Best and Most Sustainable Insulation: Safe, Eco-friendly, LEED Compliant, High R-Value

Following One Community’s commitment to upholding the Highest Good, we aim to provide an open source and freely available blueprint for ecologically-sustainable and holistic development. To do so, One Community aims to provide directly applicable information about the most sustainable options for everyday materials like insulation. This page shares our most current research on insulation and insulating materials with the following sections:

- Related Pages

- What is the “Most Sustainable” Insulation

- Why Assess Insulation

- Ways to Contribute and Consultants

- RANKING: The Best and Most Sustainable Insulations We Could Find

- The Scoring System Explained

- LEED Materials Points Explained

- Understanding R-Value and its Limitations

- Resources

- Summary

- FAQ (includes rankings only by R-value, health & safety, sustainability, etc.)

This research is 100% independent and by volunteers. We have not been paid or incentivized in any way.

RELATED PAGES (mouse-over for descriptions and click for complete pages)

WHAT IS THE “MOST SUSTAINABLE” INSULATION

If you are looking for the results of our analysis, click HERE FOR THE COMPLETE RANKING EXPLANATION or HERE FOR THE RAW-DATA SPREADSHEET. This section, though, is about how we define an insulation as “most sustainable”. To identify this, One Community decided upon 5 priorities/categories to evaluate. Here is the order (ranked from greatest to least importance) of these criteria/categories that we use for our evaluation process:

If you are looking for the results of our analysis, click HERE FOR THE COMPLETE RANKING EXPLANATION or HERE FOR THE RAW-DATA SPREADSHEET. This section, though, is about how we define an insulation as “most sustainable”. To identify this, One Community decided upon 5 priorities/categories to evaluate. Here is the order (ranked from greatest to least importance) of these criteria/categories that we use for our evaluation process:

- Health & Safety: Short-Term Toxicity, Long-Term Toxicity, Mold, Pests, and Allergens, Fire Resistance, and Health and Safety Data Sheets

- Sustainability: Materials, Manufacturing & Transportation, Direct Atmospheric Effects, and Direct Ecological Effects

- Cost (tied in priority with DIYability): Cost per ft2 per R-rating, Processes (installation, transportation, storage/handling, and cleanup/disposal), and Additional Physical Materials Needed (tools, supplies, etc.)

- DIYability (tied in priority with Cost): DIY Possibility, Complexity and Ease, and Density

- Durability: Durability and Moisture Management

- Miscellaneous (R-value, certifications and awards, sound absorbency, etc.)

These priorities serve as the main scoring criteria, with each one being broken down into subcategories that are scored. In order to provide greater weight to higher-priority categories, categories of greater importance have been granted more subcategories. Categories are scored from -2 to 2 points, unless stated otherwise. A score of 0 is intended to denote average, negative scores signify bad/harmful, and positive scores signify above average/advantageous.

See the Scoring Criteria Tab of the Spreadsheet and the The Scoring System Explained section of this page for more details:

Note: We were not paid or incentivized in any way during this research.

WHY ASSESS INSULATION

Insulation is one of the most crucial parts of the building process. Not only does it serve to protect us against the elements, but the right insulation will drastically reduce your utility bills by maintaining an ideal indoor climate, minimizing the need to continuously run the heater during cold seasons and the A/C during warm seasons. Additionally, insulation acts as a sound barrier to outside noises, and some insulations can even contribute to the structural integrity of a building.

Insulation is one of the most crucial parts of the building process. Not only does it serve to protect us against the elements, but the right insulation will drastically reduce your utility bills by maintaining an ideal indoor climate, minimizing the need to continuously run the heater during cold seasons and the A/C during warm seasons. Additionally, insulation acts as a sound barrier to outside noises, and some insulations can even contribute to the structural integrity of a building.

You might be familiar with the pink, fluffy fiberglass insulation that has long been considered the standard for commercial buildings. You may also be familiar with all the precautions that need to be taken when installing fiberglass insulation due to its toxic and dangerous materials’ properties. Despite the many negatives associated with fiberglass and its toxicity (respiratory issues, itchy and irritated skin, eyes, and nose, etc.) it is still the most used insulation out there.

Better options exist! To find them we have dedicated 100+ hours of research, doing a deep dive into the best, most sustainable, non-toxic insulation options available. In so doing we’ve been able to provide a holistic overview of insulation to better inform our own projects as well as those of others interested in healthier and more sustainable options.

As part of our open source goals and model, here we will also share our experience with the selections we use as we build the Earthbag Village and Duplicable City Center. We’ll also report durability and update the selections here as new information becomes available over time and through the construction of the other 6 villages.

To access our raw insulation evaluation and comparison data, click this image:

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Aidan Geissler: Sustainability Researcher (Insulation content)

Brianna Olsen: Sustainability Researcher (Insulation content)

James Herrigel: Student Researcher (LEED content)

THE BEST AND MOST

SUSTAINABLE & ECO-FRIENDLY

INSULATIONS WE COULD FIND

Our main driving force throughout 100+ hours of research was insulation options that are good for the planet and also good for our health. Insulation’s main purpose is to protect us from the outside elements: extreme temperatures, harsh winds and rain, humidity, loud sounds, etc. So why does something that is intended to protect us historically come with so many toxic and carcinogenic warnings? Traditional commercial insulations can contain VOCs, urea formaldehyde, and countless other toxic chemicals that can cause adverse health effects. Even in the market of sustainable “green” insulation, there are still some products containing hazardous materials such as methylene diphenyl diisocyanate, or MDI, a synthetic chemical linked to asthma, lung damage, and even death. With chemicals like this (and many others) we have compiled the list below of green insulations and ranked them based on their (in this order of importance for us) health and safety, sustainability, cost and DIYability, and durability.

Our main driving force throughout 100+ hours of research was insulation options that are good for the planet and also good for our health. Insulation’s main purpose is to protect us from the outside elements: extreme temperatures, harsh winds and rain, humidity, loud sounds, etc. So why does something that is intended to protect us historically come with so many toxic and carcinogenic warnings? Traditional commercial insulations can contain VOCs, urea formaldehyde, and countless other toxic chemicals that can cause adverse health effects. Even in the market of sustainable “green” insulation, there are still some products containing hazardous materials such as methylene diphenyl diisocyanate, or MDI, a synthetic chemical linked to asthma, lung damage, and even death. With chemicals like this (and many others) we have compiled the list below of green insulations and ranked them based on their (in this order of importance for us) health and safety, sustainability, cost and DIYability, and durability.

Note: If you’d like to see how they rank based only/exclusively on R-value, health & safety, sustainability, cost, DIYability, etc. check out the Frequently Answered Questions section.

#1 :: ROCK WOOL Comfort Batt

ROCKWOOL Comfort Batt has been determined to be our top choice, tying for the highest score (27, out of 36 possible points) with Black Mountain Sheep Wool Insulation. The many overwhelmingly positive customer reviews of this product break the tie, placing ROCKWOOL Comfort Batt at the top of the list. This product excels in almost every scoring category and did not receive negative points in any category. Of the One Community Scoring Priorities, this product was tied with the highest score for the Durability (4 points), and tied for 2nd in the Health and Safety (8 points), Sustainability (6 points), and Cost (3 points). ROCKWOOL began as a family business over 80 years ago and has grown substantially, they now operate 45 manufacturing facilities. They are headquartered in Denmark with facilities also in the US. Their products are based on sustainable stone wool technology. This product is a semi-rigid batt allowing it to be easily installed by compressing it into wall cavities. It is ideal for exterior wood and steel stud applications and can be used for both new construction and renovations.

