Eco-community Electric Vehicle Integration and Charging Infrastructure Guide

This page is part of the Highest Good energy component of One Community and an open source guide to setting up electric vehicle (EV) integration for daily use and as an emergency power option. It is purposed to help people understand the how’s and why’s of electric vehicle charging, charging infrastructure, and emergency power options.

We discuss this with the following sections:

- What Is Eco-community EV Integration?

- Why Open Source Eco-community Electric Vehicle Integration?

- Ways to Contribute and consultants

- Eco-community Electric Vehicle Integration Details

- Electric Vehicle Batteries as an Emergency Power Source

- Electric Vehicle Charging Level Details

- Understanding Different Charger Options

- Summary of EV Charging Infrastructure Costs

- One Community Considerations

- One Community’s Plan for EVs and EV Charging

- Resources

- Summary

- FAQ

NOTE: THIS PAGE IS NOT CONSIDERED BY US TO BE A COMPLETE AND USABLE TUTORIAL UNTIL

WE FINISH OUR OWN DEMO CONSTRUCTION AND ADD ALL THE VIDEOS AND EXPERIENCE FROM

THAT BUILD TO THIS PAGE ” IN THE MEANTIME, WE WELCOME YOUR INPUT AND FEEDBACK

RELATED PAGES (Click icons for the complete pages)

WHAT IS ECO-COMMUNITY EV INTEGRATION

This page aims to provide information regarding the role of electric vehicles (EVs) within a sustainable community, how to charge them, and explore the possibilities of using them for emergency power if needed. We also provide information regarding the selection process of the EVs, different industry-standard charging levels, technical and economical information on the different stages of charging the EVs, and a detailed explanation on the charging analysis that includes different scenarios that could occur while charging EVs.

This page aims to provide information regarding the role of electric vehicles (EVs) within a sustainable community, how to charge them, and explore the possibilities of using them for emergency power if needed. We also provide information regarding the selection process of the EVs, different industry-standard charging levels, technical and economical information on the different stages of charging the EVs, and a detailed explanation on the charging analysis that includes different scenarios that could occur while charging EVs.

WHY OPEN SOURCE ECO-COMMUNITY ELECTRIC VEHICLE INTEGRATION

Sustainable living and green modes of transportation are becoming more mainstream as humanity embraces the solutions needed to address pollution, ecosystem destruction, and climate change. Electric vehicles will be the foundation of the majority of people’s transportation needs in the near future. As usage of electric vehicles rises, increasing their charging efficiency and utilizing them as sources for emergency power will help save money and aid in grid stability.

Sustainable living and green modes of transportation are becoming more mainstream as humanity embraces the solutions needed to address pollution, ecosystem destruction, and climate change. Electric vehicles will be the foundation of the majority of people’s transportation needs in the near future. As usage of electric vehicles rises, increasing their charging efficiency and utilizing them as sources for emergency power will help save money and aid in grid stability.

One Community is open-sourcing our research into electric vehicles and their use as a possible emergency backup power source to help eco-communities integrate EVs faster and more effectively. We will continue to evolve this open-source resource by sharing our experience purchasing, installing, and maintaining our own electric vehicle fleet as part of One Community’s Highest Good Energy infrastructure and construction of the Duplicable City Center, Earthbag Village (Pod 1), the 6 villages to follow, and beyond.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Shreyas Dayanand: Battery Research and EV Charging Consultant

Yuran Qin: Web Designer

ECO-COMMUNITY ELECTRIC VEHICLE INTEGRATION DETAILS

Initially, the community will have 3 golf carts for short commutes within the property, and one Tesla Model 3, one Tesla Model X, and one electric Ford F150 (or Cyber truck) for all other work and recreation needs. We expect to have these integrated by Phase 1d of the initial build. We will start with just 1 or 2 golf carts in phase 1b/c and build to 5 by the end of phase Phase 1e/2. At that point we will assess if additional golf carts or Teslas are needed.

We discuss our selection process and the associated costs with the following sections:

- Reasons for Procuring an Electric Vehicle for the Community

- Eco-community Electric Vehicle Integration Details

- Community-owned Electric Vehicles Information: Golf Carts

- Community-owned Electric Vehicles Information: Utility Vehicles

- Charging Station Installation Process

REASONS FOR PROCURING AN ELECTRIC VEHICLE

For all our blog readers: Before diving into the analysis, we want to note that the electric vehicle industry is still evolving. We will continuously update this blog with the latest information. A final update will be made when the vehicles are purchased by One Community. This blog was originally posted in 2022 and updated in 2024. We’ve observed that prices have steadily dropped as EV technology advances and economies of scale take effect. For more details, please continue reading.

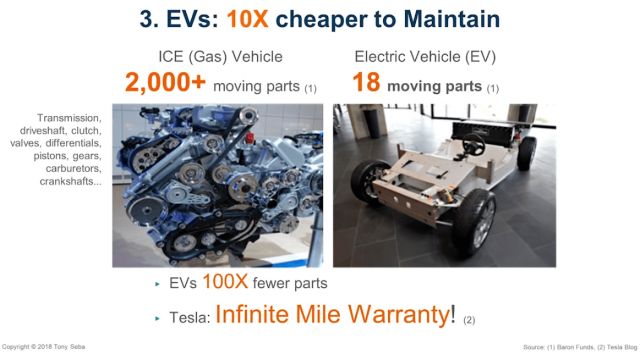

The primary purpose of eco-communities is sustainability, eliminating vehicles that use fossil fuels is in alignment with this goal. Electric vehicles require less maintenance because electric motors have fewer parts and are overall more efficient. Electric vehicles are also more economical because charging an electric vehicle is cheaper than powering it with fossil fuels.

We can understand these benefits more specifically by performing a case study using the ELECTRIC VEHICLE SAVINGS CALCULATOR. We consider the input parameters for this calculator as reliable because they are based on values taken from websites that can be cross-checked with the link attached to their respective parameters.

