Most Sustainable Adhesives: Safer, More Eco-friendly, LEED Compliant, and Healthier

Following One Community’s commitment to upholding the Highest Good, we aim to provide an open source and freely available blueprint for ecologically-sustainable and holistic development. As part of this, One Community has been researching the most sustainable options for everyday materials, hardware, and systems like paints, toilets, shower heads, faucets, lighting, HVAC Design, etc. This page is shares our research on eco-friendly and sustainable adhesives. We discuss this with the following sections:

- Related Pages

- Why Assess Adhesives

- Ways to Contribute and Consultants

- Types of Adhesives and their Applications

- Understanding the Toxic Nature of Phthalates & Formaldehyde

- Best and Most Sustainable Eco-friendly Adhesives We Could Find

- LEED: Materials Points Explained

- Resources

- Summary

- FAQ

This research is 100% independent and by volunteers. We have not been paid or incentivized in any way.

RELATED PAGES (mouse-over for descriptions and click for complete pages)

WHY ASSESS ADHESIVES

Adhesives are integral components of any modern building. With uses ranging from attaching carpet to the floor to holding shingles on a roof, adhesives are necessary for construction projects of any scale. Considering how pervasive adhesives are in our everyday environment, they are surprisingly laden with chemicals identified as toxic.

Adhesives are integral components of any modern building. With uses ranging from attaching carpet to the floor to holding shingles on a roof, adhesives are necessary for construction projects of any scale. Considering how pervasive adhesives are in our everyday environment, they are surprisingly laden with chemicals identified as toxic.

Phthalates and formaldehyde are the two common examples and we discuss them in the “Understanding the Toxic Nature of Phthalates & Formaldehyde” section below. Both of these chemicals are prone to off-gassing, which means they release emissions as they dry. These emissions can significantly impact air quality and human health and the potential side affects range from skin and eye irritation to liver and kidney damage. Phthalates and formaldehyde are just two of the most comment, there are many other chemicals in adhesives too. See the Resources Section below to learn about them.

With this in mind, we started doing research for our own ultra-sustainable construction projects and are sharing our research here for any others interested in more sustainable, holistically-minded products too. Our research goal was to find as many as we could with more natural and healthier ingredients than mainstream products.

As part of our open source goals and model, we’ll additionally share here our experience with the selections we use as we build the Earthbag Village and Duplicable City Center. We’ll also report on durability and update the selections here as new information becomes available. What we learn and experience will then be used to make our purchasing decisions for the other 6 villages.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHER FOR THIS COMPONENT:

James Herrigel: Student Researcher

TYPES OF ADHESIVES

& THEIR APPLICATIONS

Adhesives come in a range of forms: pastes, liquids, films, tapes, etc. This is because they include an amazing amount of specialization, with chemically different adhesives having substantially different uses. Depending on the surfaces/objects you are seeking to attach, certain types of adhesives will fare far better than others.

Adhesives come in a range of forms: pastes, liquids, films, tapes, etc. This is because they include an amazing amount of specialization, with chemically different adhesives having substantially different uses. Depending on the surfaces/objects you are seeking to attach, certain types of adhesives will fare far better than others.

According to Adhesives.org, adhesives “may be classified in a variety of ways depending on their chemistries (e.g. epoxies, polyurethanes, polyimides), their form (e.g. paste, liquid, film, pellets, tape), their type (e.g. hot melt, reactive hot melt, thermosetting, pressure sensitive, contact, etc.), or their load carrying capability (structural, semi-structural, or non-structural).” In this section, we will give an overview of the general types of adhesives, along with their main uses.

EPOXY ADHESIVES

Also known as Epoxy Resin, epoxy adhesives adhere to a wide variety of materials, and are the most widely used structural type of adhesive. They are known for having strong adhesion and durability, as well as exceptional water resistance. They are used extensively in structural projects for binding woods, metals, and fiberglass. Epoxies contain hardeners and solvents, with the Electronic Library of Construction Occupational Safety and Health listing their most common solvents as “acetone, methyl ethyl ketone, toluene, xylene, glycol ethers, and alcohols.” Off-gassing from these chemicals is considered potentially carcinogenic and can lead to respiratory and autoimmune dysfunction.

EPOXY ADHESIVES APPLICATIONS

Epoxy adhesives are considered “industrial adhesives” and used for a wide range of applications. They are a preferred choice for bonding plastics, woods, and ceramics, used as a protective and heat resistant coating for metals like cast iron, steel, and aluminum, and can also be used as an electrical insulator. This has made them common in the construction of aircraft, automobiles, bicycles, boats, golf clubs, furniture, skis, snowboards, and the like.

POLYURETHANE ADHESIVES

Polyurethane glues will work on just about all normal materials, including wood, metals, rubbers, cured epoxy, leather, tile, glass, plastics, concrete, bricks, and more. It does not work well on substances similar to teflon or silicone. These adhesives dry into a solid, can even set in high-moisture conditions, and are more waterproof than epoxy-based adhesives. Polyurethane adhesives are not quite as strong as epoxies, and actually requires more moisture to set. According to Adhesives.org, after curing, polyurethane adhesives are no longer chemically active and can be considered quite safe. However, as they dry, they are highly prone to off-gassing and can release toxic, irritating, and carcinogenic fumes.

POLYURETHANE ADHESIVES APPLICATIONS

Polyurethane adhesives, like epoxies, have a wide range of uses. They are commonly used for vehicle interiors, for bonding windshields, in medical devices, electronics, and sports equipment. They are also increasingly being used by the home construction industry because of their ability to bond to a diversity of different materials. In home construction, polyurethanes are now typically used for bonding ceiling drywall to rafters, for subflooring, staircases, and cabinets.

POLYIMIDES ADHESIVES

According to Epoxy Technologies Inc., polyimides adhesives are “known for their flexural strength, flame resistance and chemical resistance, as well as high temperature performance in the 400-500°C range.” They are used mainly as coatings rather than structural adhesives, due to their weak level of bonding compared to epoxy and polyurethane formulas, which Epoxy Technologies Inc. estimates to be around 1/3 to 1/2 the power of epoxies. Off-gassing from poorly ventilated polyimide use can lead to respiratory issues due to the toxic content of the fumes.

POLYIMIDES ADHESIVES APPLICATIONS

Polyimides adhesives are commonly used in the manufacture of circuits, semiconductors, and electronic cables. Polyimide fibers are also commonly woven into flame-resistant materials like protective clothing for firefighters, bags for hot gas filtration in power plants and cement kilns, and jacket insulation and jacket coatings. They are not commonly used in home construction.

UNDERSTANDING THE TOXIC NATURE OF

PHTHALATES & FORMALDEHYDE

Generally, glues and adhesives tend to include formaldehyde and phthalates. Formaldehyde resin is an integral component of nearly all available adhesives. The International Agency for Research on Cancer, a sub-agency of the World Health Organization, has concluded that formaldehyde is “carcinogenic to humans.” The exact amount of exposure that leads to negative health effects is still unclear, but exposure to large amounts of formaldehyde fumes will definitely lead to health issues.

Generally, glues and adhesives tend to include formaldehyde and phthalates. Formaldehyde resin is an integral component of nearly all available adhesives. The International Agency for Research on Cancer, a sub-agency of the World Health Organization, has concluded that formaldehyde is “carcinogenic to humans.” The exact amount of exposure that leads to negative health effects is still unclear, but exposure to large amounts of formaldehyde fumes will definitely lead to health issues.

According to Adhesives Magazine, “Formaldehyde is highly toxic to humans, regardless of the intake method. Even short-term exposure to formaldehyde irritates the eyes and causes pain, redness, blurred vision and severe watering. It can irritate the nose and throat, causing sneezing, soreness, coughing, shortness of breath, headaches, and nausea. Exposure to elevated levels can lead to the accumulation of fluid in the lungs (pulmonary edema). A large exposure to formaldehyde is converted to formic acid in the body, leading to a rise in blood acidity, rapid or shallow breathing, hypothermia, and coma or death. Long-term exposure causes chronically impaired lung function, skin hardening, swelling and flaking, dermatitis, allergic eczema, and cancer.”