ROCKWOOL Comfort Batt has been determined to be our top choice, tying for the highest score (27, out of 36 possible points) with Black Mountain Sheep Wool Insulation. The many overwhelmingly positive customer reviews of this product break the tie, placing ROCKWOOL Comfort Batt at the top of the list. This product excels in almost every scoring category and did not receive negative points in any category. Of the One Community Scoring Priorities, this product was tied with the highest score for the Durability (4 points), and tied for 2nd in the Health and Safety (8 points), Sustainability (6 points), and Cost (3 points). ROCKWOOL began as a family business over 80 years ago and has grown substantially, they now operate 45 manufacturing facilities. They are headquartered in Denmark with facilities also in the US. Their products are based on sustainable stone wool technology. This product is a semi-rigid batt allowing it to be easily installed by compressing it into wall cavities. It is ideal for exterior wood and steel stud applications and can be used for both new construction and renovations.

KEY FEATURES

- Composition: Natural rock and slag, a nontoxic and renewable resource

- R-value per inch: 4

- Cost per sq. ft. per R-rating: $0.06

- One Community Priority ratings: 1st place in Durability, 2nd place in Health and Safety, Sustainability, and Cost

- Unique Feature: Only company to place facilities strategically nearby local resources to minimize transportation energy

PROS FOR THIS INSULATION

- Entirely nontoxic

- Naturally mold and rot resistant

- Excellent flame and smoke resistance, it will not even ignite when exposed to direct flame

- Made of natural and recycled materials

- No known direct ecological or atmospheric impacts

- Extremely flame and smoke resistant

- Made from 40% recycled materials

- Production energy for wool is quite low

- Batts make DIY installation easy

- Highly durable, expected to last lifetime of the building

- Excellent moisture management and good sound absorbency

- High R-value per inch of 4.0

- GREENGUARD Gold Certified, LBC Red List Free, and contributes to LEED points

- Good price per sq. ft. per R-value

CONS FOR THIS INSULATION

- No vapor barrier, likely requiring additional installation

- Customer reviews reveal main cons to be availability and cost (though the cost per R-value is good)

ADDITIONAL INFORMATION

ROCKWOOL Website Technical Data Sheet  Safe Use Instruction Sheet

#2 :: Black Mountain USA Sheep Wool Insulation

Black Mountain Sheep Wool is a close second place. Like ROCKWOOL’s ComofortBatt, this product scored 27 points, performing strongly in every scoring category and not receiving any negative scores. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points) and Health and Safety (8 points), and tied for 2nd in DIY (4 points) and Durability (3 points). This product lost a close tiebreaker due to ROCKWOOL’s many excellent customer reviews. This company uses natural wool fibers to produce sustainable, effective insulation products. This product can be used in both new and existing buildings within the loft, rafter, internal wall, and inter-floor use. Additionally, this product is eligible for up to 9 LEED credits (see page 7).

Black Mountain Sheep Wool is a close second place. Like ROCKWOOL’s ComofortBatt, this product scored 27 points, performing strongly in every scoring category and not receiving any negative scores. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points) and Health and Safety (8 points), and tied for 2nd in DIY (4 points) and Durability (3 points). This product lost a close tiebreaker due to ROCKWOOL’s many excellent customer reviews. This company uses natural wool fibers to produce sustainable, effective insulation products. This product can be used in both new and existing buildings within the loft, rafter, internal wall, and inter-floor use. Additionally, this product is eligible for up to 9 LEED credits (see page 7).

KEY FEATURES

- Composition: Made of 98% sheep wool, a natural and renewable resource

- R-value per inch: 3.7

- Cost per sq. ft. per R-rating: $0.17

- One Community Priority ratings: 1st place in Sustainability and Health and Safety, 2nd place in DIY and Durability

- Unique feature: Sheep wool can absorb and neutralize toxins in the air

PROS FOR THIS INSULATION

- Made of 98% natural sheep wool

- Entirely nontoxic, and naturally filters out airborne toxins

- No known negative environmental side effects

- Easy DIY installation

- Lower than average density, making it easier to transport and work with

- High durability, expected to last the lifespan of the building

- Good moisture management

- Can help score LEED points

- Good sound absorbency

CONS FOR THIS INSULATION

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Black Mountain – Thermal insulation NATUWOOL   Product Brochure  Sheep Wool Insulation Brochure Article: The Advantages of Sheep Wool

#3 :: Havelock Wool’s Sheep Wool

This sheep wool product comes in 3rd. Though tied with ROCKWOOL ComfortBoard 80 at 24 points, Havelock’s product has higher customer reviews, as well as more overall reviews, breaking the tie to secure 3rd place in the overall rankings. Of the One Community Scoring Priorities, this product was tied with the second highest score for Sustainability (6 points), Health and Safety (8 points), DIY (4 points), and Durability (3 points). Cost is the only priority in which this product receives negative points (both in cost per sq. ft. per R-rating and in additional costs) causing it to fall just behind the frontrunners. Havelock Wool harvests sheep wool in New Zealand and distributes its products throughout Canada and the US. Their products include both loose-fill wool insulation as well as wool batts.

This sheep wool product comes in 3rd. Though tied with ROCKWOOL ComfortBoard 80 at 24 points, Havelock’s product has higher customer reviews, as well as more overall reviews, breaking the tie to secure 3rd place in the overall rankings. Of the One Community Scoring Priorities, this product was tied with the second highest score for Sustainability (6 points), Health and Safety (8 points), DIY (4 points), and Durability (3 points). Cost is the only priority in which this product receives negative points (both in cost per sq. ft. per R-rating and in additional costs) causing it to fall just behind the frontrunners. Havelock Wool harvests sheep wool in New Zealand and distributes its products throughout Canada and the US. Their products include both loose-fill wool insulation as well as wool batts.

KEY FEATURES

- Composition: Made of 100% sheep wool, a natural and renewable resource

- R-value per inch: 4

- Cost per sq. ft. per R-rating: $0.15

- One Community Priority ratings: 2nd place in Sustainability, Health and Safety, DIY, and Durability

- Unique feature: Company makes a point to purchase sheep wool as a byproduct of the meat production industry, reducing the impacts associated with sheep husbandry

PROS FOR THIS INSULATION

- Entirely nontoxic, and naturally filters out airborne toxins

- Naturally mold and pest resistant

- No known negative environmental side effects

- Easy DIY installation

- Below average density, improving ease of transport and installation

- Highly durable, expected to last the lifespan of the building

- Good moisture management and sound absorbency

- Many Certifications and Awards: LEED Certified, US Green Building Council Certified, LBC Red List Free, Bureau of Household Goods And Services’ Certified Insulation Material

CONS FOR THIS INSULATION

- High transportation energy because the raw materials are harvested in New Zealand

- High price per sq. ft. per R-value

- Commercial insulation blower is recommended if using loose wool, adding to costs

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Havelock Wool Full Spec Sheet Health Product Declaration Article: The Advantages of Sheep Wool

#4 :: ROCKWOOL Comfort Board 80

ROCKWOOL Comfort Board 80 comes in 4th place with a score of 24. Though tied with Havelock Wool’s Sheep Wool product, Havelock’s many outstanding customer reviews of this product break the tie. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in Health and Safety (8 points) and Sustainability (6 points). Cost and density are the only two categories in which this product received negative points, excelling across the rest of the board. ROCKWOOL is headquartered in Denmark with facilities through the US. Their products are based on sustainable stone wool technology. This product is a rigid stone wool insulation board.

ROCKWOOL Comfort Board 80 comes in 4th place with a score of 24. Though tied with Havelock Wool’s Sheep Wool product, Havelock’s many outstanding customer reviews of this product break the tie. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in Health and Safety (8 points) and Sustainability (6 points). Cost and density are the only two categories in which this product received negative points, excelling across the rest of the board. ROCKWOOL is headquartered in Denmark with facilities through the US. Their products are based on sustainable stone wool technology. This product is a rigid stone wool insulation board.

