Duplicable City Center Sprinkler and Emergency Systems Design

This page is about the open source development of the sprinkler and emergency systems for the Duplicable City Center®. It is purposed to share the specifics of the design, implementation, and maintenance of the complete City Center emergency systems and their integration with the automation, monitoring, and control systems.

We discuss this with the following sections:

- What is Sprinkler and Emergency Systems Design

- Why Open Source Sprinkler and Emergency Systems Design

- Ways to Contribute to this Open Source Component

- Key Consultants to this Component of One Community

- Open Source Sprinkler System Design Details

- Open Source Emergency Lighting Design Details

- Resources

- Summary

- FAQ

- References

NOTE: THIS PAGE IS NOT CONSIDERED BY US TO BE A COMPLETE AND USABLE TUTORIAL UNTIL

WE FINISH OUR OWN CONSTRUCTION OF THIS COMPONENT, CONFIRM ALL THE DETAILS, AND ADD

TO THIS PAGE ALL THE RELATED VIDEOS, EXPERIENCE, AND OTHER UPDATES FROM THAT BUILD.

IN THE MEANTIME, YOU CAN HELP US COMPLETE IT ALL SOONER WITH THE FOLLOWING OPTIONS:

INPUT & FEEDBACK | JOIN OUR TEAM | HELP US BUY THE PROPERTY

RELATED PAGES

WHAT IS SPRINKLER

AND EMERGENCY SYSTEMS DESIGN

Fire Suppression systems have been governed by the codes under the NFPA (National Fire Protection Association) 13D since 1980. NFPA 13 was then introduced for residential dwellings, and is commonly used in areas with heavy power equipment and/or deemed as “hazardous areas.” To meet code they use a combination of dry chemicals and/or wet agents to suppress equipment fires. Common means of detection are through heat sensors, wiring, or manual detection.1

Fire Suppression systems have been governed by the codes under the NFPA (National Fire Protection Association) 13D since 1980. NFPA 13 was then introduced for residential dwellings, and is commonly used in areas with heavy power equipment and/or deemed as “hazardous areas.” To meet code they use a combination of dry chemicals and/or wet agents to suppress equipment fires. Common means of detection are through heat sensors, wiring, or manual detection.1

This page shows how we’ve applied the most current code requirements for the Duplicable City Center® overhead and horizontal fire-suppression sprinkler systems and the related lighting and evacuation plans and designs. These integrate with the open source control and automation systems we’re designing and work in conjunction with the property-wide remote-village-construction emergency fire, medical, and evacuation plan. As we finish these designs and then install and maintain them, we will open source and share here all the data we gather, everything we learn, and our ongoing modifications and evolutions to help others to more easily learn from, replicate, and/or improve these designs.

WHY OPEN SOURCE

SPRINKLER & EMERGENCY SYSTEMS DESIGN

Fire suppression and safety during an emergency are essential components of commercial building design. Our goal in open sourcing the Duplicable City Center sprinkler systems, emergency lighting designs, evacuation plans, and related property-wide emergency fire, medical, and evacuation plan is to provide useful data for:

Fire suppression and safety during an emergency are essential components of commercial building design. Our goal in open sourcing the Duplicable City Center sprinkler systems, emergency lighting designs, evacuation plans, and related property-wide emergency fire, medical, and evacuation plan is to provide useful data for:

- Permitting and designs that meet US standards

- Open source replication and improvement

- Global collaboration and sharing

- Academic interest and reference

This open source aspect of the City Center will additionally contribute to our global-change methodology by functioning as a testing space for emergency-related equipment and planning.

