Aquapini and Walipini Open Source Hub

As part of One Community’s four-phase strategy and global change methodology, our Phase II Highest Good food infrastructure is an open source project-launch blueprinting of 6 structures that will represent 3 different in-ground, enclosed designs for food production. These 6 structures will be a part of our botanical garden model and will produce a diversity of delicious and nutritious food far beyond anything found in a typical grocery store. This open source hub includes the following sections:

- Related Pages

- What is a Walipini, Aquapini & Zenapini

- Why Build Aquapinis & Walipinis

- Ways to Contribute to these Designs

- Consultants on these Designs and Systems

- Walipini, Aquapini & Zenapini Open Source Directory (Collaborative resource and information hub)

- Walipini, Aquapini & Zenapini Details (and photos)

- Resources

- Summary

- FAQ

NOTE: THESE DESIGNS STILL NEED WORK. THIS PAGE IS NOT CONSIDERED BY US TO BE

A COMPLETE AND USABLE TUTORIAL UNTIL WE BUILD AND TEST THE AQUAPINI AND ADD

ALL THE RELATED VIDEOS AND EXPERIENCE FROM THAT BUILD TO THIS PAGE. IN THE MEANTIME, WE WELCOME YOUR INPUT AND FEEDBACK AND INVITE YOU TO JOIN THE TEAM AND HELP FINISH THE DESIGNS IF OPEN SOURCE AQUAPINI/WALIPINI DESIGN IS SOMETHING YOU ARE INTERESTED IN

RELATED PAGES (Click icons for complete pages)

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK HERE TO HELP US FINISH THE OPEN SOURCE DESIGNS FOR THESE STRUCTURES

WHAT IS A WALIPINI, AQUAPINI, AND ZENAPINI?

A walipini is an affordable, in-ground, in-door food production structure, resembling a greenhouse. An aquapini is a walipini incorporating aquaponics which lends itself to large-scale food production. A zenapini is an aquapini with a focus on aesthetics and food diversity. These structures are built into the ground because below the frost line the earth maintains a stable temperature of 55 deg F (13 deg C) year round. This helps keep these structures cool in the summer and warmer in the winter. They have additional benefits in that they require less building materials than a greenhouse, look better and maintain a lower physical profile, and are easier to service and repair since the roof begins at about ground level.

A walipini is an affordable, in-ground, in-door food production structure, resembling a greenhouse. An aquapini is a walipini incorporating aquaponics which lends itself to large-scale food production. A zenapini is an aquapini with a focus on aesthetics and food diversity. These structures are built into the ground because below the frost line the earth maintains a stable temperature of 55 deg F (13 deg C) year round. This helps keep these structures cool in the summer and warmer in the winter. They have additional benefits in that they require less building materials than a greenhouse, look better and maintain a lower physical profile, and are easier to service and repair since the roof begins at about ground level.

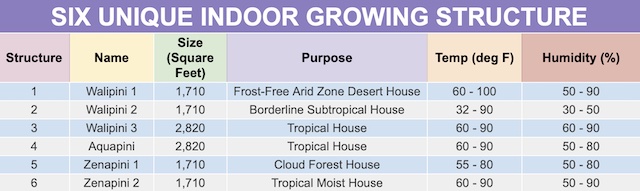

Our design includes the following 6 structures that provide different internal environments to grow a diversity of locally produced food that is not possible to grow outdoors in our location:

- Walipini #1: Frost-free Arid Zone Desert House

- Walipini #2: Borderline Subtropical House

- Walipini #3: Tropical House

- Large-scale Production Tropical Aquapini

- Zenapini #1: Cloud Forest House

- Zenapini #2: Tropical Moist House

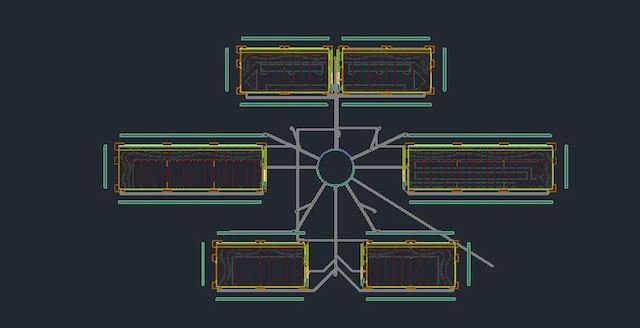

All of these growing environments are designed to maximize growing space, grow an unparalleled diversity of food, and provide a beautiful recreational space as well. This is possible by using a combination of a sloped South-terraced growing area, completely glazed South wall, and skylights. Our design maximizes needed sunlight in the winter and reduces excess sunlight (and heat) in the summer. An overhead view of the overall design is shown below.