ELECTRIC VEHICLE TREND PROJECTIONS

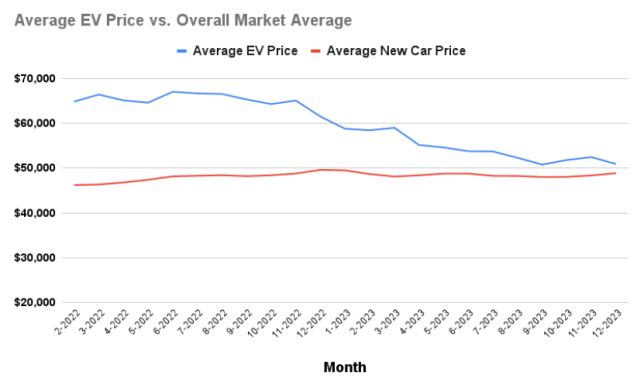

The chart below shows that the average EV price has been dropping compared to traditional vehicles. Several factors contribute to this trend, including major breakthroughs in battery technologies, economies of scale, intensified competition, and improved charging infrastructure.

Average EV Price vs Overall Market Average

This trend is expected to continue mainly due to increased competition and reduced battery costs, which have fallen by about 80% over the past decade and are expected to continue decreasing. In terms of overall cost and savings projections, the prices of gasoline and electricity are worth noting. As more people shift to electric vehicles, the demand for gasoline is expected to decrease, potentially lowering gas prices. Conversely, increased demand for electricity may drive up prices, partially offsetting the benefits from EV price drops.

INTERNAL COMBUSTION ENGINE (ICE) DRIVEN VEHICLE

For the “miles driven per year”, the United States Department of Transportation Federal Highway Administration said that the average person drove a distance of 14,263 miles/year in 2019. The cost for 1 gallon of gasoline (as of 04-04-2022) is approximately $4.422 in Utah. The mileage (or efficiency) of the vehicle is assumed as 25.4 miles per gallon. Therefore, the total cost for fuel to run the internal combustion vehicle for 14,263 miles would be $2,484.

Total cost for fuel (in dollars) = Number of gallons required x Price/gallon. So 14,263 miles/25.4 miles/gal x $4.422/gal = $2482

According to Ychart, as of July 15 2024, the cost of 1 gallon of gasoline is approximately 3.614 in the United States. Assuming the gas consumption stays constant, the total cost for fuel to run the internal combustion vehicle for 14,263 miles would be $2,029.

Total cost for fuel (in dollars) = Number of gallons required x Price/gallon. So 14,263 miles/25.4 miles/gal x $3.614/gal = $2029

BATTERY DRIVEN ELECTRIC VEHICLE

For the “miles driven per year”, the value remains the same as the above case. The average cost of electricity per kWh in Utah is taken as $0.106. The consumption for the EV is taken as 3.6 miles/kWh according to the Tesla Model 3 long range (see table above). Therefore, the total cost for electricity to run the battery powered electric vehicle for 14,263 miles would be $420.

According to Energysage, as of February 2023, the cost of electricity per kWh is $0.23. Therefore, the updated total cost for electricity to run the battery powered electric vehicle for 14,263 miles would be $911.

Total cost for electricity (in dollars) = Number of kWhs required x Price/kWh. So 14,263 miles/3.6 miles/kWh x $0.23/kWh = $911

ANALYSIS RESULTS

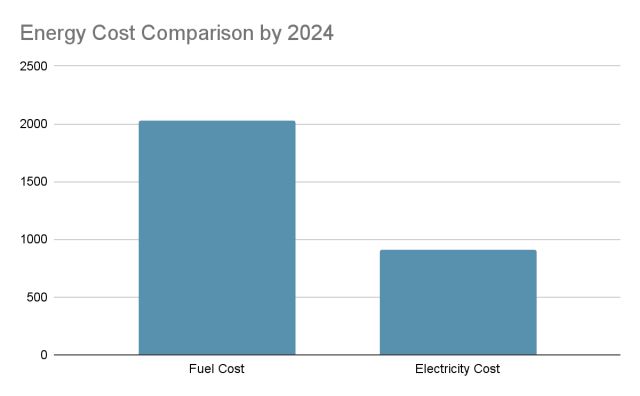

Based on the above analysis, the total yearly savings per EV would be $2,064.

Cost difference = $2482/year cost for ICE vehicle – $420/year cost for battery driven vehicle = $2064 annual savings

Updated yearly savings per EV would be $1,118

Cost difference = $2029/year cost for ICE vehicle ” $911/year cost for battery driven vehicle = $1118 annual savings

Energy Cost Comparison by 2024

Also, EVs have fewer moving parts compared to traditional ICE vehicles. Less moving parts equals less maintenance-related costs in the long run. See the following section for detailed analysis.

MAINTENANCE COST COMPARISON

Due to their simpler design and fewer moving parts, electric vehicles (EVs) have significantly lower maintenance and repair costs compared to internal combustion engine (ICE) vehicles. The reduced need for frequent servicing, such as oil changes and brake replacements, translates to less time in the shop and lower overall ownership costs.

- Annual Maintenance Costs

- Electric Vehicles: EVs generally have lower annual maintenance costs, averaging around $615 per year.

- Traditional Vehicles: The average annual maintenance cost for ICE vehicles is around $949‹.

- Battery Replacement

- EVs: The cost of battery replacement can range from $5,000 to $20,000, depending on the model and battery size‹ (EV Financing Rates). However, this is not a regular maintenance item and only occurs after many years of usage.

- Traditional Vehicles: Engine replacement costs generally range from $4,500 to $28,000. While the cost is similar, Engine repair/replacement occurs more frequently after extensive use, which causes higher cost in the long run.

- Frequency of Maintenance

- EVs: Require less frequent maintenance. No oil change and spark plug change needed, and an average of over 100,000 miles for fluid and brake pads replacement. The simpler mechanical design means fewer opportunities for wear and tear, resulting in less time spent at the repair shop‹.

- Traditional Vehicles: Require regular maintenance intervals, typically every 3,000 to 7,500 miles for services like oil changes, 30,000 to 70,000 miles for brake pads changes, 15,000 to 30,000 miles for air filtration and spark plug changes. which means more frequent visits to the mechanic‹.

MAINTENANCE COST ANALYSIS

Assuming 10 year usage for both EVs and ICEs, EV’s maintenance cost is estimated around $18,650, ICE’s maintenance cost is estimated around $25,740.

Total maintenance cost (in dollars) = Number of years x yearly maintenance costs + major transmission replacement cost.