KEY FEATURES

- Composition: Made of rock wool, a sustainable and nontoxic natural resource

- R-value per inch: 4.2

- Cost per sq. ft. per R-rating: $0.26

- One Community Priority ratings: 1st place in Durability, 2nd place in Health and Safety and Sustainability

- Unique feature: Only company to place facilities strategically nearby local resources to minimize transportation energy

PROS FOR THIS INSULATION

- Entirely nontoxic

- No known direct ecological or atmospheric impacts

- Extremely flame and smoke resistant, it will not even ignite when exposed to direct flame

- Made from 40% recycled materials

- Production energy for wool is quite low

- Batts make DIY installation easy

- Highly durable, expected to last lifetime of the building

- Excellent moisture management and good sound absorbency

- High R-value per inch of 4.0

- GREENGUARD Gold Certified, LBC Red List Free, and contributes to LEED points

CONS FOR THIS INSULATION

- Very high price per sq. ft. per R-value

- High density, heavier than most products

- No vapor barrier, likely requiring additional installation

- Customer reviews reveal availability may be a concern

ADDITIONAL INFORMATION

ROCKWOOL Website Technical Data Sheet Safe Use Instruction Sheet

#5 :: DIY Aircrete (Aka AirCrete, Air Crete, Airkrete, AirKrete, Air Krete)

DIY aircrete comes in 5th place with 23 points. Though tied with Hempitecture HempWool Fiber Batt, this is one of the few products in which both DIY manufacturing and installation are feasible, granting aircrete the victory in the tiebreaker. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Health and Safety (8 points), Sustainability (6 points), and DIY (4 points). The only category this product receives negative points in is the cost of additional labor and equipment required for mixing your own aircrete. Aircrete is made of readily accessible ingredients (cement, water, and foam) and is a nontoxic alternative to polyurethane spray foams. Spray foams make excellent insulators because they guarantee a tight seal impermeable to air, water, and vapor. However, most spray foams contain a laundry list of complex chemicals, including MDI, the composition of aircrete is just air, water, and MGO (magnesium oxide, which is nontoxic). One Community is currently performing testing on DIY aircrete, we will update this section based on what we learn from this process.

DIY aircrete comes in 5th place with 23 points. Though tied with Hempitecture HempWool Fiber Batt, this is one of the few products in which both DIY manufacturing and installation are feasible, granting aircrete the victory in the tiebreaker. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Health and Safety (8 points), Sustainability (6 points), and DIY (4 points). The only category this product receives negative points in is the cost of additional labor and equipment required for mixing your own aircrete. Aircrete is made of readily accessible ingredients (cement, water, and foam) and is a nontoxic alternative to polyurethane spray foams. Spray foams make excellent insulators because they guarantee a tight seal impermeable to air, water, and vapor. However, most spray foams contain a laundry list of complex chemicals, including MDI, the composition of aircrete is just air, water, and MGO (magnesium oxide, which is nontoxic). One Community is currently performing testing on DIY aircrete, we will update this section based on what we learn from this process.

KEY FEATURES

- Composition: cement, water, and foam

- R-value per inch: 3.9

- Cost per sq. ft. per R-rating: $0.05

- One Community Priority ratings: 2nd place in DIY, Health and Safety, and Sustainability

- Unique feature: One of only 4 products in which both DIY manufacturing and installation are feasible

PROS FOR THIS INSULATION

- Entirely nontoxic

- Extremely fire-resistant

- DIY production and installation

- No known adverse environmental effects

- Good cost per sq. ft. per R-value

- Good moisture management and sound absorbency

CONS FOR THIS INSULATION

- Likely will need to purchase some extra supplies and machinery for DIY production

- Claims to be durable, but some concerns about shrinkage over time which reduces the air seal

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

DIY Aircrete Building Dome Homes with Aircrete

#6 :: Hempitecture HempWool Fiber Batt

This hemp-based insulation comes in 6th place. Tied with DIY aircrete with 23 points, this product loses to DIY aircrete’s superb DIY-ability. Though this product doesn’t receive as many of the highest marks compared to the products ranked above this one, this product did not receive negative points in any category. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points). Hempitecture is headquartered in Idaho and its mission is to replace conventional, toxic material with sustainable, bio-based, natural building materials. HempWool is a fiber batt design that functions as a pressure fit system, requiring no glue or adhesives.

This hemp-based insulation comes in 6th place. Tied with DIY aircrete with 23 points, this product loses to DIY aircrete’s superb DIY-ability. Though this product doesn’t receive as many of the highest marks compared to the products ranked above this one, this product did not receive negative points in any category. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points). Hempitecture is headquartered in Idaho and its mission is to replace conventional, toxic material with sustainable, bio-based, natural building materials. HempWool is a fiber batt design that functions as a pressure fit system, requiring no glue or adhesives.

KEY FEATURES

- Composition: 92% hemp fibers, a renewable and sustainable process

- R-value per inch: 3.7

- Cost per sq. ft. per R-rating: $0.11

- One Community Priority ratings: 1st place in Sustainability

- Unique feature: Receives the highest Sustainability score in part because growing hemp requires little energy, sequesters carbon, and is naturally pest-resistant so doesn’t require pesticides

PROS FOR THIS INSULATION

- Entirely nontoxic, and can even absorb harmful chemicals

- Naturally hypoallergenic and mold resistant

- Good fire resistance

- A sustainable, renewable material

- Not only does it poses no negative environmental effects, but it acts as a carbon sink and is biodegradable so can sustainably be disposed of at the end of its life

- DIY installation

- Highly durable due to the natural strength of hemp fibers

- Can help score LEED credits

- Good sound absorbency

CONS FOR THIS INSULATION

- No Health and Safety Data Sheets readily provided on their website

- Inferior moisture management, no claims of water resistance, instead it is vapor permeable so water passes through it

ADDITIONAL INFORMATION

Hempitecture  Technical Data Sheet  HempWool Information

#7 :: Owens Corning ThermaFiber Ultra Batt

With a score of 22 points, ThermaFiber comes in 7th place. This product scores high marks across the board, only receiving negative marks in the long-term toxicity category due to the inclusion of an endocrine disrupter, reproductive toxin, and potential carcinogen. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points). ThermaFiber is a popular mineral wool insulation product. In fact, 4 of the 5 tallest buildings in North America utilize ThermaFiber. These semi-rigid batts can be installed in exterior walls, ceilings, basement walls, and crawl spaces.

With a score of 22 points, ThermaFiber comes in 7th place. This product scores high marks across the board, only receiving negative marks in the long-term toxicity category due to the inclusion of an endocrine disrupter, reproductive toxin, and potential carcinogen. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points). ThermaFiber is a popular mineral wool insulation product. In fact, 4 of the 5 tallest buildings in North America utilize ThermaFiber. These semi-rigid batts can be installed in exterior walls, ceilings, basement walls, and crawl spaces.

KEY FEATURES

- Composition: 96+% charge (primarily recycled blast furnace slag, supplemented with fieldspar and trap rock) and less than 4% binder (silane, surfactant, and other)

- R-value per inch: 4.0 to 4.3

- Cost per sq. ft. per R-rating: $0.05

- One Community Priority ratings: 1st place in Durability

- Unique feature: Was allegedly the first formaldehyde-free mineral wool insulation to enter the market in 2017

PROS FOR THIS INSULATION

- Excellent fire and smoke resistance

- Made of at least 70% recycled materials

- No known adverse environmental effects

- Good cost per sq. ft. per R-rating

- DIY Installation

- Highly durable, expected to last 75 years

- Excellent moisture management, very water-resistant

- Very high R-value per inch

- Can contribute to LEED credits

- Good sound absorbency

CONS FOR THIS INSULATION

- Some long-term toxicity concerns, including potential endocrine disrupters, reproductive toxins, and carcinogens

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

#8 :: ThermaCork

Scoring 20 points, ThermaCork lands in 8th place. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in Sustainability (6 points). The only two categories in which it receives negative points are density and cost per sq. ft per R-rating. ThermaCork is manufactured in Portugal, and the cork dust created by manufacturing is added to a boiler that generates 90% of the energy need to produce the cork panels. These cork boards can be used in a variety of applications, including roofs, external walls, internal partitions, slabs and floors, ceilings, and more.

Scoring 20 points, ThermaCork lands in 8th place. Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in Sustainability (6 points). The only two categories in which it receives negative points are density and cost per sq. ft per R-rating. ThermaCork is manufactured in Portugal, and the cork dust created by manufacturing is added to a boiler that generates 90% of the energy need to produce the cork panels. These cork boards can be used in a variety of applications, including roofs, external walls, internal partitions, slabs and floors, ceilings, and more.

