Best Small and Large-scale Community Plastic Recycling, Reuse, and Repurposing Options

This article is the One Community’s analysis and research condensation to understand and attack the plastic waste problem. Here is the index of the article to get a quick idea of its content:

- What is Plastic Recycling, Reuse, Reduction, and Repurposing

- Why Open Source Recycling, Reuse, and Repurposing

- Reduction of the Use of Plastic

- Refuse Unnecessary Waste

- Plastic Substitution

- Reusing and Repurposing Plastic

- Addressing Microplastics

- Recycling Codes

- Recycling Plastic

- Starting Your Own Plastic Recycling Business

- Community Cost, Labor, and Feasibility Comparison for All Options

- Conclusion ” Our Plan for Plastic

- Resources

- Summary

- FAQ

RELATED PAGES (Click icons for complete pages)

WHAT IS PLASTIC RECYCLING, REUSE, REDUCTION, AND REPURPOSING

Put simply, “reduce, reuse, repurpose, and recycle” are the main strategies to finding new ways to eliminate or deal with plastic from our lives. They are key to minimizing the amount of plastic that winds up in our bodies, landfills, and ecosystems. There are various strategies for remedying this situation, and here’s a quick summary of the primary methods:

Put simply, “reduce, reuse, repurpose, and recycle” are the main strategies to finding new ways to eliminate or deal with plastic from our lives. They are key to minimizing the amount of plastic that winds up in our bodies, landfills, and ecosystems. There are various strategies for remedying this situation, and here’s a quick summary of the primary methods:

The most important rule: if you’re not going to use it, don’t buy it. Reduce the amount you generate, both directly (using and/or throwing plastic away yourself) or indirectly (generated and wasted during the creation of the things you use).

- Minimize the use of plastic: Whenever possible, avoid purchasing plastic products, especially those designed to be single-use such as disposable dishes, packages, and straws. Before using plastic, think – do you really need to use it? Most of the time the answer is no.

- Substitute plastic with sustainable materials: Always opt for alternatives that can easily be broken down into a natural, harmless form to be returned to the environment.

- Preserve the plastic products you use: In times when plastic is the most ideal material, such as taking advantage of its non-biodegradable and durable properties for water storing barrels (like those used in the Net-Zero Bathroom), find ways to extend the plastic’s durability.

- Repurpose plastic products: Find new ways to use your plastic products, especially those that cannot be recycled, rather than just throwing them out. We’ve shared the best examples we’ve found in the Repurposing Plastic section below.

- Recycle plastic waste: Ensure that all the plastic you cannot repurpose is properly recycled.

WHY OPEN SOURCE PLASTIC RECYCLING, REUSE & REPURPOSING

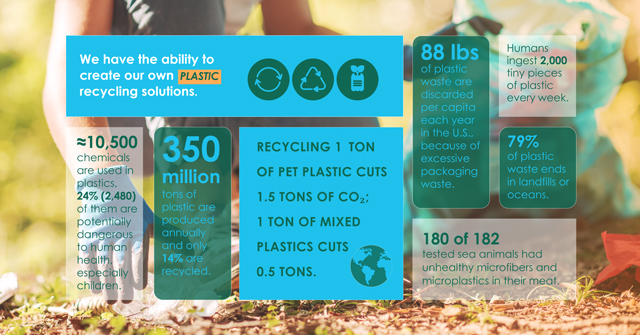

Our everyday lives constantly involve the use of a variety of plastic products: shampoo bottles, trash bags, packaging, shopping bags, water bottles, and so much more. That’s why it’s no surprise that around 35.4 million tons of plastic are generated annually in the United States alone. The problem with this mass use of plastic is that much of it isn’t being properly recycled or isn’t profitable enough to recycle. Plastic is difficult to break down and poses many environmental and health hazards as it accumulates in landfills, ecosystems, and even our bodies.

Our everyday lives constantly involve the use of a variety of plastic products: shampoo bottles, trash bags, packaging, shopping bags, water bottles, and so much more. That’s why it’s no surprise that around 35.4 million tons of plastic are generated annually in the United States alone. The problem with this mass use of plastic is that much of it isn’t being properly recycled or isn’t profitable enough to recycle. Plastic is difficult to break down and poses many environmental and health hazards as it accumulates in landfills, ecosystems, and even our bodies.

Here is a video that discusses how detrimental this problem really is:

Since the dangers of plastic are innumerable, the incentive to aggressively tackle the plastic problem is becoming increasingly urgent. Drastically reducing the amount of plastic we produce, use, and throw away can benefit humans, animals, and the environment in numerous ways:

- Reduces the amount of toxic trash in landfills

- Saves the vast amounts of resources and energy that go into producing the plastic we use

- Prevents the accumulation of plastics in ecosystems that harm animals

- Prevents the accumulation of plastics in our bodies that pose various health hazards

- Creates economic advantages from the innovations of recycling plastic into marketable products such as 3D printing materials and plastic building bricks

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS â” Â CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Aidan Geissler: Sustainability Researcher

Angela Mao: Sustainability Researcher

Tiffany Gao: Sustainability Researcher

Yomi Sanyaolu: Mechanical Engineering Graduate and Technical Writer

REDUCTION OF PLASTIC USE

The first and foremost strategy for dealing with the plastic problem is to minimize the consumption of plastic products. Since plastic production is consistently increasing, the problem continues to worsen. The most problematic plastics are often single-use plastics, plastic silverware, and plastic packaging. This concern is explicitly demonstrated by the fact that the packaging sector alone is responsible for 40% of plastic consumption in Europe. Reducing how much plastic we use, especially for single-use plastic products, is a key element to a solution to the plastic problem.

To have a little bit of context. Here are the main types of packaging:

- Primary Packaging: The material is in direct contact with the product (examples: cereal boxes and candy wrappers)

- Secondary Packaging: The material keeps the primary packaging together (examples: boxes, padding, separators, reinforcements, bags, paper, etc.)

- Tertiary Packaging: The material helps to transport secondary packaging together (examples: pallets and plastic wrapping)

The various levels of packaging demonstrate just how much plastic can be consumed in the process of packaging and distributing products (such that might even be made of plastic themselves). For this reason, zero-waste stores that do not utilize single-use plastic packaging and purchasing are an important part of the solution. Another part of the solution is minimizing plastic use during your grocery shopping by bringing your own grocery bags and refillable containers to buy food in bulk whenever possible.

REFUSE UNNECESSARY WASTE

Many plastic products offer unnecessary conveniences and comforts. These products are often single-use and can be easily avoided. By avoiding such products, we can both minimize the resources that go into their production, packaging, and transportation, as well as the accumulation of the resulting plastic in our landfills and environments. Here is a list of some plastic products we all ought to avoid:

- Plastic Straws: In nearly all cases, it is better to drink directly from the glass. If that cannot be done, reusable straws are preferable but still have negative impacts due to excessive use of water needed to wash them and the energy required to manufacture and distribute them.

- Plastic Grocery Bags: Bring your own durable grocery bags. If you forget them, opt for paper bags and properly recycle them after use.

- Plastic Water Bottles: Use reusable water bottles and get a water filter if you feel the need to purify your tap water.

- Plastic Storage and Sandwich Bags: Store food in reusable Tupperware, glassware, or reusable bags.

- Plastic Silverware and Dishes: Use reusable dishes and cutlery.

- Plastic Packaging: For all types of shopping (food, clothes, household supplies, toiletries, etc.), try purchasing products that are not packaged in plastic.

PLASTIC SUBSTITUTION

Another strategy for plastic-use reduction is to utilize sustainably made plastic alternatives. The easiest and best choice is to opt for more sustainable and reusable products such as glass and cloth. Additionally, recent solutions have been to develop plastic-like substances that are biodegradable, compostable, and/or made from natural biological substances. We will describe these varying alternatives and discuss the merits and drawbacks of each option.

REPLACE PLASTIC WITH MORE SUSTAINABLE MATERIALS

The best substitution for plastic products is products made from reusable and environmentally-friendly materials. This is especially relevant in the case of food storage. Here is a list of reusable products that are great alternatives to plastic food storage products:

- Glass jars, such as mason jars

- Glass Tupperware, such as Pyrex

- Beeswax wraps

- Cloth food sacks and produce bags

- Reusable silicone bags

BIODEGRADABLE PLASTICS

To be classified as biodegradable, plastics must be able to be completely decomposed by microorganisms in natural environments. Currently, it is difficult and expensive to produce fully biodegradable plastics. However, for specific uses of plastics, such as disposable bowls and plates, there are ways of creating fully biodegradable options made from natural materials such as potato peels (click here) and orange peels (see the Precious Plastic video below in the Bioplastics section).