WAYS TO CONTRIBUTE TO THE CITY CENTER HEATING AND COOLING DESIGN

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

KEY CONSULTANTS TO THE CITY CENTER HEATING AND COOLING DESIGN

Ashish Hirani: Fire Protection Engineer

Dehua Feng: E.I.T., Civil Engineer – Lead Project Manager & Main Designer

Diogo Rozada: Civil Engineering Student and Initial Project Coordinator

Izadora Carvalho: Civil Engineering Student

James Nance: Mechanical Engineer and Initial Project Manager

Joao Bernardes: Civil Engineering Student

Mateus Barretto: Civil Engineering Student

Roberto Santos: Civil Engineering Student

SPRINKLER DESIGN DETAILS

These open source sprinkler designs were accomplished through several steps. The first step was to classify and split the zones by their different functions, locations, and occupancy levels. Then we used the ICC and NFPA codes to check if each zone/fire area met the conditions requiring an automatic fire protection system. From there we chose the hardware, created the initial design, and ran initial calculations based on the hazard levels and related density demands. The designs were then updated and new calculations were run from the sprinkler head back to the pumps in the boiler room. Once the calculations and design updates were completed, we then produced the cost analysis.

These open source sprinkler designs were accomplished through several steps. The first step was to classify and split the zones by their different functions, locations, and occupancy levels. Then we used the ICC and NFPA codes to check if each zone/fire area met the conditions requiring an automatic fire protection system. From there we chose the hardware, created the initial design, and ran initial calculations based on the hazard levels and related density demands. The designs were then updated and new calculations were run from the sprinkler head back to the pumps in the boiler room. Once the calculations and design updates were completed, we then produced the cost analysis.

We discuss all these details of the design process with the following sections:

- Classifications

- Checking Conditions for Each Zone

- Sprinkler Head and Pipe Selection

- Sprinkler Head Location and Number

- System Demand

- Standpipe System

- Preliminary Design

- Hydraulic Calculations

- Cost and Material Analysis

CLASSIFICATIONS

The first step when designing a fire protection system is to classify the building zones based on use and occupancy. This is done using the International Code Council (ICC) and based on the characteristics of each building section. The ICC classifies structures and portions of structures using the groups and subgroups in the table below4.

International Code Council Designations Based on Use

The Duplicable City Center, like most public-use structures, has different sections for different purposes. Here are the 14 fire zones with their areas, functions, occupancy classifications, and occupancy loads. Wherever a zone was multi-functional, we assumed the most conservative/worst-case scenario.

City Center Sprinkler Zones Classifications Based on Area, Function, and Occupancy Load

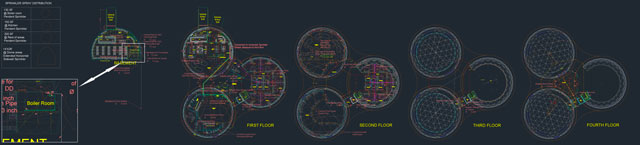

Here is the graphical (AutoCAD) representation of all these zones:

CHECKING CONDITIONS FOR EACH ZONE

The next step was to verify if each fire area/zone should or should not be covered by the automatic sprinklers system. We did this by checking the conditions for each fire zone. If any condition is met, that particular zone should be protected by the sprinklers. What follows is our analysis of each zone starting at the bottom floor (Basement Zone A) and working our way up.

FIRE ZONE AREA A

Zone area A is the basement food storage room located below the kitchen:

Basement Zone A – Outlined in Green

According to the International Building Code – Group S-1: An automatic sprinkler system shall be provided for Group S-1 occupancies in the following areas where one or more of the following conditions exist:

Zone A Evaluation Using International Building Code Group S-1 Term Conditions

None of the above conditions exist, so Area A does not require a sprinkler system.

FIRE ZONE AREA B

Zone area B is the boiler room which is considered as incidental use with high hazardous classification.

Boiler Room Zone B – Outlined in Green

According to the International Building Code, area B is considered as incidental use area because it is separate from the main area. This area includes the boiler room. If it contains any boiler over 15 psi and 10 horsepower (which it does), a one-hour fire-resistant-related separation or an automatic sprinkler system is required. With this in mind, we decided to design an automatic sprinkler system for it and to meet high-hazard classification standards.

FIRE ZONE AREAS C, D, AND I

The fire zone area C is the restaurant kitchen area and D is the dining area. These two areas have been considered and designed together because there is no fire-barrier wall between them. Area I is another dining hall located on the second floor and directly above the kitchen.

