Wind Energy Setup and Maintenance

This page is the do-it-yourself wind energy research, cost analysis, implementation, and maintenance open source hub for the Highest Good energy component of One Community. It discusses our wind energy infrastructure details with the following sections:

- What is Wind Energy

- Why Open Source Wind Energy Design and Setup

- Ways to Contribute

- Consultants

- Wind Energy Design and Implementation Details

- Wind Energy Infrastructure Cost Analysis

- One Community’s Plan for Wind Power

- Open Source Content Coming Later

- Resources

- Summary

- FAQ

RELATED PAGES (Click icons for the complete pages)

WHAT IS WIND ENERGY

Wind Energy is energy carried by winds, caused by uneven heating of the atmosphere by the sun, irregularities of the earth’s surface, and rotation of the Earth. Wind-flow patterns are modified by the Earth’s terrain, bodies of water, and vegetative cover. This wind flow (motion energy) when “harvested” by modern wind turbines can be used to generate electricity. This electricity is a renewable source because, as long as there is sun, there will also be wind.

Wind Energy is energy carried by winds, caused by uneven heating of the atmosphere by the sun, irregularities of the earth’s surface, and rotation of the Earth. Wind-flow patterns are modified by the Earth’s terrain, bodies of water, and vegetative cover. This wind flow (motion energy) when “harvested” by modern wind turbines can be used to generate electricity. This electricity is a renewable source because, as long as there is sun, there will also be wind.

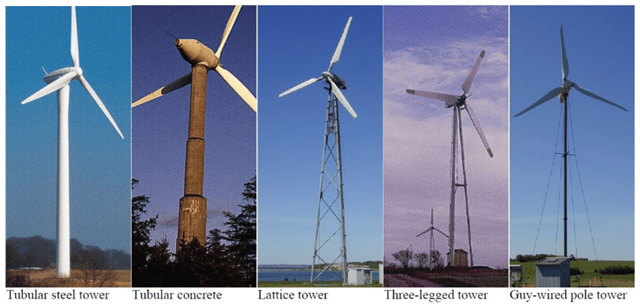

So how is power generated? In simple terms, the energy in the wind rotates the blades of a windmill or tower structure, these blades then rotate the shaft of a turbine encased inside the structure. This turbine then functions as a generator which produces electricity as its shafts turn. This electricity is then given to a customer (residential), a group of customers (community), or collected along with other windmills (wind farms) to supply to a large-scale transmission grid.

The process looks like this:

Here’s a video about how a wind turbine works:

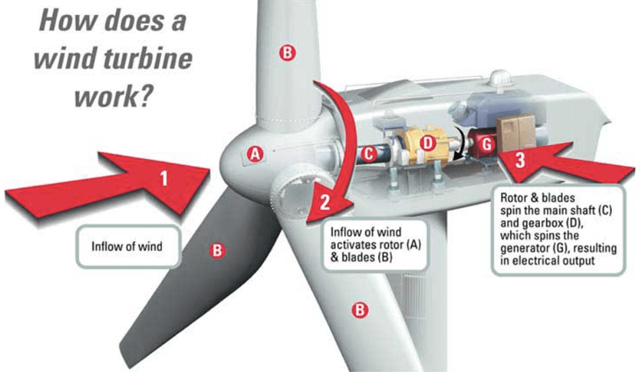

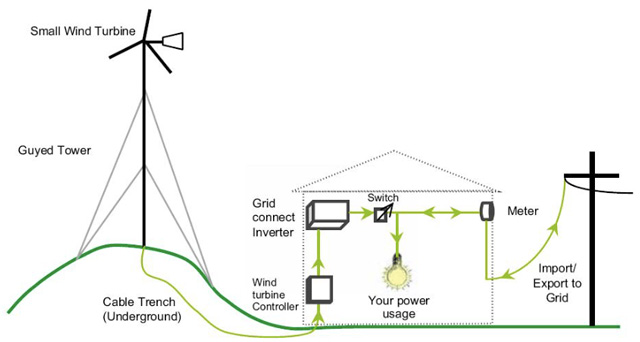

Here is a visual representation of the process of wind energy being used to provide power to a building:

WHY OPEN SOURCE

WIND ENERGY DESIGN AND SETUP

Sustainable and open-source-replicable energy infrastructure is part of One Community’s goals for helping create self-replicating and sustainable teacher/demonstration hubs collaborating for positive global change. What we see as missing, for those with a cleaner and more sustainable vision of electric power, is helpful guidance and do-it-yourself tutorials. Millions of people around the globe still lack reliable electricity and governments are still years away from connecting all these places with their respective state grids. We’re open sourcing wind energy design and setup to show how people can create electricity for themselves.

Sustainable and open-source-replicable energy infrastructure is part of One Community’s goals for helping create self-replicating and sustainable teacher/demonstration hubs collaborating for positive global change. What we see as missing, for those with a cleaner and more sustainable vision of electric power, is helpful guidance and do-it-yourself tutorials. Millions of people around the globe still lack reliable electricity and governments are still years away from connecting all these places with their respective state grids. We’re open sourcing wind energy design and setup to show how people can create electricity for themselves.

With the advent of the different types of renewable energy sources like wind, micro-hydro, solar, biogas, etc. and their constantly decreasing prices, the ability for people to create their own renewable power source is better than ever before. Add appropriate technical know-how of renewable energy systems and installation can be fairly easy.

This has the potential to help:

- People desiring a more sustainable way of living

- People in places power isn’t currently available

- People desiring more power self-sufficiency and security

Additionally, in places where there isn’t enough year-round sun, wind can be the best renewable energy option available. With this open source wind energy system tutorial, we hope to provide a replicable and easy-to-follow path to assessing, designing, installing, operating, and maintaining your own wind energy system. The easier, more affordable, and more attractive wind energy can be demonstrated, the more people will adopt it.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CONSULTANTS ON THIS COMPONENT OF ONE COMMUNITY

Ramya Vudi: Electrical Engineer

Shubham Agrawal: Electrical Engineer and Primary Contributor

Yomi Sanyaolu: Mechanical Engineering Graduate and Technical Writer

WIND ENERGY

DESIGN & IMPLEMENTATION DETAILS

Whether you are considering a grid-tied or stand-alone wind energy system, there are 4 main components that require consideration: Assessment, Design, Installation, and Maintenance. We will use our case of a small wind energy system and explore the details of these 4 components with the following sections:

- Grid-tied vs Stand-Alone Wind Systems Overview

- Assessment & Surveying

- Evaluation and Selection of Equipment

- Purchasing and Acquisition

- Placement and Tower-type Considerations

- Noise Issues

- Understanding Wind-system Components

- Installation

- Maintenance and Care Considerations

- Industry Outlook

GRID-TIED VS. STAND-ALONE WIND SYSTEMS OVERVIEW

This adoption of a wind energy system can come in the form of a grid-tied system or a stand-alone system. Both have their advantages and disadvantages. Here’s a quick overview of both. Details of all components are discussed more in the sections that follow.

GRID-TIED WIND SYSTEM EXAMPLE

In the grid-tied system example below you see energy (AC) produced by wind is sent to a controller to distribute some power to the residential area nearby and then the remaining power is sent to the grid via a grid-tied inverter. The grid-tied inverter ensures quality of power and frequency are maintained and the wind system remains isolated from faults on the grid. Nowadays companies like Schneider Electric, ABB, etc. sell advanced grid-tied inverters which play the role of controller as well, thus saving on equipment and space needs.

www.windenergy7.com

www.windenergy7.comSTAND-ALONE WIND SYSTEM EXAMPLE

In a stand-alone system as one shown below, there isn’t a need to have a grid-tied inverter or utility connection. This decreases the overall cost of connections but at the sacrifice of security and reliability because of the absence of a connection to the (usually much more resilient) electric grid.