COMPOSTABLE PLASTICS

Compostable plastics are those in which the material can only be completely decomposed under specific conditions and environments, unlike biodegradable plastics that break down naturally. Therefore, they require specialized industrial waste facilities to properly break them down. Presently, there are not enough of these facilities to handle all the plastic being mass-produced, and thus compostable plastics usually end up being disposed of in the same problematic way as regular plastic.

BIOPLASTICS

Bioplastics are defined as plastics that are made from renewable sources such as corn, potatoes, or sugarcane. This is a relatively broad category of plastics, therefore the properties of these products may differ. For instance, bioplastics can range from being compostable, biodegradable, or neither. Therefore the pros and cons of bioplastics vary based on the specific substance, so below is a general outline of the benefits and drawbacks to this approach of plastic substitution:

Benefits:

- Renewable: the sourcing of these plastics is much more sustainable and environmentally-friendly

- Can be easily implemented: the manufacturing process and end product are quite similar to that of regular plastics

Drawbacks:

- Very few bioplastics are truly compostable or biodegradable: many of them pose the same problems regarding accumulation in landfills and environments

- Harder to recycle than regular plastics: bioplastics fall under the plastic #7 recycling category known as “Other”, a category of plastics that the majority of curbside recycling programs do not accept

Here is a video that explains what bioplastics are, assesses the pros and the cons of the material, and tests their ability to biodegrade. The video also demonstrates a press that creates actual biodegradable bowls using natural ingredients such as wheat bran, coffee grinds, and orange peels. This video is produced by One Army for the Planet as a part of their Precious Plastic initiative. Precious Plastic is an incredible resource as they design and develop machines for plastic recycling, open source these designs, and create tutorial videos to encourage others to join their plastic recycling cause.

REUSING AND REPURPOSING PLASTIC

The simplest way to recycle plastic is to repurpose and continue using that product. This strategy works in two ways: it prevents the accumulation of plastic in our environments and minimizes the number of resources that go into creating new plastics. Countless products we purchase come in plastic containers (water, beverages, food, shampoo, soap, etc.). Two of the most pervasive plastic products in our society are plastic bags and plastic bottles. Below, we share some ideas on how to reuse and repurpose these items:

DIY REPURPOSED SHOPPING BAG PROJECTS

Shopping bags are a distinct type of plastic and may require techniques separate from those shared above. This includes:

- Reusing them as grocery bags

- Utilizing them to replace the use of new Saran wrap, sandwich bags, or other plastic bags

- Making them into rope

- And more: 60 Creative Ways to Reuse Plastic Bags

DIY REPURPOSED PLASTIC BOTTLE PROJECTS

You can repurpose plastic bottles into planters, a bottle garden, a soap dispenser, a pencil holder, a bottle sprinkler, a watering can, a water filter, a bird feeder, a trash can, Ecobricks, a greenhouse, rope, and more.

In some cases, plastic water bottles have been used to build schools. By “bottle bricking”, or stuffing the bottles with smaller plastic/trash bits to reinforce the hardness of the bottle, both plastic bottles, and pieces of microplastics can be repurposed for a more permanent solution. It is a great way to reuse while also providing an education to children in many communities. Here is a detailed guide on how to construct a plastic bottle school: The Bottle School Manual | Hug it Forward

- Article: 23 Creative Ways To Recycle Old Plastic Bottles Into DIY Crafts

- Article: Green Living: 20 Ingenious Ways to Reuse Plastic Bottles Instead of Trashing Them

- Article: 30 Mind-Blowing Ways To Upcycle Plastic Bottles At Home And The Office

- Article: 60 Ways to Reuse Plastic Bottles

- Article: 16 Creative Ways To Reuse Plastic ” Plastic Upcycling Ideas

SHOULD I REUSE PLASTIC CONTAINERS FOR FOOD AND BEVERAGES?

The FDA and other health and safety agencies worldwide have approved #1 plastics for reuse. #1 plastics refer to plastics listed under the #1 recycling code, which are made from polyethylene terephthalate (PET) and are utilized for many beverages and cooking oils. However, many potential health concerns stem from the reuse of PET plastics such as bacterial growth, leaching hazard chemicals, and leaching microplastics into beverages. Therefore, for safety purposes, we recommend minimizing #1 plastics for reusable food and beverage storage. More info about this here.

ADDRESSING MICROPLASTICS

A humongous part of plastic pollution is the portion we can’t see: microplastics. The reason why plastics are so harmful to the Earth is that plastic never truly degrades; rather, it just breaks down into tinier and tinier pieces. These pieces become very dangerous as animals often mistake them for food, making them a deadly force when they slowly accumulate in the stomachs of these animals and eventually kill them. And it doesn’t just affect animals – you’ve certainly accidentally consumed microplastics on your own, whether that’d be through airborne microplastics, the food you consume (microplastics landing on your meals or on the plants/vegetables you grow or purchase), drinks, and even your clothing! Let’s further investigate how microplastics contaminate our lives and the environment, and how we can prevent or deal with them.

CLOTHING

Perhaps the most common microplastics you unknowingly encounter every day are those from textiles – also known as your fabrics and your clothing. Microplastics from the air are constantly landing onto your clothing, getting stuck on the threads, and traveling with you everywhere you go. These microplastics often find themselves polluting the ocean through our laundry processes – in the washing machine, your clothes are cleansed of the dirt, bacteria, and microplastics that have accumulated. The cleaning water though now harbors all of them and this means they get flushed through the sewage system and eventually reach the ocean. Many water treatment facilities are not equipped with the proper filters to prevent microplastics from reaching the ocean, highlighting the importance of filtering them right from the source – our clothing. Here are a few items you can implement in your own washing machines to prevent microplastics from further polluting our oceans:

FILTROL

Acting as both a lint and microplastic remover, Filtrol removes the microfibers from your washing water before it reaches your septic system, allowing you to properly dispose of the microfibers (which we will discuss in a later section) It costs $139.99. Here’s a video displaying how it works:

MICROPLASTICS LUV-R

A filter that works very similarly to Filtrol, the MicroPlastics LUV-R is another option of a filter that removes microplastics and lint before reaching your septic system. It costs around $180-195 depending on your need for a wall mount. Here’s a video on the various products they sell, including the MicroPlastics LUV-R:

GUPPYFRIEND WASHING BAG

With a different approach, the Guppyfriend Washing Bag is another option for filtering out microfibers. It costs $34.95. By placing your clothing into the washing bag and the bag into your laundry machine, you protect your clothing and prevent microfibers from even reaching the laundry machine. Collected directly from the bag after a wash, the microplastics can then be properly disposed of. Here’s an animated video showing how Guppyfriend works:

GIRLFRIEND COLLECTIVE MICROPLASTICS FILTER

A popular sustainability brand, the Girlfriend Collective also sells its own microplastic filter. With a very similar approach to that of Filtrol and MicroPlastics LUV-R, the Girlfriend Collective Microplastics Filter also attaches to your laundry machine drain system to catch microfibers before they reach your septic system, and eventually the oceans. At a reasonable cost of $45, it has quite a high capture rate of 90 to 99%. If you do a bit of scrolling in the link above, they have a video explaining their product.

PLANTCARE FILTER

Another effective microplastic filter is the PlanetCare Filter. With kits ranging from $64.34 to $164.69, PlanetCare provides boxes with the filter and replacement cartridges depending on the load amount your order, with an additional option of a monthly subscription for $11.75 per month. Check out this video explaining how to use their filter:

TIRES

Shockingly, the 2nd largest source of microplastics in the ocean comes from tire dust. In fact, U.S. Tire Manufacturers report that the second most abundant material in passenger tires is synthetic polymers, with fillers coming in first and natural rubber coming in 3rd. Every time your vehicle goes for a drive, little bits of those synthetic plastics from your tires rub off as a result of friction between your wheels and the road, leading to an abundance of waste from your tires that is washed down into sewage systems or contribute to city dust and eventually led to our oceans.

Unfortunately, we were not able to find any super-efficient solutions that consumers can partake in. However, let’s talk about some solutions you can keep an eye on to hopefully gain a larger-scale reach in the near future.

