Best Small and Large-scale Community Polystyrene & Styrofoam Recycling, Repurposing, and Reuse

This page is about the best small and large-scale community polystyrene & styrofoam recycling, repurposing, and reuse strategies. For those who don’t already know, polystyrene is a polymer made from the monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum. Polystyrene is lightweight, fairly rigid, and an effective insulator. These properties make it very versatile and useful in a huge variety of products. Some common uses of polystyrene include packaging material for food and nonfood appliances, housings/casings in the electronic and communication sector, building insulation and liners in the refrigeration industry, and disposable medical ware1. For many of these uses, this hard plastic is treated with heat and pressure to form a foam product. Two of the main types of polystyrene foam are Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). Many people refer to these foam products as Styrofoam, however, Styrofoam is actually the trademark name for Dow Chemical Company’s popular XPS products. Thus, it is important to note that Styrofoam is technically a brand name for one company’s XPS products, and that XPS and EPS are types of polystyrene foam products2.

Typically, polystyrene is thrown in waste bins rather than being recycled. There are, however, processes that exist that allow it to be recycled. We discuss these here with the following sections:

- What is Polystyrene/Styrofoam Recycling, Reuse, and Repurposing?

- Why Open Source Polystyrene/Styrofoam Recycling, Reuse, and Repurposing?

- Ways to Contribute and Consultants

- Small and Large-scale Polystyrene/Styrofoam Recycling

- Conclusion – Our Plan For this Specific Item

- Resources

- Summary

- FAQ

RELATED PAGES (Click icons for complete pages)

WHAT IS POLYSTYRENE/STYROFOAM RECYCLING, REUSE, & REPURPOSING?

A simple definition for polystyrene/Styrofoam recycling is the reprocessing of used polystyrene/Styrofoam to form new polystyrene/Styrofoam. To identify this material you can look for a 6 inside an arrowed triangle like the one below.

A simple definition for polystyrene/Styrofoam recycling is the reprocessing of used polystyrene/Styrofoam to form new polystyrene/Styrofoam. To identify this material you can look for a 6 inside an arrowed triangle like the one below.

In this article, we share our research about the best way to recycle this material. While polystyrene can be recycled, it is a long process and we cannot currently recycle all of our polystyrene residues. Therefore, the most important thing we can do is to minimize our use and consumption of products containing polystyrene.

WHY OPEN SOURCE POLYSTYRENE & STYROFOAM RECYCLING, REUSE, & REPURPOSING?

One Community is working to create global sustainability, and we recognize the importance of a consumer-driven effort to recycle more. We are researching the best small and large-scale recycling, repurposing, and reuse options for polystyrene/Styrofoam so we can implement these as part of the first of our sustainable village rollouts consisting of the Earthbag Village and Duplicable City Center. As we build the 7 sustainable villages, we will add our experiences and anything else we learn to this page. We are open sourcing our research and process in order to help both those building teacher/demonstration hubs to use our plans and those who would like to better understand how polystyrene/Styrofoam recycling works and how they can positively contribute to the process.

One Community is working to create global sustainability, and we recognize the importance of a consumer-driven effort to recycle more. We are researching the best small and large-scale recycling, repurposing, and reuse options for polystyrene/Styrofoam so we can implement these as part of the first of our sustainable village rollouts consisting of the Earthbag Village and Duplicable City Center. As we build the 7 sustainable villages, we will add our experiences and anything else we learn to this page. We are open sourcing our research and process in order to help both those building teacher/demonstration hubs to use our plans and those who would like to better understand how polystyrene/Styrofoam recycling works and how they can positively contribute to the process.

WAYS TO CONTRIBUTE TO EVOLVING THIS SUSTAINABILITY COMPONENT WITH US

SUGGESTIONS | CONSULTING | MEMBERSHIP | OTHER OPTIONS

CLICK THESE ICONS TO JOIN US THROUGH SOCIAL MEDIA

RESEARCHERS FOR THIS COMPONENT:

Aidan Geissler: Sustainability Researcher

Angela Mao: Sustainability Researcher

Yomi Sanyaolu: Mechanical Engineering Graduate and Technical Writer

SMALL AND LARGE-SCALE POLYSTYRENE & STYROFOAM RECYCLING

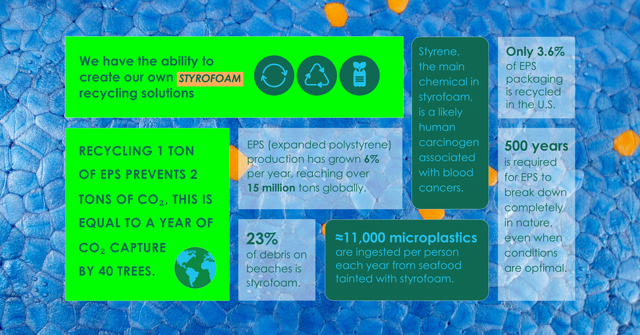

Due to its extensive use and disposal, pieces of polystyrene are quickly filling landfills, leaching toxic chemicals into our oceans, and are winding up in human bodies where they pose many potential health threats3. Eliminating or drastically reducing use is the best approach, and if we find ourselves with polystyrene/Styrofoam despite our efforts, recycling it makes a huge difference. We discuss both small and large-scale polystyrene/Styrofoam recycling here in the following sections:

- External/Commercial Polystyrene/Styrofoam Recycling Process

- Being a Good Recycler of Polystyrene/Styrofoam – how you can help

- Recycling Your Own Polystyrene/Styrofoam

- Cost, Labor, and Feasibility Comparison for All Options

EXTERNAL/COMMERCIAL POLYSTYRENE RECYCLING PROCESS

Polystyrene is 100% recyclable and in 2016 around 120 million pounds of Expanded Polystyrene (EPS) was recycled globally4. This was made possible by the commercial recycling processes discussed below. More polystyrene would be recycled, but many consider it cheaper to produce new polystyrene than to recycle it. These costs account for production costs but not long-term environmental and health costs.

HOW LARGE-SCALE POLYSTYRENE RECYCLING WORKS

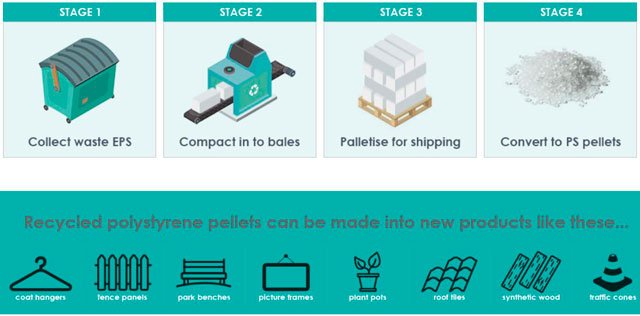

There are 2 different methods for recycling polystyrene (PS): “Granulation” for lighter polystyrene and “Compacting.”5. Compacting is the more commonly used process.

Granulation is the process of guiding recycled polystyrene through a granulator that grinds the material into beads which can then rejoin fresh polystyrene during the production process without affecting the quality. The more common compaction method involves compacting the material into dense bales, then converting them into pellets that can be used as raw material for creating new polystyrene products.

This diagram illustrates the compaction polystyrene recycling process:

Here is a video that describes the polystyrene recycling process in much more detail:

BEING A GOOD RECYCLER OF POLYSTYRENE/STYROFOAM – HOW YOU CAN HELP

Here are three of the best strategies to ensure that polystyrene is properly recycled: drop it off at appropriate recycling sites, mail it into designated mail-back locations, and reuse it for loose-fill. Here are additional details and resources for each of these options:

- Drop-off sites: Earth911 Recycling Search can help you find polystyrene recycling in your area. Make sure to call local sites in advance to make sure EPS is accepted and in what form. If they do take EPS, most accept packing materials but not food or medical containers. EPS-IA maintains a directory of EPS recycling companies, including businesses where you can drop off the material and those that will pick it up curbside. Make sure all containers are clean, empty, and free of tape, labels, plastic film, or other contamination. As you know, contaminants can ruin the recycling process. You can also check out the Home for Foam website where you can learn what the “compacted foam” recycling process looks like.

- Mail-back: If a drop-off site doesn’t exist in your area, you can use one of the mail-in options listed on EPS-IA’s website. You’ll need to pay for shipping, but given the lightweight nature of the material, it should cost less than $10 per box. Remember to remove all debris from the EPS before breaking it into smaller pieces that fit into a box for shipping.

- Reuse for loose-fill: What about packing peanuts? Their simplest reuse is in another package you need to ship. You can also donate them to The UPS Store outlets or other shipping stores, who will gladly reuse clean packing peanuts. Not sure where to go? EPS-IA e provides a drop-off map to help you find collection centers near you. You can also call them at 800-828-2214.