Understanding these differences though is only the first step. Before choosing a system, you must identify if wind energy is a good choice and allowed for your specific location. Read on for further determination.

ASSESSMENT & SURVEYING

Before deciding on wind as an energy source, check if a wind turbine installation is permissible, if there is enough wind for a system, and then the best site for construction. In the United States, some counties may not allow a wind turbine, or they may, but only with a special license. Before you invest in a wind energy system, research potential zoning and neighborhood rules and/or regulations. You can do this by contacting the county/local building inspector, board of supervisors, and/or planning board. They will tell you if a building permit is required and provide you with a list of requirements.

After that, you need to see if your area receives enough wind and with enough speed. Wind speed increases with increase in height. Generally for a small wind energy system the height is 20-30 m. So you will need the wind speed at that particular height. For that, you can use different wind-resource maps like these:

- WINDExchange: “US Utility-Scale Land-Based 80-Meter Wind Maps”

- National Renewable Energy Laboratory: “Wind Resource Assessment”

If you live out of the U.S., there should be a different database specifically for your country. If there isn’t, check meteorological websites or offices for data pertinent to your country. Otherwise, contact the nearest airport for your estimated wind speed and/or obtain a wind speed measurement from a professional.

If your area has a relatively constant wind speed of 5 meters/second (m/s) (about 10 mph) or more, a small wind turbine might be appropriate because the typical minimum speed at which a wind turbine starts to produce power is 3.5-4 m/s, known as its cut-in speed. At 10-12 m/s they produce maximum power, and when there is a storm with winds exceeding 25 m/s, the wind turbines are designed in such a way that they stop operating (by braking); this cut out speed ensures there is no damage to the turbine.

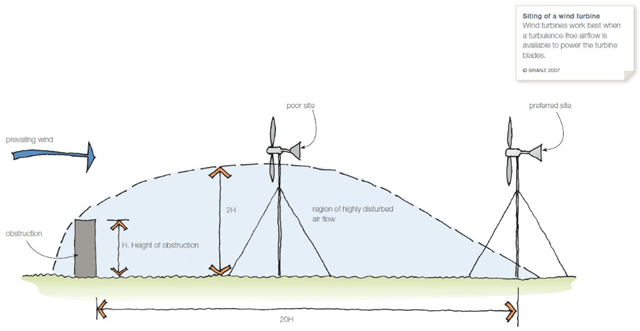

Before designing the wind energy system determine the best location for the wind tower. The rule of thumb for choosing your wind tower location is:

- No considerable hindrance in a 250-300 foot radius of the turbine

- The turbine should be mounted at least 25-30 feet above any nearby wind obstructions

Here is a picture illustrating placement with consideration of obstructions:

These height needs and desire for clearance around your wind turbine may make rooftop installation a choice worth exploring. If so, consider the strength of your building and if local codes permit such an installation. Once you believe your location is qualified per the assessment, proceed with the design of your system.

EVALUATION AND SELECTION OF EQUIPMENT

Evaluation and selection of equipment will start with designing your electrical system and consideration of the complete installation process. To identify what you can do on your own and where you may wish to seek help, ask yourself the following questions:

- Can I pour a proper cement foundation and install guy wires?

- Do I have access to a lift or other way of erecting the tower safely?

- Do I know the difference between alternating current (AC) and direct current (DC) wiring?

- Do I know enough about electricity to safely wire my turbine?

- Do I know how to safely handle and install batteries?

- Do I know how controllers, inverters, disconnect switches, and voltage stabilizers work?

If you answered yes to all of these, you can likely make a completely independent wind energy system on your own. For any areas you don’t feel comfortable or knowledgeable enough to do on your own, call a professional or conduct more research. Building a small “test model” is also helpful.

Here’s an image showing what you should expect for your equipment:

Schematic of a sample small grid connected wind energy system

STAND-ALONE VS. OFF-GRID SYSTEM EQUIPMENT CONSIDERATIONS

Next you need to decide what kind of wind system you want to build. There are two types: Stand-alone (or Off-grid) and Grid-connected. Stand-alone, as the name suggests, is a completely off-grid system supported by batteries that maintain the energy supply when there is insufficient wind. Grid-connected is when the electricity supplied by the wind is supported by the main grid to fill any voids created by intermittent wind; a disconnect switch is used in this case instead of batteries.

Grid-connected systems can be practical if the following conditions exist:

- You live in an area with average annual wind speed of at least 10 miles per hour (4.5 m/s)

- Utility-supplied electricity is expensive in your area (above 10″15 cents per kilowatt-hour)

- The utility’s requirements for connecting your system to its grid are not prohibitively expensive

- There are good incentives for the sale of excess electricity or for the purchase of wind turbines

Stand-alone systems make more sense when:

- You live in an area with average annual wind speed of at least 9 miles per hour (4.0 meters per second)

- A grid connection is not available or is only provided through a costly extension. The cost of running a power line to a remote site to connect with the utility grid can be prohibitive, ranging from $15,000 to more than $50,000 per mile, depending on terrain

- You would like to gain energy independence from the utility

In the end, if all the legal requirements are met, the major decision maker is usually economic considerations. E.g: Batteries might have a high initial cost but connecting the grid to your remote location might be even costlier. So there needs to be a careful evaluation and the sections that follow are purposed to help.

EVALUATING ENERGY NEEDS

Evaluating energy needs is one of the first steps for system design. For any wind energy system, be it off-grid or grid-connected, we have some components in common: A wind turbine, tower, concrete foundation for the tower, and cable connections from the turbine to the equipment room. The sizing and selection of this equipment will vary based on your energy needs.

For example, choosing a wind turbine requires two factors:

- Size of turbine

- Wind speed available at mounted turbine height (determined during the Assessment and Surveying section above and needed to decide the cut-in speed)

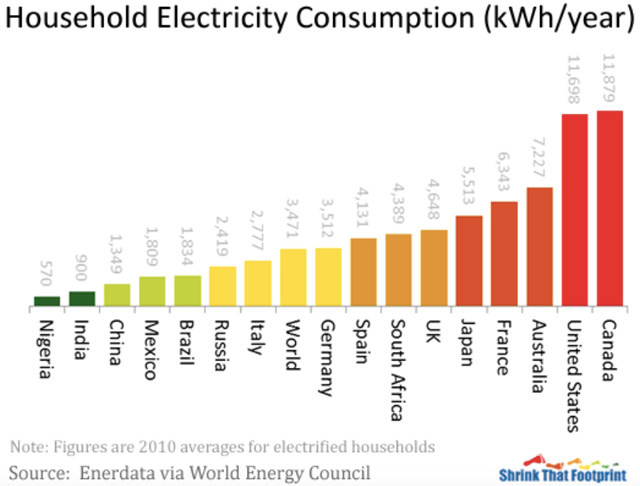

Using energy projections for your specific situation, you can then decide on what size turbine is best for you. The average yearly energy consumption of a normal household (4 members) in the US is around 12,000 kWh, which is almost the highest in the world. It is considerably less for other countries like India, where it is about 900 kWh, and changes from place to place. For reference, see this 2010 data chart:

When assessing specific energy needs calculate manually or via an energy auditor. If you provide your own estimate, there are numerous free helpful online resources available, like this one: http://www.cpi.coop/my-account/online-usage-calculator.

EVALUATING YOUR CAPACITY FACTOR

Next, evaluate your capacity factor. The capacity factor is the average power generated, divided by the rated peak power. This varies by location and is needed to size your turbine large enough to meet your needs.