THE TYRE COLLECTIVE

Winner of the 2020 UK James Dyson Award, the Tyre Collective designed a device that captures the microplastics as it breaks and flies off your tires. Watch this video to see how it works:

AUDI ENVIRONMENTAL FOUNDATION AND THE TECHNICAL UNIVERSITY OF BERLIN

The Audi Environmental Foundation has teamed up with the Technical University of Berlin to create urban runoff filters that will not only collect and prevent tire dust but also other city dust that enter the sewage system by attaching sediment filters right underneath sewer drains to capture them before they flow into our water bodies. Read more about it at the link above.

FOOD & BEVERAGES

Unfortunately, nearly everything you have probably consumed contains some amount of microplastics or another. While it’s very difficult to completely avoid them, there are many ways to prevent a large consumption of microplastics through your food and beverages. Below we explore some of the largest food contributors and sources of ingesting microplastics.

SALT

According to this National Geographic article, microplastics were found in 90% of table salts tested. That means you may have already consumed hundreds if not thousands of microplastics when eating delicious meals. While the obvious solution here would be to discontinue your use of salt, there are still a few brands proven to have zero to minimal microplastics in their salts if you still want to have that flavor in your dishes.

- Korean Purple Bamboo Salt (though very expensive, it’s made with a very precise process that allegedly removes all impurities including potential microplastics. Learn more about it here)

- Redmond Real Salt (They mine their salt from an ancient seabed “buried under protective volcanic ash that kept it entirely unpolluted and unchanged for millions of years”. Learn more here)

- Jacobsen Salt Co. (Following the release of the NatGeo article, they sought to implement a filtration system that potentially prevents microplastics from being in their salts)

CLING WRAP

While cling wrap is clearly not a food or beverage, I add it to this section because many people use cling wrap or food wrap to preserve the freshness of fruits, vegetables, leftovers, etc. However, along with the excessive use of plastic that will most likely get thrown out the minute you take the food back out of the refrigerator, cling/food/plastic wrap may actually be adding microplastics to your food.

Some great alternatives:

- Regular/glass crockery: using ceramic or glass crockery/jars with lids is the perfect reusable way to preserve your food in the refrigerator

- Beeswax Wraps: a sustainable version of cling-wrap, they’re popular and last up to 12 months

- 4myearth Cover Set: an amazing-friendly vegan cover set that can be placed right over your plate, cup, or bowl of food

COFFEE

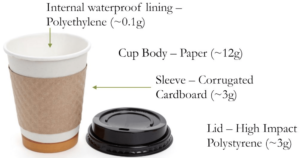

For coffee, opt for a more sustainable solution rather than the ordinary plastic cup, lid, stirrer, and straw. Oftentimes, all of these items are completely different types of plastics, making it very difficult to properly recycle them if you simply throw them out together. Additionally, many studies and articles such as this one have even reported that these plastic cups may be leaching microplastics into your coffee. Here are some solutions that we think you should try: Â

- Use reusable cups/a thermos: if you get your coffee from a shop, ask your barista if they can make or pour your coffee in your thermos.

- Attempt to make your own coffee: avoid buying cup pods and try brewing with beans. This includes buying beans that come in more sustainable packaging instead of plastic bags – here are some brands we recommend:

- Driftaway Coffee (With 100% compostable packaging, they are committed to sustainability and a carbon-neutral process, having 100% of their shipping and operations emissions offset)

- Cafe Mam (Biodegradable packaging with fair-trade and organic coffee beans, and the company even has a Climate Change Fund devoted to “the planting of over 8000 trees on 3,400 acres, and more”)

- Ethical Bean (Have a coffee bag return program in which you can return your used coffee bags and they’ll help send it to a zero-waste company and give you a free bag in return)

- Tiny Footprint Coffee (Having fully biodegradable coffee bags and being the “first carbon-neutral coffee brand”, they even dedicate their efforts to replanting native trees and the cloud forest in partnership with Mindo Cloudforest Foundation)

- Wandering Bear (For all your sustainable cold brew needs)

TEA

For tea, be wary of your teabags. Many are at least partially if not all made of plastic, which according to Beyond Plastics, can release billions of microplastics into your hot tea and eventually your body after consumption. Here are some great ways to prevent your tea from being a plastic-filled drink:

- Try loose-leaf teas: the brewing-your-own-coffee-beans equivalent, many brands sell loose leaf teas that eliminate the use of the same bags that release microplastics while also usually giving a more authentic taste in tea leaves. Here are some of our favorites:

- Arbor Teas (Fully compostable bags with an amazing range of tea kinds)

- Numi (Recycled cardboard packaging that’s made of 85 percent post-consumer waste with compostable bags)

- Good and Proper (Using NatureFlex, a home-compostable plastic replacement, their bags are 100% plastic-free and compostable)

- If you still want to use tea bags, buy ones made of sustainable packaging. Here are some more brands we recommend:

- Pukka Herbs (Their tea bags are actually completely home-compostable)

- Teapigs (They’ve never used plastic in their tea bags, and they’ve recently switched their inner bags also with the aforementioned NatureFlex. Learn more here)

- Hampstead (Fairtrade teas and all but one type of tea are wrapped in home-compostable tea bags)

- Bigelow (All three of their facilities are “Zero Waste to Landfill” statuses and their packaging is completely compostable)

Many of the brands listed overlap in selling both tea bags and loose leaf teas, so check all of them out. Additionally, many tea brands that also have sustainable practices may not be listed here, so always check your favorite tea supplier’s website to see if they partake in such practices. If not, make sure to send them a friendly message to push them towards a more sustainable direction.

PERSONAL CARE PRODUCTS

Many personal care products generally are a large source of plastic waste. However, they often also contain microbeads or microplastics in order to exfoliate your skin or clean your teeth. These greatly contribute to the growing microplastic issue so the best solution is to seek products that do not have microplastics inside. Here are a few websites loaded with great specific recommendations:

- Zero Waste Skin Care: 15 Best Brands Against Plastic

- 26 Best Eco-Friendly Beauty Products: Zero-Waste, Plastic-Free

- Products with the “Look for the Zero” or “Zero Plastic Inside” logo that guarantees the product has no plastic inside, which you can learn more about here. The label should look something like this:

DEALING WITH EXISTING MICROPLASTICS

Since microplastics are significantly smaller than regular plastics, waste disposal is slightly different. It’s very difficult to completely eradicate microplastics from your life, but using the above solutions and practicing a zero-waste lifestyle can greatly reduce your personal production of microplastics. If you don’t already live a zero-waste lifestyle or are just looking for proper ways to deal with little pieces of waste, here are a couple of ways to get rid of your current microplastics (such as the microfibers that are filtered by Filtrol, Microplastics LUV-R, etc.):

- Take a container and neatly pack all of your microfibers/microplastics into the container. When completely full, ensure that you tightly shut the lid to prevent the plastics from getting out, then dispose of it in the landfills or as you would with larger plastics. We explore those ways in our Recycling Plastic section.

- Try bottle-bricking as we’ve recommended prior in DIY Repurposed Plastic Bottle Projects. Very similarly to the prior bullet point, take any plastic bottle and stuff it with bits of waste and microplastics. When completely full, the bottles can be used to build schools or other buildings/structures. Here’s another photo of a bottle brick or “ecobrick” (taken from a guide from Ecobricks.org):

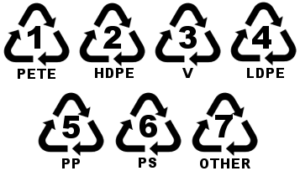

RECYCLING CODES

In order to properly and effectively recycle, it is vital that you understand the 7 types of recycling codes.

If you have a plastic water bottle nearby or any plastic item, try checking to see if there’s one of these codes on them. These codes are triangle-looking engravings or inkings on your plastic products, often resembling one of these 7 symbols:

PETE (or PET), HDPE, V (or PVC), LDPE, PP, and PS all refer to plastic types, separated into different types because they all vary in properties and therefore require different ways to be recycled. 7 or “Other” refers to any plastic types that don’t fall within 1-6, often a type that isn’t as widely known or utilized as 1-6.

Here’s a diagram from Simple Green displaying plastic examples of each type and if they are typically accepted by regular recycling programs:

As you can see, only 2 types of the 7 are the most likely to be accepted – but this does not eliminate the possibility that it doesn’t end up getting properly recycled later on in the process (more on that in a later section). While 3, 4, 5 can be recycled, it’s incredibly difficult, and very few facilities are properly equipped to deal with them. 6 and 7 are almost never recycled, as PS (also known as polystyrene or styrofoam) is very tricky to recycle because it expands and “other” refers to a huge variety of plastics that can be difficult to address all at once. Ensure you check with your local neighborhood recycling policies for which plastics are actually recycled so you can make sure you aren’t adding unrecyclable plastics to your bin.