So EV maintenance cost = 10 x $615 + ($5000 + $20000)/2 = $18650 for 10 year total maintenance cost

ICE maintenance cost = 10 x 949 + ($4500 + $28000)/2 = $25740 for 10 year total maintenance cost

MAINTENANCE COST ANALYSIS RESULTS

Based on the above analysis, the yearly savings per EV would be $709.

Cost difference = $25740/ten year cost for ICE vehicle ” $18650/ten year cost for battery driven vehicle = $7090 total savings

Annual savings = $7090/10 = $709

GOLF CARTS

Initially, the community will have 3 golf carts for short commutes within the property. The table below illustrates the various options we found for Golf carts. We will start with just 1 or 2 golf carts in phase 1b/c and build to 5 by the end of phase Phase 1e/2.

Referencing the table below, the E-Z-GO seems to be most promising as it is comparably priced and comes with a Li-ion battery pack. This is preferable because these batteries usually last for a higher number of charge and discharge cycles, providing longer battery life.

UTILITY VEHICLES

The main purpose of eco-village vehicles that are not golf carts is to help community residents commute throughout the community, to the grocery store, road trips, etc. The secondary purpose of the vehicles will be to use them as a power reserve or emergency energy source via vehicle-to-grid as illustrated below.

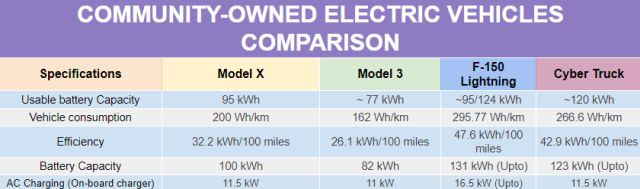

We’ve chosen to consider the Model 3 Long Range and Model X for the community due to their respective battery sizes and utilitarian factors. The Model 3 is more advantageous with respect to cost, as it packs an 82 kWh battery pack and would be primarily used by the members to commute for trips outside the community. Although the Model X is about $40,000 more than the Model 3 Long Range, the additional benefits include more room within the car for materials, groceries, etc. and a larger 100 KWh battery pack.

A primary element to consider when procuring an EV is the charging of the vehicle. There are multiple ways to charge an EV which are discussed in detail in the following sections. For Tesla vehicles they recommend charging the EVs at a residence using their Wall Connector. Charging them this way would mean charging infrastructure would be a single Tesla Wall Connector.

NOTE: This information is accurate as of 12-03-2021. It is predictable that continuous improvement in vehicle and charging technology will aid in usability and range increases. Because of this, we recommend all readers check the latest local data for increases in the range of vehicles, expanding charging networks, rate of charging, etc.

The table below illustrates the 3 models of the electric vehicle manufacturer Tesla, Inc. we are considering. The primary reason for choosing this manufacturer is based on their superior commitment to sustainability, the brand’s reliability, and the extent of service that is provided by them in the US.

Tesla uses materials in their lithium-ion battery that are recoverable and recyclable. Tesla claims that these batteries are recycled to recover the valuable materials for reuse over and over again, none of their scrapped lithium-ion batteries go to landfills, 100% are recycled. Tesla also states that extending the life of a battery pack is a superior option to recycling for environmental and business reasons. In addition, Tesla recently purchased a lithium mine in order to practice sustainable mining by using more common and accessible materials (such as table salt) to extract lithium from its ores. They also aim to build production factories on every continent to reduce the carbon footprint of delivery.

Later in this report we discuss including an electric Ford F150 in our purchasing plan. Because of Tesla’s superior commitment to sustainability, we will purchase the Tesla Cyber Truck instead if it is available.

CHARGING STATION INSTALLATION PROCESS

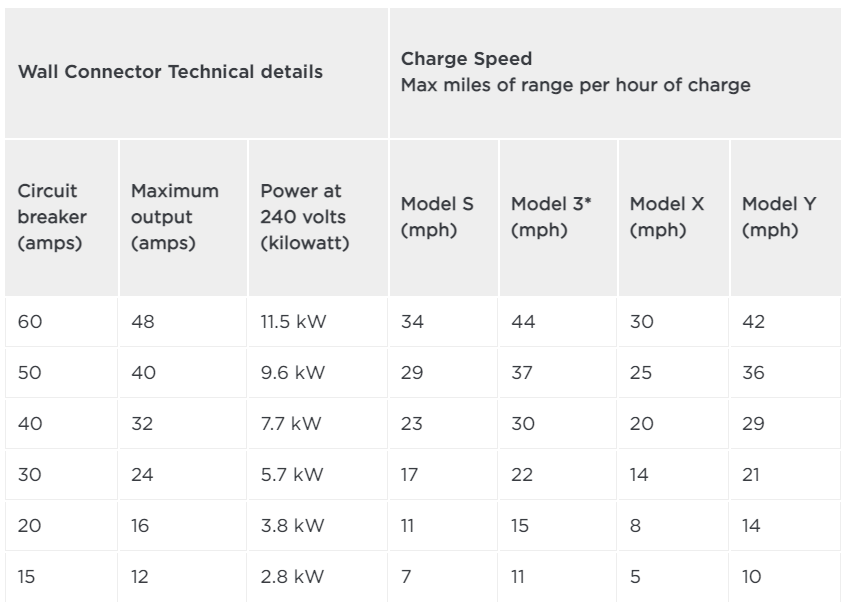

The above-mentioned vehicles need to be re-charged once the charge in the battery pack is depleted in order to continue using them. Tesla recommends using the Tesla Wall Connector ($550 + $750-$1500 installation) for this application. The Wall Connector is a Level 1 charger that can adapt to most home electrical systems with customizable power levels on a range of circuit breakers. The Second Generation Wall Connector (still being developed) will have a feature where up to 4 Wall Connectors can be linked together to intelligently share power. This function would be beneficial for locations that need to charge multiple vehicles at once, but (according to Tesla’s site) might not be able to fully power (probably at 11.5 kW) all the connected vehicles at once.

Update on Tesla Wall Connector price, as of July 2024, the price (without installation) is $450.

The image below illustrates further details regarding the Wall Connector.

Further information on the installation process and setting up of Wall Connectors can be found in the following links:

- Link: “Tesla Wall Connector Overview“: This link will take you to information regarding the Tesla Wall Connector on Tesla’s website. It breaks down the charger’s features, charging speeds, and installation process and cost.

- Link: “Second Generation Wall Connector“: This link provides more specific information regarding the Second Generation Wall Connector and it’s features.