According to the International Building Code – Group A-2: An automatic sprinkler system shall be provided for group A-2 occupancies where one or more of the following conditions exists:

Zones C & D Evaluation Using International Building Code Group A-2 Term Conditions

Zone areas C, D, and I all require the sprinkler system because they all meet condition 2. Area I also meets condition 3.

FIRE ZONE AREA E

Area E contains the outdoor swimming pool and spa located on the first floor.

According to the International Building Code – Group A-4: An automatic sprinkler system shall be provided for group A-4 occupancies where one or more of the following conditions exists:

Zone E Evaluation Using International Building Code Group A-4 Term Conditions

None of the necessary conditions exist, so area E does not require a sprinkler system.

FIRE ZONE AREAS F AND K

Fire zone areas F and K are the first and second floor guest rooms and bathrooms.

According to International Building Code – Group R: An automatic sprinkler system shall be provided throughout all hotel buildings with a Group R fire area. In order to provide sufficient sprinkler coverage of the entire area, an automatic sprinkler system shall also be provided for Group R hotel closets and bathrooms if either of the following two conditions are met:

Zones F & K Evaluation Using International Building Code Group R-1 Term Conditions

All subgroups of F and K meet either the conditions of 1 or 2 and require an automatic sprinkler system.

FIRE ZONE AREAS G, L, AND N

Area G and L are parts of the Social Dome and used for large-scale social and recreational use. On the 4th floor, Zone N is the cupola and also for social and recreational use.

According to International Building Code – Group A-3: An automatic sprinkler system shall be provided for group A-3 occupancies where one or more of the following conditions exist:

Zones G, L, & N Evaluation Using International Building Code Group A-3 Term Conditions

Area G requires a sprinkler system because it meets condition 2.

Area L requires a sprinkler system because it meets condition 2 and 3.

Area N requires a sprinkler system because it meets condition 3.

FIRE ZONE AREA H

Fire zone area H is the library and game room that is located on the first floor. We decide to classify area H as a Group B area.

According to the International Building Code – Group B: An automatic sprinkler system shall be provided for group B occupancies where one or more of the following conditions exists:

Zone H Evaluation Using International Building Code Group B Term Conditions

Area H does not require a sprinkler system, because none of the necessary conditions exist.

FIRE ZONE AREAS J AND M

Fire zone area J is the central mezzanine level and fire zone area M is the open patio. Both of these are open-air zones used for social activities.

According to International Building Code – Group A-5: An automatic sprinkler system shall be provided for Group A-5 occupancies if one or more of the following conditions exist:

Zones J & M Evaluation Using International Building Code Group A-5 Term Conditions

Areas J and M are not “concession stands, retail areas, press boxes and other accessory use areas” so they don’t meet condition 1. Area J and M do meet condition 2, but we decide not to use a sprinkler system because they satisfy the exception 8.15.7.2.

SPRINKLER HEAD AND PIPE SELECTION

The first consideration for sprinkler head and pipe selection was understanding the water pressure needed to run the sprinklers effectively. According to the terms on NFPA 13 section 23.4.4.10 and 23.4.4.11, minimum operating pressure for any sprinkler should be at least 7 psi (or 0.5 bar) to gain enough power to project water efficiently. On the other hand, extremely high pressure could change water into mist or spray that may not suppress fire well enough. This is most problematic in extra-hazard occupancies. In these areas, the maximum operating pressure is 175 psi (12.1 bar). Examples of extra hazard occupancies are palletized, solid pile, bin box, back-to-back shelf storage, shelf storage, or rack storage. You can see the NFPA 13 documentation for definitions of all of these.

Keeping this in mind, the next consideration was hardware selection. The market provides a variety of sprinkler head options and we may choose to switch the brand or type if cost analysis shows significant enough benefits. For easiest replication though, we decide to select the most common types for our initial design. This led to choosing a standard-response pendent sprinkler VK122 with a 5.6 K-factor for the indoor zones with flat ceilings such as Area A, B, C, D, F, K, and N7.

