bathroom.

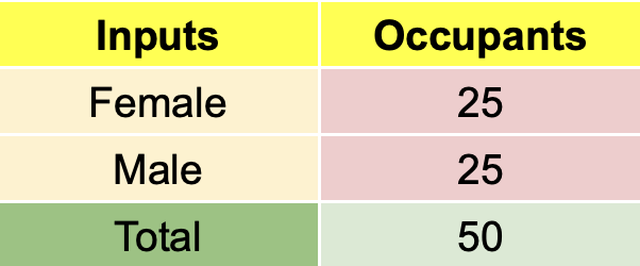

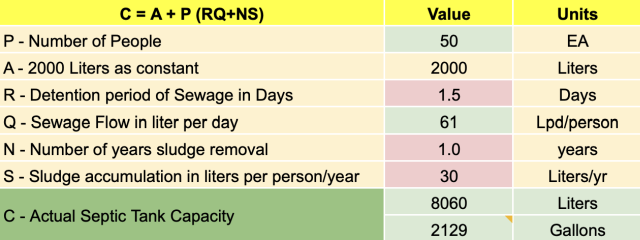

Firstly, the number of occupants for one net-zero bathroom is needed. The inputs of occupants in our calculations are shown below.

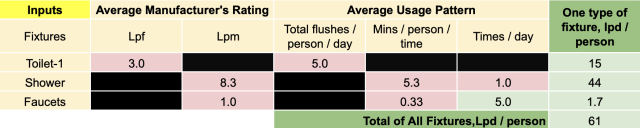

Next, an average manufacturer’s rating and average usage pattern of fixtures are needed to estimate the total daily wastewater volume with a given number of occupants. Toilet, shower, and faucets are fixtures that are sources of wastewater in the net-zero bathroom. The average manufacturing rating and usage pattern of different fixtures are shown in the following table, where Lpf is liters per fixture; Lpm is liters per minute; and Lpd is liters per day.

Average Manufacturer’s Rating and Average Usage Pattern of Fixtures for Estimated Volume of Wastewater – Click for source

Based on the wastewater flow of all fixtures per person per day, we can easily find the total daily wastewater amount of all occupants. The results of average total daily water demand (wastewater flow) are shown below. Monthly and yearly data are also presented for reference.

SEPTIC TANK MINIMUM EFFECTIVE CAPACITY

The septic tank minimum effective capacity refers to the smallest size of a septic tank that can effectively treat and store wastewater for a building or household, based on factors such as daily water usage, number of bedrooms, and soil type. Proper sizing of the septic tank is crucial to ensure safe and effective onsite sewage treatment and to prevent health and environmental hazards.

A minimum septic tank volume can be determined with a formula such that

1.5 x average total daily wastewater flow

Where 1.5 is the factor of safety.

Multiplying the factor of safety with the average total daily wastewater flow, we obtain the septic tank minimum effective capacity as shown below.

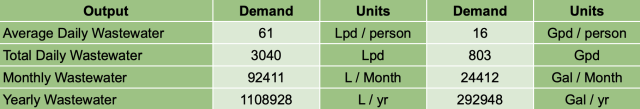

BRITISH STANDARD CALCULATION FOR SEPTIC TANK

There is another method, known as the British standard calculation for septic tanks, that may provide a more accurate estimation of the capacity of the septic tank using more input variables such as detention period of sewage in days, sewage flow in liter per day, number of years sludge removal, sludge accumulation in liters per person per year, etc. This method adds some redundancy to the septic system compared to using the minimum effective capacity. The formula of the British standard calculation for septic tank is

C = A + P(RQ + NS),

Where

P = number of people,

A = 2000 liters as constant,

R = detention period of sewage in days,

Q = sewage flow in liter per day,

N = number of years sludge,

S = sludge accumulation in liters per person/year, and

C = actual septic tank capacity.

Our calculations using this method are shown below.

Notice that the number of people is the occupants of the facilities, the detention period of sewage is ranged from 24 hours to 48 hours, and the sewage flow is calculated in the section of average daily wastewater flow per person.

SEPTIC TANK TYPES

There are four main types of septic tanks, including concrete septic tanks, steel septic tanks, plastic septic tanks, and fiberglass septic tanks. Their properties and features are shown below.