Looking at the infographic, you should really try to limit as much as possible the 3-7 type plastics you use. Even better would be to work to totally eradicate all plastic use in your life. If there’s an item we didn’t list a sustainable replacement or solution for here on our guide, a quick Google search of “(insert item name here) sustainable replacement/solution” will help bring up a plethora of alternatives for you to explore.

ADDRESSING BIOPLASTICS/COMPOSTABLE PLASTICS

If you look closely, #7 includes plastics known as “bioplastics” and “compostable plastic-ware” which we also cover here and here, but let’s give another overview. In other words, the majority if not all of the “bioplastics” we believe to be a more sustainable version of plastics are still plastics and actually are very rarely recycled at all. Bioplastics simply refer to plastics made from organic sources, such as the most common one known as PLA, which is made from sources of corn starch.

Sounds great right? It’s not. While it does break down much faster than regular plastic, it only does so under certain conditions. Meaning, if you throw it into a natural environment and expect it to eventually break down over time as your banana peels do, it will not meet your expectations.

That’s also why it falls under the #7 category – it has to be entirely separated from other plastics because it shouldn’t even be going to a regular recycling facility, it should be heading to a composting facility where they have the proper settings to deal with it. Unfortunately, as of 2021 only 113 of those facilities even existed in the entire United States according to Scientific American. Imagine how many bioplastics have reached the same landfills as plastics, even though you thought you were being more sustainable and eco-friendly by using them.

It’s the same concept for some of the items that are branded as “compostable plastic-ware”. If it is not labeled “home-compostable”, meaning that you can just throw it in your natural compost bin with your food remains and allow natural composting to do its work, it’s still plastic that is only compostable under certain conditions. Once again, only 113 facilities are actually equipped to deal with these supposedly sustainable alternatives.

Even for items that aren’t completely plastic but labeled “compostable”, you should still be wary. Make sure to do proper research into what you’re purchasing.

WHY IT’S IMPORTANT TO KNOW HOW TO PROPERLY RECYCLE

Unfortunately, only a mere 9% of plastic is actually recycled, according to this article by the UNEP. Even less is effectively recycled. Why?

Well, the majority of the population doesn’t fully understand recycling codes and therefore doesn’t know how to properly recycle. This causes a phenomenon known as “wishcycling”, where consumers feel the need to recycle “just in case”, often accidentally placing an unrecyclable item into the recycling bin. In turn, this contaminates the recycling bin, and recycling facilities end up throwing out the entire bag because the cost of purposefully picking out the non-recyclables is outweighed by the cost of just throwing the bag into the landfill. Since recycling facilities often have specialized equipment meant for a certain plastic/waste type, anything considered “unrecyclable” would damage the equipment and place a halt on recycling processes, making it extremely inefficient.

Now that you know the different recycling codes, you can sort your waste by code or the standards your local recycling facility abides by, increasing the rate of recycling. Of course, beware of products that have many separate plastic layers such as a plastic coffee cup. As you can see from this breakdown from Inside Waste, each part is made of different material and therefore would fall into different recycling categories:

Since they’re all made of different materials, it’s important that you separate each part before throwing them out to ensure the highest probability of it being recycled.

RECYCLING PLASTIC

For plastic that you cannot avoid purchasing and cannot be reused or repurposed, it is important to recycle it properly to prevent it from being sent to landfills. We discuss this with the following sections:

- External/commercial Plastic Recycling Process

- Non-commercial Plastic Processing

- Plastic Shredding

- Plastic Extrusion

- 3D Printing

- Recycled Plastic Molding

- Pyrolysis

EXTERNAL/COMMERCIAL PLASTIC RECYCLING PROCESS

Globally, plastic accounts for a vast percentage of waste generation. According to the EPA’s 2018 report, 75.4% of solid waste plastic generated was sent to landfills, 15.5% was combusted, and only 9.1% was recycled2 in the United States. In addition to plastic reduction, reuse, and repurposing, recycling is a vital solution: it can save approximately 88% of the energy used to produce plastic from scratch3.

In the following section, we describe how large-scale recycling of plastic takes place in urban communities and why it’s very important to recycle plastic in particular.

HOW LARGE-SCALE PLASTIC RECYCLING WORKS

The process in which plastic is recycled on a large scale is summarized in the diagram and bullet points below. Like many other urban recycling schemes for waste processing, it includes collection, sorting, cleaning, and creating fresh “new” material.

- Recycle: Place your plastics in the correct recycling bins

- Collection: Usually performed by the city service that handles recyclables

- Sort: The plastics are isolated from other materials and sorted by type

- Bundle: Plastics are bundled for transport to crushing machines

- Cleaning: After crushing, food, drink & other contaminants are washed off

- Pellets: The plastic is ground up and shredded into flakes4 that are melted and reformed into pellets/nurdles

- Product Creation: The pellets are sold to companies that make them into new products

Here’s another image that displays this process well:

BEING A GOOD PLASTIC RECYCLER – HOW YOU CAN HELP

The following steps should be followed to ensure the recycling process occurs smoothly and makes workers’ jobs at recycling facilities easier. To help, consider the following:

- Clean out any contaminants (food bits, dirt, etc.) before recycling your plastic

- Separate plastics into their different recycling types (if separation bins exist)

- Ensure there are sufficient recycling bins in your home (kitchen, bathroom, garage, etc.) to reduce accidental occasions of throwing recyclable products in with trash

- Squash plastic bottles to save space in your recycling bin

- Remove plastic bottle caps as they are almost always a different type of plastic that needs to be sorted separately

- Only recycle plastics your local recycling center accepts – check their website or give them a call for details as they often will have a handy sheet like the one below that will inform you on what you can and cannot recycle

NON-COMMERCIAL PLASTIC PROCESSING

This section covers methods for local communities and/or organizations to reduce their plastic waste by effectively processing plastic remains. Methods include shredding plastic for resale or reuse, transforming plastic waste into fuel, using plastic to create 3D printer filament, and using plastic to create other products for construction projects in varying ways.

PLASTIC SHREDDING

Shredding is a popular recycling technique because of its ability to significantly reduce the volume of a material, making it easier to transport and process the item. Therefore, shredding is often one of the first steps of plastic recycling. Here is a YouTube video that demonstrates the use of DIY plastic shredders and shows how the shredded plastic can then be extruded into various new products:

Benefits of shredding plastic:

- Shredded plastic takes up less space and is easier to melt

- Shredding helps maintain privacy when dealing with plastics that may contain confidential information on them

- Properly sorted and shredded plastic may be easier to sell to some purchasers of recycled plastic (check with your local recycling center to see what your local options are)

Note: It is best to separate plastics into their different types before shredding.

USES OF SHREDDED PLASTIC

Because shredded plastic melts more readily, it is perfect for any process that melts plastic and remolds it into a new product. The video above demonstrates this use by employing DIY Extruder Machines.

For large-scale applications, shredded plastic can be used for making Polymer-Modified Asphalt Cements (PMA). Adding plastic to asphalt improves several performance factors: fatigue resistance, increased durability, crack resistance to propagation, and tensile strength [8]. Here is a compelling video of combining shredded plastic, shredded car tires, crushed glass, and recycled asphalt to construct new roads:

PURCHASING A PLASTIC SHREDDER

Here are 2 plastic shredder options that we found while creating this article. Since prices may change over time, we recommend doing further research into prices if you are planning to purchase a shredder.

TECHTONGDA 3HP ELECTRIC CHIPPER

For a price of $1485, the Techtongda 3HP Electric Chipper can shred not only plastic, but also wood, nylon, cloth, paper, grain, and more.

PRECIOUS PLASTIC MARKETPLACE

Precious Plastic publishes open-source designs for plastic shredders and provides a marketplace in which you can purchase individual parts, complete kits, and fully constructed machines. Fully built motorized shredders often sell for more than $1200 on their website. There are also options for hand-crank shredders that cost approximately $230 to $440. The kits range from about $180 to $210.

DIY PLASTIC SHREDDER

Here are some Do-It-Yourself alternatives with links to where you can find further information to build them.

PLASTIC SHREDDER/GRINDER

For a price of $50, you could repurpose a paper shredder into a plastic shredder using Instrutable’s plastic shredder guide. Click the link to see the 10 step process with many photos, videos, and additional resources

PRECIOUS PLASTIC SHREDDER

With an approximated price of $477 to $600 (depending on how many new materials you buy to use vs. recycled materials), you can build a Precious Plastic Shredder if you have some basic welding skills. There are several videos, resources, tutorials, photos, and an active community on Discord to help you build, upgrade and operate this machine.