Note: The K-factor is important because it is used to calculate the PSI and related pipe size.

Our structure also has dome-shaped roof areas. These include areas G, L, and I and they need to be covered by a different type of sprinkler. The sprinkler needed for these areas are wall mounted and spray horizontally rather than hanging from the ceiling. They are called extended coverage horizontal sprinklers. Researching these, we chose the Viking Group Inc. vk630 (K-factor of 8.0) horizontal sprinkler for our preliminary design. This sprinkler had the highest width and throw combination (14 X 26 ft.) and a discharge rate and pressure requirement of 46 GPM and 33.1 PSI8.

Operation temperature was also a consideration. Wet-pipe systems are cheaper and more commonly used, but temperatures too cold or hot can cause wet-pipe sprinkler pipes to burst. About 99% of our pipe sections are located inside the building or in the wall. So the operating temperature is not a problem for any of these areas. We’ll insulate the remaining 1% of exposed pipe to protect it. Because of this, we were able to choose a wet-pipe system for our design8.

We also ran into a challenge with our horizontal sprinklers. These required a distance of 6 to 12 inches to the ceiling to trigger them during a fire8. This distance could not be accommodated for our dome-shape ceiling areas requiring these sprinklers. Because of this, we needed a special activation system to make these work properly. Viking provides this as a “Deluge & Preaction System” that activates the system and sprays water out from all the connected sprinklers when separate smoke and heat detectors are triggered10, 11.

Here is a picture of how this system addition looks:

SPRINKLER HEAD LOCATION AND NUMBER

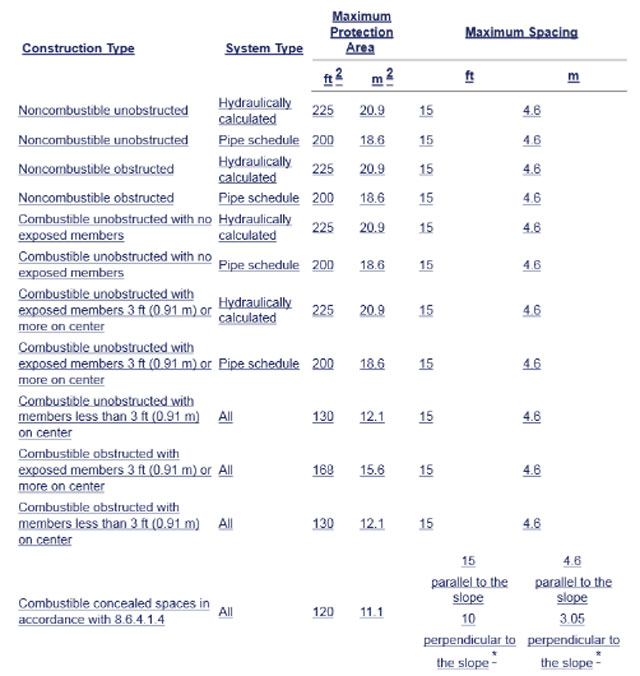

There were two main criteria for the location of sprinkler heads. First, sprinklers not on the Deluge & Preaction System described above must be located so they were within the hot-gas layer that develops near the ceiling during a fire. This is because activation occurs when the sprinkler head reaches a certain temperature. Second, they must be located so that the water that is discharged from the sprinkler was not disrupted or affected by construction elements such as beams, trusses, or soffits (arches, balconies, etc.). Additionally, depending on occupancy hazard, ICC code requires a sprinkler distance less than 12-15 feet, but no less than 6′, depending on the occupancy hazard of the zone. Sprinklers should also be between 1 to 12 inches distance from ceiling18. The detailed spacing requirements are shown here:

According to the NFPA and using the occupancy hazard data shown below, we can get a rough idea of how many sprinkler heads we’ll need in each zone before we start designing in AutoCAD.