CONCRETE SEPTIC TANK

Concrete septic tanks are underground structures made of reinforced concrete, designed for the treatment and disposal of household wastewater. These tanks are divided into two compartments: an inlet for wastewater entry and a larger compartment for the settling and decomposition of solids. As wastewater enters the tank, solids settle at the bottom, while lighter substances float to the top. Bacteria present in the tank naturally break down organic matter. The clarified liquid, called effluent, exits the tank through an outlet pipe for further treatment or dispersal into a drain field. Concrete septic tanks are known for their durability, resistance to corrosion, and ability to withstand high groundwater pressure. Regular maintenance, including periodic pumping, ensures their optimal performance.

Advantages:

- Environment-resistant: Concrete septic tanks aren’t usually affected by changes to their environment, such as changing soil conditions, tree roots, or other problems.

- They have a long lifespan of many decades.

- They are rust proof and corrosion-proof.

- They are strong enough for traffic loading.

Disadvantages:

- They are costly compared to other types of septic tanks.

- They are hard to repair.

- Large equipment is required for installation.

- Poor quality concrete tends to develop cracks.

STEEL SEPTIC TANK

A steel septic tank is an underground system designed to handle and treat household wastewater. Made of durable steel, these tanks offer strength and longevity. Steel septic tanks are typically constructed with corrosion-resistant materials to withstand the harsh underground environment. Similar to concrete tanks, they consist of two compartments, an inlet for wastewater entry, and a larger compartment for settling and decomposition. Solid particles settle at the bottom while lighter substances float to the top. Bacteria naturally break down the organic matter. The clarified liquid, called effluent, is then discharged through an outlet pipe for further treatment or dispersal. Steel septic tanks are favored for their durability, ease of installation, and resistance to environmental elements. Regular maintenance and inspections are necessary to ensure proper functioning and prevent corrosion or leaks in the tank. Steel septic tanks are a less popular choice as corrosion might occur within 25 years. Other kinds of metal tanks are not allowed to be used since they rust.

Content coming…

PLASTIC SEPTIC TANK

A plastic septic tank is an underground system designed to treat and manage household wastewater. These tanks are constructed using high-density polyethylene (HDPE) or other durable plastic materials. Plastic septic tanks offer several advantages, including lightweight construction, resistance to corrosion, and ease of installation. They are available in various sizes and configurations to accommodate different household needs. Similar to other septic tanks, plastic tanks feature two compartments for the settling and decomposition of solids. As wastewater enters the tank, solid particles settle at the bottom and lighter materials rise to the top. Bacteria present in the tank naturally break down the organic matter. The clarified liquid, known as effluent, exits the tank through an outlet pipe for further treatment or dispersal. Regular maintenance and inspection are important to ensure the proper functioning and longevity of plastic septic tanks.

Advantages:

- They are cheaper compared to other types.

- They are relatively light and offer easy handling and installing.

- Plastic is rust proof.

- Plastic has good resistance against cracking.

Disadvantages:

- They may float immersed in the saturated soil because of the light weight.

- They are prone to damage during installation.

- They are incapable of holding heavy traffic above.

FIBERGLASS SEPTIC TANK

A fiberglass septic tank is an underground system used for the treatment and disposal of household wastewater. These tanks are constructed using fiberglass-reinforced plastic (FRP), which combines the strength of fiberglass with the durability of plastic. Fiberglass septic tanks offer several advantages, including lightweight construction, resistance to corrosion and rust, and easy installation. They are available in different sizes to accommodate varying household needs. Similar to other septic tanks, fiberglass tanks consist of two compartments for the settling and decomposition of solids. As wastewater enters the tank, heavier particles settle at the bottom, while lighter substances float to the top. Bacteria present in the tank naturally break down the organic matter. The clarified liquid, called effluent, is then discharged through an outlet pipe for further treatment or dispersal. Regular maintenance and inspection are essential to ensure the efficient operation and longevity of fiberglass septic tanks.

Advantages:

- They share most of their advantages with plastic septic tanks but have better strength in comparison.

- Cheaper than concrete and steel septic tanks.

- High Durability.

- Rustproof.

- Watertight.