- PDF: “Installation Guide For Second Generation Walla Connector“: This is a link to the Second Generation Wall Connector installation manual.

ELECTRIC VEHICLE BATTERIES AS AN EMERGENCY POWER SOURCE

An interesting potential application for EVs would be to use the energy stored within them for emergency power. The Ford F-150 Lightning electric truck is designed to meet this need and we expect future EVs to follow suit. This would create new opportunities like powering a region of the community where gridlines are not accessible or when there is no power from the grid for a short period of time.

EVs may not be the most efficient option for these purposes, but could very well be the most sustainable option available for short-term and infrequent power needs in such situations. So, this could be a viable option.

BLOCK DIAGRAM OF DIY VEHICLE TO GRID (OR APPLICATION)

The block diagram below illustrates the process of how the EV’s primary battery pack can be used to provide emergency power for a short period of time. Today’s EVs have 2 energy storage devices i.e. the high voltage battery pack (used to power the vehicle) and a secondary 12V battery which is powered by the main battery pack and used for other applications in the EV. The users cannot directly access the primary battery pack as this would be highly dangerous, so for safety reasons it is completely sealed. However, the users can often access the secondary battery which is in turn powered by the primary battery pack itself. This battery is connected to an inverter (used to convert DC to AC) and the output from the inverter can be used as emergency power.

Figure1: Block Diagram of DIY Vehicle-to-X

Figure 2 below briefly explains how an electric vehicle can provide electricity to housing. The first image (A) represents the high voltage primary battery in an EV powering a 12V secondary battery (C) through a DC-DC converter (B) that is built into the vehicle itself. The 12V battery is connected to the inverter (D) where output of the desired frequency of voltage and current is used to power the house or other application (E).

Figure2: Illustration of DIY Vehicle-to-X

For a fully charged EV, up to 80% of the battery pack capacity can be used to power housing or other applications – assuming 90% is the usable portion of the battery pack, 10% is needed to drive to the nearest charging station. The energy typically stored in batteries is in the form of direct current (DC) while household appliances work with alternating current (AC). The inverter converts DC to AC, during this process there will be conversion losses due to its inherent properties, these losses must also be considered and are subject to change depending on the make of the inverters.

EXAMPLE: TESLA MODEL X LONG RANGE

- Primary battery pack capacity of EV: 100 kWh

- Usable battery capacity is 95 kWh

- Assume 5 kWh is required to reach the nearest charging station (~15 miles away)

- Consider DC-DC convertor efficiency as 95%, therefore available energy is 85.5 kWh

- Assuming efficiency of inverter is 90%, 76.95 kWh is usable at application.

Therefore, for a 100 kWh battery pack, ~77 kWh can be used, i.e. 77% of the battery pack’s capacity is usable. To put this in perspective, this would be enough to power:

- Dewalt battery tool: Required power = 80 Watt-hour. This application can be powered for 962 hours OR

- #1 rated refrigerator for 2022: Required power/day = 1.9 kWh. This application can be powered for 40 days OR

- LED Bulb: 20 of these bulbs = 190 Watts. This application can be powered for 405 hours

Additional information regarding concepts in the above sections are linked below.

With the Model X or any other EV that is under production as of today, the Vehicle-to-grid concept is more of a DIY project though and that is not the best way to provide emergency power if it can be avoided. The Ford F-150 is being developed to address this and will come with two battery sizes, the standard-range with a usable capacity of 98 kWh and the extended-range with a usable capacity of 131 kWh.

The truck has 11 outlets (4 in the front trunk, 4 in the bed, and 2 in the cab) at 120V and maximum power that can be drawn being 9.6 kWh. Therefore, 80 amps of current can be drawn to power tools/equipment/housing etc. The bed also features a 240V output if ever necessary.

(Source: http://www.ford.com/trucks/f150/f150-lightning/2022/)

The Ford F-150 Lighting could have a potential competitor in the years to come with Tesla’s creation of the Cybertruck. Information on this electric vehicle is limited due to the launch being postponed to 2023, however the characteristics of the prototype include an impressive V3 supercharging output of 324 kW (and creation of a V4 version).

RELEVANT LINKS

- Study: “The Viability of Vehicle-to-grid Operations from a Battery Technology and Policy Perspective” – This is a journal scholarship paper which talks in detail about methodologies to manage battery degradation and reliably extend battery life. The paper also reviews the associated technology and policy implications of better managing battery use in vehicle and electrical grid applications.

- Article: “Vehicle-to-grid (V2g): Everything You Need to Know” – This article explains what vehicle-to-grid technology is and its importance and benefits.

- Product Information: “Yamaha Drive Concierge 6” – This link provides technical information regarding the golf cart that is listed in the above table.

- Product Information: “E-Z-GO Express L6 Elite Lithium” – This link provides additional information/specifications regarding the golf cart as discussed previously.

- Product Information: “Tomberlin E-Merge E6” – This link provides information/specifications regarding the features, colors, range, etc. of the golf cart.

- Product Information: “Tesla Model 3” – – This is a link to support the technical information that is provided regarding the Tesla Model 3 in this document.

- Product Information: “Tesla Model X” – This is a link to support the technical information that is provided regarding the Tesla Model X in this document.

- Product Information: “Tesla Wall Connector” – This link provides information regarding the charger setup for the Tesla range of cars. It also provides information regarding the rate of charging of these vehicles.

- Product Information: “Tesla Wall Connector Installation” – – This link illustrates how to install the Tesla Wall connector at the required location.

- Product Information: “Tesla Wall Connector Firmware” – This links gives information on the firmware that can be associated with the Tesla Wall Connector.

- Product Information: “Ford F-150” – This is the link to the official Ford website that gives details about the upcoming Ford F-150 electric pick-up truck.

- Website: “Ford Launches Its Bi-directional Home Charging Station at A Surprisingly Good Price- Electrek”

- Website: “Tesla Cybertruck vs. Ford F-150 Lightning: Which Electric Truck Will Win? | Tom’e Guide”

- Website: “With The Addition Of New Electric Pick Up Trucks, Here’s Where The Tesla Cybertruck Stands Today”

- Website: “Ford Aims to Be the Tesla of Connected Commercial Vehicles | Reuters”

- Website: “2022 Ford-F-150 Lightning Battery Capacities Revealed!”