If you want to help make recycling polystyrene easier and more economical for the recyclers, wikiHow describes in detail the most helpful actions you can take. They are summarized below:

- Typically, recycle only clean, white packaging polystyrene/Styrofoam with the triangular recycling symbol on it

- Remove any labeling

- Contact local recycling services for assistance on polystyrene/Styrofoam recycling locations and protocols

- You can mail your unwanted polystyrene/Styrofoam to collection locations by checking EPS-IA mail back locations

- On the rarest of occasions when you have to dispose of the polystyrene/Styrofoam, cut it into small pieces so it takes up less space

RECYCLING YOUR OWN POLYSTYRENE/STYROFOAM

Even though polystyrene is 100% recyclable, it isn’t always collected for recycling by local services due to the expensive cost of the process. In these situations, it is advised to either recycle or reuse7 Styrofoam yourself. Benefits of recycling polystyrene yourself include:

Even though polystyrene is 100% recyclable, it isn’t always collected for recycling by local services due to the expensive cost of the process. In these situations, it is advised to either recycle or reuse7 Styrofoam yourself. Benefits of recycling polystyrene yourself include:

- Reducing the amount of petroleum used to manufacture new polystyrene

- Protecting marine life because small polystyrene particles thrown into the sea can kill marine life when digested

- Preventing toxic particles from being released when polystyrene is burned

- Reducing litter because it remains in landfills for decades

Next, we cover the different methods of recycling your own polystyrene both with and without the use of machinery.

MACHINERY OPTIONS

There are 3 main machinery options for recycling polystyrene. All 3 solutions are focused on reducing the volume of polystyrene/Styrofoam because it makes later processing much more convenient8. The three machinery options are:

- Thermal densification – Using heat to melt the polystyrene/Styrofoam and liberate trapped gas, the melted resin is then cooled into strands

- Granules – A machine that breaks down polystyrene/Styrofoam into small granules that can be added to the manufacturing of fresh material

- Compactor/Logs – The polystyrene/Styrofoam is shredded then joined together into compact logs

The solution with the best business potential is thermal densification; these are the advantages of the machine:

- 10X greater compaction rate than hydraulic compactors9

- Can achieve 98% volume reduction

- Can deal with contaminants – Resulting product is sterile and can be stored indefinitely

- Machinery requires little skill to operate and occupies a small footprint so it doesn’t take up much space

- Can sell the compacted blocks for $530 USD per ton, or melt and remold the product into other types of plastics

Unfortunately, there are drawbacks to this technology; these limitations are:

- Gases released include CO, CO2, and soot, so a proper exhaust hood is needed and it should only be operated in a well-ventilated environment

- There is virtually no on-site use for the products

- It is safe to handle but it must first be cooled and you should wear gloves as a precautionary measure

All 3 types of machines can be found on the Alibaba website and are compared below, along with the non-machinery DIY solution described in the next section.

NON-MACHINERY OPTIONS

The following is one possible method to recycle the Styrofoam yourself in your home with no special equipment needed:

RECYCLED STYROFOAM INSULATION BLOCK10

A non-machinery method to recycle waste Styrofoam is using it to form insulation blocks. Styrofoam insulation is very flammable though, so you want to only use it where safe and check with your county to make sure it is legal.

Equipment needed for this process is Great Stuff➢ binding foam, disposable gloves, cardboard boxes, old paper, and tape. This tutorial is sourced from instructables.com and goes as follows:

How to Recycle Styrofoam into Insulation Blocks – Click to open the instructable

- Measure the space you are going to fill

- Create a cardboard box mold of this gap, making it slightly larger than the gap

- Line the inside of the box with some paper

- Make chunks of Styrofoam less than 1 inch, and then fill the box with an initial layer of the Styrofoam less than 1 inch high

- Apply the Great Stuff➢ foam onto the bottom layer of Styrofoam chunks

- Fill the rest of the box with more Styrofoam chunks

- Apply more Great Stuff➢’ onto the top layer of Styrofoam

- Allow the mold to harden overnight

- Remove the Styrofoam block

- Insert block into the gap – if it doesn’t fit well, add more Great Stuff➢ to cement it into place

Warning: Don’t use in places containing fire hazards, very flammable!