Using an example of a wind turbine with a five-megawatt peak power rating: if it produces power in your location at an average of two megawatts, then its capacity factor is 40% (2 mW average ÷ 5 mW peak = 0.40, i.e. 40%). Since wind is an intermittent source of energy, it cannot power the turbine at optimum level all the time, so the design sufficient to meet your needs is contingent upon this capacity factor.

Generally, effective wind energy systems lie in the range of a 25-45% capacity factor. Wind farms are designed for maximum efficiency and have a capacity factor as high as 55%. For reference, a 1.5-kilowatt wind turbine with a capacity factor of 30% will meet the needs of a home requiring 300 kilowatt-hours per month in a location with a 14 mile-per-hour (6.26 meters-per-second) annual average wind speed.

How are these calculations made? Suppose the monthly energy requirement of a household is 1000 kWh and we know number of hours in a month is 720, so hourly power required is 1000/720 = 1.4 kW (1.388 rounded up). If we assume a 30% capacity factor, then the required size of the turbine would be (1.4/0.3=4.667) 4.67 kW or 5 kW when rounded up.

If you are willing to work from scratch and/or want to save money, you can make your own wind turbine as well. There are some interesting videos on instructables, wikihow, as well as Youtube. See our resources section for examples.

If you are considering making your own wind turbine, or want a preliminary estimate of the expected performance of any equipment not listed, use the following formula:

AEO= 0.01328 D2 V3

Where:

- AEO = Annual energy output (kilowatt-hours/year)

- D = Rotor diameter, feet

- V = Annual average wind speed, miles-per hour (mph), at your site

PURCHASING AND ACQUISITION

When you buy turbines and blades from dealers, most offer complete turnkey (ready-to-operate) installations or a customer’s purchase and installation option directly from the factory. The first option offers more customer support from the company. Self-installation offers significant savings and a hands-on understanding of the turbine. Prospective owners can discuss the options available with manufacturers to decide which method best suits their budget and technical skills.

Approach buying the equipment as you would any major purchase. You will need to weigh costs and various degrees of design ruggedness/durability. Obtain and review product literature from several manufacturers and research those you want to pursue, ensuring they are recognized businesses and their parts and service are available when needed. Determine the warranty length, what it includes, and ask for references of customers with installations similar to the one under consideration. Ask system owners about performance, reliability, maintenance and repair requirements, and whether the system is meeting their expectations. We’ll additionally be providing all these details on this page once we have our own experience to share.

Dealers should also provide the logistics of the turbine and blades delivery, but if they don’t, or if by not using their delivery service you receive a substantial discount, you will require a sufficient truck and/or tow trailer when transporting the turbine from the dealer to your home. Be very careful with the machine and only select a self-delivery option if you have previous experience moving heavy items. Remember, safety is primary and money secondary.

Once we’ve completed our own purchasing process and installation, we’ll create and add a more detailed video tutorial here.

VIDEO COMING OF: PURCHASING A WIND TURBINE SYSTEM – THIS TUTORIAL WILL SHARE WHAT WE LEARNED FROM OUR OWN WIND TURBINE PURCHASING-RESEARCH AND DELIVERY PROCESS

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

PLACEMENT AND TOWER-TYPE CONSIDERATIONS

Intelligent placement of your wind turbine is important to maximizing its function. On a plateau/mesa, winds may be very turbulent running off a cliff causing wind shears. It is important to site the generator far enough from the cliff to avoid turbulent wind.

On ridge tops, wind compresses as it blows over the top of a hill, increasing the wind speed. With proper placement, you may be able to use a shorter tower. The general recommendation though is no tower shorter than 33 feet (10 m). It is also important to follow the general rule that the tower be at least 20 feet (6 m) above any surrounding object.

Coastal or lakeside usually offers very strong prevailing winds. In the case of coastal, winds typically blow most from the ocean, so it is very beneficial to install your wind generator as close to the coastline as possible. Trees and taller structures can be downwind from the wind generator.

Wherever placed, a wind turbine must also have a clear path for the wind and machinery to perform efficiently. Turbulence reduce performance and “works” the turbine harder than smooth air. Turbulences are stronger close to the ground, diminish with height, and are generally created by obstacles. Wind speed also increases with height. The general rule, as previously stated, is to install a wind turbine on a tower at least 20 ft above any obstacles within 250 ft. Keep in mind though that large obstacles will affect wind patterns even if they are farther than 250 feet away.

Smaller turbines typically go on shorter towers than larger turbines. A 1 kW turbine is often, for example, installed on a 30-50 ft tower, while a 10 kW turbine will usually need a tower of 60-100 ft. Careful analysis and consideration are recommended if considering mounting wind turbines to small buildings that people live in because of the inherent problems of turbulence, noise, and vibration.

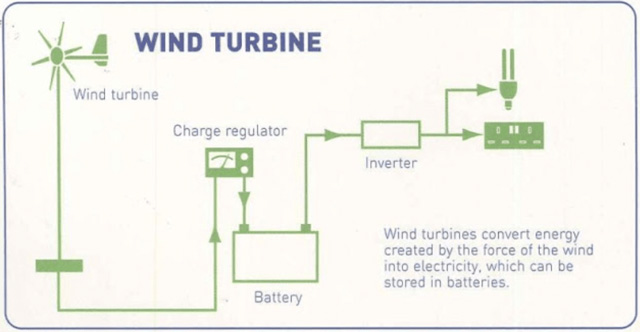

When choosing your location, keep in mind the process of erecting your tower too. The three basic tower types to consider are tilt-ups, guyed lattice, and freestanding. Most tilt-ups are made of pipe or tube and require guy wires for support. They are assembled on the ground and raised into position with a winch or tow vehicle. For turbines with a rotor diameter of 12 feet or less, this tower is usually the lowest-cost option. Guyed lattice towers are constructed on the ground and raised with a crane or assembled vertically, one section at a time, with a process known as stacking. These towers are primarily used for turbines with rotor diameters less than 25 feet and are the lowest cost fixed-tower option. Freestanding towers fall into two categories: self-supporting lattice and monopole. The self-supporting lattice tower is usually assembled on the ground and raised with a crane. These towers are typically used for turbines with a rotor diameter of 20 feet or more and require a fairly large foundation, making this option fairly expensive. Monopole towers are available for most turbine sizes and tilt-up versions are becoming more common. Although many people prefer the aesthetics of a monopole, these towers require the largest foundation of all and are usually the most expensive option.

Towers, particularly guyed towers, can be hinged at their base and suitably equipped to allow them to be tilted up or down using a winch or vehicle. This allows all work to be done at ground level. Some towers and turbines are easily erected by the purchaser, while others are best left to trained professionals. Anti-fall devices, consisting of a wire with a latching runner, are available and are highly recommended for any tower that will be climbed.

Avoid aluminum towers because they are prone to developing cracks. Towers are usually offered by wind turbine manufacturers and direct purchasing is best to ensure proper compatibility.

Again, exercise caution when mounting wind turbines on top of homes. Larger residential-home wind turbines vibrate and transmit noise to the structure on which they are mounted. This vibration can lead to noise and structural problems with the building. Mounting on the rooftop can also expose the generator to excessive turbulence that shortens its life.

Once we’ve chosen and installed our own tower, we’ll make and include here a video series on tower selection and installation.

VIDEO COMING OF: WIND TOWER SELECTION & INSTALLATION – THIS TUTORIAL WILL BE A SHORT OVERVIEW OF WHY WE CHOSE OUR SPECIFIC TOWER AND INSTALLATION APPROACH

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

NOISE ISSUES

Small wind turbines make noise, but not enough to be found objectionable by most people. A typical residential wind system makes less noise than the average washing machine. This is because most residential-sized wind generators are direct-drive devices with few moving parts. Unlike the utility-scale turbines used in wind farms, they do not have high-speed transmissions. Thus, most of the sound that comes from a residential-sized wind turbine is aerodynamic noise caused by the blades passing through the air. Noise levels of most modern residential turbines measures close to ambient noise levels under average wind conditions. It is audible if you are out of doors and listening for it, but not any noisier than your average refrigerator.