Initial Calculations for Sprinklers Needed in Each Zone

For the fire areas/zones F and K with residential occupancy, we split the zones into small parts so we could calculate each of the residential units and bathrooms separately. The table below shows these calculations:

Initial Calculations for Sprinklers Needed in Zone F and Zone K Sub-zones

Using the data in Figure 11.2.3.1.1 below, we saw that adopting a density in the range of 0.07 to 0.10 gpm/ft² was sufficient to meet the requirements of a “Light Hazard” area for zones D, F, I, J, K, L, and N. Adopting a density of 0.2 gpm/ft2 was sufficient to meet the requisites of the “Ordinary Hazard 2” that the boiler room Zone B falls into. Kitchen Zone C falls in the middle as an “Ordinary Hazard 1” area within the 0.1 to 0.15 gpm/ft2 density range.

SYSTEM DEMAND

Using the area for each zone, we could then be more specific with our densities and use this for sizing our gallons-per-minute system demand. The table below shows the addition of this data:

For residential zones F and K, the integrated system demand is shown above as 232.36 and 209.83 respectively. If we calculate separately as shown below, the average of the smaller sub-zones is 220 and 194.88 respectively.

Sprinkler System Demand Zones F and K

Comparing those two approaches, we chose to be conservative and use the larger number. With this, adding all the system demands for each group produces the following total system demand for our system: 68.76 + 351.17 + 152.40 + 232.36 + 174.08 + 208.11 + 209.83 + 177.44 + 162.42 = 1736.57 gpm

STANDPIPE SYSTEM

The purpose of installing a standpipe system is to provide a readily accessible water supply for use by fire department personnel and/or trained occupants during fire situations. Typically, standpipes are required in a building where the floor level of the highest story is located more than 30 feet above the lowest level of fire department vehicle access or where the floor level of the lowest story is located more than 30 feet below the highest level of fire department vehicle access. The cupola roof, the highest point of our structure, is roughly 50 feet above the ground. Because of this, we have to add fire hydrant access points to our pipe system.

After reviewing the layout, we decide to set up two fire hydrants located adjacent to the laundry entry in the North and the entry by the elevator to the South. Based on the requirements of NFPA 14, the minimum operating pressure and flow rates for these hydrants are 100 psi and 1000 gpm for 30 minutes.23

Using the guideline below, we decide to use a 2-hour water supply duration for our design and to size our reservoir.

The table below gives a view of the reservoir size in gallons and cubic feet. However, the calculations in the table below are only theoretical results. Next we needed to compare the designed system demand after sprinkler setup and then select the larger of the two numbers for safety purposes. We do this in the following chapter.

Sprinkler Design Reservoir Sizing – Click to open the Google Spreadsheet with the most current details

The next step was to calculate the end-head flow that is required to provide the minimum specified water density to the most remote sprinkler head for each zone. The equation used for this is: QE = Design Area Ô Design Density20 The “End-head Flow Q” for each area is the required minimum flow for proper sprinkler head function based on the manufacturer’s data tables16. Here is our calculated initial end-head flow we used for the next design steps:

Sprinkler Design End-head Flow Calculations – Click to open the spreadsheet with the most current details

Note that the K-factor (“K” above) demonstrates the size and shape of the orifice of the sprinkler head. We chose the K-factor for our sprinkler and hydraulic calculations based on our manufacturer’s data16 and this chart:

Sprinkler Discharge Characteristics Identification

In our project, we used ½ inch for the “Thread Type” with Nominal K-factor of 5.6 because these are associated with the most common and cheapest sprinkler.

Next, using 5.6 as K-factor and the corresponding end-head flow, we could then solve the end-head pressure with the following equation:

Sprinkler End-head Pressure Calculations – Click to open in a new tab the spreadsheet with the most current data

PRELIMINARY DESIGN

Using the above requirements and assumptions, we could then start to design the initial system in AutoCAD. The first step was to start placing and moving around the sprinklers to make sure their coverage overlapped each other enough to cover all the areas that need protection. The image below shows this.

Next we needed to consider the pressure threshold of each pipe. Originating from the boiler room, we split the pipe system into five vertical pipe systems plus a pipe to supply the two fire hydrants. The water riser pumps water up from the boiler room through vertical pipes. These vertical pipes then transport the water to the different sections on the various levels.