The key features and intentions of the walipini, aquapini, and zenapini (Phase II) food infrastructure include:

- 6 structures

- Artistic designs

- Multi-functional

- ADA accessibility

- Support our own bee colony

- Central amphitheater space

- Rainwater collection from all structures

- 1 large-scale food production aquapini

- 3 maximally affordable walipinis purposed for trees

- 2 zenapinis purposed for diversity and aesthetic beauty

- Enough food production for all of One Community and our visitors

- Provides system redundancy to guarantee sufficient food production

- Sufficient distance between all structures to avoid shading of other structures

- Easy foot travel (with small climb) from any point to any other

- Central pond for water storage, aesthetic benefit, edible water plants, and wading/swimming

- Easy lateral expandability in support of our open source goals for adaptability to individual needs

WHY BUILD WALIPINIS, AQUAPINIS, AND ZENAPINIS?

In accordance with our botanical garden model and our for The Highest Good of All philosophy, we will demonstrate what truly ethical and carefully planned land stewardship can accomplish. The ultimate result of this will be sustainable production of unparalleled nutrition and diversity capable of providing enough volume and variety to feed all of One Community and our visitors. Even with traditional methods one person working full-time on food production can produce enough food to feed 30; with aquaponics that same person can produce enough food to feed 300. Our goal when arriving on the property is to immediately start large-scale gardening and building ultra-affordable, easy, and fast to construct hoop houses. We will build enough hoop houses and plant enough food to make ourselves about 70% food self-sufficient within 3-4 months. Combining this with raising goats, chickens, and rabbits will provide sufficient food to feed 100+ people by the end of the first year. Until we are successfully producing enough food to sustain ourselves, we will buy it from local producers and suppliers with the goal of supporting sustainable and ethical practices.

In accordance with our botanical garden model and our for The Highest Good of All philosophy, we will demonstrate what truly ethical and carefully planned land stewardship can accomplish. The ultimate result of this will be sustainable production of unparalleled nutrition and diversity capable of providing enough volume and variety to feed all of One Community and our visitors. Even with traditional methods one person working full-time on food production can produce enough food to feed 30; with aquaponics that same person can produce enough food to feed 300. Our goal when arriving on the property is to immediately start large-scale gardening and building ultra-affordable, easy, and fast to construct hoop houses. We will build enough hoop houses and plant enough food to make ourselves about 70% food self-sufficient within 3-4 months. Combining this with raising goats, chickens, and rabbits will provide sufficient food to feed 100+ people by the end of the first year. Until we are successfully producing enough food to sustain ourselves, we will buy it from local producers and suppliers with the goal of supporting sustainable and ethical practices.

We chose walipinis, aquapini, zenapinis for our Phase II food production infrastructure because they are affordable to construct, easier than other models to control the internal temperature, can produce large volumes of year-round food, and because we feel they provide the maximum benefit to financial and labor investment ratio. This makes Walipini, Aquapini, and Zenapini designs the best choice in support of our four-phase global transformation strategy and open source project-launch blueprinting goals. The complete layout of these structures is also ideal for water catchment and conservation, creates a central recreational space, and provides extremely efficient harvesting and food removal. Once we start building these structures, the first two are estimated to take no more than 6 months to build and test and another 2 months or so to begin producing food. All six structures should be able to be completed within a year.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

Avery Ellis: Aquaponics Specialist and owner/operator of Integrated Aquaponics

Bear Stauss: Horticulturalist and Landscape Design/Recreation Area Management Specialist

Bupesh Seethala: Architectural Drafter & Designer, BS Electrical Engineering (BupeshSeethala.com)

Charles McLean: Architecture & Urban Agriculture Designer, Professor, and owner of OM Greengroup

David Sweet: Architect (DSweet.biz)

Daniela Andrea Parada: Civil Engineering Student

Diana Gomez: Mechanical Engineer

Douglas Simms Stenhouse: Architect and Water Color Artist

Gayatri Pandkar: Architect

Henry Vennard: Mechanical Engineer

Japneet Kour: Volunteer Architect

Jiayu Liang: Landscape Designer

Kim Braman: Apiary and Beekeeping Expert

Mohammad Almuzaial: Civil and Construction Engineer

Ron Payne: HVAC / Thermal Designer, Mechanical Engineer

Silin Wang: Landscape Designer

Vatsal Tapiawala: Mechanical Engineer

Zdenek Jurik: P.E. Structural, Civil and Mechanical Engineer and founder of ABC Engineering

We are starting by researching, developing, and open source and free-shared project-launch blueprinting three different sustainable food production systems: 3 separate maximally-affordable walipini greenhouses, a large-scale food production aquapini, and 2 different “backyard version” zenapini designs. As we build them, solve problems, and evolve each of them for One Community (and with others around the world) we will use this page as the portal to all the open source and free-shared project-launch blueprinting details needed for duplication of these systems including:

