Earthbag Village Engineering

Welcome to the Earthbag Village engineering details open source hub. The purpose of this page is to share the engineering steps, research, resources, and tools we’ve used to verify the safety of our earthbag designs and structures. We will continue to evolve this page until the entire Earthbag Village has been permitted and constructed. For easy reference, the page is divided into the following sections:

- Related Pages

- What is Earthbag Construction

- Why Open Source Earthbag Construction Engineering

- Ways to Contribute and Consultants

- Earthbag Construction Engineering Details

- Understanding Soil Classification

- Using the Soil Classification Spreadsheet

- Using the Nail Selection and Placement Spreadsheet

- Using the Gravity and Snow/Wind/Seismic Load Spreadsheets

- Additional Recommended Engineering Tests

- Additional Soil Classification System Training

- Resources

- Summary

- FAQ

NOTE: THIS PAGE IS NOT CONSIDERED BY US TO BE A COMPLETE AND USABLE TUTORIAL UNTIL

WE HAVE OUR PLANS PERMITTED AS PART OF THE CONSTRUCTION OF THE EARTHBAG VILLAGE.

AT THAT TIME WE WILL ADD HERE THOSE PERMITTED PLANS AND ANYTHING ELSE WE LEARNED.

IN THE MEANTIME, WE WELCOME YOUR INPUT AND FEEDBACK

RELATED PAGES (mouse-over for descriptions and click for complete pages)

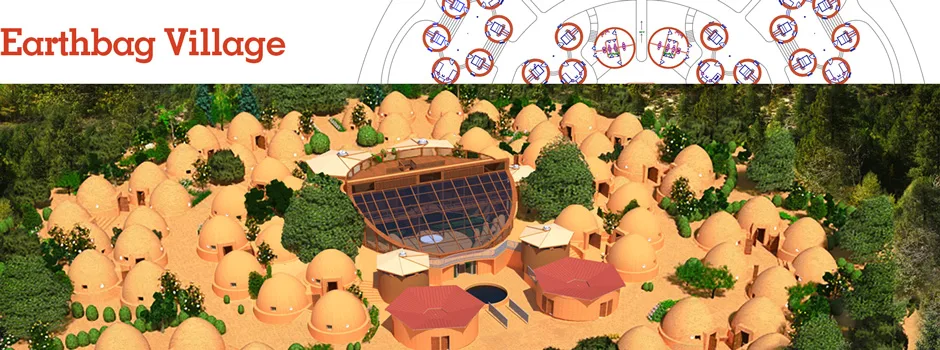

WHAT IS EARTHBAG CONSTRUCTION

Earthbag construction is a method of producing buildings that can be constructed durably, affordably, and without prior experience. To construct earthbag structures, soil is mixed with a small amount of stabilizer, usually cement or lime, and then used to fill degradable bags. The bags are tamped/packed-down to provide a uniform/flat contact area for easier stacking. Nails, rebar, or barbed wire is then used between/through the bags to improve the friction and adherence.

Earthbag construction is a method of producing buildings that can be constructed durably, affordably, and without prior experience. To construct earthbag structures, soil is mixed with a small amount of stabilizer, usually cement or lime, and then used to fill degradable bags. The bags are tamped/packed-down to provide a uniform/flat contact area for easier stacking. Nails, rebar, or barbed wire is then used between/through the bags to improve the friction and adherence.

Benefits of earthbag construction like this include:

- Low-cost

- Durability

- Low Carbon footprint

- Simple to do; potentially providing jobs for unskilled workers

- Wide range of soils can be used

- Negates the use of wood (saving trees)

WHY OPEN SOURCE EARTHBAG

CONSTRUCTION ENGINEERING

Open sourcing our earthbag engineering research is important so that it can be replicated and/or so other engineers/designers can build-upon our work to improve it and/or make changes to suit their own projects/visions. Currently, there is very little information on the engineering aspects of earthbag construction, so creating this online tutorial is helping fill the void we see in this area. Our hope in sharing what we’ve learned is to increase public safety and improve the performance of earthbag-constructed structures.