Referencing the vertical pipes from left to right:

- The pipes in light green (color code “110” in AutoCAD) cover the Dining Dome and internal Social Dome pool area.

- The pipes in magenta (color code “magenta” in AutoCAD) cross the Living Dome supplying water to the regular pendent-sprinkler system.

- The pipes in dark yellow (color code “40” in AutoCAD) reach the top floor that holds the Cupola.

- The pipes in light blue (color code “132” in AutoCAD) are the pipelines for the horizontal sprinklers covering the Social Dome.

- The pipes in red (color code “20” in AutoCAD) are supplying the Dining Dome horizontal sprinklers with the main pipes running in the ceiling of the first floor and the branches coming up inside the sidewalls of the 2nd floor.

Here is a graphic with the complete design:

HYDRAULIC CALCULATIONS

Hydraulic calculations are performed in a direction opposite to the normal direction of flow. The calculation start point is the end-head pressure and end-head flow. Calculations are then performed from there back to the source. We discuss the process with the following sections:

Hydraulic calculations are performed in a direction opposite to the normal direction of flow. The calculation start point is the end-head pressure and end-head flow. Calculations are then performed from there back to the source. We discuss the process with the following sections:

- Assumptions

- Steel vs. PVC Considerations

- Pressure Calculations

- Flow Rate Calculations

- Calculations Results Summaries

- Reservoir Sizing

ASSUMPTIONS

For these calculations we assumed the vertical pipe diameter as 3.5 inches, main pipe diameter as 2.5 inches, and the branch pipe diameter as 1.5 inches.

STEEL VS. PVC CONSIDERATIONS

Consideration of the advantages and disadvantages of steel versus PVC pipe also became important at this point. Based on NFPA 1317, we decided to use steel pipe for all the vertical pipes, boiler room pipes, and pipes in the Dining Dome. This choice was made because:

- All these pipes originate in the boiler room and that zone is classified as fire hazard “Ordinary 2,” a zone that does not allow for PVC pipe.

- They can handle higher pressures and many of the pressures of the water flowing in the vertical pipes were beyond the pressure threshold of CPVC pipe.

The rest of the areas were designed using CPVC because it is acceptable for “Light” fire hazard zones, sufficient for the pressures present in the non-vertical piping areas, and more cost-effective. The diameters mentioned above are nominal diameters, we used inner diameter for hydraulic calculations. The inner diameters of steel pipe15 are shown below.

Steel Pipe Dimensions

Here is the diameter table for Viking CPVC products18 too.

CPVC Pipe Diameter

PRESSURE CALCULATIONS

For pressure calculations, demonstrating sufficient initial pressure means the pressure should be larger or equal to the summation of whichever is larger, end-head pressure or initial pressure, plus the elevation loss, friction loss, velocity pressure loss, and 10% safety factor. End-head pressure was larger for us, so desired initial pressure = End-head pressure + elevation loss + friction loss + velocity pressure loss + 10% safety factor.

The elevation loss equation is:

Friction loss has two parts – regular friction loss and equivalent friction loss of pipe fitting and valve. This formula includes both:

The friction resistance (“p”) comes from the length of the pipes while also factoring in the equivalent friction loss of the pipe fittings and valves using this chart:

Velocity pressure loss is also a factor that must be included. The velocity loss is parallel to the friction loss. It does nothing with the above calculations. It only needs to add to the end pressure when two pipes merge together with different diameters. Here is the equation:

When two branches merge, there are two situations. If these two branches are identical, the combined pressure is the sum of both. If those two are not identical, we need to adjust the K-factor using the Conventional Method or Simple Proportion or Additive K Factor23. Because of this, we decided to modify our CAD design to make sure most of the branches were identical.