Phthalates, a carbon-based chemical used in a wide range of commercial products, is used extensively in the production of adhesives. According to SpecialChem.com, phthalates help achieve “durability, flexibility, [and] weather resistance” in adhesives, and additionally help the adhesive “to withstand high temperatures.” They are known as “plasticizers,” which is defined as a substance (typically a solvent) added to a synthetic resin to produce or promote plasticity and flexibility and to reduce brittleness.

The U.S. National Toxicology Program’s Center for the Evaluation of Risks to Human Reproduction concluded that there was “minimal concern” regarding risk of developmental or reproductive effects from current exposure levels to DINP, and there was “minimal concern” regarding risk of developmental effects and “negligible concern” regarding risk of reproductive effects from current exposure levels to phthalates in consumer products. The most recent research though disagrees with them. This article titled, “Phthalates are everywhere, and the health risks are worrying. How bad are they really?” goes into the details. This resource from the CDC is also worth reading.

THE BEST AND MOST

SUSTAINABLE & ECO-FRIENDLY

ADHESIVES WE COULD FIND

As part of One Community’s Highest Good Housing initiative, we have conducted research into sustainable, holistically-responsible alternatives to conventional adhesives. We seek to facilitate the creation of healthy, environmentally-symbiotic buildings, homes, and public spaces, free of harmful chemicals and toxins. Below, we provide a list of high-quality alternative adhesives. The products and companies below were chosen based on their chemical content, performance compared to mainstream products, affordability, and environmental footprint.

As part of One Community’s Highest Good Housing initiative, we have conducted research into sustainable, holistically-responsible alternatives to conventional adhesives. We seek to facilitate the creation of healthy, environmentally-symbiotic buildings, homes, and public spaces, free of harmful chemicals and toxins. Below, we provide a list of high-quality alternative adhesives. The products and companies below were chosen based on their chemical content, performance compared to mainstream products, affordability, and environmental footprint.

NOTE: New technology is always being invented, check the company websites for their newest products. Even as this page becomes dated, the featured products below can be used as a good base-level starting point for your selection process. We wouldn’t recommend any product that doesn’t meet or surpass the quality and performance of the products listed here. This is how we intend to use this page as we build the Duplicable City Center and 7 sustainable village models. If better products are found when we start making our purchases, we’ll open source share here what they are and our personal experience using them.

#1 :: AFM SAFECOAT

American Formulating and Manufacturing (AFM) is a Company with a history of over 30 years developing environmentally conscious products with a focus on protecting human health and restricting harmful chemicals. AFM Safecoat has a broad array of products including primers and paints, stains and sealers, cleaners and carpet care, and clear finishes. Safecoat has two types of adhesives: Safecoat Almighty Adhesive, a multi-purpose adhesive, and the Safecoat 3-in-1 Adhesive, which is designed for hard composition wall and floor tiles and carpeting. To read our review on their primers, paints, stains and sealers, visit our Most Sustainable Paints, Stains, Varnish, and Sealers page.

American Formulating and Manufacturing (AFM) is a Company with a history of over 30 years developing environmentally conscious products with a focus on protecting human health and restricting harmful chemicals. AFM Safecoat has a broad array of products including primers and paints, stains and sealers, cleaners and carpet care, and clear finishes. Safecoat has two types of adhesives: Safecoat Almighty Adhesive, a multi-purpose adhesive, and the Safecoat 3-in-1 Adhesive, which is designed for hard composition wall and floor tiles and carpeting. To read our review on their primers, paints, stains and sealers, visit our Most Sustainable Paints, Stains, Varnish, and Sealers page.

KEY FEATURES

The Safecoat Almighty Adhesive is solvent-free, odorless, does not off-gas, and meets or exceeds existing VOC and environmental regulations/certifications. This includes LEED, Declare, and similar certification systems. This product is non-toxic and environmentally safe without sacrificing quality. Almighty Adhesive provides 500 PSI shear strength, which is more than enough for most applications. Safecoat is a longstanding presence in the construction industry that has helped shape the standard for eco-friendly products while maintaining the quality people have come to expect. The Safecoat 3-in-1 Adhesive is low-odor, non-toxic, and water-based. It has a very low VOC content, meeting or exceeding all federal and state air quality regulations, including that of California (the most stringent). Neither products contain formaldehyde, and the use of these products has negligible off-gassing, making them far less problematic for people with sensitivities and mitigating potential health risks associated with most mainstream adhesives.

PROS FOR THIS COMPANY

AFM Products are trusted and guarantee an unwavering standard of holistic, sustainable, and non-toxic products that also maintain industry-standard quality. Both their adhesives are multi-use, making them more affordable because one does not need to buy as many different types. They provide extensive data on their products, including chemical inventories and overviews of ingredients. The products will also qualify for LEED or other relevant sustainability certification programs, making them an excellent choice for anyone seeking such a qualification/certification for their project.

CONS FOR THIS COMPANY

AFM Products cannot be purchased directly from the AFM website. To order, one must find an online or local retailer.

SPECIFIC PRODUCTS

Safecoat Almighty Adhesive: This is a solvent-free, non-toxic construction adhesive designed for use in a wide variety of situations. The product is environmentally safe while maintaining high-quality performance. This adhesive does not off-gas and is nearly odorless, making it safe for use in poorly ventilated areas. It exceeds all VOC and environmental regulations. The Almighty Adhesive provides 500 PSI shear strength, which should be suitable for most applications. This adhesive is most similar to an epoxy, due to its wide array of uses and intended purpose. The product’s Spec Sheet and Material Safety Data Sheet can be retrieved from the product page. AFM Products cannot be purchased directly from the AFM website. To order, one must find an online or local retailer. From www.greenbuildingsupply.com, Safecoat Almighty Adhesive can be ordered for $7.34 each, with each container containing 10 ounces.

Safecoat Almighty Adhesive: This is a solvent-free, non-toxic construction adhesive designed for use in a wide variety of situations. The product is environmentally safe while maintaining high-quality performance. This adhesive does not off-gas and is nearly odorless, making it safe for use in poorly ventilated areas. It exceeds all VOC and environmental regulations. The Almighty Adhesive provides 500 PSI shear strength, which should be suitable for most applications. This adhesive is most similar to an epoxy, due to its wide array of uses and intended purpose. The product’s Spec Sheet and Material Safety Data Sheet can be retrieved from the product page. AFM Products cannot be purchased directly from the AFM website. To order, one must find an online or local retailer. From www.greenbuildingsupply.com, Safecoat Almighty Adhesive can be ordered for $7.34 each, with each container containing 10 ounces.

Safecoat 3-in-1 Adhesive: This is a low-odor, non-toxic, multi-purpose adhesive designed for hard composition wall/floor tiles and carpeting. This product is most similar to an epoxy or polyurethane adhesive, as it is specifically intended for use in bonding tile and carpet. This product’s Spec Sheet and Material Safety Data Sheet can be retrieved from the product page. AFM Products cannot be purchased directly from the AFM website. To order, one must find an online or local retailer. From www.greenbuildingsupply.com, Safecoat 3-in-1 Adhesive can be purchased for $71.90/gallon or $27.90/quart.

Safecoat 3-in-1 Adhesive: This is a low-odor, non-toxic, multi-purpose adhesive designed for hard composition wall/floor tiles and carpeting. This product is most similar to an epoxy or polyurethane adhesive, as it is specifically intended for use in bonding tile and carpet. This product’s Spec Sheet and Material Safety Data Sheet can be retrieved from the product page. AFM Products cannot be purchased directly from the AFM website. To order, one must find an online or local retailer. From www.greenbuildingsupply.com, Safecoat 3-in-1 Adhesive can be purchased for $71.90/gallon or $27.90/quart.