Open sourcing our earthbag engineering research is important so that it can be replicated and/or so other engineers/designers can build-upon our work to improve it and/or make changes to suit their own projects/visions. Currently, there is very little information on the engineering aspects of earthbag construction, so creating this online tutorial is helping fill the void we see in this area. Our hope in sharing what we’ve learned is to increase public safety and improve the performance of earthbag-constructed structures.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Dominick Banuelos: Civil Engineering Intern

Hannah Copeman: Structural Engineer

Hemanth Kotaru: Civil Engineer, MS Structural Engineering (primary researcher, design, and calculations)

Jarot Tamba: Civil Engineering Intern

John Paul D. Matining: Civil Engineer Intern

Marcus Nguyen: Civil Engineering Intern

Yomi Sanyaolu: Mechanical Engineering Graduate and Technical Writer (editor, secondary researcher)

EARTHBAG CONSTRUCTION

ENGINEERING DETAILS

Here we discuss our earthbag engineering findings and the process we used to get the results we did. We also share how to use the various spreadsheets we created. Note that all housing plans should be checked and signed off on by an engineer licensed in your state before beginning any construction. Here are the areas covered in this sections:

- Earthbag Engineering Process Summary

- Earthbag Engineering Summary of Findings

- Earthbag Engineering Data

- Understanding Soil Classification

- Using the Soil Classification Spreadsheet

- Using the Nail Selection and Placement Spreadsheet

- Using the Gravity and Snow/Wind Load Spreadsheets

EARTHBAG ENGINEERING PROCESS SUMMARY

Summarized in this section are the steps we took to ensure the earthbag structures are safe. Included are links to the spreadsheets where the calculations were completed. Instructions for copying and modifying the spreadsheets are on the top of each tab within them. The engineering process steps are as follows:

Summarized in this section are the steps we took to ensure the earthbag structures are safe. Included are links to the spreadsheets where the calculations were completed. Instructions for copying and modifying the spreadsheets are on the top of each tab within them. The engineering process steps are as follows:

STEP 1

Determine the dead load, wind load, and snow loads for the earthbag structure based on the dimensions provided in the design drawings.

- Dead load: See Cell B23 in the “Gravity and Wind Loading” and “Gravity and Snow Loading” tabs of the spreadsheet

- Wind Load: See Cell B18 in the spreadsheet “Gravity and Wind Loading“

- Snow Load: See Cell B17 in the spreadsheet “Gravity and Snow Loading“

STEP 2

Determine the highest vertical and horizontal load per linear foot under section in cell A31 : “Maximum Load Combinations for LRFD as per ASCE 7-16 Chapter 2” in the spreadsheets “Gravity and Wind Loading” and “Gravity and Snow Loading.” The highest among both will govern, and hence be used for analysis. In this case, the highest among both was the load in B39 in the spreadsheet “Gravity and Snow Loading.”

STEP 3

Distribute the lateral load along the height of the structure and determine lateral load between two earthbag layers. Doing this gives us the height at which the maximum lateral load acts on the structure.

STEP 4

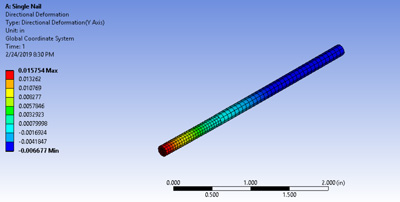

After determining the lateral load between two earthbag layers, determine the number of nails, spacing required, and their ideal embedment into earthbags. Perform finite element analysis for understanding bending, shear, and pull-out failures for the nails under the lateral loading & compressive failure of the soil mix. Also assess the displacement of the nail so as to satisfy displacement criteria recommended by building codes.