MEASURING POLYSTYRENE’S EFFECTIVENESS AS INSULATION

If you plan to use polystyrene/Styrofoam for insulation, it is important to assess its effectiveness. The R-value of a material is a measure of how well that material resists the flow of heat, and thus tells you how effective a material is at insulating. The higher the R-value, the greater the material’s insulation effects. We have researched the R-values for various commonly used insulation materials, for polystyrene products, and made predictions about the expected R-values of our recycled polystyrene products. Here are those results (per inch):

Note: recycled polystyrene is typically not recommended for insulation for two reasons: it is highly flammable and for this reason code probably does not allow its use for any type of living space. Also, in any loose-fill form, the insulation property of the material is drastically reduced. For example, packing peanuts are made from Expanded Polystyrene, so while the R-value of the material itself is about 4, all of the air in between the peanuts (R-value of about 1) makes this material a poor insulator in loose-fill form. If you compressed packing peanuts enough to eliminate all the gaps of air though, you would achieve an R-value similar to that of EPS board.

Note: recycled polystyrene is typically not recommended for insulation for two reasons: it is highly flammable and for this reason code probably does not allow its use for any type of living space. Also, in any loose-fill form, the insulation property of the material is drastically reduced. For example, packing peanuts are made from Expanded Polystyrene, so while the R-value of the material itself is about 4, all of the air in between the peanuts (R-value of about 1) makes this material a poor insulator in loose-fill form. If you compressed packing peanuts enough to eliminate all the gaps of air though, you would achieve an R-value similar to that of EPS board.

Some of the most commonly used insulation materials are Fiberglass, Rock Wool, and Cellulose. As seen in this graphic, except for rigid Fiberglass with an R-value of 4, all of these materials have an R-value of below 3.5. Meanwhile, the R-value of polystyrene Board ranges from 3.85 to 5.2. Therefore, polystyrene boards are a much better insulation material than many commonly used insulation materials.

Through our research did not yield specific R-values for the 4 different methods of recycling polystyrene into insulation materials, we made reasonable predictions. We expect loose-fill insulation such as the output from a Granule Machine to have an R-value similar to that of loose-fill polystyrene beads, which is 2.3. More promisingly, we expect any method of creating recycled polystyrene blocks to have an R-value similar to that of commercial polystyrene boards, which would fall somewhere between 3.85 and 5.2.

Due to the flammability of these polystyrene products, they are not recommended for insulation in housing structures. Therefore, One Community only plans to use polystyrene insulation in our Highest Good food structures and/or other non-housing structures.

COST, LABOR, AND FEASIBILITY COMPARISON FOR ALL OPTIONS

After completing the research above, we compared the 4 different options for processing used Styrofoam. The factors we assessed were: End-product Uses, Cost, Labor, Safety, and Sustainability. Here is the resulting table:

Styrofoam Recycling Option Comparison Table – Click to open Google Sheet

ONE COMMUNITY’S PLAN FOR POLYSTYRENE/STYROFOAM

This page is open source and its purpose is to educate people globally on how polystyrene waste is processed, their options on how to deal with it themselves, and potential business ideas for communities or organizations that receive/produce large amounts of polystyrene. Our plan to address polystyrene is first and foremost to minimize the purchase of polystyrene products as much as possible. Any polystyrene we accumulate despite these efforts will be reused as packaging material or repurposed as insulation for Highest Good food structures. We will only choose to use them for Highest Good food structures because these structures can be insulated legally and safely even with polystyrene’s highly flammable properties. If we ever happen to accumulate excess polystyrene that we cannot repurpose, we will follow best practices for recycling polystyrene.

This page is open source and its purpose is to educate people globally on how polystyrene waste is processed, their options on how to deal with it themselves, and potential business ideas for communities or organizations that receive/produce large amounts of polystyrene. Our plan to address polystyrene is first and foremost to minimize the purchase of polystyrene products as much as possible. Any polystyrene we accumulate despite these efforts will be reused as packaging material or repurposed as insulation for Highest Good food structures. We will only choose to use them for Highest Good food structures because these structures can be insulated legally and safely even with polystyrene’s highly flammable properties. If we ever happen to accumulate excess polystyrene that we cannot repurpose, we will follow best practices for recycling polystyrene.