We are starting by researching, developing, and open source and free-shared project-launch blueprinting three different sustainable food production systems: 3 separate maximally-affordable walipini greenhouses, a large-scale food production aquapini, and 2 different “backyard version” zenapini designs. As we build them, solve problems, and evolve each of them for One Community (and with others around the world) we will use this page as the portal to all the open source and free-shared project-launch blueprinting details needed for duplication of these systems including:

WALIPINI, AQUAPINI & ZENAPINI

DESIGN DETAILS

This section contains the following details related to the design of the walipini, aquapini, and zenapini:

- Design Summary

- Inside Details

- Location & Orientation

- Structural Details

- Water

- Berms and Swales

- Venting Network

- Ancillary Benefits

DESIGN SUMMARY

Our design consists of six structures that provide six different unique internal growing environments.

These growing structures will be built in the following order: Aquapini, Walipini 3, Walipini 2, Walipini 1, Zenapini 1, and Zenapini 2. A top view of the overall plan is shown in the image below, along with a video of the overall space and the internal environment for the updated large-scale Aquapini. The internal details for the rest can be seen in the floor plan examples with complete planting plans.

video coming…http://www.dropbox.com/s/g64wcum3d690f2m/FINAL%20Aquapini%20%26%20Walipini%20Video%20Walkthrough.mp4?dl=0

Here are the most current Walipini, Aquapini, and Zenapini download files.

INSIDE DETAILS

The inside of the structures have terraced growing spaces and a water storage pond. The total planted area of the 3 walipinis, 1 aquapini, and 2 zenapinis totals 10,622 square feet.

The Breakdown of the Planted Areas for Each Greenhouse – Click for the Open Source of the Spreadsheet

The purpose of the terraces is to maximize growing space in the South region of each structure by providing the ideal slope for maximum sunlight penetration and utilization. The slope is based on the sun study for our location and the sun angle on December 21st, when the sun’s path is lowest on the horizon. The terrace walls measure one foot in width. Furthermore, the curvatures of the terrace provide better sunlight penetration and less shadows during the mornings and evenings. To build this design, earthbags filled with stabilized earth mix were selected as they are easy to work with. Although this project can also be completed with cinder blocks, the approach would make the needed curvatures harder to create.

To make construction as easy as possible, the foundational dimensions of all the structures are identical and can be seen in these images. Additional details on each structure is given in the subsections below.

WALIPINI GREENHOUSES 1, 2, and 3

We will build 3 walipinis as traditional soil growing areas. The purpose of the walipini greenhouses is to provide research and development comparisons with the aquapini and zenapinis. We will open source project-launch blueprinting this maximally affordable, duplicable, and easy to maintain year-round food production option that also houses trees.

We will build 3 walipinis as traditional soil growing areas. The purpose of the walipini greenhouses is to provide research and development comparisons with the aquapini and zenapinis. We will open source project-launch blueprinting this maximally affordable, duplicable, and easy to maintain year-round food production option that also houses trees.

WALIPINI #1

Walipini #1 is a Frost-free Arid Zone Desert House providing over 1,800 square feet (167 sq meters) of growing space. The temperature range will be maintained between 60-100 F (16-38 C) with humidity ranging between 50-90%. The plantings in Walipini #1 will be in support of our botanical garden model and based on species from the world’s tropical deserts including (and centered around) specimens of the endangered species Cordeauxia edulis, the yeheb nut.

Detailed Overhead View Of The Walipini 1 – Frost-free Arid Zone Desert House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

WALIPINI #2

Walipini #2 will be the Borderline Subtropical House also providing over 1,800 square feet (167 sq meters) of growing space. It will maintain cool subtropical and temperate off-season production of plants that will enjoy its temperature and humidity ranges of 32-90 degrees F (0-32 C) and 30-50%, respectively. This house will host many of the types of crops that we will also grow outdoors, including pomegranate, loquat, figs, pineapple guava, olives, grapes, peaches, and apricots.

Detailed Overhead And Rendered Side Views Of The Walipini 2 – Borderline Subtropical House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

Here’s a 2-minutes video of these conditions already being met successfully with a passive greenhouse in Nebraska:

Here is a 20-minute more detailed version and a PDF download with additional details:

Here’s another walipini example from Colorado. It includes a few other sustainable heating options too:

Here’s an example from Bozeman, Montana:

WALIPINI #3

Walipini #3 will be the Tropical House providing over 2,900 square feet (269 sq meters) of growing space. This structure is the same size and similar internal environment (60-90 degrees F (16-32 C) and 60-90% humidity) as the large-scale production aquapini. Walipini #3 however, does not incorporate any aquaculture. Walipini 3 demonstrates a year-round affordable walipini in-ground growing food production system incorporating a diversity of trees and other tropical plants.