Note: For this step, ANSYS was used to perform a finite element analysis to support our analysis in “Nail Design” Sheet in Soil-Cement spreadsheet. See the nails section below for more on this.

EARTHBAG ENGINEERING SUMMARY OF FINDINGS

Engineering calculations on the soil, bag strength, and nails showed that using a 12″ course thickness (aka bag height) with 1000 psi Soil-Cement mix and finishing-nail strategy should produce a safe structure when constructed on flatland. For the nail strategy, 12D finishing nails placed 6 nails per foot (as 1 row) and with a 2″ embedment into the bottom course was the best choice.

Our course thickness will be approximately 4″ thick, producing an even safer structure. We ran our calculations using 12″-high bags/thick courses as a worst-case scenario, anything less than 12″ will be even safer because courses less than 12″ thick means less volume for each bag containing the mix and more nail connections between courses because there will be more of them.

EARTHBAG ENGINEERING DATA

Here is the data to support the above findings. Please note that the foundation design, groundwater control, and soil stability analysis should still be be performed to decrease settlement of earthbag structures. The tests in the “Additional Recommended Engineering Tests” section below are also recommended. All plans should also be checked and signed off by an engineer licensed in your state before beginning any construction.

GRAVITY AND SNOW LOAD DATA

To reference our Gravity and Snow Loading data, see the “Gravity and Snow Loading” spreadsheet. For detailed instructions for how to use this spreadsheet, see the section below titled “Using the Gravity and Snow/Wind/Seismic Load Spreadsheets.”

GRAVITY AND WIND LOAD DATA

To reference our Gravity and Wind Loading data, see the “Gravity and Wind Loading” spreadsheet. For detailed instructions for how to use this spreadsheet, see the section below titled “Using the Gravity and Snow/Wind/Seismic Load Spreadsheets.”

SEISMIC DATA

To reference our Seismic data, see the “ELF method for Seismic Loading” spreadsheet. For detailed instructions for how to use this spreadsheet, see the section below titled “Using the Gravity and Snow/Wind/Seismic Load Spreadsheets.”

SOIL STRATEGIES

To explore alternative soil options, edit the data in “I4, I6, I8, I10, I12 and I14” cells on the “Soil Classification” tab here. For detailed instructions for how to use this spreadsheet, see the section below titled “Using the Soil Classification Spreadsheet.”

- The soil classification done in the “Soil Classification” tab aided in determining the cement content to be used for the Soil-Cement mix to attain a minimum compressive strength of 1000 psi.

- This 1000 psi compressive strength is what is used in cell C8 of the Nail Design spreadsheet. (see below)

SOIL STRATEGIES

To explore alternative nail strategies, edit the data in cell B7, C10, and C11 of the “Nail Design” tab here. For detailed instructions for how to use this spreadsheet, see the section below titled “Using the Nail Selection and Placement Spreadsheet.”

EARTHBAG INTERFACE FINITE ELEMENT ANALYSIS DATA

Finite element analyses of Earthbag Interface models employing 10D and 12D nails produced the following results:

For 10D nails embedded 1″ in the top bag and 2″ in the bottom bags, 14 nails per foot (2 rows of 7 nails) are required to transfer lateral loads between earthbags without failure at the interface. Each nail can take 75lbs of 1000 lbs of load.

For 10D nails embedded 1″ in the top bag and 2″ in the bottom bags, 14 nails per foot (2 rows of 7 nails) are required to transfer lateral loads between earthbags without failure at the interface. Each nail can take 75lbs of 1000 lbs of load.- For 12D nails embedded 1″ inches in top bag and 2.25″ in the bottom bags, 6 nails per foot (1 row of 6 nails) are required to transfer lateral loads between earthbags without failure at the interface. Each nail can take 167 lbs of 1000 lbs load.