As a side note, small wind turbines do not interfere with TV reception. In very general terms, homes within a few kilometers of a large wind development that have TV aerials pointed towards the turbines are likely to be at the highest risk. There is a common misconception that digital TV is immune to interference from wind turbines, this is unfortunately not true. In general though, turbines with small diameters are unlikely to have effects on television and radio reception. If this occurs it is likely to be highly localized and technically easy to overcome.

UNDERSTANDING WIND-SYSTEM COMPONENTS

For a better understanding of wind energy, this section outlines the basic system components and an explanation where appropriate of these component differences for grid-tied and off-grid systems. Our hope is that you’ll make better decisions and choices by understanding the system and following components:

- Wind Generator

- Tower

- Brake

- Controller

- Dump Load

- Battery Bank

- System Meter

- Main DC Disconnect

- Inverter

- AC Breaker Panel

- Backup Generator

In addition to the above list, wiring, grounding, and other miscellaneous parts are included in the system, though we do not elaborate here on those components.

Wind Generator (aka: Wind Genny or Wind Turbine): The wind generator is what actually generates electricity in the system. Most modern wind generators are upwind designs (blades are on the side of the tower that faces into the wind) and couple permanent magnet alternators directly to the rotor (blades). Three-bladed wind generators are most common, providing a good compromise between efficiency and rotor balance.

Small wind turbines protect themselves from high winds (governing) by tilting the rotor up or to the side, or by changing the pitch of the blades. Electricity is transmitted down the tower on wires, most often as three-phase wild alternating current (AC).

It’s called “wild” because the voltage and frequency vary with the rotational speed of the wind turbine. The output is then rectified to direct current (DC) to charge batteries or inverted for grid connection.

A small 2.5 kW wind turbine

Tower: The wind generator tower is often more expensive than the turbine. The tower directs the turbine upward into the “fuel””the smooth, strong winds that provide the most energy. In support of this and as stated earlier, site wind turbines at least 30 feet (9 m) higher than anything within 250 feet; double this or even more if the object is a major land feature.

The three common types of towers are tilt-up, fixed-guyed, and freestanding. Towers must be specifically engineered for lateral thrust and turbine weight, and adequately grounded to protect equipment against lightning damage.

Brake (aka: Emergency Shutdown Mechanism): Most wind turbines have some means of stopping the turbine for repairs, in an emergency, for routine maintenance, or when the energy is not needed. Many turbines have “dynamic braking,” which simply shorts out the three electrical phases and acts as a disconnect. Others have mechanical braking, either via a disc or drum brake, activated by a small winch at the base of the tower. Still others have mechanical furling, which swings the rotor out of the wind. Mechanical braking is usually more effective and reliable than dynamic braking.

A charge controller

Charge Controller (aka: Controller or Regulator): A wind-electric charge controller’s primary function is to protect your battery bank from overcharging. It does this by monitoring the battery bank”when the bank is fully charged, the controller sends energy from the battery bank to a dump (diversion) load.

Many wind-electric charge controllers are built into the same box as the rectifiers (AC-to-DC converters). Overcurrent protection is needed between the battery and controller/dump load.

n batteryless grid-tie systems there is no controller in normal operation, since the inverter is selling whatever energy the turbine is generating. But there will be some control function in the case of grid failure, and there may be electronics before the inverter to regulate the input voltage.

A dump load controller looks similar to this

Dump Load (aka: Diversion Load or Shunt Load): Solar-electric modules can be turned off”open circuited”with no damage. Most wind generators should not run unloaded. They will run too fast and too loud, and may self-destruct. They must be connected to a battery bank or load. So normally, a charge controller that has the capability of being a diversion controller is used. A diversion controller takes surplus energy from the battery bank and sends it to a dump load. In contrast, a series controller (commonly used in PV systems), actually opens the circuit.

A dump load is an electrical resistance heater, and it must be sized to handle the full generating capacity of the wind generator used. These dump loads can be air or water heaters, and are activated by the charge controller whenever the batteries or the grid cannot accept the energy produced.

Duracell deep cycle batteries

Battery Bank (aka: Storage Batteries): Your wind generator will produce electricity whenever the wind blows above the cut-in speed. If your system is off-grid, you’ll need a battery bank, a group of batteries wired together to store energy so you can have electricity when it’s not windy. For off-grid systems, battery banks are typically sized to keep household electricity running for one to three calm days. Grid-intertied systems also can include battery banks to provide emergency backup during blackouts. These will usually be smaller than off-grid battery banks because they are purposed only for keeping critical electric loads operating until the grid is up again.

Use only deep-cycle batteries (batteries designed to be regularly deeply discharged using most of its capacity) in wind-electric systems. Lead-acid batteries are the most common battery of this type. Flooded lead-acid batteries are usually the least expensive, but require adding distilled water occasionally to replenish water lost during normal charging. Sealed absorbed glass mat (AGM) batteries are maintenance free and designed for grid-tied systems where the batteries are typically kept at full charge. Sealed gel-cell batteries are a good choice in unheated spaces due to their freeze-resistant qualities.

System Meter (aka: Battery Monitor, Amp-hour Meter, Watt-hour Meter, KWH Meter, or Utility Meter): System meters can measure and display several different aspects of your wind-electric system’s performance and status – tracking how full your battery bank is, how much electricity your wind generator is producing or has produced, and how much electricity is in use. Operating your system without metering is like running your car without any gauges. Although possible to do, it’s always better to know how much fuel is in the tank. The utility company often provides intertie-capable meters at no cost.

Main DC Disconnect (aka: Battery / Inverter Disconnect): In battery-based systems, a disconnect between the batteries and inverter is required. This disconnect is typically a large DC-rated breaker mounted in a sheet metal enclosure. This breaker allows the inverter to be quickly disconnected from the batteries for service, and protects the inverter-to-battery wiring against electrical fires.

A Sunny Boy grid-tie inverter

Inverter (aka: DC-to-AC Converter or Power Conditioning Unit): Inverters transform the electricity produced by your wind generator into AC electricity commonly used in most homes for powering lights and appliances. Grid-tied inverters synchronize the electricity they produce with the grid’s “utility grade” AC electricity, allowing the system to feed wind electricity to the utility grid.

Grid-tie inverters are either designed to operate with or without batteries. Battery-based inverters for off-grid or grid-tie systems often include a battery charger, which is capable of charging a battery bank from either the grid or a backup generator during cloudy weather. Some inverters include: Sunny Boy, Siemens, etc.

AC Breaker Panel (aka: Mains Panel, Breaker Box, or Fuse Box): The AC breaker panel, or mains panel, is the point at which all of a home’s electrical wiring meets with the “provider” of the electricity, whether that’s the grid or a wind-electric system. This wall-mounted panel or box is usually installed in a utility room, basement, garage, or on the exterior of the building. It contains a number of labeled circuit breakers that route electricity to the various rooms throughout a house. These breakers allow electricity to be disconnected for servicing, and also protect the building’s wiring against electrical fires.

Just like the electrical circuits in your home or office, an inverter’s electrical output is routed through an AC circuit breaker. This breaker is usually mounted inside the building’s mains panel. It enables the inverter to be disconnected from either the grid or from electrical loads if servicing is necessary. The breaker also safeguards the circuit’s electrical wiring.