ADDITIONAL INFORMATION

Click Here for the AFM Safecoat Company Website

#2 :: BONA®

Bona is a family-owned Swedish company founded in 1919. They have grown into an international distributor specializing in products related to the installation, maintenance, and renovation of wood floors. Committed to sustainability, the company has a longstanding history of prioritizing the minimization of their products’ environmental impact, encouraging renovation rather than replacement, and emphasizing human health. In the 1970’s, Bona was among the first mainstream wood-floor product suppliers to remove toxic and hazardous chemicals from hardwood floor finishes, innovating in the field of water-based finishes as a quality alternative. Similarly, Bona was one of the first companies to insist on dust-containment systems that remove carcinogenic wood dust from the air and environment during the hardwood floor sanding process. Bona offers a range of water-based products certified by a variety of international and national environmental organizations. One of the most prestigious is the GREENGUARD Environmental Institute Certification Program, which evaluates product emissions with criteria derived from the US Green Building Commission’s (USGBC) LEED Certification Low-Emitting Materials section. Bona products are GREENGUARD Gold Certified, the highest standard within the organization. Their products limit toxic ingredients and have Low-VOC content. Bona also reuses materials within the production process to limit waste.

Bona is a family-owned Swedish company founded in 1919. They have grown into an international distributor specializing in products related to the installation, maintenance, and renovation of wood floors. Committed to sustainability, the company has a longstanding history of prioritizing the minimization of their products’ environmental impact, encouraging renovation rather than replacement, and emphasizing human health. In the 1970’s, Bona was among the first mainstream wood-floor product suppliers to remove toxic and hazardous chemicals from hardwood floor finishes, innovating in the field of water-based finishes as a quality alternative. Similarly, Bona was one of the first companies to insist on dust-containment systems that remove carcinogenic wood dust from the air and environment during the hardwood floor sanding process. Bona offers a range of water-based products certified by a variety of international and national environmental organizations. One of the most prestigious is the GREENGUARD Environmental Institute Certification Program, which evaluates product emissions with criteria derived from the US Green Building Commission’s (USGBC) LEED Certification Low-Emitting Materials section. Bona products are GREENGUARD Gold Certified, the highest standard within the organization. Their products limit toxic ingredients and have Low-VOC content. Bona also reuses materials within the production process to limit waste.

KEY FEATURES

Bona adhesives are silane-based, rather than solvent-based, reducing emissions significantly. They are designed and intended for use on hardwood floor construction, renovation, and upkeep. Adhesives like the Bona R851 are water, solvent, and Isocyanate free with zero VOC’s, making them an excellent choice for anyone concerned with air quality. GREENGUARD Certified for Indoor Air Quality, the Bona R851 meets the criteria for LEED EQc 4.1 (v. 2.1, 2.2, 3.0), so you can be confident Bona products support healthy environmental air quality and will contribute points to LEED Certification.

PROS FOR THIS COMPANY

Bona products are high quality and employ innovative techniques to maintain great performance while limiting toxic emissions and mitigating environmental impact. With their 100-year history in the hardwood floor industry, Bona has a century of specific, applied attention to crafting the best products possible for hardwood floor installation, renovation, and upkeep, making their products more effective for this purpose than most all-purpose adhesives. Another benefit of using Bona products is that they are GREENGUARD Certified, and contribute points to LEED Certification, making them an excellent choice for anyone interested in securing LEED Credit.

CONS FOR THIS COMPANY

Because Bona products are so specific to hardwood floors, they are not the solution for someone looking for one company to provide all the adhesive products needed for a multi-faceted large-scale project. Bona products also cannot be purchased directly from the Bona website, and must instead be sourced from an online or local retailer.

SPECIFIC PRODUCTS

Bona R851 – This is a silane-based wood flooring adhesive designed for grab and shear strength. Water, solvent, and isocyanate-free mixture with zero VOC’s. Shear strength development is quite rapid, with flooring being able to withstand furniture and foot traffic one day after application. GREENGUARD Certified for Indoor Air Quality, and meets criteria for LEED EQc 4.1 (v. 2.1, 2.2, 3.0) zero-VOC standards. Technical and Safety Data Sheets, among other relevant documents for the R851 product, can be retrieved from the Bona R851 webpage. Bona products cannot be purchased directly from the Bona website, and must instead be sourced from an online or local retailer. From Amazon.com, a 3-gallon container of Bona R851 is $113.60 on Amazon.

Bona R851 – This is a silane-based wood flooring adhesive designed for grab and shear strength. Water, solvent, and isocyanate-free mixture with zero VOC’s. Shear strength development is quite rapid, with flooring being able to withstand furniture and foot traffic one day after application. GREENGUARD Certified for Indoor Air Quality, and meets criteria for LEED EQc 4.1 (v. 2.1, 2.2, 3.0) zero-VOC standards. Technical and Safety Data Sheets, among other relevant documents for the R851 product, can be retrieved from the Bona R851 webpage. Bona products cannot be purchased directly from the Bona website, and must instead be sourced from an online or local retailer. From Amazon.com, a 3-gallon container of Bona R851 is $113.60 on Amazon.

Bona R859 – Similar to the R851, the R859 is a one-component, silane-based wood flooring adhesive. Designed to be thicker than the R851, the R859 excels at reducing voids caused by uneven substrates. The adhesive has elastomeric characteristics allowing it to move with the wood as it naturally expands and contracts. This product, like the R851, is GREENGUARD Certified for Indoor Air Quality, and meets criteria for LEED EQc 4.1 (v. 2.1, 2.2, 3.0) zero-VOC standards. From Amazon.com, a 4-gallon container of Bona R859 is $218.99 on Amazon.

Bona R859 – Similar to the R851, the R859 is a one-component, silane-based wood flooring adhesive. Designed to be thicker than the R851, the R859 excels at reducing voids caused by uneven substrates. The adhesive has elastomeric characteristics allowing it to move with the wood as it naturally expands and contracts. This product, like the R851, is GREENGUARD Certified for Indoor Air Quality, and meets criteria for LEED EQc 4.1 (v. 2.1, 2.2, 3.0) zero-VOC standards. From Amazon.com, a 4-gallon container of Bona R859 is $218.99 on Amazon.

Bona R880 – Another silane-based construction adhesive, the R880 product is designed mainly for adhering vertical wood surfaces. It is also useful for trim, starter, and closeout rows, treads, risers, etc. Smaller head allows for more precision, and fast-setting initial grab allows for efficient workflow. Water and solvent free, the Bona R880 is GREENGUARD Certified, meeting VOC-content requirements derived from the LEED Low Emitting Materials component. Technical and Safety Data Sheets, as well as other relevant documents for the R880 can be retrieved from the product page. An 8-ounce Bona R880 can be purchased on Amazon for $20.00.

Bona R880 – Another silane-based construction adhesive, the R880 product is designed mainly for adhering vertical wood surfaces. It is also useful for trim, starter, and closeout rows, treads, risers, etc. Smaller head allows for more precision, and fast-setting initial grab allows for efficient workflow. Water and solvent free, the Bona R880 is GREENGUARD Certified, meeting VOC-content requirements derived from the LEED Low Emitting Materials component. Technical and Safety Data Sheets, as well as other relevant documents for the R880 can be retrieved from the product page. An 8-ounce Bona R880 can be purchased on Amazon for $20.00.

Bona R850T – Moisture curing, water and solvent free, silane-based adhesive designed for wood floors. Engineered to adhere to a variety of surfaces and allows for natural movement of wood flooring. Comes with battery powered application gun, allowing for quick, easy installation. One charge lasts over 3,000 linear feet. Pointed spout allows for precise application, making the R850T perfect for finishing rows, board replacements, and trim applications. This product is GREENGUARD Indoor Air Quality Certified, and meets or exceeds any relevant VOC-content requirement with zero VOCs. Among other documents, the Bona R850T’s Technical and Safety Data Sheets can be retrieved from the product page. Bona products cannot be purchased directly from the Bona website, and must instead be sourced from an online or local retailer. The 600-ml Adhesive Applicator Gun and the 20-oz Adhesive Tube are sold separately as components of the Bona R850T. They can be purchased from paneltown.com for $45.99 and $8.99 respectively.