CLICK HERE FOR THE NAIL FEA SOURCE FILES

COST ANALYSIS

- Pricing of 12D Nails per Home Depot Website: $18.59/5 lbs (315 Nails)

- Pricing of 10D Nails per Home Depot Website: $18.59/5 lbs (340 Nails)

Here’s what that equates to when factoring in the required spacing:

- Pricing of 12D Nails per foot = $ 0.35 / foot

- Pricing of 10D Nails per foot = $ 0.76 / foot

This shows 12D nails are the more economical choice.

WORKABILITY

Workability greatly improves if the nails are spread out instead of in a clustered formation. This makes spread-out 12D nails a preferred option over clustered 10D nails.

AVAILABILITY CONSIDERATIONS

10D and 12D nails are available in most parts of the world. They are known as “penny size nails” in the UK and sold by length of nails in some areas. So they are available pretty much everywhere.

UNDERSTANDING SOIL CLASSIFICATION

To determine the cement content necessary for preparing soil mix using soil at the site, it is of utmost importance to determine the type of soil at the site. The methods described below use the Unified Soil Classification System categories to provide a quick and approximate classification of soil while on a site.

To determine the cement content necessary for preparing soil mix using soil at the site, it is of utmost importance to determine the type of soil at the site. The methods described below use the Unified Soil Classification System categories to provide a quick and approximate classification of soil while on a site.

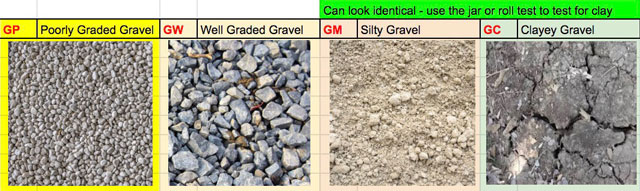

GRAVEL SOIL

Gravel soil is granular soil that consists of the following categories: Gravel Poorly Graded (GP), Gravel Well Graded (GW), Silty Gravel (GM), and Clayey Gravel (GC). Color will vary but the following are fairly good pictures of what the textures of these soils can be expected to look like:

Gravel soil is granular soil that consists of the following categories: Gravel Poorly Graded (GP), Gravel Well Graded (GW), Silty Gravel (GM), and Clayey Gravel (GC). Color will vary but the following are fairly good pictures of what the textures of these soils can be expected to look like:

This type of soil is gravely in nature with predominant portion of soil passing through >20 mm sieve. Further classification of Gravel soil depends on the contents. If one size of the particles in the soil is unevenly more than the rest, it is classified as Poorly Graded Gravel (GP). If the soil has an even proportion of fines (silt and clay), sand, and gravel particles, it is classified as Well Graded Gravel (GW). If the soil has >12% fines, it is classified either as Silty Gravel (GM) or Clayey Gravel (GC). GM vs. GC distinction can be made when the fines in the soil (when combined with sufficient water content) cannot be rolled into thin threads of 2mm thickness. If the fines in soil can be rolled into 2mm thick threads without any breakage lines, it can be classified as GC.

SANDS

Sandy soil is granular soil that consists of the following categories: Poorly Graded Sand (SP), Well Graded Sand (SW), Clayey Sand (SC), and Silty Sand (SM). Color can vary greatly, but the following are fairly good pictures of what the textures of these soils can be expected to look like:

Sandy soil is granular soil that consists of the following categories: Poorly Graded Sand (SP), Well Graded Sand (SW), Clayey Sand (SC), and Silty Sand (SM). Color can vary greatly, but the following are fairly good pictures of what the textures of these soils can be expected to look like:

This type of soil is gravely in nature with predominant portions of soil passing through >5mm sieve and <20 mm sieve. Further classification of sandy soil depends on its contents. If one size of the particles in the soil are unevenly more than the rest, it is classified as Poorly Graded Sand (SP). If the soil has an even proportion of all-sized particles, it is classified as Well Graded Sand (SW). If the soil has >12% fines, it is classified either as Clayey Sand (SC) or Silty Sand (SM). SC vs. SM distinction can be made when the fines in the soil (when combined with sufficient water content) cannot be rolled into thin threads of 2mm thickness. If the fines in soil can be rolled into 2mm thick threads without any breakage lines, it can be classified as Clayey Sand.