Detailed Overhead And Rendered Side Views Of The Walipini 3 – Borderline Subtropical House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

The large-scale production aquapini is a “tropical house,” growing a mix of perennial and annual crops in over 1,900 square feet (177 sq meters) of growing space. Our goal is to demonstrate maximum food production combined with unique biodiversity as part of our botanical garden model. This growing space will maintain an internal temperature range of 60-90 degrees F (16-32 C) and a humidity of 50-80%. The Aquapini produces many foods that cannot be purchased in most grocery stores. It has been designed to maximize the efficient utilization of every possible cubic foot of space, lumen of light, and BTU of heat. Such factors as workflow and ergonomics, light and shade requirements, pollination needs, etc. were carefully considered with the intent to incorporate these elements into a synergistic and harmonious whole. There is also a small recreational space built into the design.

The large-scale production aquapini is a “tropical house,” growing a mix of perennial and annual crops in over 1,900 square feet (177 sq meters) of growing space. Our goal is to demonstrate maximum food production combined with unique biodiversity as part of our botanical garden model. This growing space will maintain an internal temperature range of 60-90 degrees F (16-32 C) and a humidity of 50-80%. The Aquapini produces many foods that cannot be purchased in most grocery stores. It has been designed to maximize the efficient utilization of every possible cubic foot of space, lumen of light, and BTU of heat. Such factors as workflow and ergonomics, light and shade requirements, pollination needs, etc. were carefully considered with the intent to incorporate these elements into a synergistic and harmonious whole. There is also a small recreational space built into the design.

We will post complete and open source Sketchup, and CAD file downloads here for anyone to use and modify as soon as they are complete. Click Here for where we are in the process of completing these files. Click Here to see how you can help us complete them faster.

Detailed Overhead And Rendered Side Views Of The Aquapini – Tropical House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

Detailed Overhead And Rendered Side Views Of The Aquapini – Tropical House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

Each of these houses will provide over 1,400 square feet (130 sq meters) of growing space and are designed to demonstrate maximum food diversity and beautiful places to relax. They will be the last of the Phase II food structures to be completed. Our goal with both of these structures is to:

- Produce a maximum diversity of food and plant life and beauty

- Function as educational structures as part of our botanical garden model

- Inspire people with designs they can and will want to build in their backyard

Just one of these zenapini structures produces a volume and diversity of food sufficient for a large family, their friends, and several additional families while also creating an aesthetically pleasing place to go and sit “in nature” even when it’s cold and uncomfortable outside. We are also building these with the long-term intent to demonstrate that we can convert them into walipini permaculture environments once the higher production levels of the aquaponics are no longer needed due to permaculture and the other sustainable food production facilities incorporated into each of the 7 different village models.

ZENAPINI #1

Zenapini #1 will be an education food production Cloud Forest House. The cloud forest environment is characterized by an ecosystem of high humidity (50-80%) and cooler temperatures than tropical regions (55-80 degrees F (13-27 C)) and is generally frost free. As an educational structure and part of our botanical garden model, this house will feature unusual food plants, medicinal plants, species with unusual life cycles, reproduction biology, industrial uses, or other economic applications.

Detailed Overhead And Rendered Side Views Of The Zenapini 1 – Cloud Forest House – Click Image to Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

Zenapini #2 will be planted as a Tropical Moist House hosting a highly diverse range of tropical plants. It will be maintained between 60-90 degrees F (16-32 C) and with 50-90% humidity. Food diversity is being prioritized over food production for this house and it will also host a variety of non-edible rare and useful plants. This structure will be an important component of One Community’s educational infrastructure where people can gain direct experience with some of nature’s plant wonders.

Floor Plan for Zenapini 2: Tropical Moist House – Click Image to visit the related planting plan page with a click-to-enlarge image Enlarge and See Planting Plan Details (Values in Image Represent an Appointed Plant Type)

Each value illustrated in the overhead views of the 6 structures represents an appointed plant type. Specifications for plant types and internal environments of each structure are described in the Walipini, Aquapini, and Zenapini Planting and Harvesting page linked below.

LOCATION & ORIENTATION

The first step in designing indoor growing structures is to understand the sun’s path to maximize sunlight and minimize shade. For our particular location, a sun study was conducted to determine the placement of the 6 structures. The sun study simulation demonstrated the amount of sunlight exposure within the building for winter and summer. The goal is to place the structures such that indoor growing areas are not shaded by surrounding structures or other obstructions that prevent sunlight from penetrating the growing space. For optimum clearance, the structure placement is based on the day when shadows are the longest, which happens when the sun’s path is lowest on the horizon. Using the sun study, it was determined that for our specific site the sun’s path is lowest on the horizon on December 21st.