Bona R850T – Moisture curing, water and solvent free, silane-based adhesive designed for wood floors. Engineered to adhere to a variety of surfaces and allows for natural movement of wood flooring. Comes with battery powered application gun, allowing for quick, easy installation. One charge lasts over 3,000 linear feet. Pointed spout allows for precise application, making the R850T perfect for finishing rows, board replacements, and trim applications. This product is GREENGUARD Indoor Air Quality Certified, and meets or exceeds any relevant VOC-content requirement with zero VOCs. Among other documents, the Bona R850T’s Technical and Safety Data Sheets can be retrieved from the product page. Bona products cannot be purchased directly from the Bona website, and must instead be sourced from an online or local retailer. The 600-ml Adhesive Applicator Gun and the 20-oz Adhesive Tube are sold separately as components of the Bona R850T. They can be purchased from paneltown.com for $45.99 and $8.99 respectively.

ADDITIONAL INFORMATION

Click Here for the Bona® Company Website

#3 :: BOSTIK SMART ADHESIVES

Bostik, a member of the US Green Building Council (USGBC), the parent organization of the LEED Certification system, is a company with an extensive range of high-quality and innovative adhesive formulas. Their products cover nearly every conceivable industry, from aerospace adhesives to industrial sealants, with a comprehensive array of traditional construction adhesives. As one of the world’s leading adhesive retailers, Bostik is a reliable supplier that can provide the variety of adhesives needed for nearly any scale of project.

Bostik, a member of the US Green Building Council (USGBC), the parent organization of the LEED Certification system, is a company with an extensive range of high-quality and innovative adhesive formulas. Their products cover nearly every conceivable industry, from aerospace adhesives to industrial sealants, with a comprehensive array of traditional construction adhesives. As one of the world’s leading adhesive retailers, Bostik is a reliable supplier that can provide the variety of adhesives needed for nearly any scale of project.

KEY FEATURES

Many Bostik products contribute points towards achieving LEED Certification, specifically to the Indoor Air Quality Section 4.1 – Low Emitting Materials: Adhesives & Sealants section. The intent of this one-point credit criteria is to reduce the quantity of indoor air contaminants that are odorous and potentially irritating and/or harmful to the comfort and well-being of installers and occupants. Each product has comprehensive and informative Technical Data Sheets with detailed chemical inventories and ingredient overviews. Bostik adhesives are Low-VOC.

PROS FOR THIS COMPANY

Bostik is a massive company with a wide range of products and international distribution. For their scope, affordability, and convenience, Bostik products are remarkably sustainable, with minimization of toxic irritants and a general emphasis on sustainability. Furthermore, their products align easily with LEED, and can provide tangible benefit to anyone seeking LEED Certification.

CONS FOR THIS COMPANY

Their products are still chemically dense, and the company does not place much emphasis on minimizing emissions, pollution, and waste during the manufacturing and distribution process.

SELECTED PRODUCTS

Bostik GreenGrip – GreenGrip➢ is a high-performance adhesive and moisture-control membrane all in one. Bostik’s breakthrough AXIOS➢ Tri-Linking➢ Polymer Technology used in this formulation maintains the superior long-term durability and moisture protection properties of high-end urethane adhesives. However, it is easier to spread and clean off of pre-finished flooring before and after cure. This adhesive has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water. GreenGrip➢ comes with Bostik’s BLOCKADE® antimicrobial protection, which inhibits the growth of bacteria, mold or mildew on the surface of the cured membrane. The cured membrane resists stains caused by mold.

Bostik GreenGrip – GreenGrip➢ is a high-performance adhesive and moisture-control membrane all in one. Bostik’s breakthrough AXIOS➢ Tri-Linking➢ Polymer Technology used in this formulation maintains the superior long-term durability and moisture protection properties of high-end urethane adhesives. However, it is easier to spread and clean off of pre-finished flooring before and after cure. This adhesive has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water. GreenGrip➢ comes with Bostik’s BLOCKADE® antimicrobial protection, which inhibits the growth of bacteria, mold or mildew on the surface of the cured membrane. The cured membrane resists stains caused by mold.

Bostik Grip-N-Shield – Bostik Grip-N-Shield is a high performance adhesive, moisture control, and sound-reduction membrane all in one. Its superior properties provide a tough, flexible, tenacious bond to a variety of surfaces, and it is not adversely affected by exposure to moisture, water, or alkalinity. Grip-N-Shield exhibits exceptional green grab or high tack immediately after troweling, making installation easier and more secure. This adhesive contains 1% recycled rubber material, has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water. Grip-N-Shield contains Bostik BLOCKADE antimicrobial protection, which inhibits the growth of bacteria, mold, and mildew on the surface of the dried adhesive.

Bostik Grip-N-Shield – Bostik Grip-N-Shield is a high performance adhesive, moisture control, and sound-reduction membrane all in one. Its superior properties provide a tough, flexible, tenacious bond to a variety of surfaces, and it is not adversely affected by exposure to moisture, water, or alkalinity. Grip-N-Shield exhibits exceptional green grab or high tack immediately after troweling, making installation easier and more secure. This adhesive contains 1% recycled rubber material, has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water. Grip-N-Shield contains Bostik BLOCKADE antimicrobial protection, which inhibits the growth of bacteria, mold, and mildew on the surface of the dried adhesive.

Bostik DuraGrip – Bostik DuraGrip is an easy-to-trowel urethane adhesive. It provides a tough, flexible, tenacious bond to a variety of surfaces. DuraGrip’s elastomeric characteristics allow the adhesive to move with the wood as it expands and contracts over the life of the floor. This adhesive has low VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water.

Bostik DuraGrip – Bostik DuraGrip is an easy-to-trowel urethane adhesive. It provides a tough, flexible, tenacious bond to a variety of surfaces. DuraGrip’s elastomeric characteristics allow the adhesive to move with the wood as it expands and contracts over the life of the floor. This adhesive has low VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water.

Bostik Wood-Grip – Wood-Grip➢ Advanced➢ is a high performance adhesive, moisture control, and sound-reduction membrane all in one. Bostik’s breakthrough AXIOS® Tri-Linking➢ Polymer Technology used in this formulation maintains the superior long-term durability, moisture control and sound abatement properties of high-end urethane adhesives. However, it is easier to spread and clean off of pre-finished flooring before and after cure. This adhesive contains 1% recycled rubber material, has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water.

Bostik Wood-Grip – Wood-Grip➢ Advanced➢ is a high performance adhesive, moisture control, and sound-reduction membrane all in one. Bostik’s breakthrough AXIOS® Tri-Linking➢ Polymer Technology used in this formulation maintains the superior long-term durability, moisture control and sound abatement properties of high-end urethane adhesives. However, it is easier to spread and clean off of pre-finished flooring before and after cure. This adhesive contains 1% recycled rubber material, has zero VOC’s (as calculated per SCAQMD Rule 1168) and does not contain any water.

ADDITIONAL INFORMATION

Click Here for Bostik Company Website

#4 :: 3M

A Fortune 500 company with sales in 200 countries, 3M is a global leader in providing abrasives, adhesives, films, and other products to industries ranging from automotive to health care. They are lowest on our list because of their practices covered in this article: “Internal documents show 3M hid PFAS dangers for decades“. Those are not good company practices and you might be asking why we’d include them at all. The answer is that, even with things like this, 3M still is producing more sustainable products and a more sustainable distribution process than all the companies NOT on this list. Notably, 3M products are GREENGUARD Gold Certified, meaning that they comply with stringent chemical emission standards designed around the United States Green Building Council’s (USGBC) LEED Certification system’s Low-Emitting Materials component. Beyond certifications, 3M has made remarkable strides in supporting renewable energy and integrating it into their production process. Recently, 3M officially converted their entire 409-acre headquarters to be completely powered by renewable energy, and have made a commitment to move 3M’s entire global operations to 100% renewable sources of power. We think that is pretty impressive and hope that articles like the one above are reflective of a past corporate culture rather than an ongoing problem.