Backup Generator (aka: Emergency Backup, Gas-guzzler, “The Noise”): Off-grid wind-electric systems can be sized to provide electricity during calm periods when the wind doesn’t blow. But sizing a system to cover a worst-case scenario, like several calm weeks during the summer, can result in a very large, expensive system that will rarely get used to its capacity and will run a huge surplus in windy times. To spare your pocketbook, go with at least two sources of energy. Wind”PV hybrid systems are often an excellent fit with local renewable resources but a backup, fuel-powered generator still may be necessary.

Engine-generators are fueled with biodiesel, petroleum diesel, gasoline, or propane, depending on the design. Most generators produce AC electricity that a battery charger (either stand-alone or incorporated into an inverter) converts to DC energy, which is stored in batteries. Like most internal combustion engines, generators are loud and produce an unpleasant exhaust aroma that is not good for the environment, but a well-designed renewable energy system should require running them 50 to 200 hours a year or less.

INSTALLATION

Installation of a wind turbine involves assembly and construction as well as electrical integration. A typical project includes:

- Excavation

- Concrete forms and footings

- Electrical conduit installation

- Mechanical assembly of wind turbine and tower

- Placement of turbine, typically hoisted into place via a crane or any towing car

- Electrical installation of controllers/inverters and grid-tie connection

- Building and electrical utility permitting/approvals

- Commissioning/testing

We will add video tutorials here for each of these steps as we complete them.

VIDEOS COMING OF: EXCAVATION, CONCRETE FORMS & FOOTINGS, ELECTRICAL CONDUIT INSTALLATION, TURBINE AND TOWER ASSEMBLY, PLACEMENT REASONING, CONTROLLERS/INVERTERS AND GRID-TIE CONNECTION, BUILDING AND ELECTRICAL PERMITTING, AND COMMISSIONING/TESTING OF THE FINISHED SYSTEM – WE’LL CREATE A DETAILED TUTORIAL SHARING OUR PROCESS FOR EACH OF THESE

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

We will also include a video for each of the following areas.

Building codes & zoning regulations: Local building codes may dictate using a heavier tower and larger foundation than expected. Zoning regulations may limit you to a specific tower type or tower height, or impose other requirements that will affect project economics. We’ll create a video discussing our experience with our county and these issues.

VIDEO COMING OF: UNDERSTANDING BUILDING CODES FOR WIND SYSTEM INSTALLATION – THIS TUTORIAL WILL TALK ABOUT BUILDING CODES, ZONING, AND WHAT TO BE AWARE OF WHEN WORKING WITH YOUR LOCAL BUILDING AUTHORITIES

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

Engineering: Turbines exert many complex forces on the tower and its foundation. The larger the turbine, the more robust the tower and foundation required. The turbine, tower, and foundation function as a system, and need to be engineered to work together. Most turbine manufacturers offer or recommend an appropriate tower for their turbines. We’ll share our engineered plans once complete. Here’s a video about wind turbine engineering too:

Site conditions: Soil type affects foundation design and may limit tower options. Soft soil or bedrock tends to require more robust foundations than “average” soil. Uneven terrain can be a determining factor as well. Once our wind system is built, we’ll create and add here a video discussing our experience with our soil and how it affected construction.

VIDEO COMING OF: SITE CONDITION CONSIDERATIONS FOR WIND SYSTEM INSTALLATION – THIS VIDEO WILL DISCUSS SOIL TYPES AND HOW OUR CONSTRUCTION ADDRESSED THE DETAILS OF OUR SOIL TYPE

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

Site access: Site access is frequently overlooked. Can the site accommodate heavy-wheeled equipment, such as a crane and concrete delivery trucks? If it can’t, then your tower options are quite limited. Once installed, we’ll add here a video discussing everything we learned and did wrong or right in considering site access.

VIDEO COMING OF: SITE ACCESS, THINGS TO CONSIDER – THIS VIDEO WILL DISCUSS ALL THE CONSIDERATIONS WE TOOK INTO ACCOUNT FOR OUR INSTALLATION AND ANY WE MISSED AND THE CONSEQUENCES OF MISSING THEM

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

Tower Erection: There is a startup called Nabralift which promises to decrease the cost of tower erection by 30% by using their patented technology of stacking the tower from the ground up. This could replace the crane and other equipment needed for normal tower erection. This makes a huge difference because it also eliminates the process of the turbine being mounted on the tower after it is erected. You can view support videos regarding installation for help in the reference section.

Here’s an example by the team at This Old House on home wind turbine installation:

The steps involved in the example video above are as follows:

- Creating footing: 9′ diameter, 3′ deep, and including three 20-foot deep columns.

- Dig a trench from the footing to the inverter location and run underground wire in the trench.

- Assemble a 60-foot monopole.

- Pull electrical wire through the 60-foot wind tower and through the conduit of nacelle.

- Hand-tighten the threaded connection of the nacelle to the pole.

- Lock down the threaded connection of the nacelle to the pole with a chain wrench.

- Make the wire connections in the nacelle.

- Secure the tail vane with two bolts using a wrench.

- Mount the blades on the shaft of the nacelle.

- Tighten up the blades with a reverse threaded nut using a wrench.

- Place covers on the center of the blades and the sides of the nacelle.

- Connect guide wire to the wind tower and run it to the winch.

- Using a winch, pull in the wire and guide the tower into the upright position.

- Secure the tower to the base using bolts, nuts, and the wrench.

MAINTENANCE AND CARE CONSIDERATIONS

If you want a simple, reliable, maintenance-free renewable electricity system, buy solar-electric modules. Wind-electric systems are not for the faint-of-heart, and will probably never be a simple “appliance” that you can install and forget about. These are spinning machines in a very harsh environment. You don’t expect your car to operate without maintenance, and you choose and drive it carefully to avoid accidents. The same is true of wind-electric systems. Wind-electric systems are very satisfying when they work, but very disappointing (and visible) when they don’t.

If it’s human-made and has moving parts, it needs maintenance. It doesn’t matter if it’s a spinning engine, a spinning wheel, or a spinning wind generator. You can’t run a car for years, or even months, without maintenance and expect it to last long. And it’s no different with a wind generator. Once a year is a minimum for inspection and maintenance, and twice a year is usually better, especially if you have a good wind resource or experience frequent high winds or turbulence. That said, with proper installation and maintenance, a small wind electric system should last 20 years or longer.

Our research also made very clear to not buy cheap equipment and do buy a tall tower. Buying the best turbine for your site, regardless of price, and putting it on the tallest tower possible will provide more power and less headaches in the long term. Almost all the disappointment reported from wind energy users is related to buying lightweight equipment for heavy-duty sites, or installing equipment on towers that are not high enough above surrounding obstructions.

TURBINE MAINTENANCE AND CARE

Turbine maintenance and care includes everything related to the wind energy system. Annual maintenance includes:

- Checking and tightening bolts and electrical connections as necessary

- Checking all metal parts for corrosion and the guy wires for proper tension

- Checking for and replacing any worn leading edge tape on the turbine blades, if needed

- Replacing the turbine blades and/or bearings after 10 years, if needed

If you do not have the expertise to maintain the system, your installer may provide a service and maintenance program. Once we’ve installed our own system, we will also add here videos for each of the above bullets to help with understanding the specifics of each area of maintenance.

The good news is most modern wind generators do not have parts that require routine replacement, like the brushes or bearings of older machines. Routine maintenance is primarily focused on inspection of the entire machine, cleaning, and tightening hardware. The spinning turbine and wind forces acting on a tower cause vibration; loosening and/or damaging hardware, turnbuckles, and other tower and turbine components. Carefully observe these and similar instances during an inspection.

Also, before starting your inspection, it is a good idea to prepare all the climbing gear, tools, supplies, and spare parts you may need for the job. Have a good checklist prepared and use it. Another good idea is using a digital camera to record any problems found and having all the equipment manuals available. Options like this also exist.