SILTY SOIL

Silty soil is like sandy soil but the particles are smaller. Silty soil can be classified as either Low Plasticity Silt (ML) or High Plasticity Silt (MH). Color can vary greatly, but the following picture is a fairly good example of the texture of silty soil.

Silty soil is like sandy soil but the particles are smaller. Silty soil can be classified as either Low Plasticity Silt (ML) or High Plasticity Silt (MH). Color can vary greatly, but the following picture is a fairly good example of the texture of silty soil.

Silty soil is predominantly constituting of fine/silty particles. These particles pass through 5mm sieve and are classified into Low Plasticity Silt (ML) or High Plasticity Silt (MH) based on their plasticity limits. Plasticity is the property of a material to be deformed repeatedly without rupture by the action of a force, and to remain deformed after the removal of force. This classification cannot be done at the site due to experimental equipment required. However, determining if the soil present is silty is necessary and fairly easy. The usual check for clayey soils involves checking if the soil with enough water content can be rolled into 2mm thick threads without any significant break lines observable. If it cannot, it is either MH or ML silty soil.

CLAYEY SOIL

Clayey soil is soil predominantly consisting of clay. Clayey soil can be classified as either Low Plasticity Clay (CL) or High Plasticity Clay (CH). The small picture at left shows how to test if your soil has a high clay content. The picture below shows what it usually looks like when dry.

Clayey soil is soil predominantly consisting of clay. Clayey soil can be classified as either Low Plasticity Clay (CL) or High Plasticity Clay (CH). The small picture at left shows how to test if your soil has a high clay content. The picture below shows what it usually looks like when dry.

Clayey soil particles pass through a 5mm sieve and are classified into Low Plasticity Clay (CL) or High Plasticity Clay (CH) based on their plasticity limits. Plasticity is the property of a material to be deformed repeatedly without rupture by the action of a force, and to remain deformed after the removal of force. This classification cannot be done at the site due to experimental equipment required. However, determining if the soil present is clayey is necessary and fairly easy. The usual check for clayey soils involves checking if the soil (with enough water content) can be rolled into 2mm thick threads without any significant break lines observable. If it can, it is clayey soil.

You can also use what is called the “shake test” or “jar test.” This video shows a more detailed version of the roll test and the shake/jar test for clay.

USING THE SOIL CLASSIFICATION SPREADSHEET

Knowing what type of soil you have is essential when building with earthbags because it determines how much cement you need to add to your mix. This tutorial will help you understand how to use the Soil Classification spreadsheet we created to help determine what kind of soil you have and then what percentage of cement that soil would require.

Knowing what type of soil you have is essential when building with earthbags because it determines how much cement you need to add to your mix. This tutorial will help you understand how to use the Soil Classification spreadsheet we created to help determine what kind of soil you have and then what percentage of cement that soil would require.

The main task to complete when using this spreadsheet is to answer the soil classification checklist questions in cells I4, I6, I8, I10, I12 & I14. Use the notes in cells K5, K7, K9, K11, K13 & K15 to guide you towards what type of soil you are dealing with (see highlighted columns in below image). If your soil is inconsistent and preventing you from classification via the spreadsheet, sift the soil to improve consistency. You can also use external resources for more classification information.

The classification definitions on the spreadsheet give a specific description of the different types of soils. Silt and Clay soils can have very similar looking sub-types of soils therefore additional lab tests may be required to fully identify the type of soil. Basic handheld tests like the jar & roll tests (described in the video above) can also be used. Also included on the spreadsheet are examples of Silt & Clay soils which can be used as an initial identification step. Percent of cement required to obtain compressive strength exceeding 1000 psi is determined in cell I20.