A Fortune 500 company with sales in 200 countries, 3M is a global leader in providing abrasives, adhesives, films, and other products to industries ranging from automotive to health care. They are lowest on our list because of their practices covered in this article: “Internal documents show 3M hid PFAS dangers for decades“. Those are not good company practices and you might be asking why we’d include them at all. The answer is that, even with things like this, 3M still is producing more sustainable products and a more sustainable distribution process than all the companies NOT on this list. Notably, 3M products are GREENGUARD Gold Certified, meaning that they comply with stringent chemical emission standards designed around the United States Green Building Council’s (USGBC) LEED Certification system’s Low-Emitting Materials component. Beyond certifications, 3M has made remarkable strides in supporting renewable energy and integrating it into their production process. Recently, 3M officially converted their entire 409-acre headquarters to be completely powered by renewable energy, and have made a commitment to move 3M’s entire global operations to 100% renewable sources of power. We think that is pretty impressive and hope that articles like the one above are reflective of a past corporate culture rather than an ongoing problem.

KEY FEATURES

3M has 12 adhesive products certified with GREENGUARD’s Indoor Air Quality and Children & School credits. Retrieved from the list on the 3M website, these products include a wide range of adhesives, with contact, insulation, pressure sensitive, foam, and spray adhesives, as well as a range of other models. The 3M Super 77 Multipurpose Spray Adhesive is one such product. It is a versatile adhesive that bonds a range of lightweight materials including paper, cardboard, fabric, insulation, plastic, metal, and wood, making it an excellent multi-purpose option. Like the rest of the products on the list, the Super 77 Multipurpose Spray qualifies for GREENGUARD Indoor Air Quality and Children & Schools certifications. It also contributes points to LEED Credits, especially in the Low-Emitting Materials component. With these certifications, you can use these products with confidence that they have far safer VOC thresholds and far less emissions than traditional, mainstream adhesives.

PROS FOR THIS COMPANY

As a massive, multinational corporation, 3M has incredible reach and distribution, making their products easy to find, and easy to rely on as a source of adhesives. In addition, their incredible size results in an incredibly large range of products, making them a one stop shop for nearly any construction project. If one selects the right product, 3M adhesives will have remarkably low VOC content, low environmental impact, and will contribute to LEED credits, all while maintaining high-quality performance.

CONS FOR THIS COMPANY

As a result of 3M’s huge product range, one has to be careful to select products which are environmentally oriented. Not every 3M adhesive is up to the standard of those enumerated in the aforementioned list. Also, 3M products are internationally distributed and mass produced, so they do not have as much inclination to reduce waste and emissions in the manufacturing process as smaller-scale companies have. This article highlights some of these practices and the corporate culture that has hid them for years: “Internal documents show 3M hid PFAS dangers for decades“. We think practices like this demonstrate a company more interested in greenwashing their image than truly being sustainable. That said, they still produce some excellent and health-conscious products and that is why they are included here, albeit at the bottom of this list.

SPECIFIC PRODUCTS

As a Fortune 500 company, 3M has an incredibly large scope compared to other companies on our list, and as a result has far more products to choose from. Although 3M has made remarkable commitments to reducing its ecological footprint and creating more responsible products, one must exercise caution when selecting products, as not every product is designed to be more eco-friendly. In the following table are all of the 3M adhesives that are Indoor Air Quality and Children & Schools certified under the GREENGUARD Certification Program, an independent third-party testing program propagated by the GREENGUARD Environmental Institute (GEI). GREENGUARD Low-emission standards are derived from the LEED Low-Emitting Materials standard, and as a result products certified under GREENGUARD will contribute points to LEED Certification.

| PRODUCT | KEY FEATURES |

| Fastbond➢ 30NF/30H Contact Adhesive | Versatile water-based adhesive designed for high strength, high coverage, long bonding range, and good heat resistance. Bonds most foamed plastics, plastic laminate, wood, plywood, and canvas to themselves and to each other. Can be applied by spray, brush, or roller. |

| Fastbond➢ 49 Insulation Adhesive | Adhesive formulated for HVAC fiberglass insulation and other forms of insulation. It can also be used to bond lightweight materials like fabric, felt, and foam. Intended use is insulation installation. |

| Fastbond➢ 100 Foam Adhesive | Water-based adhesive designed to bond lightweight materials including paper, cardboard, fabric, insulation, plastic, metal, and wood. |

| Fastbond➢ 2000NF Contact Adhesive | Water-based contact adhesive designed for high heat resistance and high strength. Bonds most foams, plastic laminate, wood, plywood, particle board, fabrics, fiber, aluminum, galvanized steel, and most plastics. Ideal for attaching carpet, bonding wood veneer to particle board, and bonding rigid and flexible foam. |

| Fastbond➢ 4224NF Pressure Sensitive Adhesive | Adhesive designed to bond flooring materials, including vinyl, foam, and carpet tiles. High-temperature resistant, and non-flammable. Can be applied by spray, brush, or roller. Water-based. |

| Foam Fast 74 Spray Adhesive ” Low VOC < 25% | Aerosol adhesive designed to bond foam and fabric to a wide range of substrates including paper, cardboard, plastic, metal, and wood. |

| Scotch-Weld➢ Hi-Strength 94 ET Spray Adhesive | Aerosol epoxy adhesive designed to bond laminates, metals, some rubbers, as well as porous surfaces like soft foam. |

| 3M➢ Super 77 Spray Adhesive ” Low VOC < 25% | Aerosol epoxy adhesive designed to bond a wide range of lightweight materials – paper, cardboard, fabric, insulation, plastic, metal, wood, etc. |

| 3M➢ Adhesive Remover ” Low VOC < 20% | Low-VOC aerosol adhesive remover designed to soften or dissolve non-curing adhesives, grease, and dirt. Cleans glue from cured paint, chrome, and other metals. |

| 3M➢ Adhesive Remover – Renew | Sprayable adhesive remover designed to remove adhesive residue, wax, and silicone from automotive paint, vinyl, and glass. Excellent for removing scuff marks, pen, non-permanent markers, stickers, and dried latex paint. |

ADDITIONAL INFORMATION

Click Here for the 3M Company Website

LEED MATERIALS POINTS EXPLAINED

LEED is an internationally recognized green building certification system propagated by the US Green Building Council as the leading standard for green buildings worldwide. Short for Leadership in Energy and Environmental Design, LEED Version 4 (the most current as of this writing) is designed to standardize and reward environmentally conscious building practices through assessing water usage, energy efficiency, environmental impact, materials selection, air quality, and countless other environmentally relevant factors. With independent crediting systems for newly constructed buildings (Building Design and Construction), interior construction (Interior Design and Construction), individual homes (Homes), whole neighborhoods (Neighborhood Development), and even entire cities (Cities and Communities), LEED v4 aims to provide a comprehensive blueprint for any project team, business, or individual seeking to undergo a more ecologically minded construction process.

LEED is an internationally recognized green building certification system propagated by the US Green Building Council as the leading standard for green buildings worldwide. Short for Leadership in Energy and Environmental Design, LEED Version 4 (the most current as of this writing) is designed to standardize and reward environmentally conscious building practices through assessing water usage, energy efficiency, environmental impact, materials selection, air quality, and countless other environmentally relevant factors. With independent crediting systems for newly constructed buildings (Building Design and Construction), interior construction (Interior Design and Construction), individual homes (Homes), whole neighborhoods (Neighborhood Development), and even entire cities (Cities and Communities), LEED v4 aims to provide a comprehensive blueprint for any project team, business, or individual seeking to undergo a more ecologically minded construction process.

Projects that participate in the LEED program are awarded points based on their compliance with the LEED v4 Standards and on a scale of 0-100. Depending on the number of points accumulated, projects are awarded a level of certification as follows:

- 40-49 points: LEED Certified

- 50-59 points: LEED Silver Certified

- 60-79 points: LEED Gold Certified

- 80+ points: LEED Platinum Certified

Achieving LEED Certification demonstrates an intense commitment to sustainability and ecological responsibility and can be immensely beneficial for improving the public image of a company. More directly, LEED Certification can often lead to significant tax credits and has also been shown to increase property values. LEED Certification can be immensely beneficial to businesses and normal people alike and we support its use as a standard for sustainable development.