FLOW RATE CALCULATIONS

The calculations for flow rate are simpler than the pressure calculations. The flow rate for the main pipe will remain the same for every segment that doesn’t have a branch coming off of it. For flow rate calculations with branches, you add up the flow from each sprinkler in a branch. If the branch on the opposite side of the main pipe is the same, they can be summed. If the branches coming off of the main pipe are different, you calculate the new flow rate by using the following algorithm23 where the the flow rate QB is equal to QA plus Qnew.

Sprinkler Flow Rate for Branches of Different Sizes

CALCULATION RESULTS SUMMARY

Putting everything above into one chart of calculations yielded the zone charts below. You can click each image to be taken to the open source spreadsheet with the most current data. See the Classifications section above for why zones A, E, H, J, and M do not require an emergency sprinkler system.

Here is the legend of terms used in the spreadsheets:

Open Source Emergency Sprinkler Calculation Legend of Terms

For easy reference, here (again) is the graphical (AutoCAD) representation of all the zones:

In the images below, colored cells have colors that correspond to the best of our ability with the same colored pipes in the AutoCAD file. “Horizontal Heads” mean horizontal spray disbursement and “Regular Head” means top-down pendant-style sprinklers. If not labeled otherwise, they are regular heads.

Also, only the sprinkler heads have results as either “valid” or “invalid” because that point represents the entire line. By calculating backwards (as described above) we were able to design to confirm they are all valid.

Here are the calculations for Fire Zone B:

Fire Zone B Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Fire Zone B Fire Hydrant Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone C:

Fire Zone C Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Fire Zone C Horizontal Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone D:

Fire Zone D Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Fire Zone D Horizontal Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone F:

Fire Zone F Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone G:

Fire Zone G Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Fire Zone G Horizontal Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone I:

Fire Zone I Horizontal Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone K:

Fire Zone K Regular Head Calculations – Click to open the Google Spreadsheet with the most current data

Here are the calculations for Fire Zone L:

Here are the calculations for Fire Zone N:

RESERVOIR SIZING

Using the data above and a worst-case scenario of needing 2-hours of total building sprinkler system operation, the following table was created to size the reservoir. This table calculates how much water the reservoir must contain for this purpose by multiplying the number of sprinkler heads in a zone by the flow rate of each head times the duration desired.

COST AND MATERIAL ANALYSIS

The last part of this tutorial is the fire sprinkler cost analysis and materials summary. The cost analysis for this component of the Duplicable City Center can be divided into two categories:

WATER RESERVOIR COSTS

Based on the Practical Reservoir Sizing table above, we know the reservoir size we’ll need to provide two hours of water for the complete City Center sprinkler system is 504,221 gallons. The property/location our structure will be built on is too remote to be connected to a municipal water system. This means we’ll need a reservoir of at least this size. It will need to be much larger if it is to service the fire and other water needs of any or all of the other 7 villages too.

Costs for building a reservoir of this size were hard to find. To get an estimated cost, we used data we found for construction of large reservoirs in the state of Pennsylvania. The table below shows our data and yields an average reservoir construction cost of $0.38 per gallon. This would mean spending $191,604 to build a reservoir to meet our sprinkler needs for the City Center.

Water Tank Construction Costs in Pennsylvania – Click for the open source spreadsheet with the most current data

We could easily need a reservoir ten times this size (or even larger) to also meet the needs of the other 7 villages. Because of this and the high per-gallon costs for a reservoir of this size, we are exploring the process and costs associated with creating a lake to meet these needs instead. This would have the the added benefits of providing something beautiful and usable in the summer and may function as a natural greywater processing option too.

PIPING AND FITTINGS COSTS

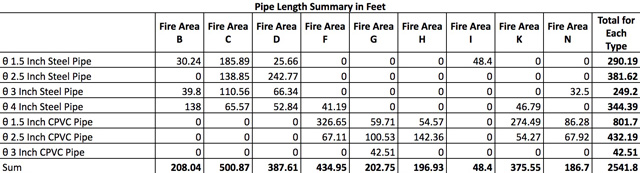

Pipe, fittings, and valves for the complete system can be deduced from the spreadsheets and AutoCAD file. Here is the chart showing the total pipe lengths needed for the various diameters.

Here is the chart with all of the fittings and valves.