VIDEO COMING OF: WIND TURBINE MAINTENANCE AND CARE PROCESS – THIS VIDEO WILL DISCUSS ALL ASPECTS OF ONE COMMUNITY’S ONGOING MAINTENANCE AND CARE PROCESS FOR THE WIND TURBINES, OUR CHECKLIST, PROCESS FOR REPAIRS WHEN NEEDED, AND TUTORIALS FOR ALL THE MAINTENANCE PROCESSES

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

ELECTRICAL COMPONENT MAINTENANCE AND CARE

In addition to maintenance and care of the aerial hardware, there is also maintenance and care of all ground electrical components. Prior to climbing and working on the turbine, first diagnose and resolve any problems on the ground. The following areas to check are associated with any kind of electrical system, which could be solar or wind.

Turbine to Inverter/Controller Wire Run

- Look for signs of damage on all conduit, wire runs, junction boxes, and conduit fittings, such as water intrusion, condensation, chew marks from critters, cracks, frost-heaving, and so on. Long conduit runs improperly installed can store several gallons of water, so be aware when opening junction boxes.

- Check wire terminals on all components (disconnects, junction boxes, inverter, controller) for proper tightness and signs of arcing or other degradation.

- Test all fuses and circuit breakers for electrical deterioration using the continuity tester on a multimeter and look for physical deterioration. Cartridge fuses can deteriorate over time, especially in outdoor installations.

- Use a multimeter to check all surge arresters. (surge arresters are things like lightning rods)

- Use a megohmmeter on wire runs to check for ground faults. Skinned or cracked wire insulation in underground conduit is one of the most common causes of ground faults. At the very least, system performance will suffer. Some older inverters can be damaged by ground faults. Worse yet, if the equipment grounding system is compromised as well, a shock hazard can result.

- While the turbine is operating, check for balanced three-phase output (when applicable, it could be single phase too). Allow for the fact that there will be variations in the wind speed and thus the voltage while you are moving the meter probes”you’re looking for variations of 10% or more between phases. Test two or three times to rule out variations caused by changing wind speed.

- Perform other turbine-specific electrical tests per the manufacturer’s recommendations. A good owner’s manual will include testing protocols for the turbine electronics.

As with above, once we’ve installed our own system, we will add here videos for each of the above bullets to help with understanding the specifics of each areas of maintenance.

VIDEO COMING OF: WIND-SYSTEM ELECTRICAL MAINTENANCE AND CARE – THIS VIDEO WILL DISCUSS ALL ASPECTS OF OUR MAINTENANCE AND CARE PROCESS FOR THE WIND SYSTEM ELECTRICAL FROM THE WIND TURBINE TO THE BREAKER BOX FOR THE BUILDING

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

INDUSTRY OUTLOOK

Wind energy is arguably the most underappreciated and underutilized source of energy. This is mostly due to three reasons:

- The initial cost is high and the setup and maintenance are complex for individual use. Maintenance on a large scale (such as farms) also requires skilled workers.

- It is not available everywhere (like sunlight) and this poses some limitations. Also, it is an intermittent source of energy due to unpredictable and uncontrollable winds.

- Many believe that wind mills cause too much noise and/or bird deaths that disturb the avian ecology of the area.

All these reasons have made wind less popular and more costly. The price of wind energy continues to fall though, and subsidies and incentives exist that further lower prices and make these systems more attractive. Intermittencies are being combated with better and better battery technologies, and bird deaths can be avoided by proper siting and ultrasonic deflectors. Systems are also becoming quieter.

Looking at wind power systems over the next 10 years, the popularity and broad-scale implementation will predictably continue to increase for these additional reasons:

- Huge incentives and subsidies that some countries like China and India have started to give to those who use wind power.

- Extensive amounts of research (e.g. Tesla Powerwall) is going into making batteries cheaper and more powerful.

- Research that some companies are doing regarding huge offshore turbines along the coastlines of their countries. Offshore is certainly the future of large wind farms. Some oil companies are planning to make use of their dried up offshore drilling platforms as the site of windmills.

- Some companies are working on airborne wind turbines as well. An airborne wind turbine is a design concept for a wind turbine with a rotor supported in the air without a tower. These systems benefiting from more mechanical and aerodynamic options, the higher velocity and persistence of wind at high altitudes, and avoiding the expense of tower construction. An electrical generator may be on the ground or airborne too. Challenges include safely suspending and maintaining turbines hundreds of meters off the ground in high winds and storms, transferring the harvested and/or generated power back to earth, and interference with aviation. Many companies have already come out with their own designs though and are in their testing phases. These designs are broadly classified as: systems supported by balloon buoyancy, kites (lifting aerofoils), and tethered auto gyros. Some of the companies developing these are Makani Power (Google), Windlift, and Altaeros BAT.

- An Indian start up by the name Avant Garde innovations is also making wind turbines to power an average Indian home with a wind system for under $1,000.

In short, the future of wind power is bright with governments across the world becoming more and more aware of the economic and environmental benefits of sustainable energy. Depending on the country you live in and your wind availability, most people have access to viable and relatively affordable wind power systems right now, and these systems are expected to get cheaper, easier to install, and more widespread from this point forward.

WIND ENERGY INFRASTRUCTURE COST ANALYSIS

Modern methods for harnessing wind energy typically consist of windmills and wind turbines. For our cost analysis, we’ve focused on turbines because they are what are most commonly used and what we’ll be installing. Different wind turbine options are compared in this section, with the focus mainly on costs for their construction and installation. Recommendations for choosing the most suitable option are then made based off our research. We’ll also update this section with the cost analysis details of our specific system when we purchase it and install it.

The following areas are discussed in this section:

- Wind Turbine Generator Cost Analysis

- Tower Cost Analysis

- Installation and Maintenance

- Other Costs

- Cost Summary

- Cost Analysis References

For reference, in 2018, the Wind Technologies Market Report provided an extensive analysis of the wind installation costs and trends in the US. The graphic below shows the cost differences of various sizes of large-scale installations and showing the larger the installation the cheaper the cost per kiloWatt.

WIND TURBINE GENERATOR COST ANALYSIS

Wind turbine generators are the most important part of a wind system and should be carefully considered before making a decision. The wind turbine generator is potentially the most expensive part of your system and it also determines the output of your system. Our average cost per kW for a wind turbine was estimated as $1,037 (see spreadsheet).

Parameters that were considered when making recommendations were: rated power, cost per kW, and the durability of the turbine. The combination of these main factors are what we’d recommend focusing on to help you select an appropriate turbine to suit your own application. In rows 4 to 12 of the cost analysis spreadsheet, different wind generators are analyzed in terms of their performance, cost, and the applications it is best suited for.

Another noteworthy factor is the power coefficient of the turbine1. This takes into account rated power, rated wind speed, and rotor diameter. Theoretically, a higher power coefficient means you are getting better output for how much wind you input. The calculations for this are included in cells J4 to J12.

For a medium-to-large scale operation such as the One Community’s Highest Good Housing component, the 10 kW horizontal turbine (row 4) is the best choice out of the these initial options we explored. This turbine is our top choice because it offers easy installation, cost efficiency, high power capability, and durability. Home applications will be better suited with the smaller 2 kW wind turbine (row 5) as its much lighter, takes up less space, and the blades automatically adjust wind angle to increase efficiency and reduce noise/vibrations. In cells M4 to M12 are our notes covering compatibility for different scaled projects (small & large) for each of the other generator options we researched.