Disadvantages:

- Similar to the plastic septic tanks, fiberglass septic tanks are prone to damage during installation.

- Fiberglass septic tanks cannot resist buoyant forces and will float or shift when the water table is nearer to them.

SELECTION OF SEPTIC TANK

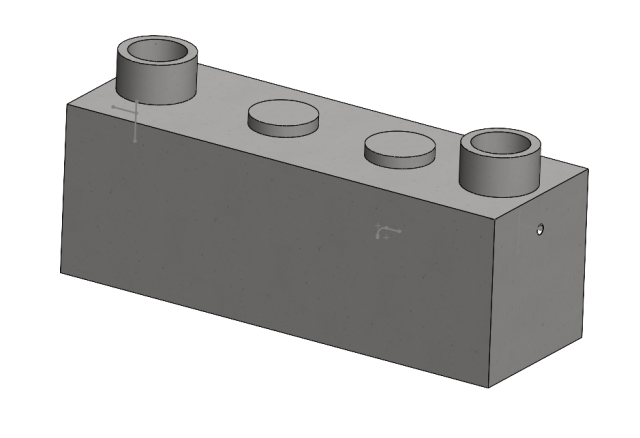

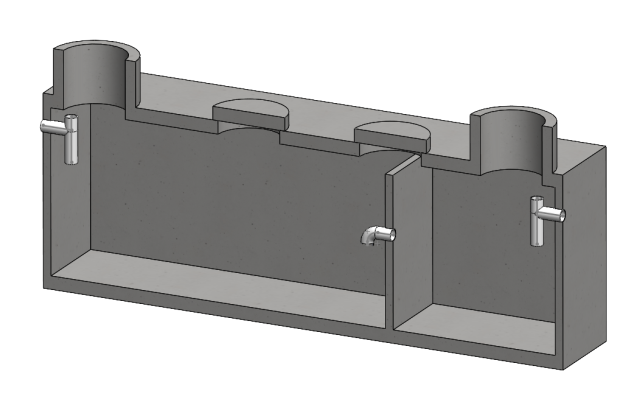

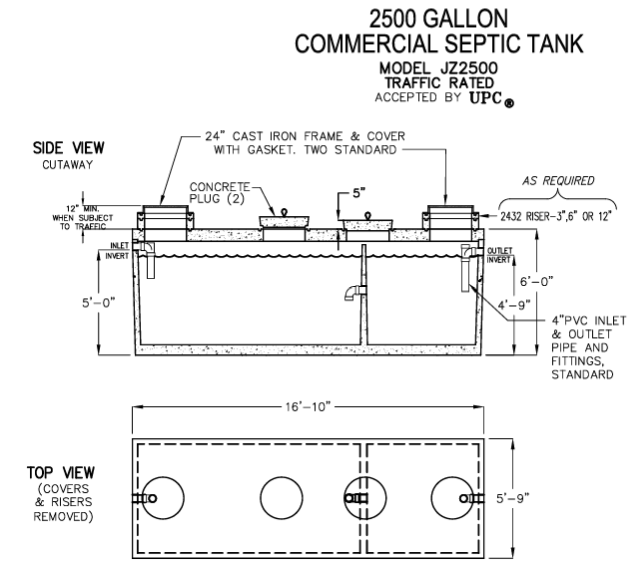

When selecting a septic tank, it is important to consider that a tank with a size larger than the calculated capacity should be used. For the case of a net-zero bathroom with 50 occupants, a 2,500 gallon two-chamber precast concrete septic tank is used. For our Earthbag Village septic tank design, we are choosing to install either precast concrete septic tanks or plastic septic tanks. Ultimately, all of our four septic tanks on site will be the same kind, and we will update this page when our final decision has been made.