USING THE NAIL SELECTION AND PLACEMENT SPREADSHEET

Similar to the soil classification tutorial, this tutorial will help users understand how to modify the nail properties in the Nail Design spreadsheet. The different failure modes for nails are analyzed using that spreadsheet. If you make a copy of the spreadsheet, you have the complete freedom to edit it.

Similar to the soil classification tutorial, this tutorial will help users understand how to modify the nail properties in the Nail Design spreadsheet. The different failure modes for nails are analyzed using that spreadsheet. If you make a copy of the spreadsheet, you have the complete freedom to edit it.

EDITING THE MATERIAL PROPERTIES

Note: only 3 cells on the Nail Design spreadsheet should be edited/changed: B7 and C10 & C11. In the picture below, these are the (yellow) nail drop down and the two numbers in the green rows. Editing any other data could modify a calculation cell and make it so your copy of the spreadsheet no longer works. If this happens, undo your changes or just make a new copy of the spreadsheet.

- To change the nail/rebar choice, modify cell B7 (notations are used in USA terms)

- Next, input the spacing (in inches) you intend to us in cell C10

- And then input in cell C11 the number of rows you’d like to use with this spacing

- Check cells B29, B32, and B36 to see if your strategy passes each of the necessary tests. If it does, you will see “PASS” in row 48*. If it doesn’t, you need to revise your spacing and row choices.

- The table starting in J6 shows the individual nail and rebar properties and the table starting in row 51 shows the nail/rebar spacing and configurations we tested successfully (including bending*) and their associated costs.

*Note: Our spreadsheet is mainly concerned with compression, shear, and deflection. It also tests for bending, but will issue a “Pass” in cell B48 as long as deflection passes. A structure that passes shear, compression, and deflection should be safe. You need to confirm this though with a licensed engineer in your area and for your specific structure and circumstances. For maximum safety, we also think (as we’ve said above) that the tests listed in the “Additional Recommended Engineering Tests” section should be performed. These tests will provide additional confirmation, in real-world situations, whether or not what the calculations are showing is correct.

Building a structure that passes in cell B42 would be even safer. See row 51 and below for the nail/rebar spacing and configurations we tested as successfully passing the “Bending Strength of Nail” (cell B42) criteria also.

UNDERSTANDING FAILURE MODES

This section is designed to help you understand the various failure modes described on the Nail Design spreadsheet.

COMPRESSIVE FAILURE OF SOIL MIX AT INTERFACE OF SOIL MIX AND NAIL

Compressive failure is due to crushing of the soil mix via load transfer between two subsequent Earthbag layers. The output in cells B29 & B32 show whether the soil mix will fail due to compressive loads.

SHEAR FAILURE OF NAIL

Shear failure is caused by sliding between two subsequent earthbag layers; this friction induces shear loads. Failure of the soil mix due to shear loads is analyzed and output in cell B36.

BENDING STRENGTH OF THE NAIL

When a large moment is induced due to load transfer between two subsequent earthbag layers, the nails can fail due to bending. Cell B42 outputs whether this failure occurs.

DEFLECTION FAILURE

Lateral load causes deflection and if the deflection exceeds a specific limit, nail failure due to bending occurs. The result of whether the nail fails due to deflection is output in cell B48.

SYMBOLS & EQUATIONS

- N – Number of Nails per foot

- D – Diameter of Nail (inches)

- E – Embedment of nail in the top or bottom bag (inches)

- L – Lateral load (kip/ft)

The following formula are taken from the Nail Design cells: C28, C35 & C41

- C28: Compressive stress on soil at the face each nail surface (psi/nail) = 1000L x N / 12xExD different at top & bottom of nail

- C35: Shear stress in each nail (psi/nail) = L x 1000 / 0.25 x N x pi x D

- C41: Moment demand (lb-in) = L x 1000 x E(top nail)2 / 3 x N x E

USING THE GRAVITY AND SNOW/WIND/SEISMIC LOADING SPREADSHEETS

The engineering calculation spreadsheets are designed for the domes to be constructed within the Earthbag Village. The calculation spreadsheets though can be used for initial calculations for other domes as well. This section describes how to do that. You will need the help of an engineer and your own copy of the spreadsheet, which you can create the same way previous sheets were copied.