The video below shows the sun studies for the summer and winter, respectively. During the summer you will notice more hours of sunlight and in the winter you will notice longer shadows.

The screenshots below are from the following two videos: SUMMER | WINTER

Sun Study Results For December 21st, Which Is When Sun’s Path Is Lowest On The Horizon

7am (Sun Begins to Shine into Structures at 7am)

3pm (After This Point, the Structure’s Shadows Appear to Impact Sunlight within Structures.)

The structures need a minimum clearance from South to North of 38 feet to eliminate shadows falling on the backs of structures when the sun’s path is lowest on the horizon for our property. Also, the structures will be oriented towards the South so the sloped glazing roofs admit the maximum possible sunlight into the planted areas inside the structures. Roof glazing utilizes a material to increase natural light within a structure by allowing light to penetrate straight down into the space. On December 21st, structures are exposed to the sun from 9:15 am to 5:35 pm.

STRUCTURAL DETAILS

Geologic Map That Illustrates The Types Of Soils In The Immediate Site Location

Each structure is 6 feet deep with sloped roofs. The roofs have a rise of 2 feet in elevation per a run of 12 feet, which equates to a 17% slope. The growing area is the open, native soil, meaning that the property soil is utilized within the greenhouses.

The native soil with the largest surface area is eolian and alluvial sand (Qea). Eolian sediments are mainly composed of silt and sand sized particles, while alluvium is a sand composed of silty clay and sandy silt. Overall, mixed eolian and alluvial sand is mostly sand with minor amounts of clay, slit, and gravel. Sandstone (Jt), alluvium (Qa), limestone/limey shale (Jcc), and Navajo sandstone (Jn) are also found on the site, but less prominent. Since Qea is mostly sand with minor amounts of clay and silt, the USDA Textural Soil Classification is sandy loam.

Qea (Sand + Minor Amounts Clay And Silt) Is Sandy Loam

The site geology is also crucial for the foundation design, as it relates to the columns supporting each structure. Additionally, soil characteristics provide engineers with additional insight for rainwater runoff flow, more efficient roadway designs, and vegetation types the soil can naturally supplement. For instance, sandstone weathers into silty loam, while shale weathers into either silty loam, silty clay loam, or silty clay (Carter, 1931). This aspect affects various design elements because weathering will produce unconsolidated material which forms soil that a system has to withstand now and after the results of weathering. A more definite analysis of the existing native soil types will be developed once the exact locations of the greenhouses are specified. Current designs are based on the assumption of sandy loam, a soil type composed primarily of sand and clay.

For a longer life span of the structure, the structural frame will be composed of galvanized steel. This material withstands wind loads, retaining wall loads, and rust. Additionally, isolated concrete footings were chosen because it optimizes cost efficiency and material can be mixed on site, as opposed to bringing cement trucks.

The Structural Design

The walls of the Walipini, Aquapini, and Zenapini can be constructed with earthbags or cinder blocks. Both building materials are considered structurally sufficient for this application. The entryways to the structures are accessible using paved pathways. In plan view, entrances to each structure are semi-circles. This layout is constructed by retaining walls in order to aesthetically enhance the architectural design and make small-vehicle access to the doorways easier.

Entryway for Aquapini, Walipinis, and Zenapinis

To establish a good foundation for the growth of produce, open soil with stone walkways are utilized for the floor of these structures.

The glazing of the roofs use SolaWrap, a greenhouse plastic that saves energy, protects against UV rays, and has a lifespan of over 15 to 25 years. This material weighs 410 g/m2 (0.084 lb/ft2). SolaWrap diffuses (spreads out) up to 83% of light, and transmits 83% of light. The transparency of SolaWrap allows for a faster plant growth rate and extends the growing season. SolaWrap is strong enough to withstand wind loads up to 100 mph, making it a durable and energy saving material. The roofing material details are the same for smaller structures (namely Walipini 1, Walipini 2, Zenapini 1, and Zenapini 2) and the same for the larger structures (namely Walipini 3 and the Aquapini). Beams needed for roofing are detailed below.

WATER

Each planted square foot requires about 0.5 gallons of water. Each structure’s daily consumption estimates are based on the planted area and the gallons required per planted square foot. The largest structure, Walipini 3, demands the most water. Collectively the total water consumption is 5,418 gallons per day. An additional 15% of water is included within this value as a precautionary measure. Therefore, the daily total water consumption is 6,170 gallons and monthly is 187,669 gallons.

The water needs are satisfied by way of swales, rainwater catchment, and an off-site, naturally replenishing storage pond. Swales are sunken or depressed sections of land intended to slow and/or channel rainwater runoff to increase water penetration. There are 6 water-collecting swales in total. Each swale is located at the base of the terraced berms on the side of the structures that do not have glazed walls. The swales of the shorter structures measure 80′ x 3′ and the 2 for the longer structures measure 100′ x 3′. These have drains that feed water to the central storage pond. These swales are for catchment and permeation during large rain events that could cause runoff from the terraces.