STEPS FOR USING ELECTRIC VEHICLES AS A POWER SOURCE

Two of the three potential vehicles are available on the market (as of 01-30-2022) and the F-150 has yet to come into the market as a consumer EV. Some details regarding the 3 EV choices are provided in the table below.

Choices: Ford F-150 Lightning, Tesla Model X, and Tesla Model 3

To consider implementation before appropriate charging infrastructure is in place on the property, charging by generator or local charging station are the only two options. Considering we’ll have generators until our solar infrastructure is in place, vehicles really only make sense as emergency power in truly emergency situations because meeting any other charging needs would be more efficient using the generator.

If, however, the vehicles are needed, the most important thing to keep in mind is maintaining enough power in their batteries to get them to a charger for recharging. Assuming the nearest charging station would be X kilometers away from the application, we would need 216 Wh/km*X kms (for the Model X) and 162 Wh/km*X kms (for the Model 3) to reach the charging station to recharge the vehicles. Let’s say the vehicle is 30 kms from the nearest charging station, therefore X=30 kms. The Tesla Model X would consume ~ 6.4 kWh and the Tesla Model 3 would consume ~ 4.86 kWh. Considering this, 1 Tesla Model X can offer ~ 88.6 kWh and 1 Tesla Model 3 can offer 72.2 kWh to power any application. Details regarding the F-150 will be updated when the information is available.

According to the above information, for every 1 km, the Model X would consume 216 Wh and the Model 3 would consume 162 Wh of power. Depending on the minimum distance between the vehicle and the nearest compatible charging station, a certain amount of power is reserved in the primary battery pack to propel the EV to the charging station.

One appropriate charging infrastructure is in place on the property, the vehicles would be rechargeable within a maximum travel distance of 2 miles (~3.22 kms). Therefore, the Tesla Model X will consume only ~696 Wh and the Model 3 would consume ~522 Wh, these figures are negligible as they are much less than 1% of the total capacity of the battery pack.

ELECTRIC VEHICLE CHARGING LEVEL DETAILS

Now let’s explore charging options for an eco-community EV vehicle fleet and, for a project that intends to cater to as many visitors as ours will, additional charging stations for potential visitors.

The values for charging time (hours) in Table 1 below may vary depending on the charging profiles adopted by the EV manufacturer. Every EV manufacturer follows their own optimal charging profile which is dependent on various factors (battery type, internal hardware, etc.). Therefore, this table can be a reference to consider while choosing the levels of charging stations within the community.

An off-grid development like ours will charge electric vehicles using solar panels. This means the solar farm design must account for the additional power needed to charge the EVs and the type of chargers that are planned. The flowchart below explains the process of integrating solar panels to charge EVs.

The PV panel converts the solar energy to usable electrical energy (required to charge EV batteries), but the power that is generated from these solar panels may not be in the required range to charge EV batteries. Because of this, a DC-DC converter and maximum power point tracking (MPPT) converter are needed to provide the range needed for charging.

This incoming power is then monitored with the EV’s Battery Monitoring System (BMS) which controls the rate of charging based on its algorithms. To make this process more user friendly, a Human Machine Interface (HMI) can be installed that communicates with the EV and the Solar Grid while safely charging the EVs.

EV CHARGING INFORMATION AND POWER REQUIREMENTS

Next you need to understand your power needs so you can properly size the additional solar infrastructure. We present 3 case studies below to help you do this. The first is a method based on the distance you expect to drive the vehicle each day. The second case study is based on the number of charge cycles you expect per day. The third is a “maximum use” example assuming you are charging all your EVs fully every day.

Understanding and carefully considering the difference between the three is important for choosing the proper type of charger.

CASE 1: BASED ON DISTANCE

Let us consider a case study to understand the charging frequency and power needed to charge EVs using the expected distance you will travel daily. For example, if one Tesla Model 3 (LR AWD) is driven for 200 miles every day of the year, the user would have to charge at least 6/10ths of its battery pack daily. In order to charge the EV battery upto this requirement, ~46 kWh of power needs to be dedicated for the purpose of charging. In summary, the major parameters to consider while analyzing the charging frequency and power requirements would be the number of EVs, battery pack size of each EV, and user day-to-day requirement (in miles).

Major Parameters While Analyzing the Charging Frequency and Power Requirements ” Click for the Open Source Spreadsheet

CASE 2: BASED ON NUMBER OF CHARGING CYCLES

Now let us consider a case study to understand the range that is obtained from the charging frequency. Referencing the table below, if one Tesla Model X (LR) is charged once every two days (same as charging to half battery pack capacity), the user would have on average 180 miles of driving on a day-to-day basis. In summary, the major parameters to consider while analyzing the range of an EV would be charging frequency/day and range/complete charge.

CASE 3: BASED ON MAXIMUM USE

Now let us consider that One Community has six electric vehicles of varying sizes that need to be charged using solar power only. As stated earlier, One Community intends these 6 vehicles to consist of 3 golf carts for short commutes within the property, and one Tesla Model 3, one Tesla Model X, and one electric Ford F150 (or equivalent) for all other work and recreation needs. We expect to have these integrated by Phase 1d of the initial build.

The power needs of these are illustrated in the table below. It shows the number of EVs to be charged and the size of the battery pack for each. It assumes maximum use requiring 100% of the battery pack needing to be charged each day.

Using the following calculation, we can arrive at the total amount of power required from the solar panels.

Total power required/per charging cycle = ∘ ((No. of EVs to be charged) x (Size of battery pack))

*The battery pack size (in kWh) specifications for the “2021 E-Z-GO EXPRESS L6 ELITE LITHIUM” could not be found. However, we do know that the battery pack consists of six 12V batteries. Using a commercially available battery, a conservative estimate can be made. Power (kWh) = Voltage (Volts) x Current (Amp hour), for the aforementioned battery, the voltage is 12 V and the current rating would be 100 amp hours. Therefore the power with 6 such batteries would be 7.2 kWh. With a factor of safety, we have assumed the golf cart to have 10 kWh battery packs.