PLASTIC EXTRUSION

Extrusion is the process of shaping a material by forcing it through a cross-sectional profile. This process often entails a process of melting the material, compressing it, thoroughly mixing it, and squeezing it out of a small hole to convert it into a usable form. In terms of recycling, this process can convert plastic waste into plastic filament or granules which can be readily converted into a wide range of new plastic products.

Summary of how an extruder works:

- Small pieces of plastic* are placed into the hopper, which feeds the plastic into the extruder

- The plastic flows into a horizontal barrel with a spinning screw where it is heated to its melting point and thoroughly mixed by the screw

- The plastic then flows into a breaker plate and screen, which ceases the rotational motion of the plastic and removes contaminants and inconsistencies

- Different dyes are placed at the end of the barrel which controls the size and shape of the plastic that is ejected from the machine

Further info can be found here.

* Note: Depending on the specific extruder you are working with, you can add plastic flakes, pellets, granules, or powders to the hopper. The key here is that the plastic material is converted into small enough pieces that can fit into the barrel. Therefore, it is highly recommended to shred your plastic waste before extrusion. See the plastic shredding section above for more details about how to shred plastic waste.

FILAMENT EXTRUDER: TURNING PLASTIC INTO 3D PRINTER FILAMENT

One of the most promising applications of plastic waste extrusion is converting it into 3D printer filament. A filament extruder converts plastic pellets or flakes into plastic filament, which can then be used by a 3D printer to create an incredible variety of new plastic products. Here’s a graphic from Open Source Ecology showing the complete concept of the filament extruder.

PURCHASING A PLASTIC EXTRUDER

Below we list some plastic extruder options you can purchase and use:

FILASTRUDER KIT

This is an affordable, easy-to-assemble Filastruder Kit that allows you to build a machine that will extrude plastic pellets into filament for a 3D printer. This kit costs $299.

FELFIL EVO

Felfil Evo has three filament extruder options depending on what you are looking for: a $780 Assembled Kit, a $650 Complete Kit that you build yourself, or a $355 Basic Kit that only includes the uniquely-made, difficult-to-handcraft equipment.

PRECIOUS PLASTIC MARKETPLACE

Precious Plastic publishes open source designs for various types of plastic extruders, which can produce 3D printer filament, plastic granules, or other extruded products. They provide a marketplace where you can purchase individual parts, complete kits, and fully constructed machines. The full setup for this machine is estimated to cost about $1300.

DIY FILAMENT EXTRUDER

If you are more interested in building an extruder yourself, here are some designs we recommend:

LYMAN FILAMENT EXTRUDER

The Lyman Filament Extruder converts plastic flakes or pellets into 3D printer filament suitable for use in 3D printers and Lyman filament. It is open source hardware and you can download all of the plans from Thingiverse. This DIY filament extruder costs less than $250.

DIY 3D PRINTER FILAMENT FACTORY

The DIY 3D Printer Filament Factory is based on the Lyman Filament Extruder listed above but is a more affordable build. This machine costs about $130-$150 to build and accomplishes the same goals.

REPRAPABLE RECYLOBOT

The RepRapable Recylobot describes how to make and operate a machine that uses extrusion to convert plastic waste into a 3D printer filament. This Recyclobot is “RepRapable”: “RepRap” stands for replicating rapid prototyper, meaning that this machine can produce filaments that can be re-converted into the necessary parts to make more Recyclobots by using a RepRap 3D printer. This design costs about $670. It can convert both commercial pellets into commercial-grade filament and waste plastic into usable filament that is less than 1000 times the cost of commercial filament.

PRECIOUS PLASTIC DIY EXTRUDER

The Precious Plastic DIY Extruder can make 3D printer filament, plastic granules, and even various molds (as described in the molding section). If you use recycled materials to build this design, it should cost about $250 but can be well over $500 if you purchase new materials.

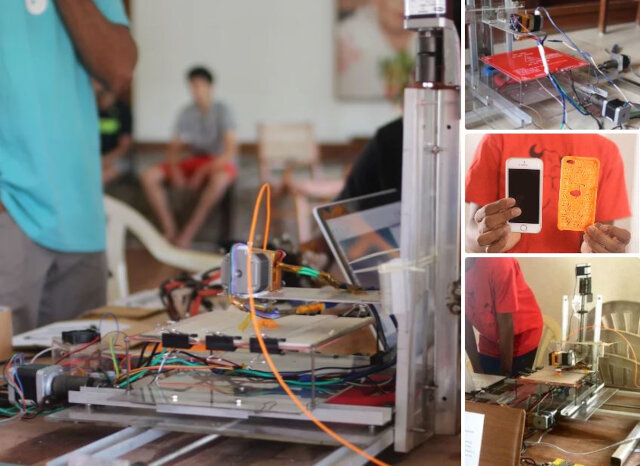

3D PRINTING

3D printing is one of the most versatile ways of recycling plastic. Once the plastic waste has been converted to 3D printer filament via shredding and extrusion, it is ready to be transformed into almost anything!

- Modeling: Obtain or design a 3D model of your product using modeling software (such as CAD)

- Printing: Your model file is sent to the printer, which builds the product by melting plastic filament and depositing it one layer at a time where it hardens

- Finishing: Depending on the product, this can entail sanding, coloring, polishing, and/or removing supports that might have been used to hold up the object during printing

Databases for models:

- Thingiverse: Featuring over 9,000 free models with a huge variety of products, this is one of the most popular 3D model databases

- Cults 3D: This site includes about 5,000 models (some free and some paid for) which are organized into categories including art, jewelry, home, architecture, and gadgets

- Pinshape: With a target audience of hobbyists and designers, this site contains over 13,000 models (free and paid for)

- GradCAD: If you are in or would like to work with engineering, this is the site for you as it features over 27,000 free technical 3D files

USES OF 3D PRINTING

The possibilities for what you can create via 3D printing are endless. It has incredibly useful applications in a variety of different industries:

- Aerospace & Defense: Functional prototypes, lightweight structural components, spacer panels, tools such as jigs and fixtures, injector heads (see image below)

- Automotive Industry: Cushion sections, tools such as injection molds and fixtures, roof brackets, lift assist (see image below)

- Medical and Dental Industry: Prosthetics and orthopedic devices, models of organs for research and surgical practice, dental aligners, and orthodontics (see image below)

- Consumer Goods: sneakers soles, mascara brushes, bike frames, jewelry, razer handles (see image below)

- Industrial Goods: manufacturing aids such as jigs and gauges, molds for injection molds and die casting, spare parts, bearing cages (see image below)

PURCHASING A 3D PRINTER

3D printer technology is growing and evolving rapidly as new technology and designs emerge every year. Here are some things to consider when purchasing a 3D printer:

- Price: Prices can vary vastly from $200 to over $2000 depending on the printer functionality

- Resolution: Keep in mind what you are trying to print and how important/precious it is

- Build Volume: Carefully consider the maximum size of an object you want to be able to produce

- Materials Accepted: Many printers only accept specific materials

DIY 3D PRINTER

In this section, we share various plans with instructions on how to create a 3D printer on your own. You may also want to check out this helpful page.

INSTRUCTABLES – HIGH RESOLUTION, LOW-COST 3D PRINTER

For around $87, you can get a high resolution, low cost 3D printer with a build volume of 20cm x 15cm x 35cm with a resolution of 0.2mm (200 microns) from Instructables. A detailed 16 step process with numerous helpful images, files, guides, and pages for products are provided in the link above.

INSTRUCTABLES – 3D PRINTER

This Instructables 3D Printer is a detailed 19 step process with many images, files, listed resources, and videos shared to create a 3D printer for approximately $470.

HOW TO MAKE A BIG 3D PRINTER AT HOME USING ARDUINO

With a printing area of 400 x 400 x 400 mm, this printer has a step-by-step guide with files, listed resources, and many images included that depict the process.

MAKER’S MASHUP DIY 3D PRINTER BUILD FOR BEGINNERS

Maker’s Mashup DIY 3D Printer Build for Beginners is a 8-part DIY series includes a document displaying a list of parts, a variety of other helpful links, and a calculated total price of approximately $280-$480 for the build in the video along with a guide for a more economical build.