Our site receives 12 inches of annual precipitation and if all the rainwater could be captured, the following rule of thumb applies: 1 gallon of water is collected per ft2 for every inch of rain. Rainwater collection is not 100% efficient though. Different surfaces have different collection potentials, like grass only captures 22% because most of the rainwater infiltrates into the ground before it runs off into the rainwater collection storage areas. Even a pond only has 90% collection efficiency because of splashing, and evaporation losses. Information about the rainwater collection surfaces and annual precipitation were used to determine that 4,512 ft3 (33,752 gallons) of rainwater can be harvested per month. Given the monthly water needs of over 32,000 ft3, the rainwater alone does not meet estimated, albeit high, watering requirements. Multiple water conservation measures will be implemented, such as hugelkultur and other methods to reduce the estimated water needs as much as possible.

There was an attempt made to design a central pond that held a 6-month supply, namely 150,526 ft3 (1,126,013 gallons), but it was determined that the volume of water needed was too large. Once we realized we’d need to have an external pond for our water needs, the central pond was redesigned for easy roadway access around it and with a smaller diameter to be more easily covered so it can be used as a stage for music and other presentations.

The property has a natural pond southwest and adjacent to the proposed walipini, aquapini, zenapini location. The plan is to dam this external storage pond better and increase its volume with swales and other harvesting methods. The existing natural pond has a capacity of 54,373 ft3 and will be expanded to a capacity equivalent to 150,000 ft3 to maintain a 6-month supply. The external pond will be replenished by way of the dam or fed from a well.

The primary purpose of the central pond is to function as a distribution water storage for irrigation. The swales and rainwater gravity feed to this central pond. Paved areas have a slope of 2% towards the central pond, therefore allowing the water to drain. The structures are created with slanted roofs and designed with a change in elevation of 2 feet for every 12 feet so as to direct the water on to the paved areas and then to the central pond. Overflow water from the central pond gravity feeds to an external natural pond outside the Walipini, Aquapini, and Zenapini footprint. A pump in the external natural pond will be used to refill the central pond, if needed.

The central pond has a diameter of 24 feet 8 inches and a depth of 8 feet. Harvested rainwater from surrounding structures and runoff from pavement all supply the central pond. Depending on the structure, it is located anywhere from 38-55 feet away from the door of each structure. The maximum water level is 11 inches below the surface of the concrete perimeter. The depth of the central pond was made shallow just in case digging any deeper is not viable. In reality, the pond will be dug as deep as possible to maximize water storage capacity. With a depth of 8 feet, the central pond capacity is designed to hold 3,385 ft3 of water.

In order to support Walipinis, Aquapinis, and Zenapinis needs, a month’s storage of 25,088 ft3 is required, therefore requiring a capacity for 150,529 ft3 of water over a span of 6 months. Water from the existing natural pond can be pumped to the central pond in order to maintain the desired water level. Furthermore, when necessary, the central pond will gravity-overflow to the existing pond.

The water circulation within the indoor growing structures uses a siphon system. This system places the inflow and outflow of the piping at different heights and gravity pulls the water in the downhill direction. The siphon system therefore minimizes energy usage and operational costs. Water flow within all structures with a pond is maintained by one pump. Water gravity feeds from the pond through a drip feeder along the back of the structure. That drip feeder waters the media beds beneath it and drips into a pond below that gravity feeds through the series of all the smaller ponds and is then pumped back into the main pond. Water storage ponds within the greenhouses are an aesthetic feature that also function as a thermal mass to help regulate the temperature within the structures. They provide humidity and house fish that help fertilize the water for the plants that grow in the ponds and media beds. Running water through the media beds feeds the plants there and cleans the water for the fish. The water storage ponds also provide a portion of irrigation to the planted areas within the aquapini and zenapinis. The following images show the water flow of the aquapini/zenapini structure, as well as dimensions of each water retention pond:

Starting point: Ponds supplying water to drip feeders that water the media beds. The smaller, lower pond has a pump that pumps water into the larger pond, where the system uses gravity to water the system and is high enough that the percolated water and overflow water gravity feed back to the smaller pond with the pump.