The engineering calculation spreadsheets are designed for the domes to be constructed within the Earthbag Village. The calculation spreadsheets though can be used for initial calculations for other domes as well. This section describes how to do that. You will need the help of an engineer and your own copy of the spreadsheet, which you can create the same way previous sheets were copied.

Here’s how to understand and use these sheets:

- The green cells in the design sheets titled “Gravity and Snow Loading,” “Gravity and Wind Loading,” and “Gravity and Seismic Loading” are the cells which pertain to the dimensions of the earth-bag structures. These cells can be edited with enough information on the dimensions of your own earthbag structure.

- The orange cells are to be edited with care and by a qualified engineer who understands the loading on the earthbag structure.

- The “ELF method for Seismic Loading” is the spreadsheet to calculate the vertical distribution of seismic loading. The results from this sheet are used to fill out the Seismic loading in cell B15 of “Gravity and Seismic Loading.”

Looking at the Gravity and Snow Loading and Gravity and Wind Loading sheets, the maximum buckling moment (lb/ft) is calculated in cells B42 and B48 [as per ASCE 7-16 Chapter 2] respectively. See rows 24 and below for the process of calculating this value.

The shear resistance of the earthbags is the resistance to friction/sliding occurring between subsequent earthbags. There is a critical total length/perimeter of the earthbags required for safe performance of the structures. For safe performance, the length of the earthbag circle provided needs to be longer than the length of earthbag needed to resist “H.” Cells E21 and F21 (respectively) confirm this.

The following symbols are used within these spreadsheets, taken from cells A5 to A18 in both sheets.

- R – Radius of Dome @ H2 above ground

- H2 – Height of Doorway

- WD – Weight Density of Earthbag

- W – Width of Door

- H1 – Height of Earthbag dome above Door Opening

- B – Breadth of Earthbag

- Θ – Slope of Dome in Radians

- RP – Distance of Point of application of axial load from top of doorway

- T – Thickness of Wall

- AT – Tributary area of load due to dome sloping

- DS – Dead Load due to Stucco Finishing

- SL – Snow Loading

- P – Wind pressure

The snow load is due to the total downward forces of the earthbags (weight) acting on the roof on the earthbag building. It is calculated in cell B24 and using this formula: S (Snow load) = SL x AT.

ADDITIONAL RECOMMENDED ENGINEERING TESTS

The following are additional recommended tests. Conducting these tests would confirm if the mathematical calculations demonstrating safety are as safe as they show.

TEST 1: COMPRESSION

Physically test the specific earthbags to be used to determine their compressive strength. To do this, perform a compression test using a universal testing machine (UTM) and a soil mix cube (of your specific mix) to determine the compressive strength of the combined earthbag and soil mix.

TEST 2: LATERAL LOAD

This would be a test to determine the nail behavior between the earthbags. To do this test, you would set up two earthbags as per the dimensions in the drawings and using nails determined as per the design spreadsheet. Then perform a lateral load test to determine the loads for bending, shear, and pull-out failures of the nails. You would also perform this to determine the load at which the compression failure of soil mix around the nails occurs during the test.

TEST 3: SEISMIC LOAD

This test is to determine the performance of the nail-to-earthbag connection in the event of an earthquake. To do this you would test a scaled-down earthbag structure on a shake table.

TEST 4: STABILITY

This test would be for the arches at door. To perform it, you would set up an arch as per the drawings and apply a point load at the top of the arch to determine the displacement. Stop the test at displacement of L/360 (where L is the height of the arch) and determine the load corresponding to it.