RECYCLED PLASTIC MOLDING

Another way plastic waste can be processed into new and usable products is by molding. There are two main types of molding plastic: injection molding and compression molding. During injection molding, plastic flakes are melted, injected into a hollow mold under high pressure, and then cooled to solidify. During compression molding, plastic is placed onto the mold where it is heated and slowly compressed to fit the shape of the mold. For both of these processes, the plastic must be shredded into small pieces.

Some interesting uses of recycled plastic molding to read about:

DIY INJECTION MACHINE

Here are a few injection machine options you could consider purchasing:

PRECIOUS PLASTIC INJECTION MACHINE

For around $179-358 (depending on how many new materials vs. recycled materials you buy), the Precious Plastic injection machine is primarily used to make small objects. Their website also links several how-tos for the creation of spinning tops, doorknobs, paperweights, broom hangers, phone cases, jewelry, carabiners, and sunglasses.

PRECIOUS PLASTIC EXTRUDER

The Precious Plastic extrusion machine discussed above in the extrusion section can also be easily used for molding as you can simply add molds directly to the end of the extruder. If you use recycled materials, this design should cost around $250 but using new materials can bump the cost well over $500. The video below demonstrates how using molds with this machine can create various sizes of beams.

DIY COMPRESSION MACHINE

Here’s a compression machine design you can build yourself:

PRECIOUS PLASTIC COMPRESSION MACHINE

For around $179-428 (depending on how many new materials vs. recycled materials you buy), the Precious Plastic Compression Machine utilizes a carjack to apply compression pressure. Compression molding is a slower process than injection molding, but it allows the user to create larger objects. Their webpage demonstrates and provides various links for creating bowls and sheet materials, which can further be used to make other products.

COMMERCIAL PLASTIC COMPRESSION AND MOLDING MACHINE

Commercial compression machines are being created now too. Here’s one by ByFusion Global, a company creating a better version of the concrete block through a steam-based process called ByFusion. ByFusion uses steam and compression to produce blocks that don’t require chemicals, additives, or fillers, compressing both hard-to-recycle and recyclable plastics like plastic bags, yogurt containers, and water bottles into “ByBlocks” that can be used exactly the same way standard concrete blocks are in modern building construction. But unlike regular concrete, ByBlocks won’t break, crumble, or crack:

The block-making machinery is available now for waste management companies, governments and corporations to install and begin creating more sustainable building materials. They are also already producing their own products using their blocks.

PYROLYSIS

Though it is neither efficient nor sustainable, another possible option for recycling plastic is pyrolysis. Pyrolysis is the process of decomposing or transforming a compound by exposing it to heat. In the case of recycling plastic, pyrolysis can be used to convert plastic waste into fuel. In this section, we will discuss the potential of pyrolysis as a recycling process, advantages and disadvantages, and processes for DIY Plastic Pyrolysis recycling.

HOW PYROLYSIS WORKS

There are two types of pyrolysis: thermal and catalytic. Thermal pyrolysis is a recycling technique whereby plastic waste is converted at high temperatures into liquid fuel, char, and vapor. This reaction is known as thermal degradation. Catalytic pyrolysis involves the use of catalysts (such as silica and alumina) and requires lower temperatures and reaction times to produce higher-quality fuel.

Here is a summary of how the pyrolysis of plastic works:

- Pretreatment: Foreign matter is removed from the plastic waste

- Shredder: The plastic waste is shredded into smaller pieces

- Pyrolysis: In the pyrolysis chamber, plastic is heated in the absence of oxygen, slowly melted, and turned into a gas

- Condensation: The gas produced by pyrolysis is condensed into a liquid fuel

- Refining: In an oil refinery, the product is converted into usable oil, gas, or ash

For more details on the process of pyrolysis, here’s a video that describes the process and the uses for its resulting products:

Here are the primary products produced by plastic pyrolysis:

- Oil: Can generate electricity, be processed into diesel fuel, and be used as a heating material in all sorts of factories

- Gas: Can be used as a heating material instead of coal, wood, or oil

- Ash: Can be used in construction or as a replacement for coal

BENEFITS OF PYROLYSIS

One of the main benefits of pyrolysis is that it can be applied to any plastic waste, including mixed plastics. Many plastic products cannot be easily recycled by other means. For various reasons, plastic waste may not be sorted properly due to mechanical sorting complications. Additionally, some plastic waste may be degraded to the point where melting it would only shorten its carbon chains and result in a weakened product. Therefore, the pyrolytic process would decompose plastic molecules of all types and qualities into monomers that can be transformed into usable fuels.

DRAWBACKS OF PYROLYSIS

The primary drawback of pyrolysis is that it is too energy-intensive to be sustainable. More energy is consumed in the process of recycling than what is recovered in the end product. Additionally, the product of pyrolysis is often a fuel that is burned, which sends more carbon into the atmosphere. Therefore, as a whole, pyrolysis is an inefficient and unsustainable process.

DIY PYROLYSIS

The Instructables website provides a tutorial on how to produce a mini DIY pyrolysis reaction plant for turning plastic into oil. Below, we provide a simplified explanation of the process and you can visit the linked source page to see the full details for replication.

Precautions:

Do not inhale the fumes produced! You can reduce your risk by working in a well-ventilated area and wearing the correct PPE (Person Protect Equipment) such as gloves, masks, safety glasses, etc.

Since the substances used are highly flammable, ensure the fumes produced are far away from fire and electrical appliances. Additionally, always have water and a fire extinguisher ready in case of an accident.

Equipment needed:

- Stainless steel vessel

- Steel condensation tube

- System for monitoring temperature

- System for condensing & collecting products

- Stove

- Water supply

Summary of the Process:

- Collect waste plastic and shred it into smaller pieces for easier thermal decomposition

- Seal the shredded plastic tightly in the reaction chamber

- Set up the equipment on your stove and turn on the inlet water flow

- Turn on the stove and allow the process to occur

CONCLUSION ABOUT PYROLYSIS

While pyrolysis is a compelling method for recycling unrecyclable plastic, this is far outweighed by the inherent inefficiency and unsustainability. One of the key concerns is that both pyrolysis recycling and the burning of its products release carbon (and potentially other toxic byproducts) into the atmosphere. Since plastics store vast quantities of carbon, a better alternative might be to recycle existing plastic into new plastics or materials. To make this recycling most sustainable, the energy required for the recycling process ought to come from sustainable sources, like wind or solar.

STARTING YOUR OWN PLASTIC RECYCLING BUSINESS

To start your own plastic recycling business, you’ll first need to understand how it typically operates. To start, a person who wishes to establish their own plastic recycling business will need, as recommended here, to choose a product, establish funding, find a business space, obtain machinery, and find a source of plastic waste. We will further discuss considerations for each of these steps in the bullet points below:

- Choose your product: You have two options for your plastic recycling business. You can either sell the raw, finished plastic as pellets or bricks, or you can manufacture finished products. Manufacturing finished products will generate more of a profit and potential products will be discussed in more detail below.

- Establish funding: As with any business, you will need money to get things started. You can either secure funds of your own or receive a loan. The amount of startup money needed will depend on the scale of your operation.

- Find a business space: If you are looking to start your own small business, your garage or shed (with access to electrical power) should be sufficient. You could even work with 50 square feet for a small-scale plastic recycling operation. However, it is recommended to get a space of around 200 square feet or more for a more professional business.

- Obtain machinery: You cannot recycle plastic without the necessary equipment. There are several options for machinery, whether that’d be an all-in-one machine or several machines that each carry out specific functions. You should conduct research to see which option best suits your business. To properly select the machinery, keep in mind that you will have to accomplish these stages: separating, grinding, compressing, melting, filtering, and reforming the plastic (and perhaps creating the finished plastic products).

- Obtaining waste plastic: You can collect waste plastic from your local community/surrounding area, find some in various landfills and scrap heaps, or source it from organizations or businesses.

PRECIOUS PLASTIC PRO MACHINES

A great resource for understanding how to set up and operate a small-scale plastic recycling business is Precious Plastic’s website. They provide potential product ideas, business tools, specific instructions on how to construct the machines yourself and everything is open source.

We’ve already discussed the four Basic Precious Plastic machines in prior sections (Shredder Machine, Extrusion Machine, Compression Machine, and Injection Machine), but Precious Plastic also shares plans for building “Professional” models of these machines, which allow for bigger volumes of plastic to be processed and recycled. Bigger volumes equal bigger business.