Pond for water percolated through media bed and overflow from supply pond, as well as 1st pond as the water makes its way back to supply pond

BERMS AND SWALES

In addition to having sunken indoor growing spaces, berms are used on the north end of the structures, as well as the short outer side. Berms are utilized to capitalize on the insulating properties of soil, which are pretty average when not below the frostline. With this in mind, studies* were then done to determine if the sun we’d get from leaving parts of the East and West transparent would be better than covering these areas with berms. Berms proved to be better than the added sun and the video below shows our studies to demonstrate this:

* Please note that the calculations in the (older design) video above, in all cases except the complete glazed roof, are taking into account a hatch system we were designing that would allow us to insulate the entire structure at night. The complete glazed roof does not include this because it would not be possible with that design. Even though our design is now different from the one shown in this video, the analysis demonstrating the benefits of berms vs. no-berms on the East and West walls are still valid.

Berms are mounds of soil that vary in height and angle depending on its use and design. There was greater benefit to insulate the non-south facing walls with earth using the material that was dug to have sunken indoor growing areas then to have the walls made of material that the sun can penetrate and therefore theoretically warm. The heat gain is greater with berms as compared to large or small windows that would have allowed thermal energy in directly from the sun. This is especially true in northern regions because they don’t get enough sun to make a greenhouse with all glass or light-penetrating walls worthwhile. For these reasons, the north and short outer walls are bermed and the south wall is glass. The east wall is partially bermed and serves as the entrance. The berms help to regulate the temperature and create a more constant inside temperature that is not as dependent on season.

The berms also slow water runoff, and direct it. Berm angles typically range between 25° – 35°. However, the berm angle chosen for our design is 23° because of our soil type (sandy loam) and we plan to create terraces since we may be working with sandy soil. This smaller angle was selected based on the angle of repose of sandy loam. The angle of repose defines the greatest inclined angle between the material and the horizontal plane without the soil sliding or slumping. A smaller angle is preferable in many cases, because it provides exceptional flow properties, also known as the material’s mechanical properties. These qualities are dependent on parameters such as moisture, temperature, and particle size. The less terraces, the better, since terraces require retaining walls, which we plan to make using earthbags. Each terrace is sloped towards the greenhouse walls at a 1 to 2 degree angle.

VENTING NETWORK

There are empty pipes leading from each structure that function as cooling-vents for the structures. These pipes draw cool air off of the Central Pond in order to ventilate the structures during warm weather seasons. The negative internal pressure needed to create the “pull” for this air is created by vents that will open at the tops of the structures anytime the temperature in the structures gets too high. As outdoor temperatures rise, so will the temperatures indoors and in order to reduce energy of ventilating six large structures, the cooling vent pipes provide a sustainable alternative.

This venting system utilizes 8-1/8 inch diameter pipes. The lengths of the pipes vary depending on the location of the structure and its proximity to the central pond, as well as elevation change of the site. The pipe lengths provided below do not take into account changes in elevation (which for our design is 6-1/2 feet at the most):

- Pipes leading to Walipini 1 and 2 are 78 linear feet.

- Pipe leading to the Walipini 3, Large-scale Production Aquapini are 40 linear feet, because it is closest to the pond.

- Pipes leading to the Zenapini 1 and 2 are 53 linear feet.

These pipes can be used for water too, because they slope downward to the central pond. Their main function though is to draw cool and moist air off the pond and into the structures.

ANCILLARY BENEFITS

SEATING AREAS

The top of the pond includes a design feature which allows it to be covered and used as a presentation stage. Seating is placed around the central pond in order to provide a location to host events. The design includes 4 rows of seating, having a level designated for ADA seating. The elevation of each level is a 6″ difference to provide easy viewing from each row behind another. All together the seating area accommodates 95 individuals. The ADA row provides spacing for 17 wheelchairs or an additional 78 persons. Therefore, the total seating capacity in this area is around 170 people. The surrounding paved and landscaped areas provide standing room and additional seating for hundreds more.

CIRCULATION

The pathway circulation (i.e. flow patterns of people) of the site allows proper ADA access to the central seating area around the pond and the structures. Each ADA access point is 4′ wide with a change in elevation of 1 foot per 12 feet, creating an 8% slope. To establish proper service truck access, entrances are designed at 10′ wide along with a circulation path 16′ wide around the central pond.

RECREATION AREAS

The site includes 4 recreational areas. They are situated North-east, North-west, South-east, and South-west of the layout. These recreational and relaxation areas are purposed to encourage outdoor activities for children and adults. The design consists of 4 areas leveled 6′ above the structures’ finish grade.

PREVIOUS DESIGN RESEARCH

CURRENT ROOF DESIGN RESEARCH

MORE SUNLIGHT STUDIES ” CLICK IMAGES TO ENLARGE

Seasonal Direct Sunlight ” Annual Direct Sunlight ” Direct & Indirect Light

Here is a skylight study we did for these designs. It was to test the difference between flush skylights, horizontal skylights, 50% versus 100% solar penetration, and the addition of reflective surfaces versus non-reflective surfaces. The results show that flush skylights combined with 100% solar penetration and the addition of reflective surfaces will maximize sunlight in these structures and increase this sunlight where we will need it most: against the North wall. The skylights in this video are placed 8′ from the North wall (shown) and (for easier viewing of the anelemma) the wall is only 5′ high, placing the ground at grade versus 6.5′ below grade as it will be in the walipinis and aquapinis.