RESOURCES

- Book Chapter: “Polystyrene – an Overview”

- Article: “Difference Between Expanded and Extruded Polystyrene”

- Article: “Impacts and Risks of Polystyrene”

- Article: “Extended Polystyrene Foam Recycling (EPS) Facts”

- Article: “Polystyrene is Fully Recyclable and Clean to Manufacture”

- Website: “Loose Fill Insulation”

- Article: “How Does Polystyrene Recycling Work? | HowStuffWorks”

- Article: “Trends in Recycling of EPS Foam”

- Article: “Polystyrene Recycling ( Styrofoam Recycling )”

- Instructable: “Recycled Styrofoam Block Insulation : 4 Steps”

- Article: “10 Ways to Reuse Polystyrene”

- WikiHow: “How to Dispose of Styrofoam”

- Alibaba search: “Styrofoam Recycling”

- Search engine: “Recycling Center Search”

- Interactive map: “Find a location”

- Article: “Cities Weigh in on the Cost of Contamination | Earth 911”

- Article: “Foam Recycling Programs”

- PDF: “EPS”IA Mail Back Program”

- Interactive Map: “Find a Location – 2”

- Article: “Is Polystyrene Recyclable? Yes. Polystyrene is 100% recyclable”

- Website: “Table of Insulation Material R-values”

- Article: “Insulation R-Values Chart and Buyer Guide”

SUMMARY

One Community has invested extensive time and research into the best small and large-scale recycling, repurposing, and reuse options for polystyrene/Styrofoam (and plastic, glass, paper, clothing, metal, food, and other perishable and non-recyclable items). For polystyrene/Styrofoam that cannot be reduced or reused as packaging, a great option is repurposing it as insulation. We will open source share our group’s experience reducing, reusing, and recycling our polystyrene as part of the development of the Earthbag Village and Duplicable City Center. We will evolve this page with videos and other data from this process as we use what we learn to help us improve our recycling, repurposing, and reuse strategies as we build each of the next 6 sustainable village models and grow to a community of hundreds.

One Community has invested extensive time and research into the best small and large-scale recycling, repurposing, and reuse options for polystyrene/Styrofoam (and plastic, glass, paper, clothing, metal, food, and other perishable and non-recyclable items). For polystyrene/Styrofoam that cannot be reduced or reused as packaging, a great option is repurposing it as insulation. We will open source share our group’s experience reducing, reusing, and recycling our polystyrene as part of the development of the Earthbag Village and Duplicable City Center. We will evolve this page with videos and other data from this process as we use what we learn to help us improve our recycling, repurposing, and reuse strategies as we build each of the next 6 sustainable village models and grow to a community of hundreds.

FREQUENTLY ANSWERED QUESTIONS

Q: What is the difference between Styrofoam and Polystyrene?

Polystyrene is a polymer made from the monomer Styrene, a liquid hydrocarbon that is commercially manufactured from petroleum. There are three main types of polystyrene products: regular plastic, foam, and film. The most widely used varieties of polystyrene foam are Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). Styrofoam is technically the trademark name of XPS products sold by Dow Chemical Company, but is colloquially used more generally to refer to any polystyrene foam products (just as we use Kleenex to refer to facial tissues).2

Q: What are the potential human health impacts of Polystyrene?

Styrene, the building block of all polystyrene products, has been deemed a possible carcinogen by the World Health Organization (WHO). The EPA also notes that Styrene can cause a host of effects such as headaches, fatigue, dizziness, confusion, and malaise. Additionally, Styrene can disrupt regular hormone cycles, cause menstrual irregularities, and high exposure can even damage liver and nerve tissue.3

Q: What are some of the environmental impacts of Polystyrene?

The manufacturing process of polystyrene foam releases hazardous chemicals, such as Chlorofluorocarbons (CFCs) and Hydrochlorofluorocarbons (HCFCs), that deplete the ozone layer, which acts as a shield protecting us from much of the harmful UV radiation from the sun. Polysytrene products also pose a great threat to oceanic ecosystems: these products contain toxic chemicals that are leached into the ocean and consumed by marine life.3

Q: Is this guide complete?

No, we won’t consider this guide a complete tutorial until we finish our own construction of this component, confirm all the details, and add to this page all the related videos, experiences, and other updates from that build. In the meantime, we’re always happy to have the help of any qualified and experienced individuals with input that may make it better. If you are especially interested in this topic and would like to collaborate with us please click the button below. Any further questions related to this article you can contact us here, we will answer them and add them to this section.

One Community

One Community