SHREDDER PRO

The Shredder Pro price is about $2625 if you purchase all new materials. Make sure to check out the Precious Plastic Marketplace for individual parts, kits, and community-built machines. This beast can shred up to 50kg of plastic per hour (vs. the 10kg per hour efficiency of the Basic Shredder), producing tons of plastic flakes and plastic granules. Precious Plastic also provides resources for How to Setup a Shredder Workspace

EXTRUSION PRO

For about $2385 you can purchase all the necessary materials for the Extrusion Pro, but check out the Precious Plastic Marketplace for individual parts, kits, and community-built machines. It can recycle approximately 20kg of plastic per hour (vs. the 5kg per hour efficiency of the Basic Extrusion Machine), which can be used to produce beams and bricks. Check out How to Setup an Extrusion Workspace.

SHEETPRESS PRO

The Sheetpress Pro costs about $3040 for all the necessary materials, but check out the Precious Plastic Marketplace for individual parts, kits, and community-built machines. It can create 20 kg 1×1 meter sheets. Read the following page How to Setup a Sheetpress Workspace

EXAMPLES OF PRODUCTS FOR YOUR BUSINESS

Precious Plastic also has a page dedicated to plastic products with instructions and molds on how to create them. If you want more inspiration for products, here are some examples from Etsy.

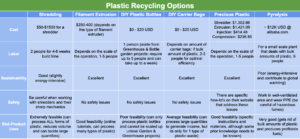

COMMUNITY COST, LABOR, AND FEASIBILITY COMPARISON FOR ALL OPTIONS

In this section, we aim to open source a detailed comparison between the recycled plastics’ alternatives. We will include the cost, labor, sustainability, safety, and feasibility of all the varying waste processing methodologies to analyze which ones are best to implement into communities and sustainable community projects like One Community.

OTHER INTERESTING PLASTIC OPTIONS

Here are some other interesting alternatives to recycling plastic we did not explore in this guide but we suggest you check out:

CONCLUSION ” OUR PLAN FOR PLASTIC

The best course of action for One Community will first and foremost be to reduce our use of plastic as much as possible. We have plans for bulk buying and hope to establish large-scale purchasing (think 50-gallon drums of soap, toothpaste, paint, etc.) as well. You can read about these on the Highest Good Lifestyle Considerations page.

Instead of every member of One Community buying their own groceries, we are aiming to buy things collectively by buying in big quantities. We will get better prices and by asking our providers to send them in bulk, we avoid excessive secondary and tertiary packaging. For example: for toothpaste, instead of receiving a large shipping box with a smaller box reinforced with plastic with smaller boxes of each plastic tubes inside, we can directly ask manufacturers to send 15L or bigger toothpaste containers that will be placed in the One Community dispensary. Each of the residents and visitors will be able to refill their toothpaste tubes from the dispensary. If you would like to know more about the inner workings of the dispensary, we will post the full process documentation, tools, tips, and tricks.

Another great advantage of this method is that all the residents will get most of their stuff from the best and most sustainable providers without researching and comparing them. We have already researched the most sustainable alternatives sources for a variety of services here and throughout this site.

Once the primary packaging of our supplies is used up, we can reuse them on the property like using empty 50-gallon drums to carry gardening equipment. Some of the bottles and containers visitors bring with them to the property will be reused as well. For example, a resident lacking a specific container could retrieve one in the dispensary after it was cleaned. This is our second strategy to deal with plastic waste – reuse as much as we can instead of purchasing new items.

Of course, not all the plastic waste that comes into One Community can be reused, so we plan on repurposing part of it. For example, the 2-liter soda bottle that a family brings with them can also be transformed into a soap dispenser for the zero waste bathrooms, a bird feeder, a sprinkler, or other useful tools. Other similar products that could also be repurposed include shampoos, lotions, soap, toothpaste, glue (with little modifications using a screw on the top), gasoline, perfumes, etc.

The remaining amount of plastic waste will be moved to the recycling center where we will sort, shred, store plastic flakes and create new products out of it.

We will invest in an industrial plastic shredder for the plastic we receive from packaging or plastic brought onto the property by others. This will help us process as much plastic as needed and make it easy to sell and/or create 3D printer filament and/or other products. We’ll also explore repurposing plastic for construction or useful creations such as sprinklers, bird feeders, etc.

To meet these needs, collected plastic for shredding and other uses will be sorted by the people who used it. Bottles and other plastic items that are good for specific purposes will be used as needed. Shredded flakes will be sold to plastic manufacturers to melt and mold into new products and/or turned into new products on the property using the plastic filament extruder offered by Open Source Ecology. The filament extruder will be up and running during phase 4 once we have more than 50 people living on the property who are generating more flakes than can be simply managed by sorting them in buckets. We’ll also have some residents in charge of maintaining the machine working properly and leading the plastic extrusion operations.

One Community’s recycling plastic bottles flowchart: it is a draft we will test out once on the property and update later – Click here to open the diagram

Precious Plastics equipment will also be used to turn our plastic waste into a diversity of useful plastic products for a fairly low upfront investment:

- Open Source Ecology Filament Extruder. (approx. cost $250)

- Precious Plastics Shredder: cuts plastic items into small flakes. (approx. cost $1300)

- Precious Plastics Extrusion Machine: plastic flakes are inserted into the hopper and extruded into a line of plastic. (approx. cost $1400)

- Precious Plastics Injection Machine: plastic flakes are heated and injected into a mold. (approx. cost $400)

- Precious Plastics Compression Machine: plastic is heated inside the oven and slowly pressed into a mold. (approx. cost $250)

We will share our reduction methods, uses, products, and recycling processes to educate communities, organizations, and individuals on different approaches to tackle the ongoing battle against plastic waste.

Note: We will not be pursuing the pyrolysis plant plan because it produces fossil fuels and has numerous safety issues. It also requires a lot of energy and financial input to run the plant (around 25kW and $850/day).

Not all plastics can be transformed into filaments or extruded with these machines, so we will compost compostable plastics and the rest will be washed, shredded, and stored in 50-gallon barrels. Once the barrels are full, we’ll send them to a pyrolysis facility that uses sustainable energy sources so the plastics can be transformed into new plastics.

Plastics that cannot be efficiently cleaned, like bottles of oil or dissolvents whose contents could end up contaminating our water, will be placed with our other non-recyclable wastes. Investigation on this topic is being done at this time, with plasma incinerations as a potential solution to dealing with them.

RESOURCES

Here are resources referenced above:

- Article: “Facts and Figures about Materials, Waste, and Recycling”

- Article: “Plastic Recycling Facts and Figures”

- Article: “An Overview of Plastic Recycling”

- Article: “How are Plastic Bottles Recycled?”

- Article: “7 benefits of recycling”

- Article: “The Importance of Recycling and Reusing Plastics”

- Article: “All About Plastic Shredders: From Applications to Advantages”

- Article: “Polymer-Modified Asphalt Cement”

- Article: “Catalytic pyrolysis of plastic waste: A review”

- Article: “Pyrolysis Plant”

- Article: “19 Ways to Reuse and Recycle Empty Plastic Bottles”

- Article: “DIY Homemade Bottle Sprinkler”

- Article: “How to Make a Bottle Watering Can”

- Article: “Simple Water Filter Out of a Waterbottle”

- Article: “Make Rope from Plastic Bags (without tools)”

- Article: “Start A Shredder Workplace”

- Article: “Buy waste plastic pyrolysis tire”

- Article: “Turning waste into power: the plastic to fuel projects”

- Article: “Advanced Recycling Alliance for Plastics (ARAP)”

- Article: “Global plastic production 1950-2019”

- Article: “Primary, secondary and tertiary packaging: What’s the difference? | CARTIER”

- Article: “One Army for the Planet”

- Article: “Precious Plastic solutions”

- Article: “23 Genius Ways to Repurpose Plastic bags”

- Article: “60 Ways to Reuse Plastic Bags”

- Article: “Reusing Plastic Bottles: Best Use Practices”

- Article: “How to Make Plastic Bottle Planters”

- Article: “25 Plastic Bottle Vertical Garden Ideas | Soda Bottle Garden”

- Article: “How to Make Pencil Case With Bottle | Zipper | Pencil Holder”

- Article: “Next How to Make a Bird Feeder Out of a Plastic Bottle”

- Article: “Trash Can Made of Plastic Bottles (with Pictures)”

- Article: “How to Build Your Own Recycled Plastic Bottle Greenhouse ” DIY projects for everyone!”