UNDERSTANDING DIFFERENT CHARGER OPTIONS

Now that we understand how much power we would need to charge our EVs, let’s consider the various types of chargers we could choose. This is important because it costs more for infrastructure that will charge an EV faster

To properly evaluate them, we’ll revisit the costs for fueling a gasoline powered/internal combustion engine (ICE) vehicle. The average miles per gallon (mpg) for the US, as per the United States Environmental Protection Agency Automobile statistics for 2020, is 25.4 mpg. If this “average vehicle” travels a distance of 353 miles every day, it would be equal to the range of a Tesla Model 3 and would require 13.897 gallons of gas every day. Assuming a conservative cost of $4/gallon as the gasoline price, it would cost approximately $62.539/day and $22,827/year (=$1,902.25/month).

The above is an average of all vehicles though. Let’s also use a fuel efficient comparison vehicle. If our vehicle were a new model Prius, it would average closer to 52 mpg and require 6.788 gallons of gas for the same distance at a cost of $27.15/day or $9,910/year (=$825.83/month).

Using these amounts as a reference, let us now look at the different charging scenarios for EVs. The following tables show the 5 different levels of charging that are available and the cost difference between various charging levels and fuel cost to run the two different vehicles. The case studies that follow it start with the fastest (Level 5) charger and share the associated charging-time benefits for each level and the associated costs for the infrastructure needed to provide the faster charging.

Note: These analyses were completed using the trial version of the HOMER (Hybrid Optimization of Multiple Energy Resources) GRID software.

Case 1: Generic Internal Combustion Engine with an Average Mileage of 25.4 mpg ” Click for the Open Source Spreadsheet

The below image illustrates the cost difference to run the ICE vehicles using gasoline vs running a battery powered electric vehicle with electricity. The level 5 charging is more expensive than running the ICE vehicle with 52 mpg, and the level 1 charging is most profitable for both, especially compared to the 25.4 mpg ICE vehicle. The trends in cost differences are shown with the Prius (52 mpg) represented by red and the Average US Vehicle (25.4 mpg) represented by blue.

ON-DEMAND EV CHARGING: (350 KW – LEVEL 5 DC ULTRA FAST CHARGING

The two images below show the input parameters for the analysis of a level 5 DC UFC where the EV is connected to a 350 kW DC UFC for approximately 17 minutes. This is how long it would take to charge an EV battery pack with a capacity of 100 kWh (equal to a Tesla Model X). To particularly understand the charging costs, the type of EV is assumed to be the same in all the following cases. At this time the majority of the EV manufacturers have not enabled Level 5 charging in mass produced EVs. Level 5 ultra-fast DCFC, also requires heavy duty insulation equipment (for safety).

Input Parameters for Case 3 Analysis

RESULTS:

The figures below illustrate the results from the analysis. At $18,324/year (or $1,527/month = $50.20/day), the demand charge* is the highest in comparison to the other charges that make up the summary The consumption charges* are determined by the consumption rate of a battery, or the amount of power it consumes, which depends on the size of the battery pack. In this case, the consumption rate is not changing, but the rate/speed at which the battery packs are being charged is varying. The fixed rate* is relatively higher at $806.73.

*Definition from the manual for Homer Grid: “Grid charges can be categorized into energy charges, demand charges and fixed charges. Energy charge is the cost ($/kWh) of consumption. Demand charge is the cost ($/kW) of demand. Demand charges are the utility’s way of discouraging sudden spikes in demand. Peak shaving or demand charge reduction aims to reduce a customer’s electricity bill by reducing these demand charges. To reduce demand charges, HOMER Grid will try to limit the peak power purchased during each month.”

A “fixed charge” is a charge that is the same every month and is not affected by your consumption or peak demand. Fixed charges are monthly fees you incur no matter how much power you consume. Increasingly, utilities are attempting to restructure electricity bills so that more of each bill is made up of these charges. Source, “What are fixed charges?“, Resource 2 In the software, these fixed charges are dependent on the type of utility, the bigger the utility (more equipment), the more the charges.

Results from Case 3 Analysis

If you choose to use the HOMER GRID tool like we did, you can also produce graphics like the one below showing the distribution of these costs every month. We’re only choosing to share the one image below though because, in all 5 case studies, the major changes are seen in the demand charges and the fixed charges, the energy consumption though is considered the same throughout the year.

Annual Price Variation for Case 3 Analysis

ON-DEMAND EV CHARGING: (150 KW – LEVEL 4 CHARGING)

The two figures below show the input parameters for the Level 4 charging analysis. The EV is connected to the charger for a duration of 40 min, charging at 150 kW/hr to completely charge the battery pack from 0% to 100%. This means the charging time is 23 minutes more compared to level 5 charging. The input value for the “number of chargers” is 1 as we are considering the rates per charger.

Input Parameters for Case 4 Analysis

The figures below illustrate the results from the analysis. Looking at the demand charge at $18,250/year (or $1520/month = $50.7/day), you can see that it is on the higher side and is only $74 less than level 5 charging. The fixed rate is at $873.65.

Commercials for Case 4 Analysis

ON-DEMAND EV CHARGING: (50 kW – LEVEL 3 DC CHARGING)

Here is the analysis for level 3 DC Charging where the EV is connected to a 50 kW charger for 120 min as illustrated in the pictures below. The average charging duration is input as 120 min because the electric vehicle (i.e. the Tesla Model X) is assumed to have a 100 kWh battery pack as discussed earlier. This charging time is approximately 2 hours to recharge the battery pack when connected to a 50 kW charger. This is 120 minutes longer than Level 4 charging and 103 minutes more compared to level 5 charging.

RESULTS:

An average of ~ $770 per month or $9,239 per year is charged as “demand charge” which is shown in the picture below. Comparatively, this amount is $670 more when compared to Level 4 DC Charging. The figure below illustrates the results from the analysis. The demand charge again, is the highest in comparison to the other charges that make up the summary at $9,239/year (or $770/month = $25.50/day). The fixed rate came in at $767.12.

ON-DEMAND EV CHARGING: (19.2 kW – LEVEL 2 AC CHARGING)

Here’s the analysis we carried out for level 2 AC Charging where the EV is connected to a 19.2 kW charger. It would take an average charging duration of 313 min (approximately 6 hours) to charge a vehicle with a 100 kWh battery pack. So 93 minutes longer Level 3 charging.

The figures below illustrate the results from the analysis. The demand charge, again, is the highest in comparison to the other charges that make up the summary at $3,548/year (or $296/month = $9.856/day). The fixed rate is slightly less comparatively at $742, as illustrated in the below figures.