KEY FEATURES

- Composition: Made entirely of cork and water, without any additive or adhesives

- R-value per inch: 4.0

- Cost per sq. ft. per R-rating: $0.56

- One Community Priority ratings: 1st place in Durability, 2nd place in Sustainability

- Unique feature: The waste from the industrial process is 100% reusable (cork granules and powder), and the cork dust is converted to 90% of the energy to produce the panel

PROS FOR THIS INSULATION

- Entirely nontoxic and VOC-free

- Naturally hypoallergenic and mold resistant

- Cork is renewable, requires little energy to produce, and improve soil health

- Cork acts as a carbon sink

- DIY installation

- Nonhazardous and flexible disposal at the end of the product’s life, it is recyclable and compostable

- High durability, expected to last 50-60 years without loss of characteristics

- Great moisture management, low water absorption

CONS FOR THIS INSULATION

- Class B Fire Rating

- The majority of cork is harvested in Portugal, causing high transportation costs to get this product to the US

- Very expensive per sq. ft. per R-rating

- High density, making installation and transportation more difficult

- Poor sound absorption

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

ThermaCork Homepage  Product Brochure  Ò Ò Spec Sheet  Safety Data Sheet

#9 :: Hempitecture HempCrete

Coming in 9th place with 19 points is HempCrete. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points), and tied for 2nd in Health and Safety (8 points) and Durability (3 points). The categories in which this product receives negative points is cost per sq. fr. per R-rating, cost of additional supplies, complexity and ease of installation, and R-value per inch. This product is made of limestone and woody core fibers of hemp stalks. Hempitecture is headquartered in Idaho and its mission is to replace conventional, toxic material with sustainable, biobased, natural building materials.

Coming in 9th place with 19 points is HempCrete. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points), and tied for 2nd in Health and Safety (8 points) and Durability (3 points). The categories in which this product receives negative points is cost per sq. fr. per R-rating, cost of additional supplies, complexity and ease of installation, and R-value per inch. This product is made of limestone and woody core fibers of hemp stalks. Hempitecture is headquartered in Idaho and its mission is to replace conventional, toxic material with sustainable, biobased, natural building materials.

KEY FEATURES

- Composition: Made of limestone and woody core fibers of hemp stalks

- R-value per inch: 2.5

- Cost per sq. ft. per R-rating: No price listed

- One Community Priority ratings: 1st place in Sustainability, 2nd place in Health and Safety and Durability.

- Unique feature: Receives the highest Sustainability score in part because growing hemp requires little energy, sequesters carbon, and is naturally pest-resistant so doesn’t require pesticides

PROS FOR THIS INSULATION

- Entirely nontoxic, and even absorbs harmful chemicals

- Naturally pest, rot, and mold resistant

- Excellent fire resistance, Class A rating

- Renewable resource that is sustainably grown and not energy-intensive

- Acts as a carbon sink, the growth of hemp locks in CO2 from the atmosphere

- Hemp is biodegradable

- DIY installation

- Highly durable due to the natural strength of hemp fibers

- Good moisture management, but not ideal for very humid climates

- Helps score LEED points

- Good sound absorbency

- Allegedly doesn’t require a vapor barrier as it allows moisture to pass through without getting trapped

CONS FOR THIS INSULATION

- No specific data sheet provided for this product, because you buy the ingredients and mix it yourself

- Unknown cost per sq. ft. per R-rating

- Will need extra supplies and machinery to mix the HempCrete yourself, also more labor-intensive than other options

- Low R-value per inch, which may require thicker walls to reach sufficient insulation, which can cut into living space

ADDITIONAL INFORMATION

Hempitecture Homepage Hemp Hurd Technical Sheet  Standard Wall Section

#10 :: Air Krete GREENsulation

This product scores 18 points, tying with Straw Bales, but breaking the tie due to its accolades, reviews, and it being a specific product that can be regulated and reviewed. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Sustainability (6 points). This product only receives negative points in DIY possibility and cost per sq. ft. per R-rating. Spray foams make excellent insulators because they guarantee a tight seal impermeable to air, water, and vapor. However, most spray foams contain a laundry list of complex chemicals, including MDI, a toxic chemical linked to many health concerns. Meanwhile, the composition of Air Krete is just air, water, and MGO cement. Air Krete is the consistency of shaving cream when initially sprayed in, which then hardens to cement.

This product scores 18 points, tying with Straw Bales, but breaking the tie due to its accolades, reviews, and it being a specific product that can be regulated and reviewed. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Sustainability (6 points). This product only receives negative points in DIY possibility and cost per sq. ft. per R-rating. Spray foams make excellent insulators because they guarantee a tight seal impermeable to air, water, and vapor. However, most spray foams contain a laundry list of complex chemicals, including MDI, a toxic chemical linked to many health concerns. Meanwhile, the composition of Air Krete is just air, water, and MGO cement. Air Krete is the consistency of shaving cream when initially sprayed in, which then hardens to cement.

KEY FEATURES

- Composition: Made of cement, water, and foam

- R-value per inch:3.9

- Cost per sq. ft. per R-rating: $0.10-$0.25

- One Community Priority ratings: 2nd place in Sustainability

- Unique feature: One of only 4 products in which both DIY manufacturing and installation are feasible, also MGO in Air Krete scrubs CO2 out of air

PROS FOR THIS INSULATION

- No long term toxicity

- pest and mold repellent

- Excellent fire resistance (Class A), anecdotes of this product stopping house fires (at least in the video demos on the Air Krete site)

- Made of sustainable and renewable resources

- Low production energy

- Magnesium oxide scrubs CO2 out of the air, benefiting the air quality and atmosphere

- Good moisture resistance, but over time it absorbs moisture so cover is required

- Winner of the 2007 Nobel Peace Prize for Climate Change

- Good sound absorbency

CONS FOR THIS INSULATION

- Claims to be nontoxic, though magnesium oxide is on OSHA’s regulated Hazardous Items List

- High price per sq. ft. per R-rating

- DIY not possible, this product is installed by technicians

- Expected to be durable and long-lasting, but some accounts of shrinkage over time, reducing air seal, and repeated exposure to moisture will decrease the product’s insulative performance

- No vapor barrier, and will likely need to install one to prevent moisture damage

ADDITIONAL INFORMATION

Company Website  Spec Sheet Safety Data Sheet  Article: “How Does Air Krete Work”  Material Safety / Data Sheet

#11 :: Straw Bales

Straw Bales score 18 points, tying Air Krete GREENsulation, but losing to the tie due to Air Krete’s accolades, reviews, and status as a specific product that can be regulated and reviewed. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points), but has the lowest score for DIY (-1 point). The only categories in which straw receives negative points are density, complexity and ease of installation, and additional costs. Straw bale construction has been gaining traction as a sustainable way to insulate and construct your home. Closely stacked straw bales sealed with an earthen plaster provide an excellent barrier between you and the elements. We’ll also be open sourcing complete DIY straw bale construction details when we construct the Straw Bale Village. Note though that straw bale construction is really only an option for new construction rather than a replacement for your current insulation. Additionally, this product is best suited for warm, arid climates, because in humid climates and in heated homes the straw is susceptible to condensation. The cost and availability of straw bales nearby is another important variable factor.

Straw Bales score 18 points, tying Air Krete GREENsulation, but losing to the tie due to Air Krete’s accolades, reviews, and status as a specific product that can be regulated and reviewed. Of the One Community Scoring Priorities, this product was tied with the highest score for Sustainability (7 points), but has the lowest score for DIY (-1 point). The only categories in which straw receives negative points are density, complexity and ease of installation, and additional costs. Straw bale construction has been gaining traction as a sustainable way to insulate and construct your home. Closely stacked straw bales sealed with an earthen plaster provide an excellent barrier between you and the elements. We’ll also be open sourcing complete DIY straw bale construction details when we construct the Straw Bale Village. Note though that straw bale construction is really only an option for new construction rather than a replacement for your current insulation. Additionally, this product is best suited for warm, arid climates, because in humid climates and in heated homes the straw is susceptible to condensation. The cost and availability of straw bales nearby is another important variable factor.