3D Modeling of Two-Chamber 2,500 Gallon Precast Concrete Septic Tank

Sectional View of Two-chamber 2,500 Gallons Precast Concrete Septic Tank

Technical Drawing: Two-Chamber 2,500 Gallon Precast Concrete Septic Tank

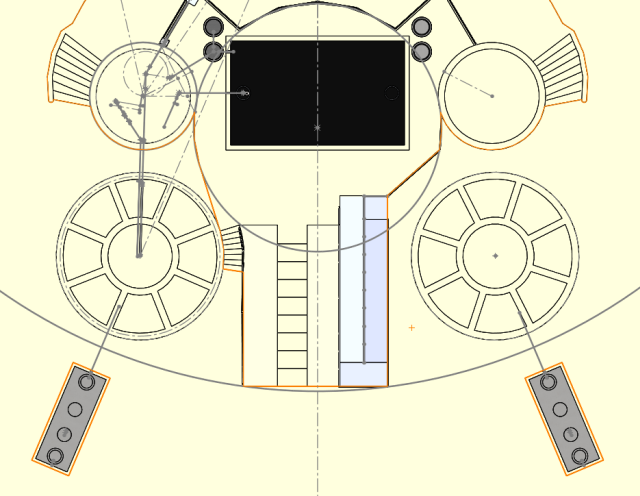

LOCATION OF SEPTIC TANK

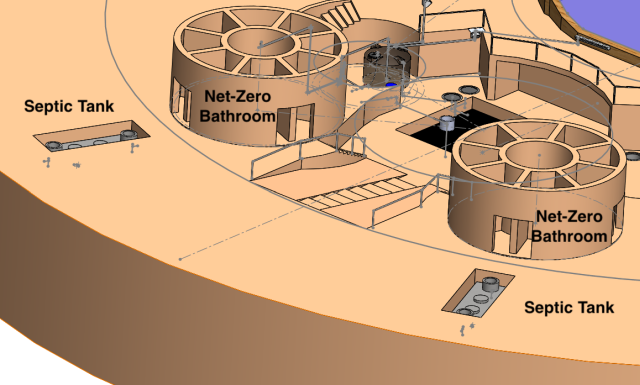

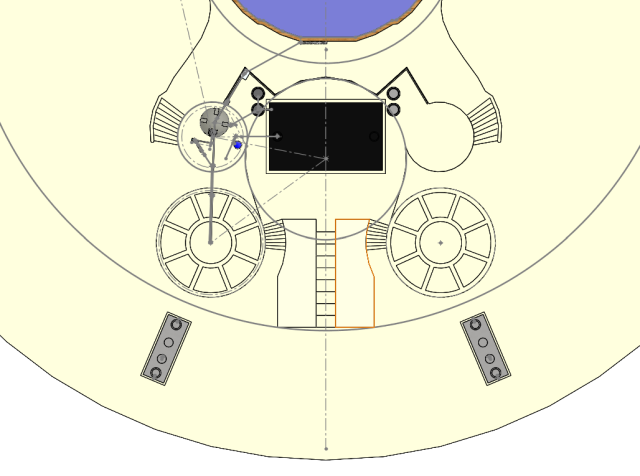

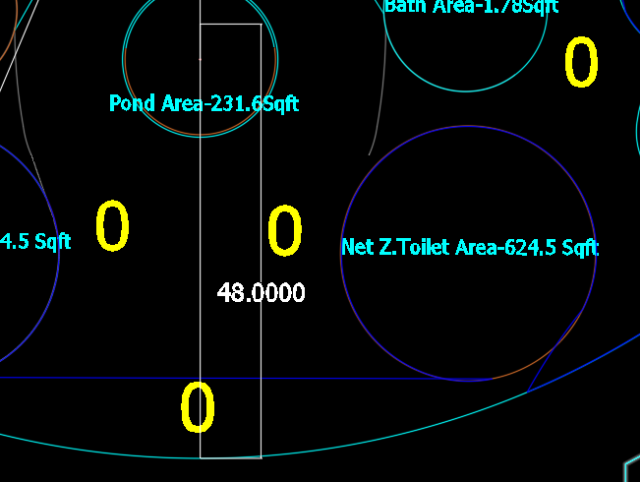

It is recommended that the location of your septic tank location be as close as possible to the facilities in order to avoid long wastewater conveyance distances which might cause clogging. The positions of our two septic tanks for this design relative to their corresponding net-zero bathroom are shown in the following figure.