ON-DEMAND EV CHARGING: (1.4 kW – LEVEL 1 AC CHARGING)

The final analysis is for a level 1 AC Charger and an EV with a 100 kWh battery pack, in this case connected to a 1.4 kW charger. See below for the discussion of a Tesla Level 1 charger rated at 11.5 kWh.

As illustrated in the pictures below, a level 1 AC Charger rated at 1.4 kWh and charging an EV with a 100 kWh battery pack would require 4,285 min (about 3 days) to charge. This lower level of Level 1 charging, although economical, is not suggested for use due to the unreasonably long waiting time.

The images below illustrate the charges that make up the annual utility bill. The demand charges are significantly less compared to the DC fast charging at $258 per year or $21.5 a month. The consumption charges are also much less at ~ $443. The fixed rate is slightly less comparatively at $723.

TESLA WALL CHARGING ANALYSIS (11.5 kW)

The Tesla wall charger is rated at 11.5 kWh and the cost is a bit more expensive at approximately $2050 (see above), but it is significantly faster and still considered a Level 1 charger. This is the charging equipment we plan to use for the initial rollout and 100 kWh battery pack (Tesla Model X) would need approximately 8.5 hours for a full charge from 0% battery capacity. As the community vehicles would not be used for 100% of their capacity on a daily basis, this charging level would be more than sufficient. Even if the battery were fully depleted, the vehicles could fully charge overnight.

Here is the analysis for the Tesla Wall charger. It shows a Tesla Model X will charge fully if connected for a period of 521 min (about 8.7 hours). For comparison, the charging time would be approximately 6.7 hours longer than a Level 3 charger and 3.5 hours longer than a Level 2 charger.

The image below illustrates the charges that make up the annual utility bill. The demand charges are at $2,099 per year or $175 a month. The consumption charges are at ~ $1308. The fixed rate is at $737.58.

CHARGING LEVEL COST ANALYSIS RESULTS

Here is a summary of the charging level cost analysis from above. The difference to charge a 100 kWh battery pack with a level 4 and 5 charger would be negligible for a community situation but significant for a busy commercial recharging situation. Level 2 and 3 chargers are 6x and 15x slower (respectively) than a level 4 charger but would still be effective for any situation where a person has 2-5 hours to spend doing something else while their car charges. A level 1 charger rated at 1.4 kW would not be practical with a required charging time of almost 3 days. A Tesla Level 1 charger rated at 11.5 kW would only require 520 minutes (about 8.7 hrs) to charge though and this would be reasonable for any situation (like ours) where overnight charging was sufficient.

SUMMARY OF EV CHARGING INFRASTRUCTURE COSTS

EV users have two main costs: the equipment to recharge the vehicle (fixed costs) and the power that is consumed (variable or energy costs).

The fixed costs associated with different types of electric vehicle supply equipment (EVSE) have three main components:

- The cost of installing the equipment and, where relevant, the cost of site preparation.

- Utility system upgrades such as new transformers.

- The cost of the charging equipment.

The first two are readily available infrastructure, which includes everything except the charging equipment itself. Cost of installation and site preparation includes electrical service extension, permitting, labor costs, and trenching to lay cables. These costs are generally non-existent for Level 1, and minimal for residential Level 2 unless the installation of new circuitry is required.

Installation costs are substantially higher for commercial or public Level 2 chargers, which usually consist of a physical tower. Commercial Level 2 usually requires some form of wiring extensions, the installation of signage and trenching to install additional connections to the grid or off-grid energy infrastructure. Installation costs are majorly location-specific since each EVSE setup has unique requirements. Thus, there is a wide range of cost estimates.

Table 2.2 below summarizes estimates of the different fixed cost categories for each level of charging.

Source: “Charging the Future: Challenges and Opportunities for Electric Vehicle Adoption“

The utility infrastructure update necessary to deliver electricity to the EVs is the second main expenditure. This is because a number of chargers are often connected to the same local network and transformer. A single Level 2 EV charger is unlikely to necessitate a transformer update, but multiple charging at the same time on the same circuit (for example, numerous EV owners charging at the same time in the same neighborhood) could overload the present transformer, necessitating an upgrade. As the popularity of electric vehicles grows, several utilities will need to invest in improving their distribution infrastructure. The rate of investment will be influenced by local taxes and incentives and the commercial penetration of smart-charging systems to optimize the demand on the system over time. Costs will be much higher for Level 3-5 fast charging installations.

Currently, facilities equipped with fast charging capabilities typically require a new transformer at a cost of $30,000-$40,000. However, increasing the number of chargers per station can reduce the per-charger cost of a transformer to $10,000-$25,000, and the per-charger cost of service extensions to $3,500-$9,500.

The third cost is that of the equipment itself. These costs will vary across charger types, and several estimates are available for each type. A typical Level 1 home charger requires no additional equipment. Level 2 home EV chargers can cost up to $1,000, while commercial Level 2 EVs can cost $3,000-$4,000 for a charger with an electronic interface, payment system, and network connection. Level 3-5 EVs are significantly more expensive, typically costing about $30,000-$40,000 for a single-port charger and $50,000-$60,000 for a dual-port charger.

ONE COMMUNITY CONSIDERATIONS

The EV charging infrastructure won’t be significant during Phase 1d of the roll out: 50″100-person team lasting for longer than six months. During this period, considering the population is relatively low, it would be preferable to set up the charging infrastructure for Level 1 charging as the residents will have the necessary time during the night (i.e. about 7 hours for the Model 3 and about 8.5 hours for the Model Y) to charge the vehicles. There would not be enough on-site driving that we’d do where we’d need to recharge the EVs in the middle of the day and long-distance off-site driving would give us access to off-site commercial chargers. This would mean we’ll be saving thousands of dollars by not setting up the higher level charging infrastructure.

Initially, the community will be equipped to charge 3 golf carts (used as on-site transportation vehicles) each day, 1 Model 3 vehicle (also for recreation needs), 1 truck for on-property needs that can’t be handled by golf carts, and one SUV as a backup to fill in as needed for recreation or work needs. Additional charging infrastructure for visitors will be added during Phase 1e/2 and based on the need identified up until that time. During this period, it would be preferable to set up the charging infrastructure for level 3 charging as this is the median considering the amount of time required and cost for charging. For cost analysis purposes, we’re estimating that we will start with 4 additional EV chargers as part of the public parking lot. The infrastructure installed for these will be designed for easy expansion.