KEY FEATURES

- Composition: 100% straw

- R-value per inch: 1.5 (but the thickness of the bales makes the R-rating exceed that of most other products)

- Cost per sq. ft. per R-rating: $0.01-$0.05

- One Community Priority ratings: 1st place in Sustainability, last place in DIY

- Unique feature: Not only does this act as insulation, but it also provides structural integrity

PROS FOR THIS INSULATION

- Entirely non-toxic

- Good fire resistance when properly installed, the bales are dense enough that it doesn’t allow oxygen for the fire to spread (Here you can find specific examples of straw bale constructed homes that were often the only homes still standing after outbreaks of forest fire in Northern California)

- Straw is a naturally occurring byproduct of other agricultural harvesting that is typically just composted or burned

- Low production energy

- Straw absorbs CO2 from the atmosphere

- Straw is 100% biodegradable

- Excellent cost per sq. ft. per R-rating

- DIY installation

- Good durability, can last 100 years if properly installed and maintained (but if it gets wet the lifespan is reduced)

- Can help score LEED points

- Good sound absorbency

- Not necessary/recommended to install a vapor barrier to allow bales need to breathe

CONS FOR THIS INSULATION

- If the straw gets wet it becomes susceptible to mold growth

- Transportation energy and costs can be high depending on proximity

- Storage of bales may require extra costs and effort to keep them dry

- May need additional supplies, such as chainsaw to cut bales to size and may require thicker plaster

- Installation is more labor-intensive than that of other products

- High density makes transportation and installation more challenging

- Average moisture management, if bales absorb more than 20% of their weight they may be subject to rot and they lose insulative qualities

- Cost and availability of straw bales varies widely depending on location

- Only an option for new construction

- Will need to check your local building codes to see if straw bale construction is even a feasible option as it is not always compliant with local building codes.

ADDITIONAL INFORMATION

StrawBale.com Pros and Cons of Straw Bale Buying the Right Straw Fire Resistance of Straw Bale Walls Forum about Straw Bale Costs  Straw Bale Home Inspection

#12 :: Bonded Logic UltraTouch Denim Insulation

Another innovative idea is to use recycled jeans and denim as insulation. Bonded Logic’s product scores 15 points, coming in 12th place. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Cost (3 points). The only categories in which this product receives negative points are direct atmospheric effects and moisture management. UltraTouch is made of recycled fiber products and is treated with boric acid to serve as a fire retardant. This U.S.-based company has 35+ years of insulation experience. This product is installed with a simple friction fit and can be used in interior walls, exterior walls, and most ceiling applications.

Another innovative idea is to use recycled jeans and denim as insulation. Bonded Logic’s product scores 15 points, coming in 12th place. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Cost (3 points). The only categories in which this product receives negative points are direct atmospheric effects and moisture management. UltraTouch is made of recycled fiber products and is treated with boric acid to serve as a fire retardant. This U.S.-based company has 35+ years of insulation experience. This product is installed with a simple friction fit and can be used in interior walls, exterior walls, and most ceiling applications.

KEY FEATURES

- Composition: 80% post-consumer Recycled Fiber Products (i.e. denim, cotton), ammonium sulfate, binder fiber, and boric acid (fire retardant, antifungal, antimicrobial)

- R-value per inch: 3.7-4.0

- Cost per sq. ft. per R-rating: $0.06

- One Community Priority ratings: 2nd place in Cost

- Unique feature: Very user-friendly DIY installation, perforated batts allow for quick and easy off-size cavity installation

PROS FOR THIS INSULATION

- No long-term toxicity dangers

- Good mold, fungi, and bacteria resistance, though if it becomes wet this resistance is decreased

- Good fire resistance (Class A) due to being treated with boric acid

- Cotton is a renewable resource

- Very low manufacturing energy since this is made from 80% recycled fiber

- Good cost per sq. ft. per R-rating

- DIY installation

- Low density, making transportation and installation easier

- Highly durable, should last 30-50 years

- LEED Certified Green building material

- Good sound absorbency

CONS FOR THIS INSULATION

- Post-consumer denim could contain residues of chemically-based laundry products, which likely is not widely toxic but might be a potential problem for those who are chemically sensitive

- Though cotton has a small carbon footprint, the processing of dying the denim results in significant emissions

- Should be biodegradable when its time to dispose of, however, there are environmental concerns of various chemicals in the recycled materials

- Very poor moisture management, since it’s cotton-based it does not dry easily once it becomes wet

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Bonded Logic Website Product Specifications Safety Data Sheet  Bonded Logic: UltraTouch Denim

#13 :: Kenafcrete

Another innovative, bio-based insulation option is Kenfacrete. This product scores 10 points, tying with GreenFibers Blended Blow-In Insulation. This product wins the tiebreaker because many of its cons (cost, high transportation energy, and lack of transparency such as Health and Safety Data sheets) could be mitigated by mixing your own Kenafcrete, while the cons of Greenfiber’s product (primarily toxicity concerns, as well as durability) cannot be mitigated. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Sustainability (6 points), but has the lowest score for Cost (-2 points). Kenafcrete is a simple recipe: kenaf wood core chips, hydrated lime, and water. This particular company selling Kenafcrete blocks is based in Malaysia, but it is possible to purchase the ingredient and mix your own Kenafcrete. Both lightweight insulative blocks and structural panels are available.

Another innovative, bio-based insulation option is Kenfacrete. This product scores 10 points, tying with GreenFibers Blended Blow-In Insulation. This product wins the tiebreaker because many of its cons (cost, high transportation energy, and lack of transparency such as Health and Safety Data sheets) could be mitigated by mixing your own Kenafcrete, while the cons of Greenfiber’s product (primarily toxicity concerns, as well as durability) cannot be mitigated. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Sustainability (6 points), but has the lowest score for Cost (-2 points). Kenafcrete is a simple recipe: kenaf wood core chips, hydrated lime, and water. This particular company selling Kenafcrete blocks is based in Malaysia, but it is possible to purchase the ingredient and mix your own Kenafcrete. Both lightweight insulative blocks and structural panels are available.

KEY FEATURES

- Composition: Kenaf wood core chips, Hydrated lime, and Water

- R-value per inch: 2.0-3.2

- Cost per sq. ft. per R-rating: $0.13-$0.21

- One Community Priority ratings: 2nd place in Sustainability, last place in Cost

- Unique feature: A simple 100 sq. meter house usKenfacrete can lock down the equivalent of an entire year of CO2 emissions by a standard passenger car.

PROS FOR THIS INSULATION

- Entirely nontoxic, made of natural, organic materials

- Mold and pest proof

- Good fire resistance

- Kenaf is a renewable resource

- Low production energy

- Kenaf absorbs CO2 from the air at a fast rate, acting as a carbon sink and locking down CO2

- Growing kenaf can remediate soil by removing heavy metals and other toxic chemicals

- Easy DIY installation, and DIY construction of product is possible

CONS FOR THIS INSULATION

- No healthy and safety data sheets provided

- High transportation energy and costs due to this product being made in Malaysia

- High price per sq. ft. per R-rating

- High density, making transportation and installation more challenging

- No durability claims or data, some concerns regarding this given that it is made of organic material

- Kenaf has high moisture absorptivity, so it must be treated with sodium hydroxide and have a lime plaster installed

- Low R-value per inch

- Poor sound absorbency

ADDITIONAL INFORMATION

KenafPartnersUSA Performance Parameters

#14 :: Greenfiber Blended Blow-In Insulation

This product comes in 14th place with 10 points. Though it was tied with Kenafcrete, Greenfiber’s product lost the tiebreaker because the most concerning issues with the product (primarily toxicity, also durability) cannot be easily mitigated, while Kenafcrete’s drawbacks (primarily cost, high transportation energy, and lack of Health and Safety Data Sheets) have the possibility of being mitigated by mixing your own Kenafcrete rather than purchasing it from Malaysia. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Cost (3 points), but it receives one of the lowest scores for Sustainability (-1 point). This product is suitable for any blow-in applications, like attics, walls, and floors.