Positions of Two Septic Tanks Relative to the Net-zero Bathrooms

Top View of Two Septic Tanks

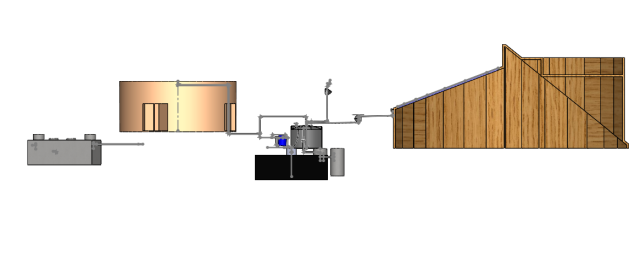

Rainwater Tank, Stormwater Tank, and Septic Tanks

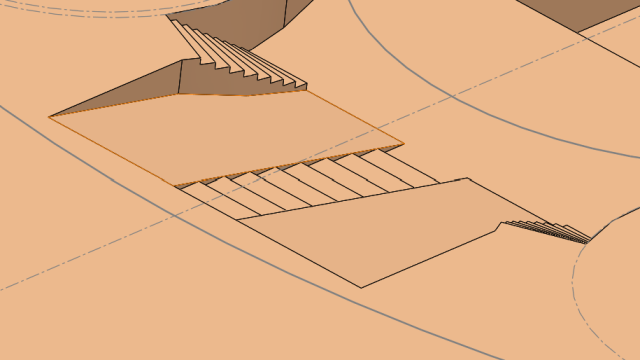

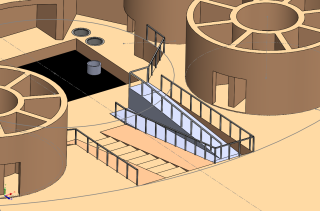

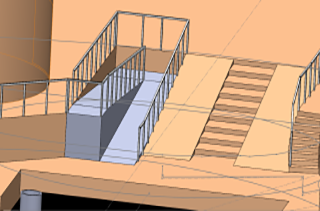

The track width of typical cars is about 60 inches. Accordingly, in order to ensure vehicles such as fire trucks or water trucks are able to access the central area, the width of the staircase is designed as 60 inches, with a vehicle ramp on either side. This is illustrated in the image below.

Staircase & Vehicle Ramp

According to recommendations by the United States Environmental Protection Agency, as well as the Department of Housing and Urban Development, a septic tank should be at least 50 feet (600 inch) away from a well that is used for drinking water.

ADA REQUIREMENTS

As the space is limited, the ramp we have (as shown above) is angled at about 10 degrees which does not satisfy the wheelchair ramp slope requirement for hand-propelled wheelchair. The requirements are as follows:

- Maximum slope for hand-propelled wheelchair ramps should be 1″ of rise to every 12″ of length (4.8 degree angle; 8.3% grade).

- Maximum slope for power chairs should be 1.5″ rise to 12″ length (7.1 degree angle; 12.5% grade).

- Minimum width should be 36″ (inside rails), but 48″ is ideal.

Areas and Distribution

To satisfy a 1:12 standard wheelchair slope requirement, a 48 ft length ramp is needed for 4 ft height. As shown in the figure below, a 48 ft length ramp is too long for the current layout. Accordingly, we propose a zig-zag wheelchair ramp design along one side of the entrance.

ADA Compliant Wheelchair Ramp Design

ADA Compliant Wheelchair Ramp Design

ADA Compliant Wheelchair Ramp Design – Top View

RESOURCES

- Septic Tank Size Requirements – Septic tank size calculations, size tables & codes

- “How to Calculate the Size and Capacity of Septic Tank: Formula” by Engr Waseem Raja

- 6 Advantages of Concrete Septic Tanks – Southport Concrete Corp

- Steel Septic Tanks: History and Information for Homeowners

- A Short Guide on Fiberglass Septic Tanks (Updated for 2023)

- The Constructor – 4 Types of Septic Tank Materials

- Texas Pride Septic Inc. – How Long Will My Septic System Last?

- Jensen Precast Septic Tank JZ 2500 gal. 24″E, 24″B, 24″E Incidental Traffic Rated

- Wheelchair Ramp Information – Northeast Rehabilitation Health Network

- Quora – What is the typical wheel to wheel width of cars in the United states?

SUMMARY

Content coming…

FREQUENTLY ANSWERED QUESTIONS

Content coming…

One Community

One Community