TOWER COST ANALYSIS

Similar to the wind generator, there is a large cost diversity for the tower, ranging from $25 to $1,200 (average around $850). The most common tower solution we found was the guyed tower. Other options included are free standing and crank-up towers. Guyed towers use supporting cables to keep them standing securely2 & are popular for their reasonable price and strength. A concrete foundation is required for the base of the tower’s main pole3 which according to HomeGuide, costs roughly $6 per square foot4.

For small-scale projects, guyed towers are preferred because they are quicker to install and cheaper because they require a smaller foundation5. A downside, however, is that they take up more land space. As a recommendation for these smaller projects, we’d suggest the “Leading Edge” tower (row 17) because of its compatibility with the LE-300 turbine and easy installation.

INSTALLATION AND MAINTENANCE

Maintenance and installation are another significant expense for wind systems. Installation costs can vary significantly between different wind projects due to the scale of the project, geographic location etc. However, two components that were researched are: excavation and electrical installation. Excavation costs on average $120 per cubic yard8, whilst electrical conduit installation of a 30-foot circuit will be around $170. Other aspects of installation such as assembly and testing are hard to estimate so will be at the project owner’s discretion.

An example of a maintenance schedule for a wind turbine can be found in the LE-300 wind turbine manual6. It’s possible to avoid spending money on maintenance for the first few years of the system’s life. It’s recommended though to invest approximately $200 annually on a professional to check your system7.

OTHER COSTS

A budget of around $400-600 should be enough to purchase the remaining 4 primary components of a wind system: Controller, Regulator, Grid Tie Inverter, and Battery Bank. Example products for these are displayed in cells C18 to C25. These parts go for typically around $100-200 per item. The same can be said for the other small parts like the system meter and backup generator.

COST SUMMARY

In the US, a wind turbine of any size could be estimated to cost around $3500 per kW to buy and install. There are other costs that are harder to account for such as obtaining ownership of land or cost to attach system to the grid. Wo with this in mind, and to avoid the risk of under-budgeting for the project, we’d suggest estimating around $4,500 per kW for the average wind project. This is similar to the weighted average cost for <5 MW wind projects reported by 2018 Wind Technologies Market Report. For comparison, wind system price estimates from the UK (where wind systems are currently more expensive) range from about $4,600 to $6,000 per kW10, 11.

COST ANALYSIS REFERENCES

The following are the superscript references numbered in the section above.

- Small Wind Guidebook

- Guyed towers

- Concrete foundation

- Concrete Slab Cost

- Guyed vs Free-standing

- LE-300 wind turbine manual

- Maintenance costs

- Excavation

- Electrical costs

- Wind system cost ref 1

- Wind system cost ref 2

ONE COMMUNITY’S PLAN FOR WIND POWER

Wind power is a renewable resource throughout the year, but does not yet appear to be a good investment for our location due to low mean wind speed. The wind speed at our location is just 4.6 m/s at 40 m of height according to the NREL database (online tool). This is considered low.

The chart below shows the hourly values of wind speed (m/s) in one year at 40 m (Source: SAM simulation) for our location.

Hourly Values of Wind Speed for the One Community Location

Monthly values representing the average day are collected in the following picture (Y axis: wind speed; X axis: 0-24 h). Looking at that data, reasonably good values of wind speed (> 8 m/s) are limited to just a few hours within the period of April – June (Source: SAM simulation). Because of this, the capacity factor (the ratio between the energy yield in one year and the energy that the system would produce in the (theoretical) case of operating one year at its nominal power) obtained from a wind simulation is just 12.4 %, quite lower than for PV generation (19.2%). Finally, the LCOE (Levelized Cost of Energy) of the wind case (17.47 cents/kWh) is twice the PV case (8.25 cents/kWh). So solar appears to be a significantly better choice.

Monthly Values of Wind Speed for the One Community Location

Consequently, the investment to install a wind farm in this location is not recommended. Individual wind turbines may still make sense though if property-specific wind patterns differ and demonstrate enough wind to justify turbines. We won’t know this until we’ve lived on the property for at least a couple years and take actual measurements in any locations we think may be good for installing a turbine. We’ll share this process and the data here once we’ve gathered it.

VIDEO COMING OF: ANEMOMETER (WIND MEASURING TOOL) INSTALLATION AND DATA GATHERING AND ANALYSIS PROCESS

SEE OUR HOW TO HELP AND/OR CROWDFUNDING CAMPAIGN PAGE TO HELP CREATE ALL THE TUTORIAL VIDEOS FASTER

OPEN SOURCE CONTENT TO BE ADDED LATER

Once on the property, One Community will open source project-launch blueprint the complete process of installing and maintaining our wind-energy infrastructure. We will do this for everything we think will be helpful for those replicating our system(s) as part of the One Community complete open source self-sufficient teacher/demonstration community, village, and/or city model. Upcoming resources will include:

Once on the property, One Community will open source project-launch blueprint the complete process of installing and maintaining our wind-energy infrastructure. We will do this for everything we think will be helpful for those replicating our system(s) as part of the One Community complete open source self-sufficient teacher/demonstration community, village, and/or city model. Upcoming resources will include:

- Layperson’s guide to purchasing all equipment

- Layperson’s guide to working with your county

- Layperson’s guide to installation

- Layperson’s guide to maintenance and upkeep

- Energy production details

- Lessons learned during setup and ongoing use/maintenance

- Use this page (click here) if you have a guide/tutorial you’d like to suggest be added here

RESOURCES

- Article: Is Wind Energy Harmful to Wildlife?

- All you need to know about US and its renewable energy initiatives

- Wikihow: “Make Your Own Electricity” – A great article on outlines of electricity; although it mainly concerns solar PV installation but has some good points about battery and inverters.

- Wikihow: “Build Your Own Wind Turbine”

- Choosing a Wind Turbine and Tower PDF: In this article you can find the chart to calculate your energy needs. This link talks about choosing your tower and guy wires too. Also, has a schematic for a hybrid wind-solar system.

- Resource for leasing a turbine

- Australian government resource for designing wind energy system for your home

- Article: “How to Install a Home Wind Turbine”

- Instructables.com: Installing a Wind Turbine

- 2018 Wind Technologies Market Report

- Use this page (click here) if you have a resource you’d like to suggest be added here

How to install a home wind turbine:

SUMMARY

One Community will continue to develop this page until every aspect of a working and replicable system is described with written, video, and downloadable tutorials. We will do this as part of constructing the Duplicable City Center and the Earthbag Village, then continue updates as we expand and build the other 6 villages. In the meantime and if you are building a system before we do, here’s a summary of the information you’ll need and the decisions you have to make:

One Community will continue to develop this page until every aspect of a working and replicable system is described with written, video, and downloadable tutorials. We will do this as part of constructing the Duplicable City Center and the Earthbag Village, then continue updates as we expand and build the other 6 villages. In the meantime and if you are building a system before we do, here’s a summary of the information you’ll need and the decisions you have to make:

- Amount of wind at your site

- Zoning requirements and covenants in your area

- Economics, payback, and incentives of installing a wind system at your site

- Deciding whether to connect the system to the electric grid or not

- Siting/finding the best location for your system

- Estimating the system’s annual energy output and choosing the correct size turbine and tower

Regarding installation and maintenance: (Only if you are doing it yourself)

- Pouring a proper cement foundation.

- A way of erecting the tower safely

- Knowing the difference between alternating current (AC) and direct current (DC) wiring

- Knowing enough about electricity to safely wire the turbine

- Knowing how to safely handle and install batteries

There are pros and cons and good times and bad times for everything. But one thing is for sure, the future of wind energy is bright.

FREQUENTLY ANSWERED QUESTIONS

Q: I would like to put up a wind turbine at my house or property. How do I get started?