This product comes in 14th place with 10 points. Though it was tied with Kenafcrete, Greenfiber’s product lost the tiebreaker because the most concerning issues with the product (primarily toxicity, also durability) cannot be easily mitigated, while Kenafcrete’s drawbacks (primarily cost, high transportation energy, and lack of Health and Safety Data Sheets) have the possibility of being mitigated by mixing your own Kenafcrete rather than purchasing it from Malaysia. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Cost (3 points), but it receives one of the lowest scores for Sustainability (-1 point). This product is suitable for any blow-in applications, like attics, walls, and floors.

KEY FEATURES

- Composition: 85% recycled newsprint (cellulose fiber), <10% boric acid (for flame retardant), and <10% ammonium sulfate

- R-value per inch: 3.7

- Cost per sq. ft. per R-rating: $0.01

- One Community Priority ratings: 2nd place in Cost

- Unique feature: Products use 13x less energy to manufacture than fiberglass insulation

PROS FOR THIS INSULATION

- Good fire resistance (Class A) due to boric acid treatment

- Low manufacturing and transportation energy

- No direct atmospheric effects

- Excellent price per sq. ft. per R-rating

- DIY Installation

- Readily available at local hardware stores

- Good moisture management

- Contributes to LEED points

- No need for a vapor barrier

CONS FOR THIS INSULATION

- Toxicity issues, can cause eye and skin irritation, difficulty with breath when inhaled, diarrhea or vomiting if ingested, and contains reproductive toxins

- Concerns of mold growth due to being made of cellulose

- Some materials have ecotoxicity concerns, making safe disposal questionable

- May need to rent a blow-in machine for installation, slightly more involved of a process than other products

- Less durable than other products, typical lifespan is 20-30 years

- Poor sound absorbency

ADDITIONAL INFORMATION

Greenfiber Company Website  Spec Sheet PDF Download  Blended Blow-in Insulation  Safety Data Sheet

#15 :: Styrofoam Board Insulation

Styrofoam Board Insulation scores 10 points and comes in 15th. Though tied with Aspen Aerogels Spaceloft, Styrofoam breaks the tie in part because it is more established as an insulation product and is far more available, but also because Spaceloft is far and away the most expensive product (about 5x more expensive than the next most expensive product) and has the highest Global Warming Potential of any product (about 4x higher than the second most). Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in DIY (4 points), but receives one of the worst scores for Sustainability (-4 points) and Health and Safety (-1 point). This product is widely available at local hardware stores, and the installation process consists of cutting the foam boards to size and fitting to the wall studs. Unfortunately, this process leaves a lot of unusable styrofoam scraps that will end up in a landfill where they leach toxic chemicals, don’t decompose, and pose environmental hazards.

Styrofoam Board Insulation scores 10 points and comes in 15th. Though tied with Aspen Aerogels Spaceloft, Styrofoam breaks the tie in part because it is more established as an insulation product and is far more available, but also because Spaceloft is far and away the most expensive product (about 5x more expensive than the next most expensive product) and has the highest Global Warming Potential of any product (about 4x higher than the second most). Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), and tied for 2nd in DIY (4 points), but receives one of the worst scores for Sustainability (-4 points) and Health and Safety (-1 point). This product is widely available at local hardware stores, and the installation process consists of cutting the foam boards to size and fitting to the wall studs. Unfortunately, this process leaves a lot of unusable styrofoam scraps that will end up in a landfill where they leach toxic chemicals, don’t decompose, and pose environmental hazards.

KEY FEATURES

- Composition: Styrofoam (the monomer styrene is converted into polystyrene, then a hydrofluorocarbon agent is added, then the material is extruded and expanded under pressure to form a foam board)

- R-value per inch: 5.0

- Cost per sq. ft. per R-rating: $0.10

- One Community Priority ratings: 1st place in Durability, 2nd place in DIY

- Unique feature: One of the most widely available products, can be found, readily at local hardware stores

PROS FOR THIS INSULATION

- Mold and fungi resistant as it is not a nutrient source for them

- DIY installation

- Readily available at local hardware stores

- Low density, making transportation and installation less challenging

- High durability, expect to last at least 50 years

- Good moisture management, low water absorption

- Can contribute to LEED points

- Acts as a vapor barrier, so no need to install one separately

CONS FOR THIS INSULATION

- Contains toxic chemicals that are released when exposed to excessive heat, including 1,1,1,2-Tetrafluoroethane, which can cause dizziness or asphyxiation

- Contains teratogenic (causing harm to fetuses) and reproductive toxins

- Mediocre fire resistance (Class A or B), customer reviews cite flammability concerns

- Only made of 20% recycled material, not a renewable resource

- Manufacturing is energy-intensive

- May contain HCFCs, which deplete the ozone layer

- Non-biodegradable, so when disposed of it accumulates in the environment and leaches toxic chemicals into ecosystems

- Average price per sq. ft. per R-rating

- Poor sound absorbency

ADDITIONAL INFORMATION

DOW: Building Insulation Data Sheet Safety Data Sheet

#16 :: Aspen Aerogels Spaceloft

This product scores 10 points and comes in 15th place. Though tied with Styrofoam Boards, Spaceloft loses in the tiebreaker in part because it is less established as an insulation product and is far less available, but also because Spaceloft is far and away the most expensive product (about 5x more expensive than the next most expensive product) and has the highest Global Warming Potential of any product (about 4x higher than the second most). Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), but receives the lowest score for Sustainability (-5 points) and the 2nd lowest score for Cost (-1 point). Though this product boasts the highest R-value per inch of any product (10.3), the significant sustainability and cost concerns make this a poor choice for insulation. This product is designed to address insulation needs when there is a lack of space to accommodate typical products.

This product scores 10 points and comes in 15th place. Though tied with Styrofoam Boards, Spaceloft loses in the tiebreaker in part because it is less established as an insulation product and is far less available, but also because Spaceloft is far and away the most expensive product (about 5x more expensive than the next most expensive product) and has the highest Global Warming Potential of any product (about 4x higher than the second most). Of the One Community Scoring Priorities, this product was tied with the highest score for Durability (4 points), but receives the lowest score for Sustainability (-5 points) and the 2nd lowest score for Cost (-1 point). Though this product boasts the highest R-value per inch of any product (10.3), the significant sustainability and cost concerns make this a poor choice for insulation. This product is designed to address insulation needs when there is a lack of space to accommodate typical products.

KEY FEATURES

- Composition: Made primarily of 40-50% Synthetic Amorphous Silica, Methylsilylated Silica, Polyethylene Terephthalate (PET or polyester), and Fibrous Glass.

- R-value per inch: 10.3

- Cost per sq. ft. per R-rating: $2.56

- One Community Priority ratings: 1st place in Durability, last place in Sustainability

- Unique feature: Spaceloft is a top choice for engineers and architects in space-challenged designs

PROS FOR THIS INSULATION

- No long-term toxicity concerns

- Mold and fungi resistant

- Good fire resistance (Class A)

- DIY installation

- High durability, minimum 50-year service life

- Good moisture management, low water absorption coefficient

- Highest R-value per inch of any product at 10.3

CONS FOR THIS INSULATION

- Minor exposure concerns, inhalation of dust can cause irritation, eye contact can cause temporary redness

- Made of synthetic, non-renewable resources

- Production and transportation processes are energy-intensive

- Adverse atmospheric effects, Global Warming Potential of 4.3 (highest of any product)

- Poor price per sq. ft. per R-rating

- High density, making transportation and installation more challenging

- Poor sound absorbency

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Aspen Aerogel: Spaceloft Technical Guidance Document Safety Data Sheet

#17 :: Fiberglass Insulation

Scoring 7 points, Fiberglass comes in 17th place. Of the One Community Scoring Priorities, this product was tied with the highest score for Costs (4 points), but falls behind in every other Priority. This product is typically made with a blend of sand, limestone, soda ash, and recycled glass cullet. Fiberglass insulation might come in batt, blanket, or loose-fill form. The applications have a wide range: cavity walls, exterior and partition walls, floors, ceilings, attics, basements, and crawlspace. Though this is a popular, affordable product, it is far from sustainable and has health and safety concerns.