RESOURCES

- Pinterest walipini board

- Walipini construction pdf from the Benson Institute

- Walipini wiki

- Suggest an addition to this section by clicking here

- Carter, W. T. Color Analysis of Soils WITH Spectrophotometer. 1 Jan. 1931, acsess.onlinelibrary.wiley.com/doi/10.2136/sssaj1931.036159950B1220010027x.

SUMMARY

One Community’s Phase II food infrastructure consists of 6 different indoor growing structures that we are open source project-launch blueprinting. There are three primary designs: Large-scale Production Aquapini, Aesthetic and Diversity Focused Zen Aquapini, and the Maximally-affordable Walipini Greenhouse Design. Each of the 6 structures will provide a different internal environment and grow a different variety of food. The structures will be the Large-scale Production Tropical Aquapini, Zen Aquapini #1: Cloud Forest House, Zen Aquapini #2: Tropical Moist House, Walipini #1: Frost-free Arid Zone Desert House, Walipini #2: Borderline Subtropical House, and the Walipini #3: Tropical House. These 6 structures will be a part of our botanical garden model and will produce a diversity of delicious and nutritious food far beyond anything found in a typical grocery store.

One Community’s Phase II food infrastructure consists of 6 different indoor growing structures that we are open source project-launch blueprinting. There are three primary designs: Large-scale Production Aquapini, Aesthetic and Diversity Focused Zen Aquapini, and the Maximally-affordable Walipini Greenhouse Design. Each of the 6 structures will provide a different internal environment and grow a different variety of food. The structures will be the Large-scale Production Tropical Aquapini, Zen Aquapini #1: Cloud Forest House, Zen Aquapini #2: Tropical Moist House, Walipini #1: Frost-free Arid Zone Desert House, Walipini #2: Borderline Subtropical House, and the Walipini #3: Tropical House. These 6 structures will be a part of our botanical garden model and will produce a diversity of delicious and nutritious food far beyond anything found in a typical grocery store.

FREQUENTLY ANSWERED QUESTIONS

Q: Will you be getting permits for these structures?

Yes, all of our food structures will be permitted and we will be open source sharing the permitting process also.

Q: How much will these structures cost to build?

Please see our open source aquapini and walipini cost analysis page.

Q: How much food will these structures produce?

Please see our open source aquapini and walipini planting and harvesting page.

Q: What is One Community’s stance on pesticides, herbicides, and fungicides?

If it is not safe to eat, we will not be spraying it on our food.

Q: Is One Community going to be a vegetarian community?

The One Community team consists of vegans, vegetarians, and omnivores. In accordance with our philosophy for The Highest Good of All we are maintaining a non-idealogical approach to food choices. That said, also in accordance with this philosophy, we will only support and consume food items that are ethically and sustainably raised, managed, and produced. The consensus process will be used to decide the evolution of the One Community food plan.

Q: How do you intend to produce spices, mill grain for flour, produce cooking oil, etc. etc.

To us, “100% food sustainability” means we will demonstrate and open source share a model that doesn’t need external food sources. Having achieved this, what we produce internally versus choosing to buy will be decided through the consensus process.

Q: The Walipini, Aquapini, and Zenapini structures are closed-loop systems, will you be supplementing them with CO2 to improve plant growth?

Based on the research we did, we believe that we should not be concerned about the CO2 levels in our growing structures. The CO2 generated by the decomposition of organic material within these structures, from the plants themselves at night, people working in and visiting the structures, and from outside when people enter and exit will be sufficient. Recent research also showed that excessive CO2 can actually be detrimental to the nutritional value of plants. Intentional increases to 1500 ppm (for production increases of 30%) can be created by various means but this extra CO2 decreases levels of key nutrients while also creating excess carbohydrate/sugar content. This results over the long run in plants becoming more like junk food than the nutritions foundations of a healthy diet they are meant to be.

WHO WE ARE

MAIN OPEN SOURCE HUBS

KEY FOOD COMPONENTS

- OS Hub

- Grow

- Build

- Ethical, Humane, & Conscientious Goat Stewardship

- Ethical, Humane, & Conscientious Rabbit Stewardship

- Ethical, Humane, & Conscientious Chicken Stewardship

- Food Forest

- Hoop Houses

- Apiary/Bee Yard

- Botanical Garden Creation & Inventorying

- Conscientious Wildlife Stewardship and Habitat Development

- Large-scale Gardening

- Soil Amendment & Site Preparation

One Community

One Community