Paints, stains, sealants, and primers are a group of products crucial to achieving LEED Certification. Using products compliant with LEED Standards is an invaluable tool for accruing points and certification. Depending on which area of LEED Certification one is aiming for, paints, stains, sealants, and primers can help with a significant portion of the necessary points. The amount of potential points, including paints etc. and organized by LEED Certification area, is as follows:

- Building Design and Construction (BD+C) – 9 points

- Interior Design and Construction (ID+C) – 7 points

- Homes – 3 points

- Building Operations and Maintenance (O+M) – n/a

- Neighborhood Development (ND) – n/a

- Cities and Communities – n/a

BUILDING DESIGN AND CONSTRUCTION

In order to secure the maximum of 9 points, one must complete the following requirements:

1. MATERIALS AND RESOURCES – ENVIRONMENTAL PRODUCT DECLARATIONS

Materials and Resources – Building Product Disclosure and Optimization – Environmental Product Declarations (1-2 points): This component stresses selecting products from manufacturers with completed and environmentally preferable life-cycle impact analyses for their products. There are 2 options within the credit, each worth 1 point. Completing both earns the maximum of 2 points.

Option 1 – Environmental Product Declaration (EPD): In order to earn this credit, the project team must provide proof that they have used at least 20 different products sourced from at least 5 different manufacturers, meeting at least 1 of the following criteria:

- Products have publicly available and critically reviewed life-cycle assessments conforming to ISO 14044.

- Products have publicly available Environmental Product Declarations (EPDs) as standardized by ISO 14025 and ISO 21930. EPDs must have at least cradle to gate scope, with industry-wide and/or product-specific certification.

- Alternatively, project teams can use USGBC approved products and/or certification programs.

Option 2 – Multi-Attribute Optimization: In order to earn this credit, project teams use 3rd-party products with available life-cycle analyses demonstrating reduction above industry averages in:

- Global Warming Potential (GWP)

- Depletion of Ozone Layer

- Acidification (land/water)

- Eutrophication

- Tropospheric Ozone Formation

- Depletion of Nonrenewable Energy Sources

Industry averages can be retrieved from relevant Environmental Product Declarations in same product categories. To ease the process, use products/materials from the USGBC List of Certified Products/Materials. In addition, products sourced within 100 miles yield 200% value consideration.

2. MATERIALS AND RESOURCES – MATERIAL INGREDIENTS

Materials and Resources – Building Product Disclosure & Optimization – Material Ingredients (1-2 points): This component emphasizes material ingredient reporting and certification. There are 3 options within the credit, each worth 1 point. Complete 2 of the 3 following options for a maximum of 2 points.

Option 1 – Material Ingredient Reporting: In order to earn this credit, one must initially utilize (and provide evidence of utilization of) at least 20 different products from at least 5 different manufacturers. With that prerequisite completed, one must then provide a fully realized chemical inventory for each product, conforming to or certified by a USGBC approved program/standard. USGBC approved chemical inventory services are as follow:

- Manufacturer Inventory – chemical inventories conducted by manufacturer of product(s) are accepted if they are registered through the Chemical Abstract Service Registration Number (CASRN) service and/or the European Community Number (EC Number) service. If not, then manufacturer inventories are not considered for crediting. If a product is protected from disclosing the above due to trade secret or intellectual property status, refer to p.97 LEED BD+C Handbook

- Health Product Declaration certification

- Cradle to Cradle – certification at v2 Basic or v3 Bronze level

- Declare Product label certification

- ANSI/BIFMA e3 Furniture Sustainability Standard

- Cradle to Cradle Material Health Certificate

- ProductLens Certification

- NSF/AINSI 336: Sustainability Assessment for Commercial Furnishings Fabric

Option 2 – Material Ingredient Optimization: To achieve this credit, at least 25% of products (by cost) must have documented material ingredient optimization crediting from one or more of the following USGBC approved programs:

Option 3 – Product Manufacturer Supply Chain Optimization: To achieve this credit, at least 25% (by cost) of building products must meet the following criteria: Products must be sourced from product manufacturers with comprehensive safety, health, hazard, and risk program validations, which document at least 99% of materials used.

If the product manufacturer has conducted and completed third party verification that meets the following criteria, that would qualify as well:

- There is active, transparent effort to evaluate chemical makeup of all products, especially those with more pressing hazard, exposure, and use information.

- There is documentation on health, safety, and environmental characteristics of chemical ingredients.

- There is active effort to productively manage products based on above information on characteristics.

- Optimize health, safety, environmental impacts when designing and improving chemical ingredients.

- Communicate, receive, evaluate chemical ingredient safety and stewardship information along supply chain.

- Has publicly available info about chemical ingredients at every point along the supply chain.

Note: Products sourced within 100 miles of project site valued at 200% for Options 1 & 2.

3. MATERIALS AND RESOURCES – PBT SOURCE REDUCTION: LEAD, CADMIUM, AND COPPER

Materials and Resources – PBT Source Reduction: Lead, Cadmium, and Copper (2 points): This credit is intended to reduce use and release of Persistent, Bioaccumulative, and Toxic chemicals (PBT) within the life cycle of materials. To achieve the credit, project teams must specify and provide proof that there is no use of interior or exterior paints containing lead or cadmium.

4. INDOOR ENVIRONMENTAL QUALITY – LOW-EMITTING MATERIALS

Indoor Environmental Quality – Low-Emitting Materials (1-3 points): This credit is intended to reduce concentrations of chemical contaminants in interior products with a focus on reducing Volatile Organic Compound (VOC) concentrations and emissions. There are 2 options for achieving this credit. Each option contains the possibility to achieve all 3 points.

Option 1 – Product Category Calculations: To complete this credit, one must comply with chemical content thresholds up to the percent listed in the table below. Threshold resources are listed and, depending on the extent of one’s compliance, points are awarded:

- If 3 categories comply, 1 point

- If 5 categories comply, 2 points

- If 6 categories comply, 3 points

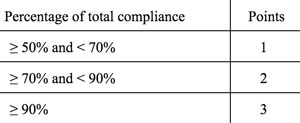

Option 2 – Budget Calculation Method: If products do not meet the above criteria, points can still be awarded using the budget calculation method. Based on the percentage of total compliance across all categories, points can be awarded. There are 3 Budget Calculation equations, all of which are listed below:

- (% compliant walls + % compliant ceilings + % compliant insulation + % compliant furniture) / 5

Equation 2: System Percentage Compliant

- Flooring, walls, ceilings, insulation % compliance: [ (compliant surface area of layer 1 + compliant surface area of layer 2 + etc) / (total surface area of layer 1 + total surface area of layer 2 + etc) ] * 100

Equation 3: Furniture Systems Compliant (use ANSI/BIFMA)

- % compliant for furniture by calculating surface area based on manufacturers documentation for application: [ (0.5 * cost compliant with §7.6.1 of ANSI/BIFMA e3-2011 + cost compliant with §7.6.2 of ANSI/BIFMA e3-2011) / total furniture cost) ] * 100

If project is greater than or equal to 90% compliant based on equations, the system counts as 100% compliant. If project is less than or equal to 50% compliant based on equations, the system counts as 0% compliant.

VOC Emission and Content Requirements for Options 1 and 2:

- A product must meet all relevant requirements to be considered compliant.

- Inherently Non-emitting Sources: automatically considered fully compliant without VOC emissions testing as long as they do not include integral organic-based surface coatings, binders, sealants.

- General Emissions Evaluation: Building products must be tested and determined compliant with California Department of Public Health (CDPH) Standard Method v1.1″2010 using applicable exposure scenario. The default scenario is private office – project teams must pick the scenario most applicable to the product and report which exposure scenario was used.

- Must state amount of wet-applied products used in mass per surface area.

- Manufacturers’ claims of compliance with the above requirements must also state the range of total VOCs after 14 days (336 hours), measured as specified in the CDPH Standard Method v1.1: 0.5 mg/m3 or less; between 0.5 and 5.0 mg/m3 ; or 5.0 mg/m3 or more.

- Supplementary VOC Content Requirements for Wet-Applied Products – wet applied products are required to meet all of the above, as well as the following (whenever relevant): Manufacturer must disclose VOC content; All paints and coatings must meet VOC limits of 1+ of following: California Air Resources Board (CARB) 2007, Suggested Control Measure (SCM) for Architectural Coatings, South Coast Air Quality Management District (SCAQMD) Rule 1113. All adhesives and sealants must meet SCAQMD Rule 1168.