The basic steps for installing a small wind turbine on your property are:

- Determine whether the wind resource in your area makes a small wind system economical

- Determine your household electricity needs by looking at monthly or yearly electricity usage

- Find out whether local zoning ordinances will allow wind turbine installations

- Purchase and install a wind turbine sized to the needs of your household

Q: Should I connect to the grid?

Small wind energy turbines may be installed as stand-alone systems, or connected to the utility grid. Connecting to the grid requires approval of the utility. Technical and insurance requirements for interconnection vary, as do metering arrangements. Connecting your system to the utility grid allows you to sell excess power that you generate to the utility, as well as buy electricity from the utility when your needs exceed your wind-powered generation. Interconnected systems do not require batteries. If your utility offers a net metering or billing arrangement, you can even sell your excess power at the same price you pay for electricity you purchase, thereby increasing the value of your wind energy system investment and shortening your payback period.

Q: What is “capacity factor”?

A conventional utility power plant uses fuel, so it will normally run much of the time unless it is idled by equipment problems or maintenance. A capacity factor of 40% to 80% is typical for conventional plants.

A wind plant is “fueled” by wind, which blows steadily at times and not at all at other times. Most modern utility-scale wind turbines operate with a capacity factor of 25% to 40%, although they may achieve higher capacity factors during windy weeks or months. It is possible to achieve much higher capacity factors by combining wind with a storage technology such as pumped hydro or compressed-air energy storage (CAES).

Q: What are wind turbines made of?

Wind turbine towers are generally made of steel. The blades are made of glass-fibre reinforced polyester or wood-epoxy. The finish in most models is matte, to reduce reflected light.

Q: How often do wind turbines produce electricity?

A modern wind turbine produces electricity 70-85% of the time, generating different outputs at different times depending on wind speed.

Q: Are wind turbines noisy?

The majority of modern small wind turbines have been designed to be very quiet. They achieve this through technology like direct-drive systems that avoid gearbox noise and increase efficiency. Nowadays, the wind itself makes more noise than a wind turbine and it is unlikely that any noise will be heard from small wind turbines at more than 50 meters.

Q: Are there any problems with low frequency noise?

Small wind turbines do not cause low frequency noise issues.

Q: Do wind turbines affect radar systems or TV reception?

Small wind turbines are unlikely to have any detrimental effects on aviation and associated radar or navigation systems. In general, turbines with small diameters are unlikely to have effects on television and radio reception. If this occurs it is likely to be highly localised and technically easy to overcome. It is also unlikely that building-mounted wind turbines will affect either mobile phone reception or fixed radio or microwave communications links.

Q: Do turbines affect ground-based animals?

Turbines do not adversely affect ground-based animals. Installations exist on farms, nature centers, and equestrian centers with no problems for the animals.

Q: Do wind turbines kill birds? Birds and bats are occasionally killed in collisions with wind turbines. Like any form of development, wind projects can also negatively impact wildlife by altering habitat. Over the past two decades, the impact of wind development on birds has been greatly reduced by improvements in turbine design and particularly through improved project and turbine siting, also use of ultrasonic deflectors. Even if all existing systems were older systems though, global bird deaths and environmental damage from wind systems would still be significantly lower than that caused by non-renewable energy sources like oil and coal.

Q: What about lightning strikes?

Lightning strikes can cause damage to any structure raised from the ground. However, lightning protection is a well-known practice and can be applied to wind turbines the same as for other equipment.

Q: How long will a turbine take to pay back its installation costs?

Paybacks depend on several factors, primarily your wind resource and size of turbine, what you pay/receive for your electricity, and whether you obtain any sort of grants for the project. You should also factor in maintenance costs and long-term price increases (above inflation) for electricity.

Q: What is the life of a turbine?

Freestanding turbines typically have a design life of 20-25 years.

Q: How far away can I mount the turbine from a building?

Turbines can be mounted as close as 20m or as far away as 500m depending on the turbine type and the cable used to bring the electricity back to the building. The latter point is important as the further away the turbine is, the bigger the cable required to minimize transmission losses, adding to the total cost.

Q: How much space do I need to erect a turbine?

Each turbine and tilt-up tower combination requires its own “footprint” on the ground. As a rough guide, the tower height multiplied by 2.5 provides an approximate horizontal length required on the ground. The width is the rotor diameter plus 2 meters, to allow enough space for raising and lowering. Guyed towers require more space.

Q: Will the turbine affect my own or my neighbor’s property price?

Chances are that it will add value to your property. There is no evidence of wind turbines, large or small, affecting property prices adversely in the long term.

Q: Do I need three-phase electricity supply to host a turbine?

To extract full value from a turbine rated at 5 kW or more, it is preferable (but not essential) to have a three-phase electricity supply. Less than 5 kW, it is not necessary and the power generated is handled comfortably by a single phase connection.

Q: Can a turbine be re-sited?

Yes, provided the new site is suitable. Costs will be incurred to dismantle the turbine, transport it to the new site, and re-install it. An estimate of these costs is determined by a survey of the old and new sites.

Q: Why are small wind turbines better than diesel generators or extension of utility lines in developing countries?

Small wind turbines are better because they are more sustainable and offer a number of other socioeconomic benefits. Wind systems come in smaller sizes than diesel generators and have a shorter lead time than extending the utility lines (“grid”). For grid extension distances as short as one kilometer, a wind system can be a lower cost alternative for small loads. While wind turbines cost more initially than diesels, they are often much better from the user’s point of view because of typical foreign aid practices. Donor agencies, for example, typically supply diesels at no cost, but leave operational costs (fuel, maintenance and replacement) to be supplied by the local people. These expenses (in particular, fuel and parts) require hard currency. This usually leads to limited utilization and a shortened diesel lifetime due to inadequate maintenance. Many countries must also import their fossil fuels, further magnifying the burden imposed by diesels. Environmental costs are also a factor.

Q: Aren’t wind turbines too “high-tech” for rural people?

The high technology of a wind turbine is in just a few manufactured components such as the blades. A wind turbine is simpler than a diesel engine, and also requires substantially less attention and maintenance. Some types of small turbines operate for extended periods, five years or more, without any attention. With training and spare parts, local users can support the wind turbine equipment they use.

Q: What is “net metering” (“net billing”) and how does it work?

Net metering or net billing is a term applied to laws and programs under which a utility allows the meter of a customer with a residential power system (such as a small wind turbine) to turn backward, thereby in effect allowing the customer to deliver any excess electricity produced to the utility on a one-for-one credit basis against any electricity the utility supplies the customer.

Example: During a one-month period, John Doe’s wind turbine generates 300 kilowatt-hours (kWh) of electricity. Most of the electricity is generated at a time when equipment in John’s household (refrigerator, lights, etc.) is drawing electricity and is used on site. However, some is generated at night when most equipment is turned off. At the end of the month, the turbine has generated 100 kWh in excess of John’s instantaneous needs and has transmitted this excess to the utility system. The utility has also supplied John with a total of 500 kWh for his use at times when the wind turbine has not been generating or has been insufficient for his needs. Since the meter ran backward while 100 kWh was transmitted to the utility, the utility will only bill John for 400 kWh, rather than 500 kWh.

Net metering dramatically improves the economics of a residential wind turbine by allowing the turbine’s owner to use their excess electricity to offset utility-supplied power at the full retail rate, rather than having to sell the power to the utility at the price the utility pays for the wholesale electricity it buys or generates itself. Many utilities have argued against net metering laws, saying they are required, in effect, to buy power from wind turbine owners at full retail rates, and are therefore being deprived of a profit on part of their electricity sales. However, wind energy advocates have successfully argued that what is going on is a power swap, and that it is standard practice in the utility industry for utilities to trade power among themselves without accounting for differences in the cost of generating the various kilowatt-hours involved.

One Community

One Community