For any EV, ranging from golf carts to Tesla’s, the amount of energy required per-charge per-vehicle (including a factor of safety) would be 1.1 times the battery pack size of said vehicle. With all this in mind, the data that is presented here shows us the costs for charging EVs and the amount of energy required to charge the EV. This is dictated mainly by the rate of charging (i.e. AC slow charging or DC Fast charging).

As discussed earlier in the document, the cost for the Tesla Wall Charger would be (500+1550) fixed + 1331 (electricity cost/year) and three of them placed near the Duplicable City Center would be sufficient for our initial needs.

Note: It could be true that a certain set of people are willing to spend more on charging equipment to charge their EVs faster. For them, Level 3 or Level 4 charging would be appropriate.

The graph below illustrates the charging prices versus charging levels. This does not include other costs like wiring needed for setting up the chargers. The prices are based on cost estimates for Utah, in the USA. The EV is considered to be equipped with a 100 kWh battery pack without any inherent defects.

Charging levels 4 and 5 appear to cost roughly the same amount, indicating that after a certain bandwidth the demand charges and consumption charges remain the same. Between levels 1-3 the costs and charging levels are positively correlated as they increase.

ONE COMMUNITY’S PLAN FOR EVS AND EV CHARGING

Based on the previously discussed results, we plan to use the Tesla Wall Chargers to charge the Tesla Model 3 and Model X for the initial phase 1d rollout. We’re choosing this as it would be the ideal for our requirements. The consumers will be using the vehicles during the day and be charging them overnight depending on the requirements. There would not be any additional cost needed for the charging infrastructure apart from buying and installing the wall chargers (Approximately $2050 each – see above). These initial 3 chargers will be installed near the City Center. The golf carts can be plugged into a wall-socket and charged with the help of a 1050w on-board smart charger, so no additional infrastructure is required for them.

When the community development progresses beyond phase 2 or 3, we will implement smart charging with level 3 charging. This faster charging will better support the larger number or electric vehicles we expect on the property from visitors and to support our own needs.

For a level 3 charging infrastructure, installation charges are $22,626 per charger, site preparation charges are $12,500 per charger, utility service and transformer chargers can be split among the number of chargers (as this would be the shared equipment) and would amount to $50,000 per 2 chargers. The equipment charges are about $35,000 per charger.

The tables below show the total costs and power requirements for this EV plan.

PHASE 1: LEVEL-1 TESLA WALL CHARGERS (3)

PHASE 2/3: LEVEL-3 CHARGERS (2)

PHASE 1 POWER NEEDS

Total Power Requirements for EVs/day: 362 kWh, so we’d consider 400 kWh to include a factor of safety (FOS).

Note: For the Phase 2 and 3, the “High Voltage Battery Electric Vehicles” will have the additional option of two level-3 chargers. We estimate a maximum of 4 charges each per day, charging 100 kWh batteries from zero to full, so 1600 kWh of additional power will be needed for these.

OPEN SOURCE CONTENT TO BE ADDED LATER

Once on the property, One Community will open source project-launch blueprint the complete process of installing and maintaining our solar-energy infrastructure. We will do this for everything we think will be helpful for those replicating our system(s) as part of the One Community complete open source self-sufficient teacher/demonstration community, village, and/or city model. Upcoming resources will include:

Once on the property, One Community will open source project-launch blueprint the complete process of installing and maintaining our solar-energy infrastructure. We will do this for everything we think will be helpful for those replicating our system(s) as part of the One Community complete open source self-sufficient teacher/demonstration community, village, and/or city model. Upcoming resources will include:

- Layperson’s guide to purchasing all equipment

- Layperson’s guide to working with your county

- Layperson’s guide to installation

- Layperson’s guide to maintenance and upkeep

- Lessons learned during setup and ongoing use/maintenance

- Use this page (click here) if you have a guide/tutorial you’d like to suggest be added here

RESOURCES

- Website: “Electric Vehicle Savings Calculator”

- Website: “Utah Average Gas Prices”

- Article: “Highlights of the Automotive Trends Report”

- Website: “Table of Average Electricity Rates by State”

- Website: “Second Generation Wall Connector”

- PDF: “Installation Guide For Second Generation Walla Connector”

- Website: “AAA Gas Prices”

- Website: “Commercially Available Battery”

- Website: “Environmental Protection Agency Automobile Statistics for 2020”

- Website: “HOMER (Hybrid Optimization of Multiple Energy Resources) GRID Software”

- Article: “What Are Fixed Charges?“

- PDF: “Feasibility Study on Renewable Energy-Based Micro Grid Power Generation System in Rural Areas of Yobe State Nigeria”

- Study: “The Viability of Vehicle-to-grid Operations from a Battery Technology and Policy Perspective”

- Article: “Vehicle-to-grid (V2g): Everything You Need to Know”

- PDF: “Charging the Future: Challenges and Opportunities for Electric Vehicle Adoption”

- Website: “US Retail Gas Price Weekly Insights”

- Website: “How much does electricity cost by state?”

- Article: “Maintenance Costs Compared: EV vs ICE”

- Use this page (click here) if you have a resource you’d like to suggest be added here

SUMMARY

Electric vehicle (EV) integration is part of the Highest Good energy component of One Community. This open source tutorial aims to provide information regarding the role of electric vehicles (EVs) within a sustainable community, how to charge them, and explore the possibilities of using them for emergency power if needed. As we implement them as part of constructing the Duplicable City Center, Earthbag Village (Pod 1), the 6 villages to follow, we will add and update here our experience regarding the selection process, increasing their charging efficiency, utilizing them as sources for emergency power, etc.

Electric vehicle (EV) integration is part of the Highest Good energy component of One Community. This open source tutorial aims to provide information regarding the role of electric vehicles (EVs) within a sustainable community, how to charge them, and explore the possibilities of using them for emergency power if needed. As we implement them as part of constructing the Duplicable City Center, Earthbag Village (Pod 1), the 6 villages to follow, we will add and update here our experience regarding the selection process, increasing their charging efficiency, utilizing them as sources for emergency power, etc.

FREQUENTLY ANSWERED QUESTIONS

Q: Is this guide complete?

This page is not considered by us to be a complete and usable tutorial until we finish our own EV integration, EV-infrastructure demo construction and add all the videos and experience from that build to this page.

One Community

One Community