Da Ku

Da Ku – Mechanical Engineer: Da Ku received his Master’s Degreee in Mechanical Engineering from University of Illinois at Urbana-Champaign, and his Bachelor’s Degree in Civil Engineering from Zhejiang Univeristy in Hangzhou, China. He is skilled in 3D modeling softwares (SolidWorks, ProE), and FEA packages (ANSYS, Abaqus, etc). Mechanical design and analysis experience, as well as hands on experience conform his passion for making real things that work. As a One Community partner, Da Ku helped with the designs, thermal and structural analysis of the transition door for the Duplicable City Center eco-pool and spa and the earthbag village structural engineering.

Da Ku – Mechanical Engineer: Da Ku received his Master’s Degreee in Mechanical Engineering from University of Illinois at Urbana-Champaign, and his Bachelor’s Degree in Civil Engineering from Zhejiang Univeristy in Hangzhou, China. He is skilled in 3D modeling softwares (SolidWorks, ProE), and FEA packages (ANSYS, Abaqus, etc). Mechanical design and analysis experience, as well as hands on experience conform his passion for making real things that work. As a One Community partner, Da Ku helped with the designs, thermal and structural analysis of the transition door for the Duplicable City Center eco-pool and spa and the earthbag village structural engineering.

DA KU ON LINKEDIN ┏ EMAIL DA KU

EXAMPLES OF DA KU’S WORK AND EXPERIENCE

3D Modeling (SolidWorks Motion& Simulation)

3D Modeling (SolidWorks Motion& Simulation):

1. Modeled 3D crank slider motion, force and power in SolidWorks Motion

2. Modeled the piston motion in SolidWorks Motion

3. Conducted FEA modal analysis of the turbine impeller for 4 modes in SolidWorks Simulation

4. Modeled the driver shaft motion in SolidWorks Motion, and analyzed stress of the journal cross in SolidWorks Simulation

Stress Analysis of Axial Flow Pump Blades

FEA & CFD analysis – Fluid Solid Interaction

Stress Analysis of Axial Flow Pump Blades:

* Created blade geometry in BladeGen (ANSYS)

* Generated mesh for flow domain using TurboGen (ANSYS)

* Computed flow field of the axial flow in the pump using CFX (ANSYS)

* Analyzed strain and stress of the blades in ANSYS by importing pressure from flow field

Modal and Stress Analysis of Pre-stressed Mud Mixer

FEA & CFD analysis – Fluid Solid Interaction

Modal and Stress Analysis of Pre-stressed Mud Mixer:

* Computed 2 phase (mud and water) fluid flow of mud mixer using Fluent (ANSYS)

* Solved stress distribution of the solid mixer in ANSYS by importing pressure from flow field

* Conducted modal analysis of the pre-stressed mud mixer

3D Modeling & Simulation

Creo/ProE Design & Modeling

* Simulation of the four bar linkage in ProE Mechanism

* Design of the Cell Phone: Modeled and assembled 8 parts

* Design of the Phone: Curved surface design

Transient Thermal Analysis of the Quenching Process of a Wheel

FEA Thermal Analysis – Transient Thermal Analysis

Transient Thermal Analysis of the Quenching Process of a Wheel:

* Analyzed the temperature evolution process of the wheel for 5 minutes after it was put into 0 degree water, using ANSYS APDL

* Obtained temperature evolution of various points on the wheel

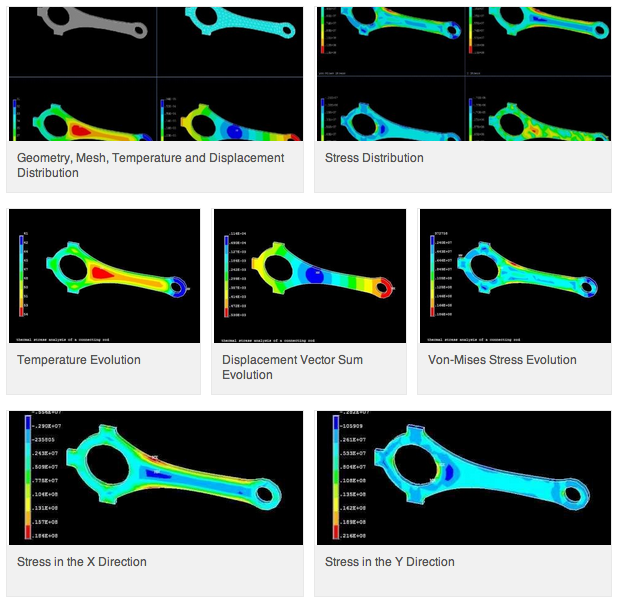

Transient Thermal Stress Analysis of a Connecting Rod

FEA Thermal Analysis – Transient Thermal Analysis

Thermal Stress Analysis of a Connecting Rod:

* Analyzed the temperature, displacement and stress evolution process of the connceting rod for 5 minutes after it cooled down naturely in air of 20 degree, using ANSYS APDL

* Obtained temperature, displacement and stress evolution of different points on the connecting rod

Stress Analysis of the Pre-stressed Mirror

Nonlinear FEA Analysis

Stress Analysis of the Pre-stressed Mirror:

* Conducted nonlinear stress analysis and displacement analysis to the pre-stressed mirror, compared 2 materials, aluminum and structural steel, in COMSOL

* Investigated the center point displacement dependence on the pre-stress

* Studied the influence of the pre-stress on the displacement distribution on the mid line

Hand Made Kayak

Manufacturing Hand On Experience

1. CAD/FEA Design: Designed parts in SketchUp, AutoCad, analyzed boat body stress in Abaqus

2. Procurement & Planning:

“Selected & Purchased Materials/Tools: hardwood floor, epoxy resin, fiberglass fabric, etc

“Scheduled manufacturing stages, practical oriented, with alternatives for unexpectedness

3. Manufacturing:

“Built framework, strengthened and waterproofed, finally polished and spray painted

“Adjusted plans/methods due to design errors, tooling limitation, material defects, climates

4. Field Testing & Improvements:

“Boated on the lake guarded by inflatable boats (safety priority), resulted very successful

“Improved operability by upgrading the seat, also included life jacket

TRANSITION DOOR

Natural swimming pool indoor/outdoor pool transition door design so the door can be closed anytime it would be beneficial. Examples of when this might be desirable would be insulation in the winter, sound control when events are being hosted inside or outside, and separation of the swimming areas whenever needed. Da Ku’s heat loss calculations for this design in a worst case scenario (subzero outdoor temperatures) is around 325W, which is the energy lost per second, for a total evening energy heat loss of around 4kWh, or 0.014 MMBtu.

One Community

One Community