Costs will vary by location and purchasing source. That said, here is our initial cost analysis summary for all of the above when sourced using internet providers like Home Depot, Amazon, etc. We expect buying locally and in bulk will be cheaper.

Image coming…

EMERGENCY LIGHTING DESIGN DETAILS

The emergency lighting details have not yet been designed. Contact us if you have the necessary experience and would like to volunteer your time to help us finish them.

RESOURCES

- Article about the properties of Chlorinated Polyvinyl Chloride (CPVC) pipe

- Article: “The Benefits of CPVC Fire-Sprinkler Systems”

- Article:”Pennsylvania American Water Announces $16.5 Million Investment to Construct and Rehab Water Storage Tanks”

SUMMARY

Fire safety design is an important part of building safety. We’re sharing here how we’ve applied the most current code requirements for the Duplicable City Center® overhead and horizontal fire-suppression sprinkler systems and the related lighting and evacuation plans and designs. These integrate with the open source control and automation systems we’re designing and work in conjunction with the property-wide remote-village-construction emergency fire, medical, and evacuation plan. As we finish these designs and then install and maintain them, we will open source and share here all the data we gather, everything we learn, and our ongoing modifications and evolutions to help others to more easily learn from, replicate, and/or improve these designs.

Fire safety design is an important part of building safety. We’re sharing here how we’ve applied the most current code requirements for the Duplicable City Center® overhead and horizontal fire-suppression sprinkler systems and the related lighting and evacuation plans and designs. These integrate with the open source control and automation systems we’re designing and work in conjunction with the property-wide remote-village-construction emergency fire, medical, and evacuation plan. As we finish these designs and then install and maintain them, we will open source and share here all the data we gather, everything we learn, and our ongoing modifications and evolutions to help others to more easily learn from, replicate, and/or improve these designs.

FREQUENTLY ANSWERED QUESTIONS

Q: What measures are in place to protect the building from external fire threats?

The Duplicable City Center is being designed with aluminum cladding covering the domes, fire-resistant plaster on all other external surfaces, and fire-resistant flooring on all open-air exposed walking surfaces. The building additionally includes two appropriately placed fire hydrants and 360° easy access for fire trucks. We also have a comprehensive and open source fire-preparation and medical emergency plan for protecting the property from forest fires and during other natural disasters.

REFERENCES

This DropBox link also contains all the PDFs below: DCC Dropbox Folder #9 – FAPA – Fire and Sprinkler

- Reference 1: Residential Sprinkler Systems PDF

- Reference 2: NYC Chapter 29 Sprinkler Systems PDF

- Reference 3: NJ Fire Protection System PDF

- Reference 4: NYC Use and Occupancy Classification PDF

- Reference 5: Fire-flow Requirements for Building PDF

- Reference 6: Exit Discharge

- Reference 7: Viking Spec Sheet – VK122 (K5.6) PDF

- Reference 8: Viking Spec Sheet – VK630 (k8.0) PDF

- Reference 9: Automatic Sprinkler System Calculations PDF

- Reference 10: Viking Deluge System Spec Sheet PDF

- Reference 11: Viking Pre-action System Spec Sheet PDF

- Reference 12: National Fire Protection Association Report PDF

- Reference 13: NFPA Water Tanks for Private Fire Protection PDF

- Reference 14: Fire Protection Systems End-flow Resource PDF

- Reference 15: Steel Pipe Inner Diameter Dimensions

- Reference 16: Viking Horizontal Head Spec Sheet – (VK638) Tech Table PDF

- Reference 17: NFPA 13 Pipe Material PDF

- Reference 18: Viking CPVC Pipe and Fittings Spec Sheet PDF

- Reference 19: 2015 International Building Code section 903.2

- Reference 20: GPM Calculations

- Reference 21: Pressure drop calculation of branch pipes

- Reference 22: NFPA 14 Standard for the Installation of Standpipe and Hose Systems PDF

- Reference 23: Sprinkler System Hydraulics PDF (auto downloads – check your downloads folder)

One Community

One Community