- Article: “The Bottle School Manual | Hug it Forward”

- Article: “10 Step Guide to Making an Ecobrick”

- Article: “Plastics Recycling ” American Sustainable Recycling”

- Article: “TECHTONGDA 3HP Electric Chipper Granulator Heavy Duty Plastic Shredder Grinding Machine for Plastic Bottle, Rubber, Wood, Grain, Herbs 208V/240V”

- Article: “Machines: Shredder”

- Article: “$50 Plastic Shredder / Grinder / Recycler : 11 Steps (with Pictures)”

- Article: “Build a Shredder Machine Precious Plastic Community”

- Article: “How Plastic Extrusion Works”

- Article: “Lyman Filament Extruder – Open Source Ecology”

- Article: “Filastruder Kit”

- Article: “Filament Extruder Kit or Assembled for 3D printers”

- Article: “Machines: Extruder: Extruder Fully Built”

- Article: “Build Your Own 3d Printer Filament Factory (Filament Extruder)”

- Article: “RepRapable Recyclebot: Open Source 3-D printable extruder for converting plastic to 3-D printing filament”

- Article: “Precious Plastic Community”

- Article: “The 3 Basic Steps of 3D Printing”

- Article: “Thingiverse – Digital Designs for Physical Objects”

- Article: “Cults ・ Download for free 3D models for 3D printers”

- Article: “Pinshape: Free 3D Printable Files and Designs”

- Article: “GrabCAD: Design Community, CAD Library, 3D Printing Software”

- Article: “Industrial Applications of 3D Printing: The Ultimate Guide”

- Article: “You Have the Power How to Build a 3D Printer: From a Kit or Scratch”

- Article: “DIY High Resolution, Low-Cost 3D Printer: 16 Steps (with Pictures)”

- Article: “3D Printer : 21 Steps”

- Article: “How to Make a Big 3D Printer at Home Using Arduino”

- Article: “DIY 3D Printer Build for Beginners – LayerFused C201 (Open Source Design and under $200)”

- Article: “RPM Pipes ” Australian owned recycled pipe manufacturers”

- Article: “Precious Plastic’s building brick from plastic waste”

- Article: “Build an Injection Machine Precious Plastic Community”

- Article: “Build a Compression Machine Precious Plastic Community”

- Article: “Shredder Pro information Precious Plastic Community”

- Article: “Set up a Shredder Workspace Precious Plastic Community”

- Article: “Extrusion Pro information Precious Plastic Community”

- Article: “Start an Extrusion Workspace to Recycle Plastic”

- Article: “Sheetpress information Precious Plastic Community”

- Article: “Start a Sheetpress Workspace to Recycle Plastic”

- Article: “Precious Plastic Products”

- Article: “Turning Plastic Bags into Carbon Nanotubes ” Sustainable Nano”

- Article: “Fungi Mutarium”

- Article: “Sustainable Coffee Packaging Microplastics”

- Article: “Microplastics in Sea Salt”

- Article: “Sustainable and Eco-Friendly Tea Brands”

- Article: “Is there Plastic in Your Salt”

- Article: “5 Minute Guide to Plastic Free Tea”

- Article: “9 Proven Ways to Avoid Eating Microplastic”

- Article: “Best Alternatives to Plastic Wrap”

- Article: “Filtrol”

- Article: “Microplastics LUV-R”

- Article: “Guppyfriend Washing Bag”

- Article: “Girlfriend Collective Microplastic Filter”

- Article: “PlantCare Filter”

- Article: “What’s in a Tire?”

- Article: “The Tyre Collective”

- Article: “Filtering out Microplastics Where They are Created”

- Article: “Microplastics Found 90 Percent Table Sea Salt”

- Article: “Ultimate Purple Bamboo Salt Crystal”

- Article: “Korean Purple Bamboo Salt”

- Article: “Redmond Real Salt”

- Article: “Has Real Sea Salt Been Contaminated by Plastic”

- Article: “Jacobsen Salt Co Water Filtration Prevents Microplastics”

- Article: “How You Can Cut Down Exposure to Microplastics”

- Article: “4MyEarth Food Cover Set”

- Article: “Are Microplastics Leaching into Your Coffee”

- Article: “Driftaway Coffee”

- Article: “Cafe Mam”

- Article: “Ethical Bean”

- Article: “Tiny Footprint Coffee”

- Article: “Wandering Bear Coffee”

- Article: “Microplastics in Tea”

- Article: “Arbor Teas”

- Article: “Numi Tea”

- Article: “Good and Proper Tea”

- Article: “Pukka Herbs”

- Article: “Teapigs”

- Article: “Is There Plastic in Our Tea and Packaging”

- Article: “Hampstead Tea”

- Article: “Bigelow Tea”

- Article: “What Happens When the Wrong Things Go Into Recycling”

- Article: “Recyclable Packaging”

- Article: “Where Biodegradable Plastic is Not Biodegradable”

- Article: “Environmental Impact of Corn-Based Plastics”

- Article: “Zero Plastic Products”

- Article: “Plastic-Free Beauty Products”

- Article: “Ecobricks”

- Article: “Sustainable Zero-Waste Skin Care”

Use this page (click here) if you have a resource you’d like to suggest be added here.

SUMMARY

One Community has invested extensive time and research into the best small and large-scale recycling, repurposing, and reuse options for plastic (and paper, glass, polystyrene/styrofoam, clothing/cloth, metal, food and other perishable items, and non-recyclables). Reducing and reusing plastic use looks to be the easiest, safest, and most sustainable option. We will open source share here our group’s experience with reducing and reusing our plastic as part of the development of the Earthbag Village and Duplicable City Center. We will evolve this page with videos and other data from this process as we use what we learn to help us improve our recycling, repurposing, and reuse strategies as we build each of the next 6 sustainable village models and grow to a community of hundreds.

One Community has invested extensive time and research into the best small and large-scale recycling, repurposing, and reuse options for plastic (and paper, glass, polystyrene/styrofoam, clothing/cloth, metal, food and other perishable items, and non-recyclables). Reducing and reusing plastic use looks to be the easiest, safest, and most sustainable option. We will open source share here our group’s experience with reducing and reusing our plastic as part of the development of the Earthbag Village and Duplicable City Center. We will evolve this page with videos and other data from this process as we use what we learn to help us improve our recycling, repurposing, and reuse strategies as we build each of the next 6 sustainable village models and grow to a community of hundreds.

FREQUENTLY ANSWERED QUESTIONS

Q: What are the differences between plastic bottle recycling and reuse?

“An item is ‘recyclable’ per APR definition when the following three conditions are met:

- At least 60% of consumers or communities have access to a collection system that accepts the item.

- The item is most likely sorted correctly into a market-ready bale of a particular plastic meeting industry-standard specifications, through commonly used material recovery systems, including single-stream and dual-stream MRFs (Material Recovery Facility), PRF’s (Plastic Recycle Facility), systems that handle deposit system containers, grocery store rigid plastic and film collection systems.

- The item can be further processed through a typical recycling process cost-effectively into a post-consumer plastic feedstock suitable for use in identifiable new products.”

This was extracted from the Full APR’s design guide for plastics recyclability

You can’t recycle dirty plastic. Plastic materials with food residues or dirt on (or in) them cannot be recycled. Plastics must be of decent quality to be transformed into recycled goods. Washing is an important step in this process.

Q: How does recycling plastics compare to returnable glass bottles?

According to this article about rPET (recycled polyethylene terephthalate), the advantages of plastic are:

- The process of converting rPET to a virgin equivalent requires much less energy than glass, aluminum, or other materials. Although PET’s feedstocks are derived from crude oil and natural gas, approximately 40% of that energy is trapped within the PET polymer for recapture and reuse every time PET is recycled. This means rPET leads to greater conservation of raw materials and a reduction in greenhouse gas emissions by 65%.

- Since PET is lightweight and more compact, it allows for more products to be delivered with less packaging, less weight, less fuel for transport, and have fewer trucks on the road.

- It takes 27 pounds of glass versus 2 pounds of plastic to deliver 1,000 ounces of a beverage.

- rPET plastic means a reduction in breakage and damaged goods compared to glass packaging.

- PET virgin bottle resin pellets between 83 and 85 cents a pound, compared to only 58 to 66 cents a pound for rPET pellets.

Some disadvantages to plastic named by the IBWA:

“Virgin PET material is produced by combining raw material inputs [purified terephthalic acid (PTA) and monoethylene glycol (MEG)] in a polymerization process. In contrast, post-consumer recycled PET must travel from consumer to MRF to reclaimer / re-processor to end user”at each stage, there is potential for yield loss and inefficiency.