Scoring 7 points, Fiberglass comes in 17th place. Of the One Community Scoring Priorities, this product was tied with the highest score for Costs (4 points), but falls behind in every other Priority. This product is typically made with a blend of sand, limestone, soda ash, and recycled glass cullet. Fiberglass insulation might come in batt, blanket, or loose-fill form. The applications have a wide range: cavity walls, exterior and partition walls, floors, ceilings, attics, basements, and crawlspace. Though this is a popular, affordable product, it is far from sustainable and has health and safety concerns.

KEY FEATURES

- Composition: A blend of sand, limestone, soda ash, and recycled glass cullet

- R-value per inch: 2.2 to 3.8 (average of 2.0)

- Cost per sq. ft. per R-rating: $0.04

- One Community Priority ratings: 1st place in Cost

- Unique feature: Despite sustainability and toxicity concerns, fiberglass has long been one of the most popular insulation choices due to its availability, cost, and ease of installation

PROS FOR THIS INSULATION

- No known long-term health hazard

- Good fire resistance (Class A)

- No known atmospheric hazards

- Excellent price per sq. ft. per R-rating

- DIY installation is possible

- Good availability, can be found at local hardware stores

- Low density insulation, making transportation and installation less challenging

- Can contribute to LEED credits

- Good sound absorbency

CONS FOR THIS INSULATION

- Short term toxicity concerns such as rashes, itches, throat irritation, and aggravation of asthma

- Though the insulation is mold resistant, many products have a paper backing, which is susceptible to mold growth

- Mostly nonrenewable/non-recycled materials, may contain 0-30% recycled materials (such as crushed recycled glass)

- Energy-intensive manufacturing process

- Non-biodegrable and may contain toxins that can leech into the soil and cause harm to animals and humans

- Though DIY installation is possible, it is more complicated and often it is recommended to hire technicians to install it

- Less durable, average lifespan of 15 years

- Poor moisture management, when it gets wet its insulative properties are impaired and it can slump or sag

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Article: “What is Fiberglass Insulation? How it Works and What it’s Made of”  Example 1: Owens Cornering PINK Fiberglass Insulation Data Sheet  Ò Ã’ Ã’ Example 2: Knauf Insulation EcoBatt Data Sheet  Example Safety Data Sheet

#18 :: Demilec HeatlokSoya 2000

A green alternative to petroleum-based spray foam insulations is soy-based spray foam insulation. Demilec’s Heatlok Soya 2000 is one such option, but it scores only 4 points and comes in 18th place. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Durability (4 points), but receives the lowest DIY score (-1 point) and very low score for Health and Safety (1 point), Sustainability (-3 points), and Costs (-1 point). Because it is a spray foam insulation that uses soy in place of petroleum, many external articles reference this product as a great option for sustainable insulation. However, in reality, it is only 14% soy while the other 86% is a myriad of complex and sometimes hazardous chemicals. One of the biggest concerns is the use of MDI, the toxic chemical linked to respiratory issues previously mentioned. Though this is an innovative idea, in practice it is not a good option, and we were unable to find a soy-based spray foam insulation that did not include the toxic MDI component.

A green alternative to petroleum-based spray foam insulations is soy-based spray foam insulation. Demilec’s Heatlok Soya 2000 is one such option, but it scores only 4 points and comes in 18th place. Of the One Community Scoring Priorities, this product was tied with the second-highest score for Durability (4 points), but receives the lowest DIY score (-1 point) and very low score for Health and Safety (1 point), Sustainability (-3 points), and Costs (-1 point). Because it is a spray foam insulation that uses soy in place of petroleum, many external articles reference this product as a great option for sustainable insulation. However, in reality, it is only 14% soy while the other 86% is a myriad of complex and sometimes hazardous chemicals. One of the biggest concerns is the use of MDI, the toxic chemical linked to respiratory issues previously mentioned. Though this is an innovative idea, in practice it is not a good option, and we were unable to find a soy-based spray foam insulation that did not include the toxic MDI component.

KEY FEATURES

- Composition: Side A is totally MDI/pMDI, Side B is 50% polyester polyol, 25% polyether polyol, <10% each pentafluoropropane (an HFC), dichloroethylene, flame retardant, triethyl phosphate, tertiary amine catalyst, surfactant (unclear where the 14% renewable/recycled content is found)

- R-value per inch: 6.0

- Cost per sq. ft. per R-rating: unknown

- One Community Priority ratings: 2nd place in Durability, last place in DIY

- Unique feature: Acts as insulation, air barrier, vapor barrier, rain screen, and radon protection

PROS FOR THIS INSULATION

- Inhibits mold, mildew, and bacterial growth

- Good fire resistance (Class A)

- Allegedly high durability, but no clear claims or evidence

- Good water management, low water absorption

- Very high R-value per inch (6)

- Greenguard Gold Certified and can contribute to LEED points

- Good sound absorbency

- Acts as insulation, air barrier, vapor barrier, rain screen, and radon protection

CONS FOR THIS INSULATION

- Significant short-term toxicity concerns, including skin irritation, headaches and dizziness if inhaled, and diarrhea and vomiting if ingested

- Contains chemicals suspected to be carcinogenic and toxic to internal organs

- Only 22% of the materials are recyclable or renewable

- Uses a blowing agent that contributes to global warming

- May be harmful to the environment if disposed of in large quantities, especially hazardous to fish

- Cost not listed anywhere

- DIY installation not possible, it’s performed by technicians

ADDITIONAL INFORMATION

Huntsman Build Solutions: Heatlok SOYA HFO Technical Data Sheet Safety Data – A-Side Safety Data – B-Side Resin  Safety Data – Rigid Foam

#19 :: DIY Recycled Styrofoam

On the Styrofoam Recycling Page, we cover the possibility of using recycled styrofoam to make DIY insulation. Here we assess this option and find that it only scored 2 points and comes in 19th place. Of the One Community Scoring Priorities, this product has the highest score for DIY (5 points), but receives the worst score for Health and Safety (-3 points) and Durability (-2 points), and low scores in Sustainability (1 point) and Costs (1 point). Not only does this product pose health, safety, and environmental hazards, it hasn’t been established as an insulation product so the effectiveness is unknown and it might not adhere to building codes.

On the Styrofoam Recycling Page, we cover the possibility of using recycled styrofoam to make DIY insulation. Here we assess this option and find that it only scored 2 points and comes in 19th place. Of the One Community Scoring Priorities, this product has the highest score for DIY (5 points), but receives the worst score for Health and Safety (-3 points) and Durability (-2 points), and low scores in Sustainability (1 point) and Costs (1 point). Not only does this product pose health, safety, and environmental hazards, it hasn’t been established as an insulation product so the effectiveness is unknown and it might not adhere to building codes.