- If a product cannot be tested using above methods, must comply with the following: ASTM D2369-10, ISO 11890 – part 1, ASTM D6886-03, ISO 11890-2.

- Methylene chloride and perchloroethylene may not be intentionally added in paints, coatings, adhesives, or sealants.

- For furniture and composite wood requirements, refer to p. 61 LEED ID+C Handbook

- For projects outside of US, refer to p. 60 LEED ID+C Handbook

Laboratories that conduct the tests specified (for VOC emissions + content) must be accredited under ISO/IEC 17025.

For manufacturer claims, first and third-party statements of product compliance must follow CDPH SM V1.1″2010, Section 8. Organizations that certify manufacturers claims must be accredited under ISO Guide 65.

INTERIOR DESIGN AND CONSTRUCTION

In order to secure the maximum of 7 points, one must complete the following requirements:

1. BUILDING PRODUCT DISCLOSURE AND OPTIMIZATION – ENVIRONMENTAL BUILDING DECLARATIONS

Building Product Disclosure and Optimization – Environmental Building Declarations (1-2 points, CI, Retail, Hospitality) – This credit emphasizes the procurement and disclosure of Environmental Product Declarations for products used in the project. It also includes a Multi-Attribute Optimization framework, intended to encourage project teams to demonstrate above average reductions in environmentally relevant fields, with life-cycle analyses serving as proof. In order to secure the maximum of 2 points, project teams must complete both of the options below:

Option 1 (1 point) – Environmental Product Declaration (EPD): To achieve compliance with this option, project teams must have at least 20 permanently installed products from at least 5 manufacturers meeting at least 1 of the following criteria:

- Must have product-specific declarations with public, critically reviewed life cycle assessment conforming to ISO 14044, with at least cradle to gate scope. Declarations of this type are valued at 1/4 of a product for crediting, meaning 80 products are required instead of 20 to secure the credit.

- Must have Environmental Product Declarations conforming to ISO 14025, 14040, 14044, and EN 15804 or just ISO 21930, also with at least cradle to gate scope. Industry Wide (Generic) EPD’s are valued at 1/2 product, meaning a total of 40 are required, while Product Specific EPD’s are valued at 1 whole product, meaning 20 products is adequate. For a concise explanation of the differences between the various types of Environmental Product Declarations, follow this link.

Option 2 (1 point) – Multi-Attribute Optimization: To achieve compliance with this option, at least 50% by cost of permanently installed products must meet at least 1 of the following criteria:

- Uses 3rd party products with life-cycle analyses demonstrating reduction above industry average in: GWP, Depletion of Ozone Layer, Acidification (land/water), Eutrophication, Tropospheric Ozone Formation, and Depletion of Nonrenewable Energy Sources, with industry averages retrieved from relevant EPD’s in same product category.

- Products sourced within 100 miles are valued at 200%.

- Structural and enclosure materials may not constitute more than 30% of value.

2. BUILDING PRODUCT DISCLOSURE AND OPTIMIZATION: MATERIAL INGREDIENTS

Building Product Disclosure and Optimization: Material Ingredients (1-2 points, Commercial Interior, Retail Commercial Interiors, Hospitality Commercial Interiors) – This credit is intended to promote prioritization of products and materials with positive, publicly available life-cycle information. It is intended to reward project teams for having comprehensive inventories of the chemical ingredients of their products and materials, demonstrating minimization of harmful substances. The credit is composed of 3 options, each of which is worth 1 point. In order to secure the maximum of 2 points, 2 of the 3 options must be completed:

Option 1 (1 point): To achieve compliance with this option, project teams must have at least 20 products from at least 5 manufacturers, and must use one of the following methods to demonstrate completed chemical inventories of products to at least 0.1%:

- Manufacturer Inventory – complete chemical inventories with public, registered inventory of ingredients through Chemical Abstract Service Registration Number (CASRN)

- Health Product Declaration certification

- Cradle to Cradle – certification at v2 Basic or v3 Bronze level

Option 2 (1 point): Material Ingredient Optimization – 25%+ by cost of products document material ingredient optimization using one of following:

- GreenScreen v.1.2 Benchmark – If all ingredients undergo full assessment, valued at 150% for crediting.

- Cradle to Cradle Certification – v2 Platinum and v3 Gold/Platinum accrue 150% value

- REACH Authorization List

Option 3 (1 point): Product Manufacturer Supply Chain Optimization – to achieve compliance with this option, at least 25% (by cost) of building products must be sourced from product manufacturers with third party verification that:

- There is active, transparent effort to evaluate chemical makeup of all products, especially those with more pressing hazard, exposure, and use information.

- There is documentation on health, safety, and environmental characteristics of chemical ingredients.

- There is active effort to productively manage products based on above information on characteristics.

- Optimize health, safety, environmental impacts when designing and improving chemical ingredients

- Communicate, receive, evaluate chemical ingredient safety and stewardship information along supply chain

- Has publicly available info about chemical ingredients at every point along supply chain.

- Has comprehensive safety, health, hazard, and risk program validations.

- Documents at least 99% of materials used.

Note: For options 2 and 3, products sourced within 100 miles valued at 200%.

Structure and enclosure materials may not constitute over 30% of value.

3. LOW-EMITTING MATERIALS

Low-Emitting Materials (1-3 points) – This credit is intended to reduce concentrations of chemical contaminants in interior products, with a focus on reducing Volatile Organic Compound (VOC) concentrations and emissions. There are 2 options for achieving this credit. Each option contains the possibility to achieve all 3 points.

Option 1 – Product Category Calculations: To complete this credit, one must comply with chemical content thresholds up to the percent listed in table. Threshold resources are listed.Depending on the extent of one’s compliance, points are awarded:

- If 3 categories comply, 1 point.

- If 5 categories comply, 2 points.

- If 6 categories comply, 3 points.

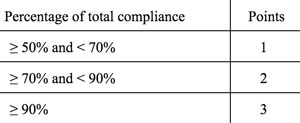

Option 2 – Budget Calculation Method: If products do not meet the above criteria, points can still be awarded using the budget calculation method. Based on the percentage of total compliance across all categories, points can be awarded. There are 3 Budget Calculation equations, all of which are listed below:

Equation 1: Total Percentage Compliance

- (% compliant walls + % compliant ceilings + % compliant insulation + % compliant furniture) / 5

Equation 2: System Percentage Compliant

- Flooring, walls, ceilings, insulation % compliance: [ (compliant surface area of layer 1 + compliant surface area of layer 2 + etc) / (total surface area of layer 1 + total surface area of layer 2 + etc) ] * 100

Equation 3: Furniture Systems Compliant (use ANSI/BIFMA)

- % compliant for furniture by calculating surface area based on manufacturers documentation for application: [ (0.5 * cost compliant with §7.6.1 of ANSI/BIFMA e3-2011 + cost compliant with §7.6.2 of ANSI/BIFMA e3-2011) / total furniture cost) ] * 100

If project is greater than or equal to 90% compliant based on equations, the system counts as 100% compliant. If project is less than or equal to 50% compliant based on equations, the system counts as 0% compliant.

VOC Emission and Content Requirements for Options 1 and 2:

- A product must meet all relevant requirements to be considered compliant.

- Inherently Non-emitting Sources: automatically considered fully compliant without VOC emissions testing as long as they do not include integral organic-based surface coatings, binders, sealants.

- General Emissions Evaluation: Building products must be tested and determined compliant with California Department of Public Health (CDPH) Standard Method v1.1″2010 using applicable exposure scenario. The default scenario is private office – project teams must pick the scenario most applicable to the product and report which exposure scenario was used.

- Must state amount of wet-applied products used in mass per surface area.

- Manufacturers’ claims of compliance with the above requirements must also state the range of total VOCs after 14 days (336 hours), measured as specified in the CDPH Standard Method v1.1: 0.5 mg/m3 or less; between 0.5 and 5.0 mg/m3 ; or 5.0 mg/m3 or more.