ADDITIONAL SOIL CLASSIFICATION SYSTEM TRAINING

The Natural Resources Conservation Service created a Unified Soil Classification System Training PowerPoint that we found pretty useful. Click the picture below for the complete Google PPT presentation.

Unified Soil Classification System Training by the Natural Resources Conservation Service – Click for the Google Presentation

RESOURCES

Extensive research was done to complete the engineering details on this page. So others can replicate our work, here are the resources we found helpful. Use this page (click here) if you have a resource you’d like to suggest be added here.

DROPBOX FOLDER OF RESOURCES AND RELEVANT STUDY PDFS

BACKGROUND INFORMATION ON EARTHBAG STRUCTURES

- Comprehensive design method for earthbag and superadobe structures (Materials & Design, Volume 96, 15 April 2016, Pages 270-282)

- Earthbag Building in the Humid Tropics: Simple Structures 2nd edition Patti Stouter (PDF)

- Earthbag Building The Tools, Tricks, and Techniques, Kaki Hunter and Donald Kiffmeyer (PDF)

KEY LINKS ON SOIL MIX

- Article: Cement-Modified Soil (CMS)

- Article: Cement-Treated Base (CTB)

- Article: Determine Unconfined Compressive Strength of Cohesive Soil

- Wikipedia: Soil Cement

- Article: Construction Specification 29 – Soil Cement

- Article: Estimates of Elasticity and Compressive Strength in Soil Cement Mixed With Ijuk-Aren (PDF)

- Article: Strength Assessment of Soil Cement

- Article: Test Procedure for Soil-Cement Testing (PDF)

- Article: Mix design and strength of soil”cement concrete based on the effective water concept

- Article: Soil-Cement

- Article: Soil Cement Stabilization – Mix Design, Control and Results during Construction (PDF)

- Article: Construction Specification 29″Soil Cement (PDF)

- Article: Soil Cement

- Article: Soil-Cement Inspector’s Manual (PDF)

- Article: Interpretation of Geotechnical Properties of Cement Treated Soils (PDF)

- Article: Cement in Soil Stabilization

- Article: ICC-ES Evaluation Report – Power-driven Staples and Nails (PDF)

- Article: Natural Building Blog – Lunar Earthbag Structures

- Article: Earthbag/SuperAdobe House

- Use this page (click here) if you have a resource you’d like to suggest be added here

SUMMARY

Earthbag construction is a method of producing buildings that can be constructed durably, affordably, and without prior experience. Open sourcing our earthbag engineering research is important so that it can be replicated and/or so other engineers/designers can build-upon our work to improve it and/or make changes to suit their own projects/visions. Summarized in this page are the steps we took to ensure the earthbag structures are safe. While our research has been extensive, all housing plans should be checked and signed off on by an engineer licensed in your state before beginning any construction.

Earthbag construction is a method of producing buildings that can be constructed durably, affordably, and without prior experience. Open sourcing our earthbag engineering research is important so that it can be replicated and/or so other engineers/designers can build-upon our work to improve it and/or make changes to suit their own projects/visions. Summarized in this page are the steps we took to ensure the earthbag structures are safe. While our research has been extensive, all housing plans should be checked and signed off on by an engineer licensed in your state before beginning any construction.

FREQUENTLY ANSWERED QUESTIONS

Q: Where do I learn more about One Community’s earthbag structures?

The best place to start is on the Earthbag Village open source hub.

Q: If I want to reproduce/check your engineering calculations, how do I do that?

All the resources used are in the Dropbox folder of Earthbag Resources and Research.

Q: I trust you’ve done your research correctly, can I just build one of your structures using this?

No. We won’t consider this research sufficient to build even our own structures until we’ve received a stamp on the final plans from an engineer licensed in the state we’ll be building in and finished construction of our first one. We’ll share those stamped plans here when we have them. We will also share anything new we learn through that process.

One Community

One Community