KEY FEATURES

- Composition: Styrofoam is a polymer made from monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum

- R-value per inch: Unknown

- Cost per sq. ft. per R-rating: Unknown, variable

- One Community Priority ratings: 1st place in DIY, last place for Health and Safety and Durability

- Unique feature: One of only 4 products in which DIY manufacturing and installation is feasible

PROS FOR THIS INSULATION

- Mold and fungi resistant, because it is not a nutrient source for them

- Low transportation energy if you’re using your own recycled products

- DIY production of product and installation

- Low density, making transportation and installation less challenging

- Almost 100% recycled material (recycled Styrofoam)

CONS FOR THIS INSULATION

- Contains toxic chemicals that are released when exposed to excessive heat, including 1,1,1,2-Tetrafluoroethane, which can cause dizziness or asphyxiation

- Contains teratogenic (causing harm to fetuses) and reproductive toxins

- Extremely flammable, and releases dangerous gases when burned

- May contain HCFCs, which deplete the ozone layer

- Non biodegradable, so when disposed of it accumulates in the environment and leaches toxic chemicals into ecosystems

- Unknown price, very variable

- Unknown durability, new styrofoam insulation can last 50 years, but DIY insulation likely won’t last as long

- Unknown moisture management abilities

- Poor sound absorbency

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Instructables: Recycled Styrofoam Block Insulation Safety Data Sheet for purchased Styrofoam Insulation  Great Stuff Big Gap Filler Safety Data Sheet

#20 :: Icynene Classic Plus

This product scores -2 points, the only one to score below 0, and comes in last place (20th). Of the One Community Scoring Priorities, this product is tied for the worst score for DIY (-1 point), and receives negative scores in Health and Safety, Sustainability, and Costs as well. The only category in which this product scores positive points is Durability. This is a standard polyurethane spray foam. Among the biggest drawbacks of this product are the lack of renewable or recycled materials and the use of multiple hazardous chemicals (including MDI and Benzene).

This product scores -2 points, the only one to score below 0, and comes in last place (20th). Of the One Community Scoring Priorities, this product is tied for the worst score for DIY (-1 point), and receives negative scores in Health and Safety, Sustainability, and Costs as well. The only category in which this product scores positive points is Durability. This is a standard polyurethane spray foam. Among the biggest drawbacks of this product are the lack of renewable or recycled materials and the use of multiple hazardous chemicals (including MDI and Benzene).

KEY FEATURES

- Composition: -Diphenylmethane-4,4′-diisocyanate, Benzene -1-isocyanato-2-[(4-isocyanatophenyl)methyl]-.

- R-value per inch: 3.7

- Cost per sq. ft. per R-rating: Unknown

- One Community Priority ratings: Last place in DIY

- Unique feature: Claims to have the lowest Global Warming Potential (GWP of 1) value for foam insulation products

PROS FOR THIS INSULATION

- Mold, bacteria, and allergen resistant

- Good fire resistance (Class A)

- Low density product, making transportation and installation less challenging

- Allegedly high durability, claims it’ll last the lifespan of the building, but no evidence. to back this up

- Good moisture management

- Can contribute to LEED points, can contribute to NAHB Green Building Standard, and green-approved according to the National Green Building Standard of the National Association of Home Builders.

CONS FOR THIS INSULATION

- Various short-term toxicity concerns including irritation of the eyes, nose, skin, and throat

- Contains carcinogens and various hazardous decomposition products such as carbon monoxide, hydrogen cyanide, and nitrogen oxides

- No renewable or recyclable materials

- Has a Global Warming Potential of 1

- Nonbiodegrable and may meet the definition of hazardous waste in many cases

- Unknown price

- DIY installation not possible, technicians perform installation

- Poor sound absorbency

- No vapor barrier, likely requiring additional installation

ADDITIONAL INFORMATION

Huntsman Building Solutions Technical Product Data Safety Data Sheet: A-Side Safety Data Sheet: B-Side Safety Data Sheet: Foam

THE SCORING SYSTEM EXPLAINED

To create the ranking above, One Community decided upon 5 priorities for an insulation product. The categories are as follows, ranked in the order of greatest to least importance: Health and Safety, Sustainability, Cost, DIYability, and Durability. These priorities serve as the main scoring criteria, with each one being broken down into subcategories that are scored.

See the Scoring Criteria Tab of the Spreadsheet for the raw data used for each category and subcategory:

We were not paid or incentivized in any way during this research.

SCORING CATEGORIES AND SUBCATEGORIES

In order to provide greater weight to higher-priority categories, categories of greater importance have been granted more subcategories. Categories are scored from -2 to 2 points, unless stated otherwise. A score of 0 is intended to denote average, negative scores signify bad/harmful, and positive scores signify above average/advantageous.

PRIORITY 1: HEALTH AND SAFETY (5 SUBCATEGORIES)

- Short-Term Toxicity: Assesses acute health concerns, such as irritation, dizziness, nausea, vomiting, etc…

- Long-Term Toxicity: Assesses hazards to lasting health concerns, such as carcinogens and reproductive toxins

- Mold, Pests, Allergens: Is the product resistant or prone to these pests?

- Fire Resistance: Based on Fire Retardant Class, Flame Spread Index, and Smoke Developed Index

- Health and Safety Data Sheets: Based on how much information is readily accessible in data sheets

PRIORITY 2: SUSTAINABILITY (4 SUBCATEGORIES)

- Materials: Based on the percentage of product that is made from renewable/recycled materials

- Manufacturing & Transportation: How energy-intensive is the production and distribution?

- Direct Atmospheric Effects: Scored on the amount and severity of adverse consequences, with full points if it can act as a carbon sink

- Direct Ecological Effects: Scored on the amount and severity of adverse consequences, with full points if it is also biodegradable

PRIORITY 3: COST (TIED AT 3 SUBCATEGORIES WITH DIYABILITY)

- Cost per ft2 per R-rating: This metric was designed to compare price while taking into account differences in size and R-value per inch

- Processes: Instead of a scale of -2 to 2, this subcategory is split into 4 sections

- Installation: On a scale of -1 to 1, with the highest score being DIYable and the lowest score requiring technicians

- Transportation: On a scale of -1 to 1, taking into account location of availability and whether it must be transported as hazardous waste

- Storage/Handling: Either 0 points or -1 point, taking into account additional requirements/considerations

- Cleanup/Disposal: One a scale of -1 to 1, based on whether the product is hazardous and/or biodegradable

- Additional Physical Materials (Tools, Supplies): On a scale of -2 to 0 points, assessing the need and costs of additional supplies

PRIORITY 3 (TIED): DIYABILITY (TIED AT 3 SUBCATEGORIES WITH COST)

- DIY Possibility: Whether the product can be produced and/or installed DIY

- Complexity and Ease: Assesses the straightforwardness, complications, and labor-intensiveness of installation

- Density: On a scale of -1 to 1, used as a proxy to assess the physical labor required to transport and install the product

PRIORITY 4: DURABILITY (2 SUBCATEGORIES)

- Durability: Primarily based on the expected lifespan

- Moisture Management: Based on moisture resistance, primarily assessed using the metrics of water absorbency or moisture absorbance coefficient

MISCELLANEOUS SCORING CATEGORIES

- R-value: A metric of resistance to heat loss

- Certifications and Awards: Either 0 or 1 point, 1 point awarded when the product has notable accolades or can contribute to LEED credits

- Sound Absorbency: Either 0 or 1 point, 1 point awarded if the product’s Noise Reduction Coefficient is greater than 0.75

- Vapor Barrier: Either 0 or 1 point, 1 point awarded if the product does not require the additional installation of a vapor barrier

- Misc Notes, Pros, and Cons: Various additional features and reviews are used as a tiebreaker when products have received the same cumulative score

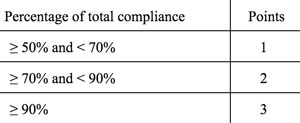

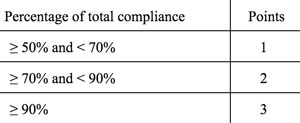

LEED MATERIALS POINTS EXPLAINED

LEED is an internationally recognized green building certification system propagated by the US Green Building Council as the leading standard for green buildings worldwide. Short for Leadership in Energy and Environmental Design, LEED Version 4 (the most current as of this writing) is designed to standardize and reward environmentally conscious building practices through assessing water usage, energy efficiency, environmental impact, materials selection, air quality, and countless other environmentally relevant factors. With independent crediting systems for newly constructed buildings (Building Design and Construction), interior construction (Interior Design and Construction), individual homes (Homes), whole neighborhoods (Neighborhood Development), and even entire cities (Cities and Communities), LEED v4 aims to provide a comprehensive blueprint for any project team, business, or individual seeking to undergo a more ecologically minded construction process.