- Supplementary VOC Content Requirements for Wet-Applied Products – wet applied products are required to meet all of the above, as well as the following (whenever relevant): Manufacturer must disclose VOC content; All paints and coatings must meet VOC limits of 1+ of following: California Air Resources Board (CARB) 2007, Suggested Control Measure (SCM) for Architectural Coatings, South Coast Air Quality Management District (SCAQMD) Rule 1113. All adhesives and sealants must meet SCAQMD Rule 1168.

- If a product cannot be tested using above methods, must comply with the following: ASTM D2369-10, ISO 11890 – part 1, ASTM D6886-03, ISO 11890-2.

- Methylene chloride and perchloroethylene may not be intentionally added in paints, coatings, adhesives, or sealants.

- For furniture and composite wood requirements, refer to p. 61 LEED ID+C Handbook

- For projects outside of US, refer to p. 60 LEED ID+C Handbook

Laboratories that conduct the tests specified (for VOC emissions + content) must be accredited under ISO/IEC 17025.

For manufacturer claims, first and third-party statements of product compliance must follow CDPH SM V1.1″2010, Section 8. Organizations that certify manufacturers claims must be accredited under ISO Guide 65.

HOMES

In order to secure the maximum of 3 points, one must complete the following requirements:

INDOOR ENVIRONMENTAL QUALITY (EQ) – LOW-EMITTING PRODUCTS

Indoor Environmental Quality (EQ) – Low-Emitting Products (3 points): This credit is intended to reduce exposure to airborne chemical contaminants through product selection. There is only one aspect to this credit, and it must be completed in full to accrue the maximum 3 points:

- Use products for interior of home that have been tested and found to be compliant with California Department of Public Health Standard Method V1.1″2010 using CA Section 01350, Appendix B, New Single-Family Residence scenario. For emission testing, products must meet 90%+ of requirements to be considered compliant.

- Interior paints and coatings must meet requirements of CA Section 01350 (0.5 points).

- Flooring, insulation, site applied adhesives and sealants, must all meet requirements of CA Section 01350 – 0.5 points each.

- Composite woods have different grading system, and is worth just 1 point. For more information on this credit, refer to p.100 of Homes.

RESOURCES

To facilitate further independent research into adhesives and sustainable products we have compiled a list of helpful resources related to adhesives, including their composition, uses, and toxicity. In addition, this list comprises some useful databases and services to ease the discovery of sustainable products.

- Article: “Adam Savage’s definitive guide to every kind of glue”

- SPOT Sustainable Product Database – Recognized by the US Green Building Council (USGBC) as the official search engine for LEED, SPOT is a comprehensive product search database that allows for advanced, personalized searches across countless industries, with the ability to specify criteria based on product type, standard numbers, certifications, sustainable credits, and a range of other options. It is partnered with the USGBC, as well as Energy Star and Cradle to Cradle Products Innovation Institute. Designed to ease the LEED Certification process, SPOT is an excellent, reliable choice for finding sustainable, ecologically-minded products across countless countries, industries, fields, and product types.

- Overview of Phthalates by SpecialChem – Provides general background information on phthalates, including their chemical composition, and broader explanations of their purpose and uses. Provides insight into associated health risks as well as presence in industry.

- Overview of Formaldehyde and Associated Health Risks by ASI Adhesives & Sealants – Provides an overview of formaldehyde including its chemical composition, purpose, and use in industry. Summarizes health risks associated with formaldehyde and its use specifically in the adhesives and sealants industry.

- Overview of Formaldehyde and Associated Health Risks by American Cancer Society – Broader, less technical overview of formaldehyde, with a focus on its health risks and carcinogenic properties.

- Overview of Polyimides by EPOTEK – Provides an overview of polyimide-based adhesives and sealants, with specific insight into their use in industry and pros/cons compared to other types of adhesives.

- Overview of Epoxy Adhesives by ASI Adhesives & Sealants – Provides in-depth insight into epoxy-based adhesives, including their scope, function, purpose, and use in industry, as well as their benefits and drawbacks compared to other types of adhesives. Also includes brief insight into associated health risks.

- Overview of Volatile Organic Compounds by American Lung Association – Provides general information on Volatile Organic Compounds, including a description of what exactly they are, impacts on human health, as well as major sources.

- US Green Building Supply Council – Direct link to the latest version of the LEED Certification system. LEED is one of the most comprehensive and internationally recognized environmental certification services, setting the standard for sustainability in building design, construction, renovation, and maintenance. With credits specifically developed for Building Design & Construction, Interior Design & Construction, Operations & Maintenance, Cities & Communities, and Residential style projects, LEED provides incredible attention to detail and covers all bases in relation to sustainability in construction along all stages of the process, from material sourcing to waste disposal.

- Green Building Supply – online retailer dedicated to locating and selling eco-friendly alternatives to traditional building products, including flooring, paints and coatings, home goods, cleaners, and much more.

- Suggest an addition to this section by clicking here

SUMMARY

Adhesives come in a range of forms: pastes, liquids, films, tapes, etc. This is because they include an amazing amount of specialization, with chemically different adhesives having substantially different uses. Depending on the surfaces/objects you are seeking to attach, certain types of adhesives will fare far better than others. Generally, glues and adhesives tend to include formaldehyde and phthalates. Formaldehyde resin is an integral component of nearly all available adhesives. The International Agency for Research on Cancer, a sub-agency of the World Health Organization, has concluded that formaldehyde is “carcinogenic to humans.” The exact amount of exposure that leads to negative health effects is still unclear, but exposure to large amounts of formaldehyde fumes will definitely lead to health issues. With this in mind, it is prudent to pay close attention to the ingredients in our adhesives. Ourselves, our families, and our communities benefit from selecting adhesives which engage in responsible manufacturing processes and do not include hazardous chemicals. This page shares our research into this topic as a component of our open source sharing model for providing free and accessible blueprints for sustainable development. We’ll evolve this page continuously with everything we learn about sustainable paints as we build the Duplicable City Center and 7 sustainable village models.

Adhesives come in a range of forms: pastes, liquids, films, tapes, etc. This is because they include an amazing amount of specialization, with chemically different adhesives having substantially different uses. Depending on the surfaces/objects you are seeking to attach, certain types of adhesives will fare far better than others. Generally, glues and adhesives tend to include formaldehyde and phthalates. Formaldehyde resin is an integral component of nearly all available adhesives. The International Agency for Research on Cancer, a sub-agency of the World Health Organization, has concluded that formaldehyde is “carcinogenic to humans.” The exact amount of exposure that leads to negative health effects is still unclear, but exposure to large amounts of formaldehyde fumes will definitely lead to health issues. With this in mind, it is prudent to pay close attention to the ingredients in our adhesives. Ourselves, our families, and our communities benefit from selecting adhesives which engage in responsible manufacturing processes and do not include hazardous chemicals. This page shares our research into this topic as a component of our open source sharing model for providing free and accessible blueprints for sustainable development. We’ll evolve this page continuously with everything we learn about sustainable paints as we build the Duplicable City Center and 7 sustainable village models.

FREQUENTLY ANSWERED QUESTIONS

Q: Was One Community paid or incentivized in any way to choose the toilets we chose?

No, the research to identify and make the selections we made was done by a volunteer researcher without incentives or input from One Community or any company.

Q: What is LEED? What about WELL?

The LEED Green Building Certification System, propagated by the US Green Building Council (USGBC), is designed to standardize and reward environmentally conscious business practices related to construction and general building projects. With independent crediting systems for newly constructed buildings (Building Design and Construction), interior construction (Interior Design and Construction), individual homes (Homes), whole neighborhoods (neighborhood development), and even entire cities (Cities and Communities), LEED aims to provide a comprehensive blueprint for any project team, business, or individual seeking to undergo a more ecologically minded construction process. Each rating system has a wide, in-depth selection of potential credits, each of which cites relevant standards and goals.

The WELL Standard, supported by the International WELL Building Institute, is a similar but more accessible accreditation system. In favor of readability, WELL sacrifices some of the specificity so characteristic of the LEED system. Both support the same general mission, and can be effectively used individually or in tandem.

One Community

One Community